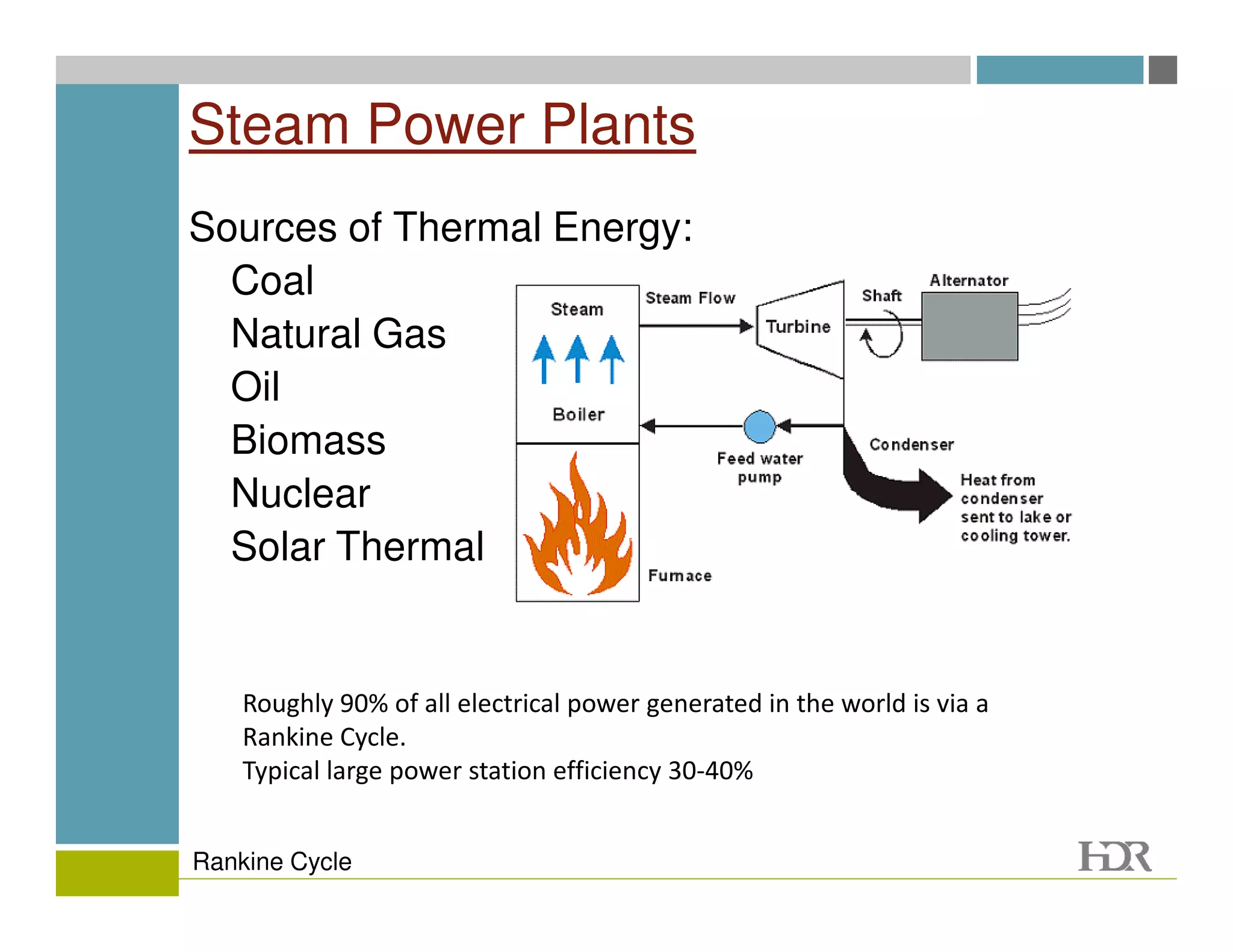

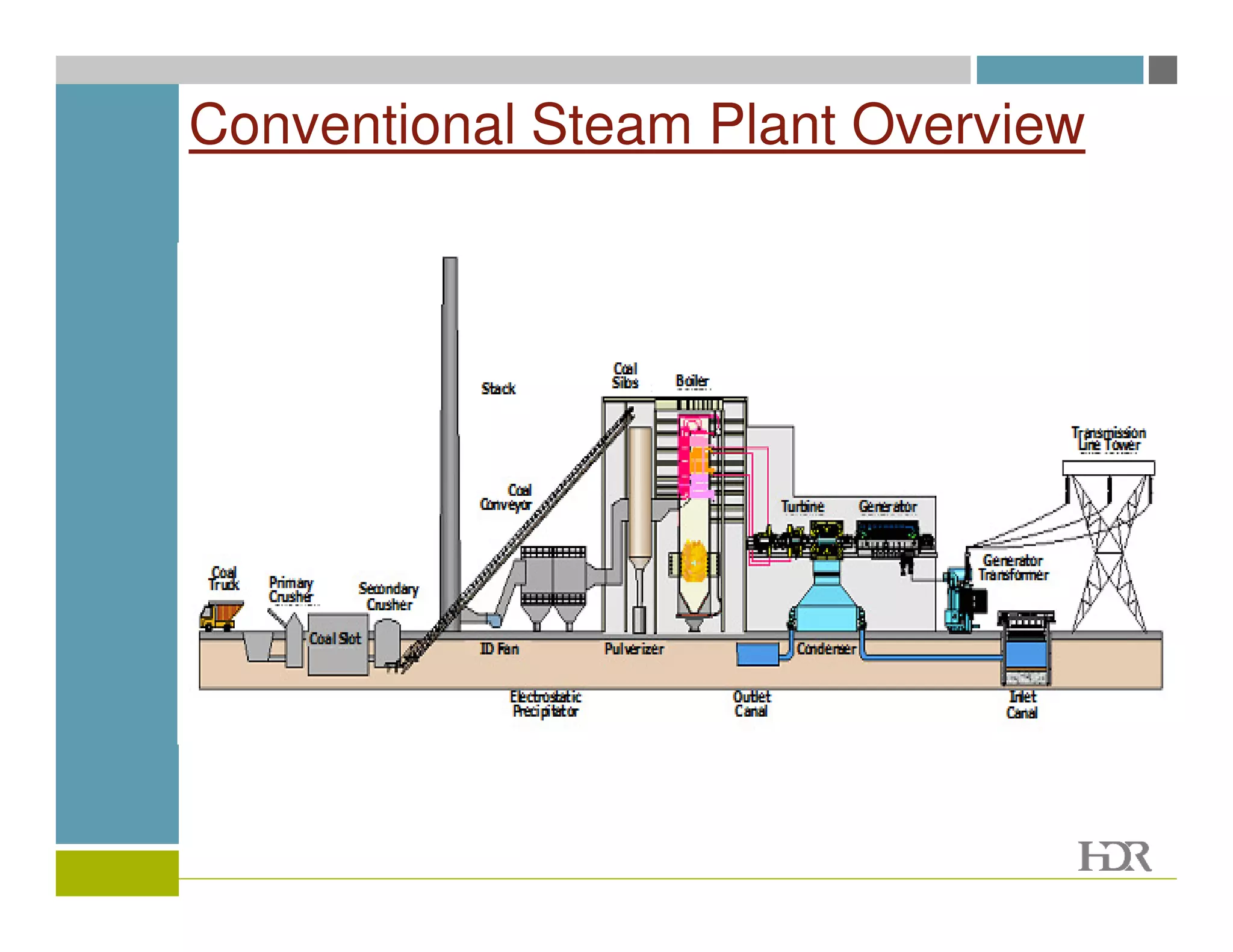

