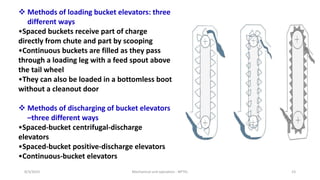

The document discusses mechanical unit operations related to the storage and conveying of bulk solids. It covers topics like the properties of bulk solids, different types of storage methods (bulk and bin storage), solid flow patterns, and methods of conveying bulk solids. Specifically, it describes the pressure characteristics in bulk and bin storage, the three main solid flow patterns (mass, funnel, and expanded flow), and the main types of conveyors used for bulk solids including belt, chain, screw, and pneumatic conveyors.

![8/3/2023 Mechanical unit operation - NPTEL 28

[1] W.L. McCabe, J. Smith and P. Harriot, Unit Operations of Chemical Engineering, 7thEd.,

McGraw -Hill, International Edition, 2005.

[2] E. Ortega-Rivas, Unit Operations of Particulate Solids: Theory and Practice, CRC Press, FL,

2012.

[3] J.F. Richardson, J.H. Harker, Coulson and Richardson’s Chemical Engineering, 2ndVolume,

5thEd., Butterworth-Heinemann, 2003.

[4] C.J. Geankoplis, Transport Processes and Unit Operations, 4thEd., Prentice Hall, India, 1993.

[5] G.G. Brown et al., Unit Operations, 1stEd., CBS Publishers & Distributors, 2005.

[6] W. L. Badger and J. T. Banchero, Introduction to Chemical Engineering, Tata McGraw-Hill,

International Edition, 1997.

Books and references](https://image.slidesharecdn.com/mechanicalunitoperations22081-230803112522-b699e9ad/85/Mechanical-unit-operations-22_08-1-pptx-28-320.jpg)