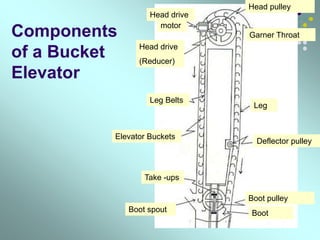

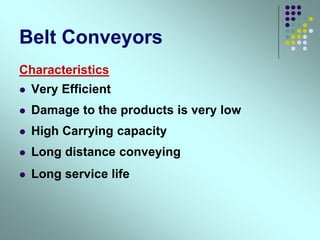

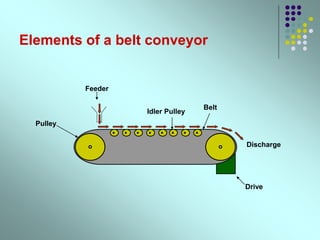

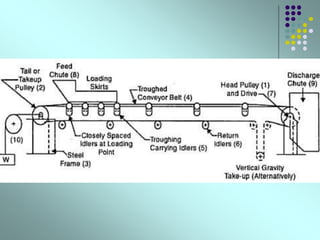

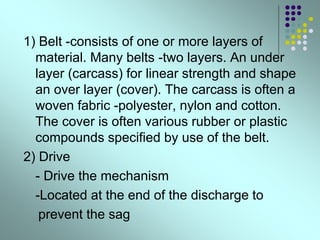

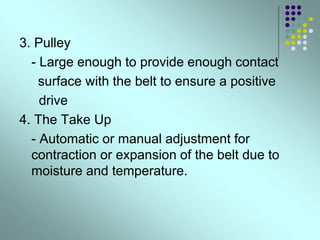

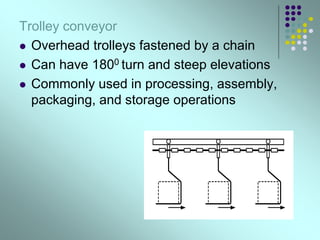

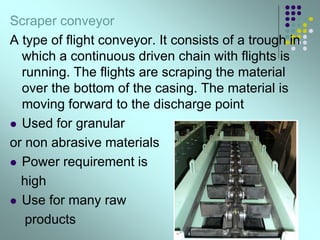

The document provides information on various types of conveyors used in material handling. It discusses belt conveyors, chain conveyors, scraper conveyors and bucket elevators in detail. Belt conveyors are very efficient and cause low damage to products. They are used for long distance conveying. Chain conveyors operate at slower speeds but cause more noise. Scraper conveyors use a trough and chain with flights to scrape materials along the bottom. Bucket elevators efficiently move materials vertically using buckets attached to a belt or chain. The document also provides equations to calculate conveyor design parameters such as belt tension, power requirements, and acceleration.

![The basics of the Calculations of

Conveyor Belt Design Parameters

Belt tension: The belt of the conveyor always

experience a tensile load due to the rotation of

the electric drive, weight of the conveyed

materials, and due to the idlers. The belt

tension at steady state can be calculated as:

Tb = 1.37*f*L*g*[2*mi+ (2*mb + mm)*cos (δ)]

+ (H*g*mm)…….eqn.1.1](https://image.slidesharecdn.com/conveyors-220722191718-1f03d276/85/CONVEYORS-ppt-24-320.jpg)

![ Acceleration :

The acceleration of the conveyor belt can be

calculated as:

A= (Tbs – Tb)/ [L*(2*mi + 2*mb+mm)]………eqn.1.6

Where,

A is in m/sec2

Tbs = the belt tension while starting in N.

Tb = the belt tension in steady state in N.

L = the length of the conveyor in meters.

mi = Load due to the idlers in kg/m.

mb = Load due to belt in kg/m.

mm = Load due to the conveyed materials in kg/m.](https://image.slidesharecdn.com/conveyors-220722191718-1f03d276/85/CONVEYORS-ppt-29-320.jpg)

![ Tb = 1.37*0.02*250*9.81*[16.67+ {2*25+

(416.67/1.5)}*cos (5)] + (20*9.81* (416.67/1.5)) =

77556.88 N.

The belt tension while starting the system can be

calculated by using the eqn.1.4:

Tbs = 1.5 * 77556.88 = 116335.32 N

For calculating the power at drive pulley, we will use

the eqn.1.3:

Pp = (77556.88*1.5)/ 1000 = 116.335 kw

We will use the eqn.1.5 estimate the size of the motor:

Pm = 116.35/0.9 = 129.261 kw](https://image.slidesharecdn.com/conveyors-220722191718-1f03d276/85/CONVEYORS-ppt-32-320.jpg)

![ We will use the eqn.1.6 to find out the

acceleration of the motor:

A = (116335.32 - 77556.88)/

[250*{(2*16.67) + (2*25) + (416.67/1.5)}]

= 0.429 m/sec2](https://image.slidesharecdn.com/conveyors-220722191718-1f03d276/85/CONVEYORS-ppt-33-320.jpg)

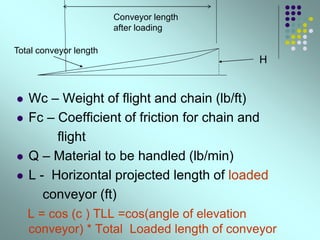

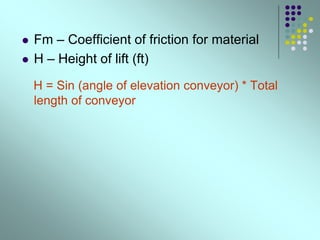

![Chain conveyor design

Generally flight speed – 75 -125ft/min

Capacity decreases with inclination

Horse power requirement

Horse power = 2* V *Lc* Wc* Fc + Q(L *Fm +H)

33000

V – Speed of the conveyor

Lc - Horizontal projection length of conveyor (ft)

Lc = cos ( c) * TCL

[ =cos(angle of elevation conveyor) * Total conveyor

length]](https://image.slidesharecdn.com/conveyors-220722191718-1f03d276/85/CONVEYORS-ppt-40-320.jpg)