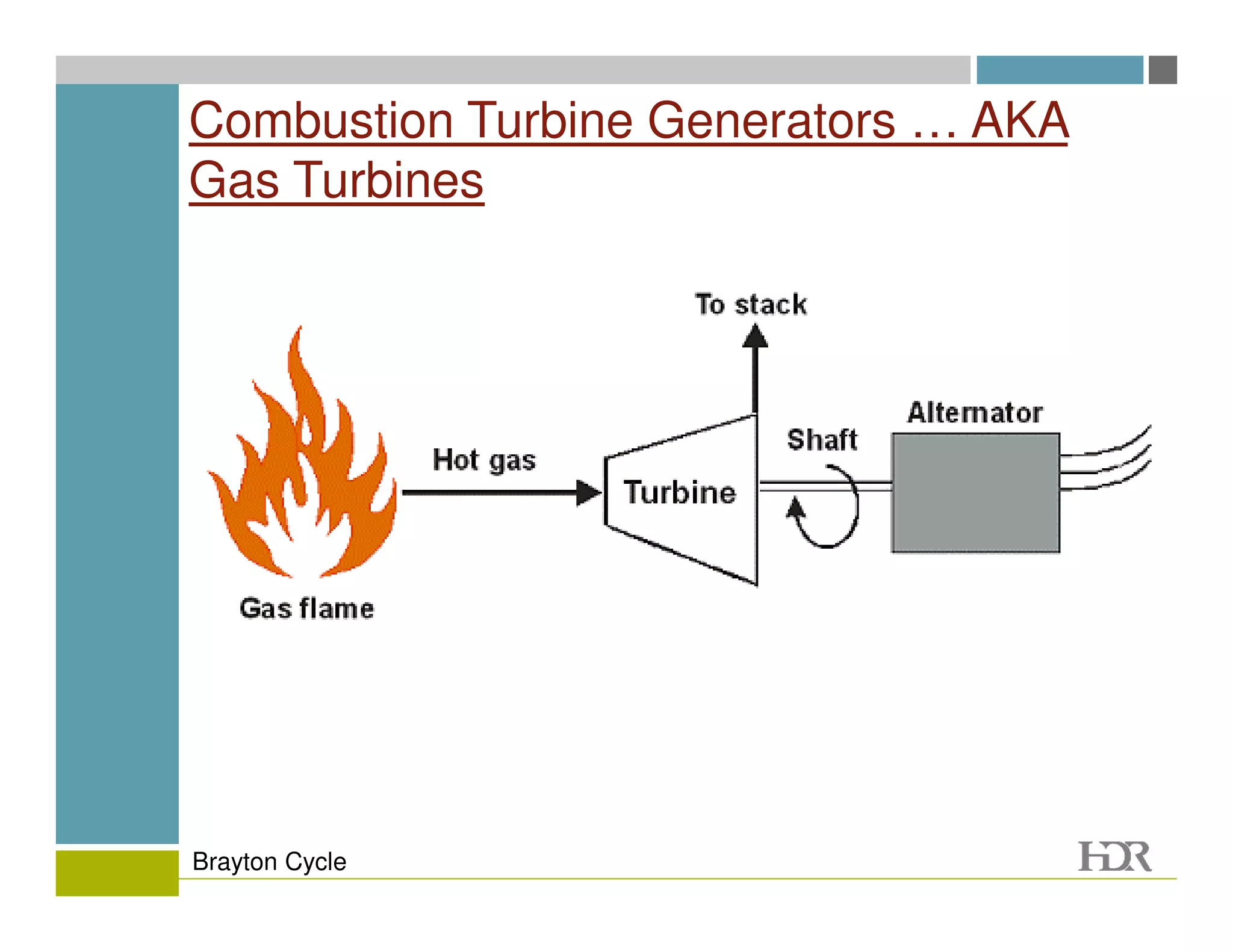

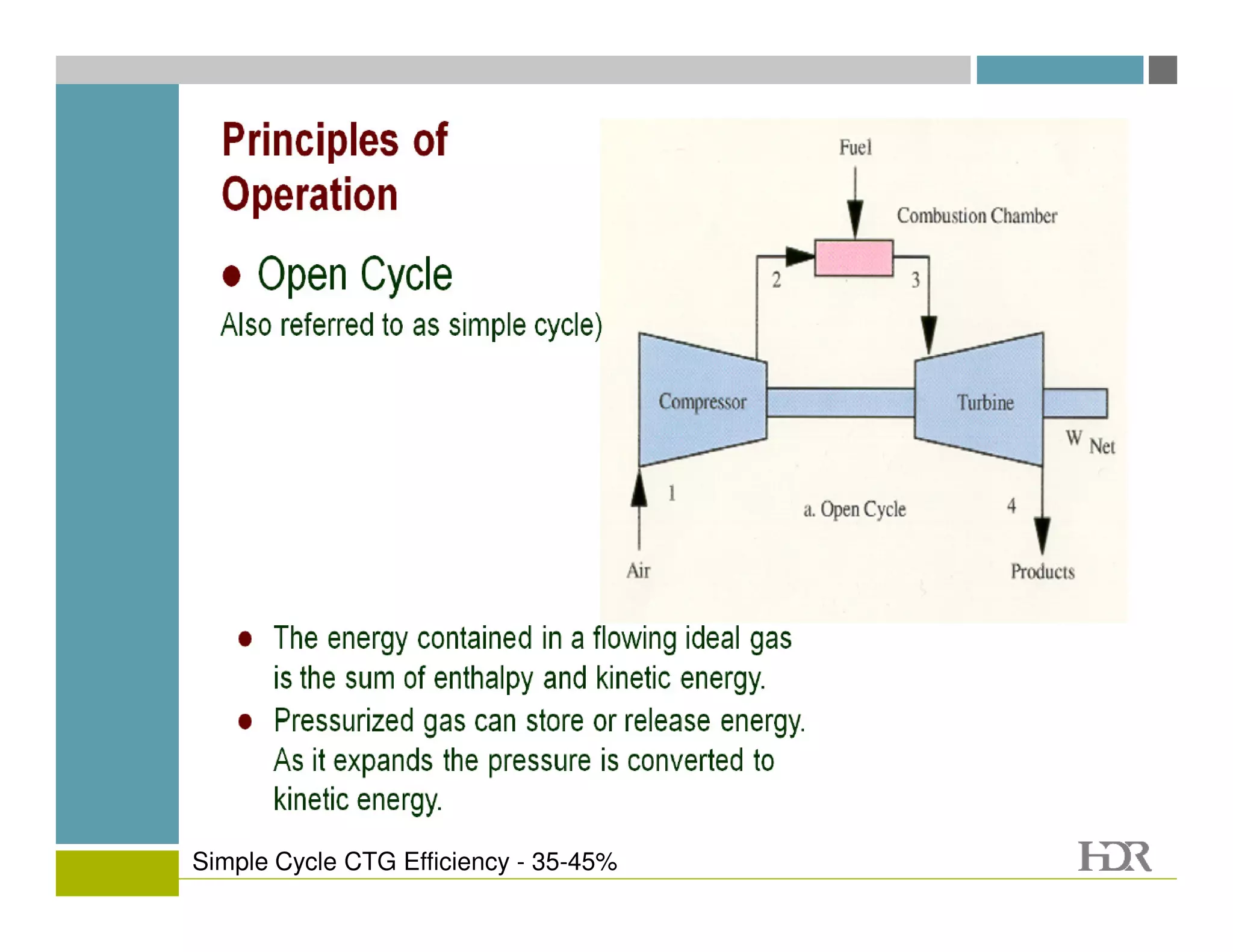

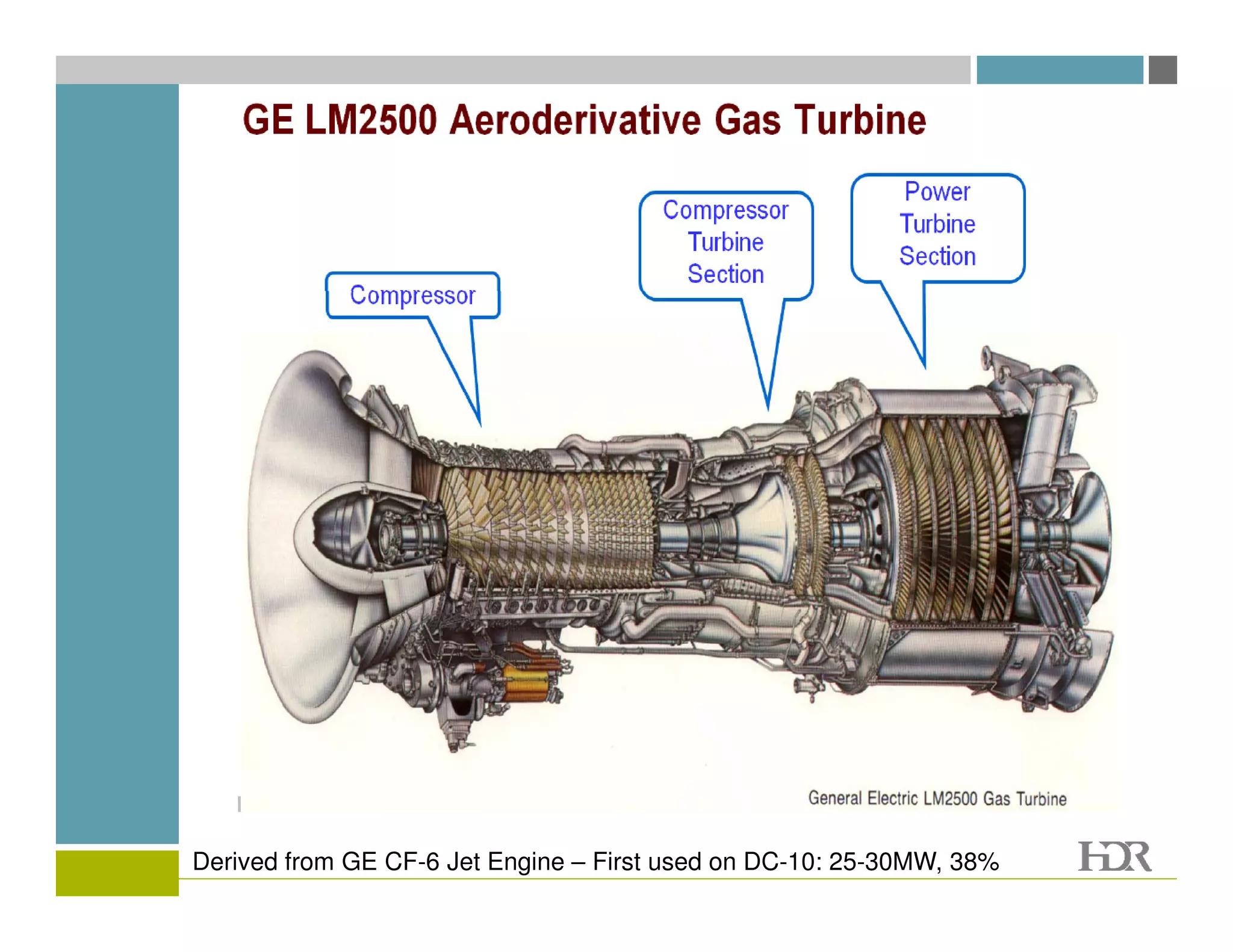

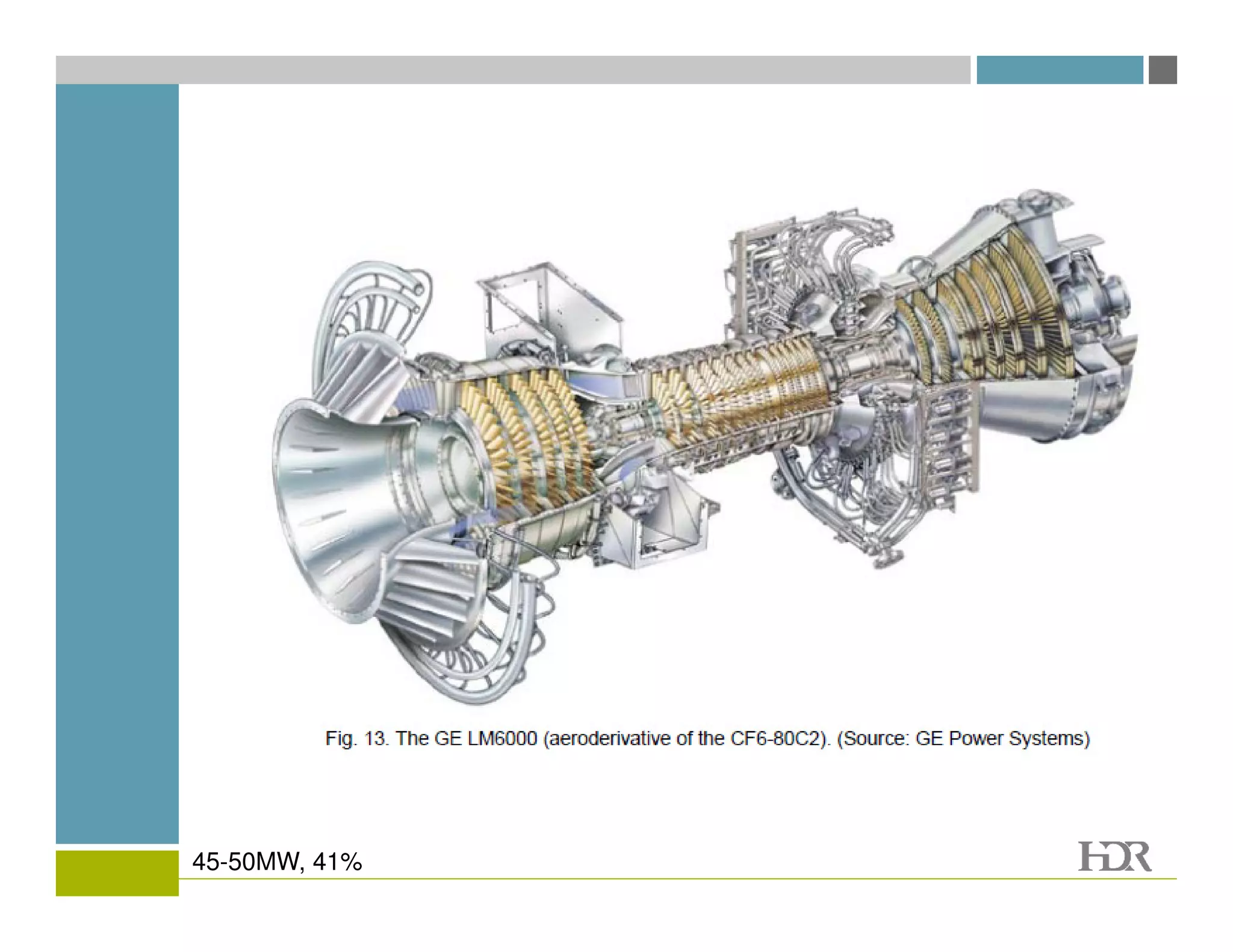

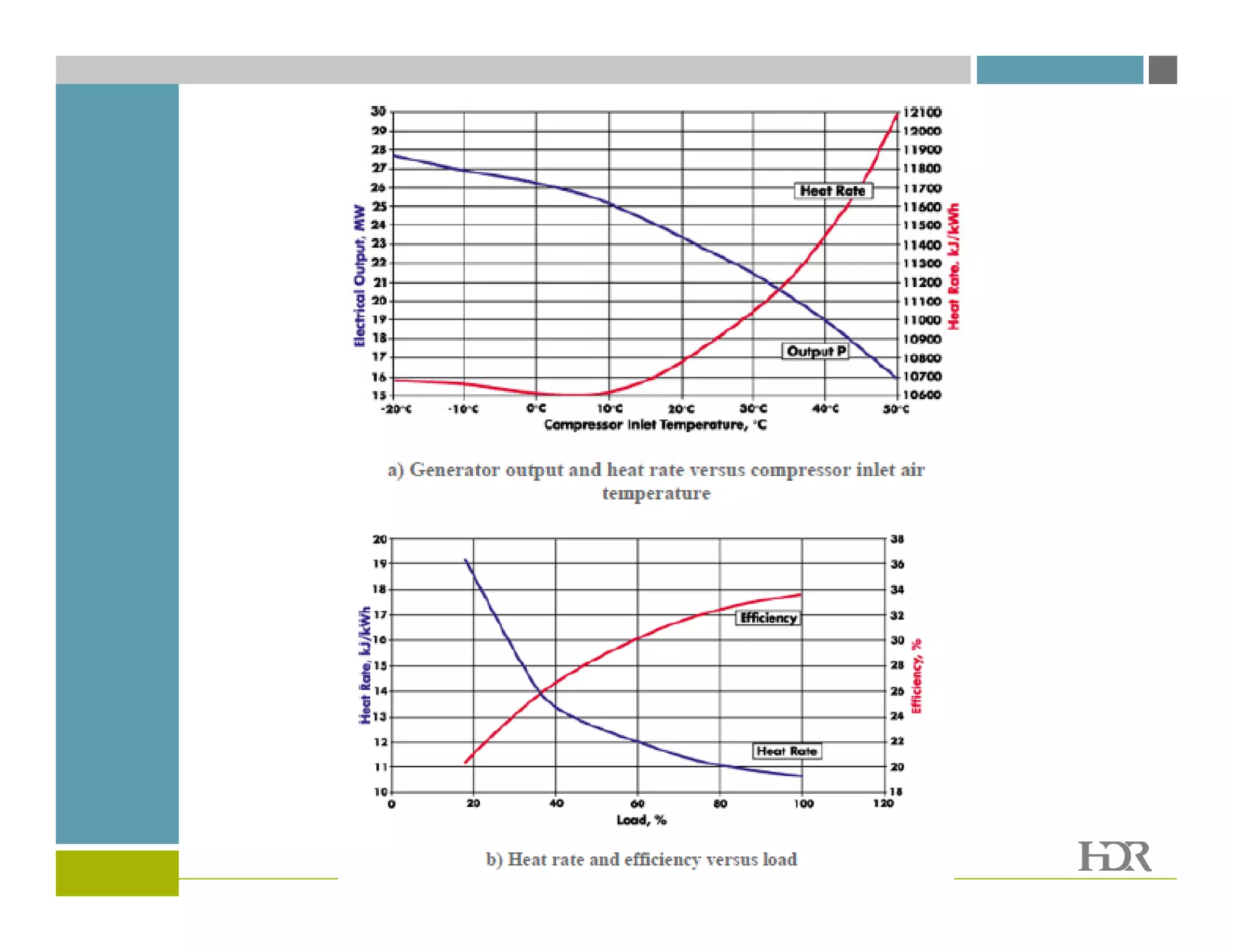

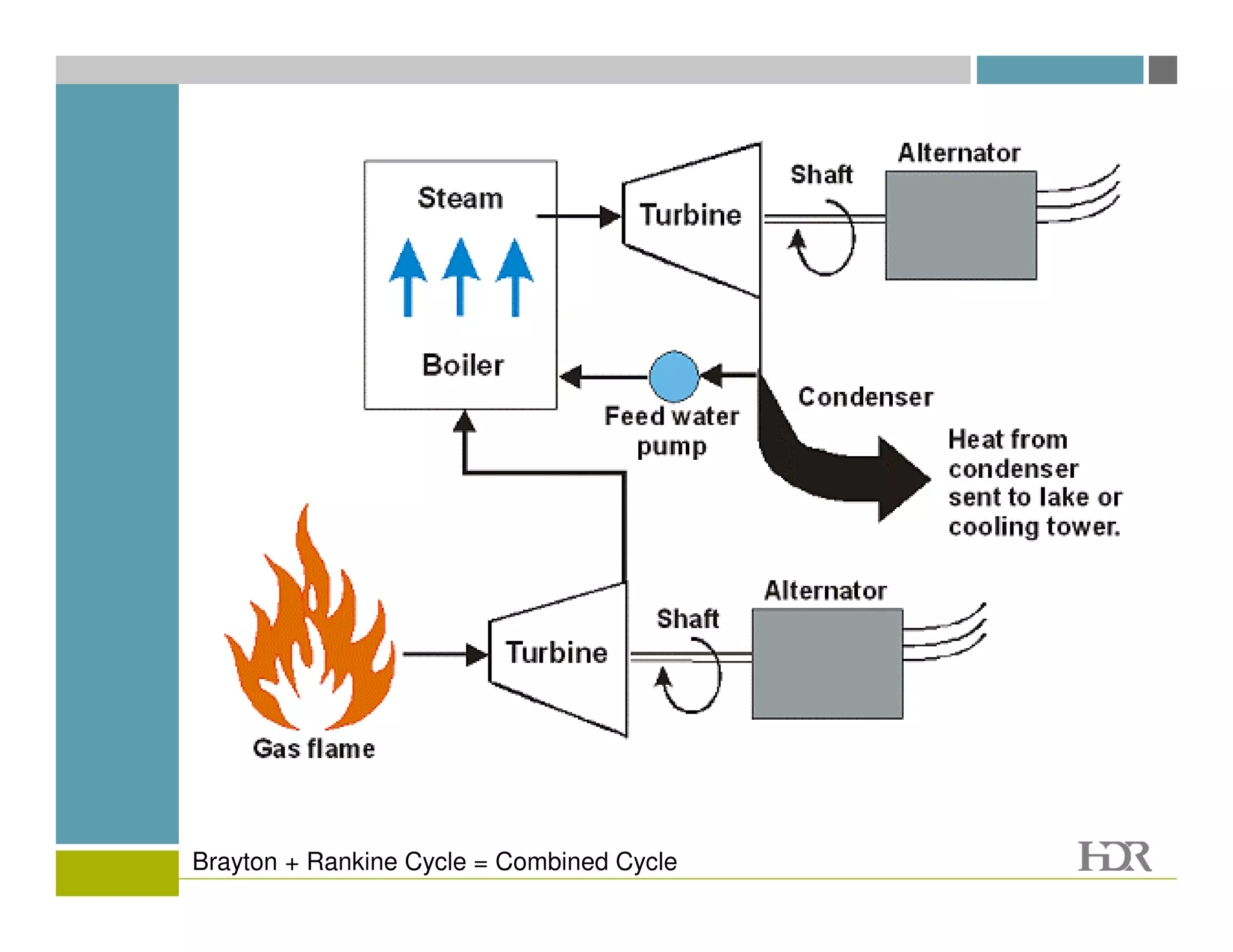

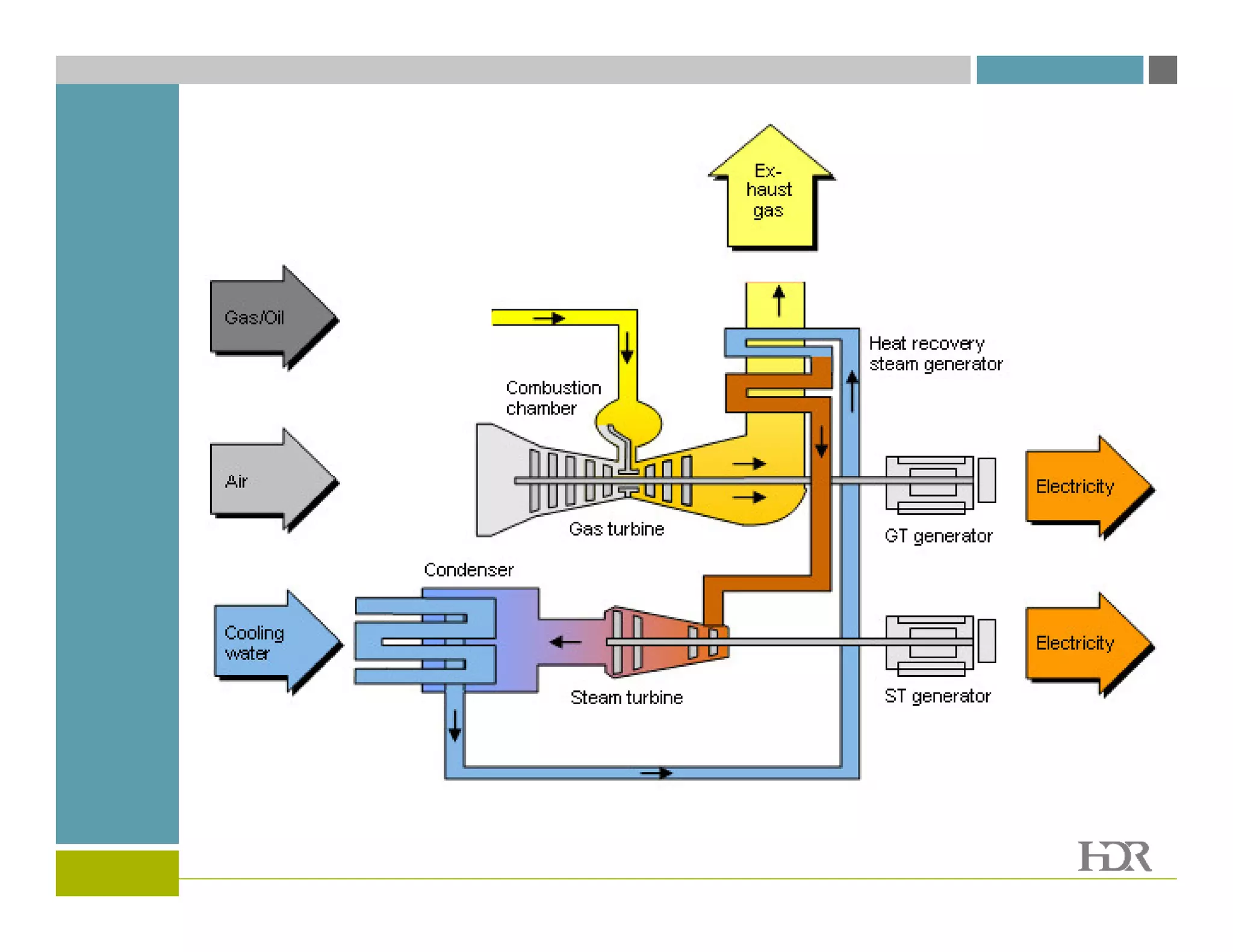

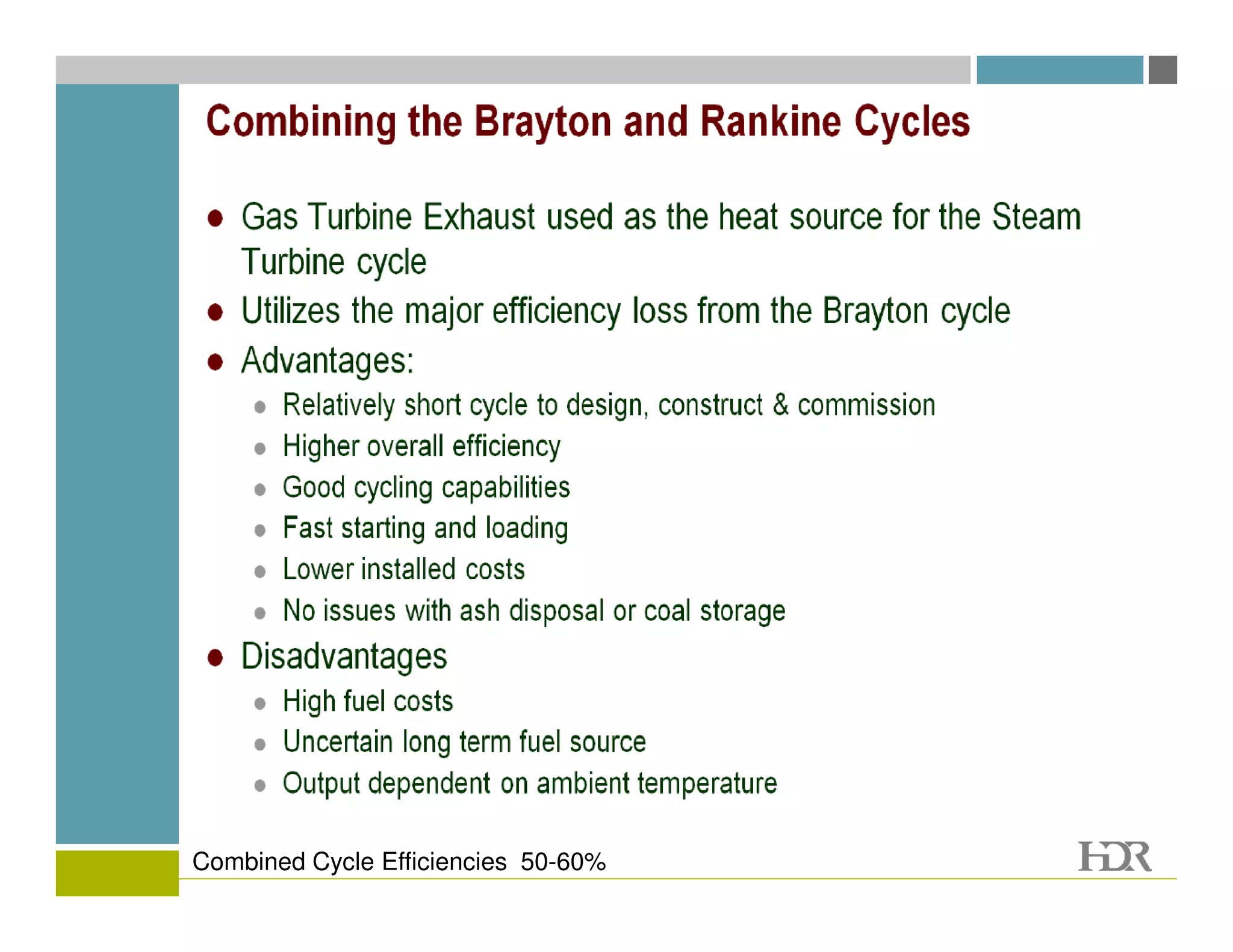

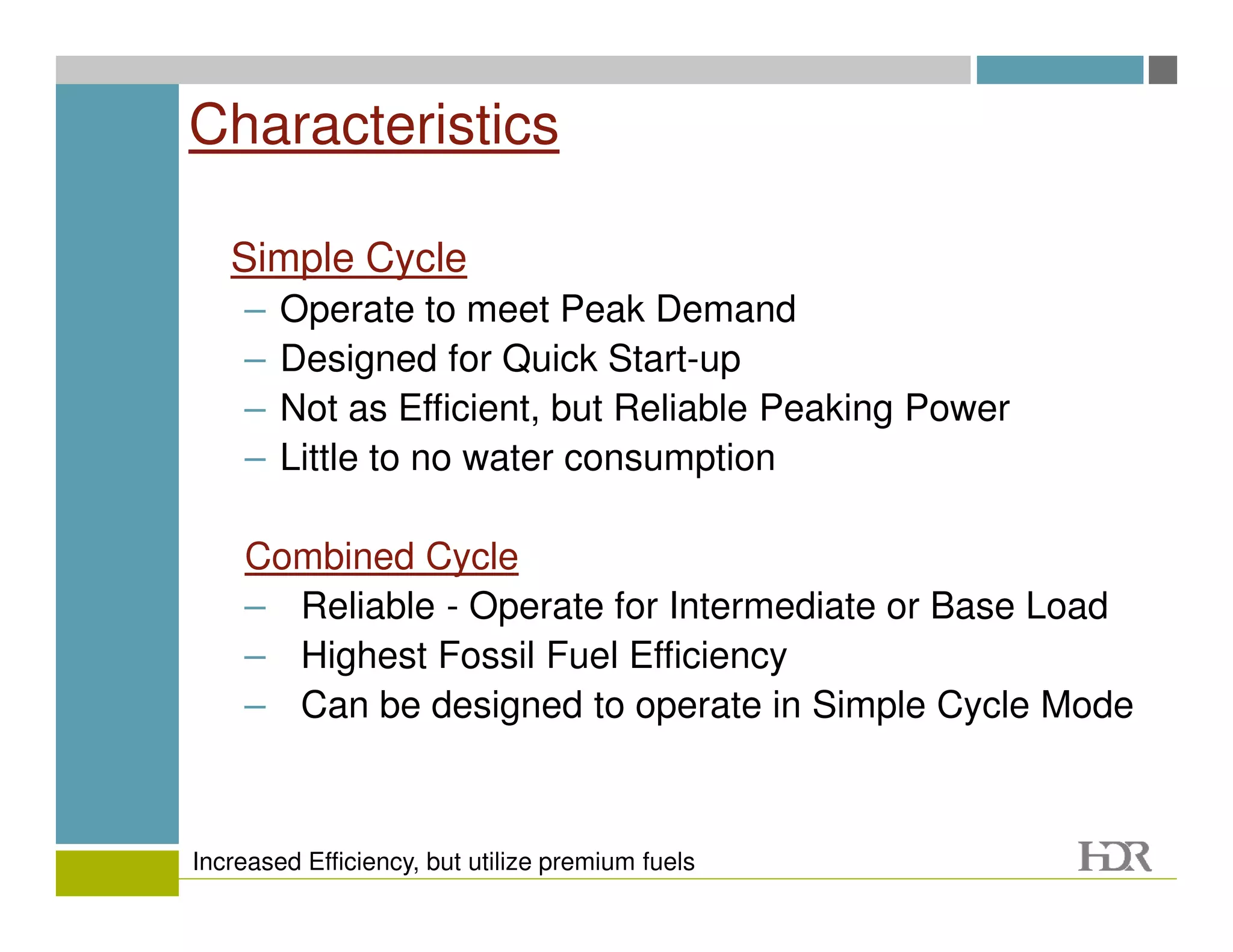

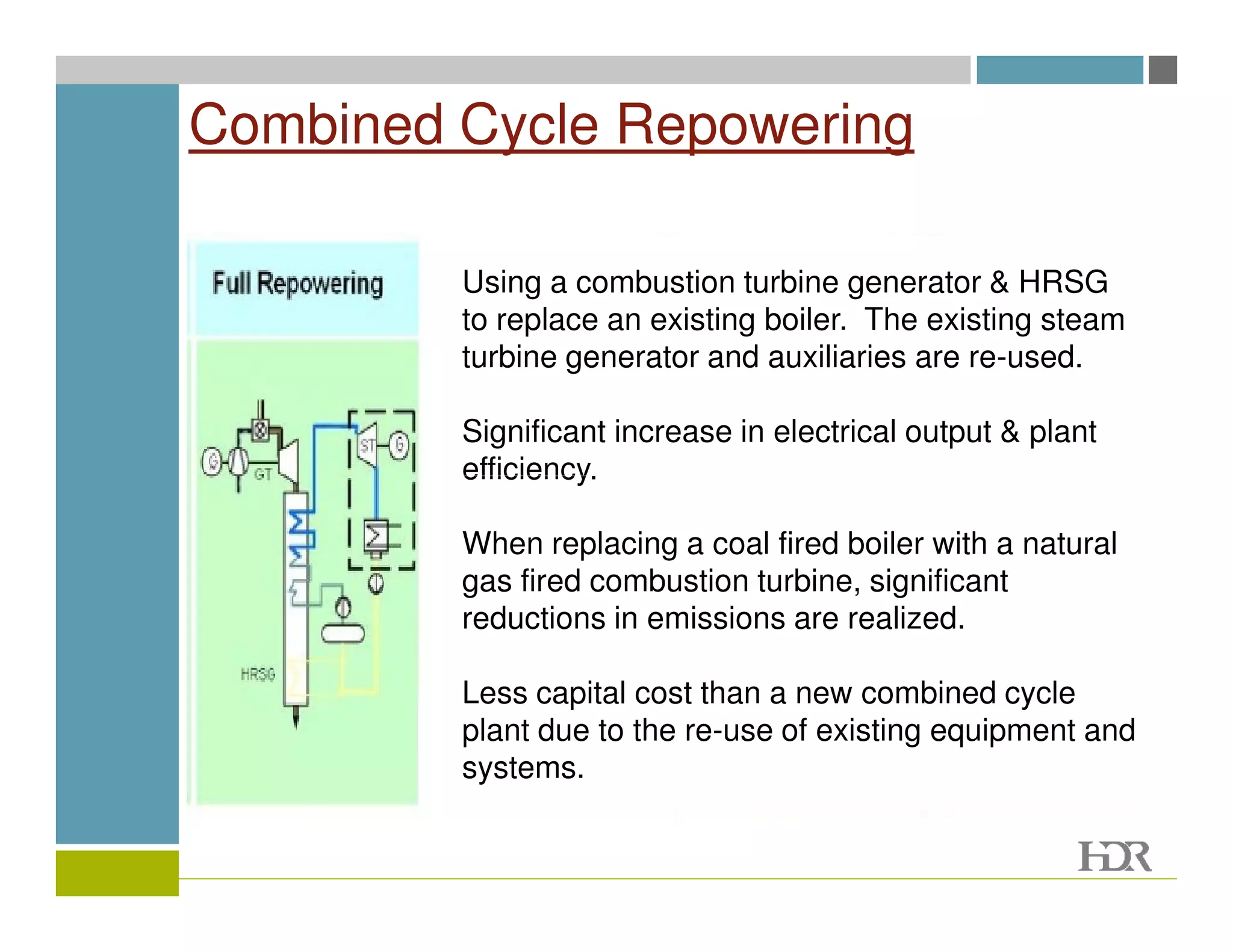

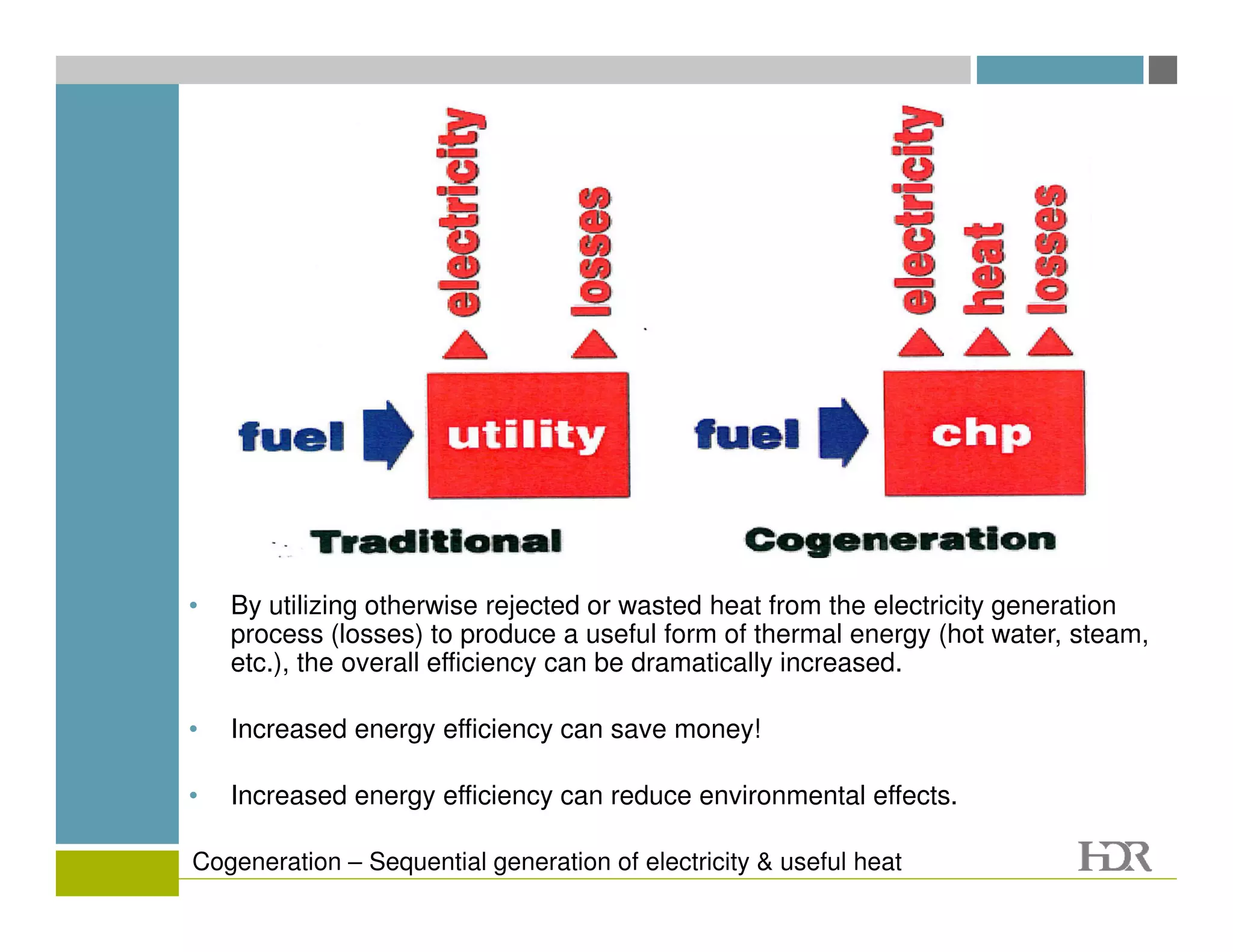

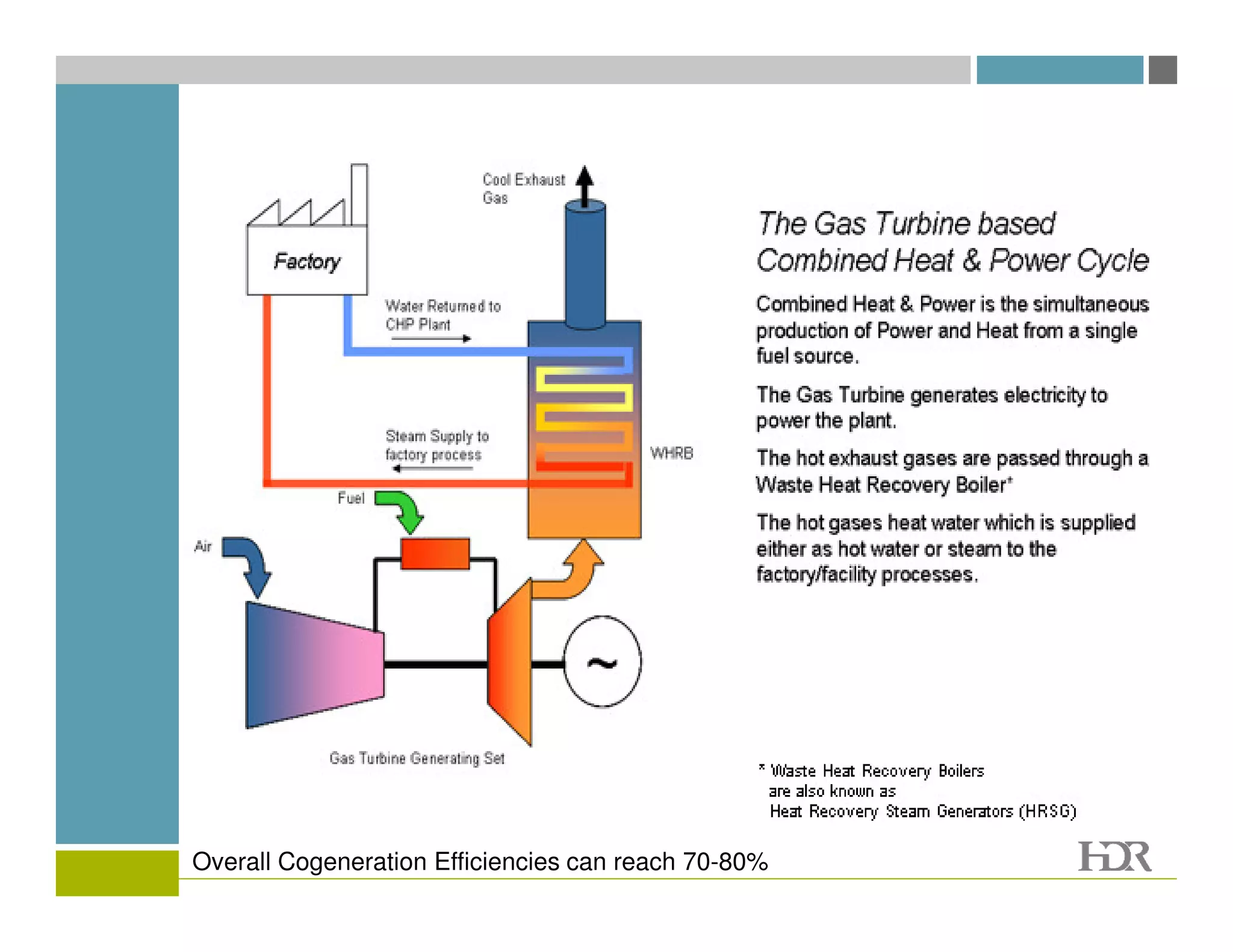

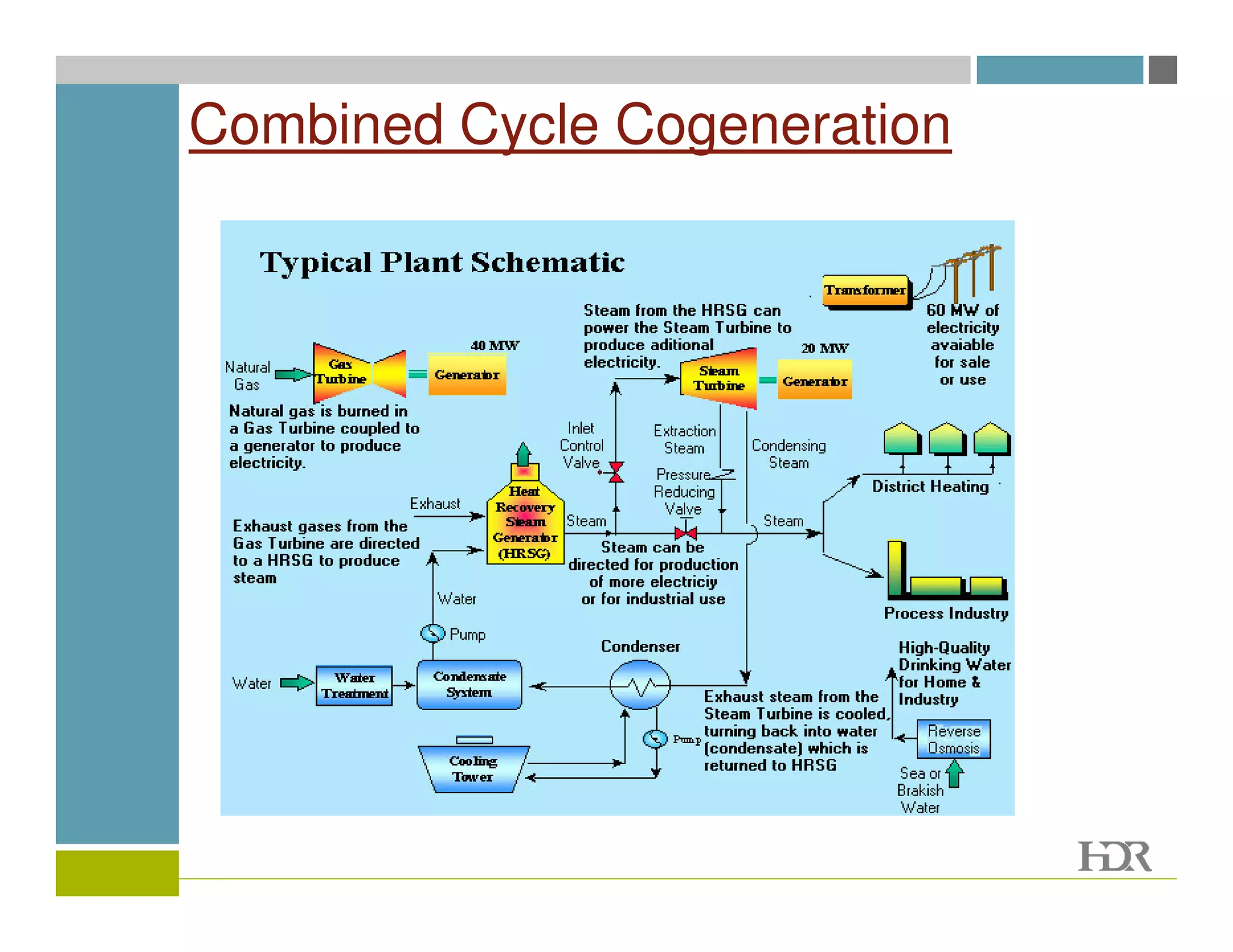

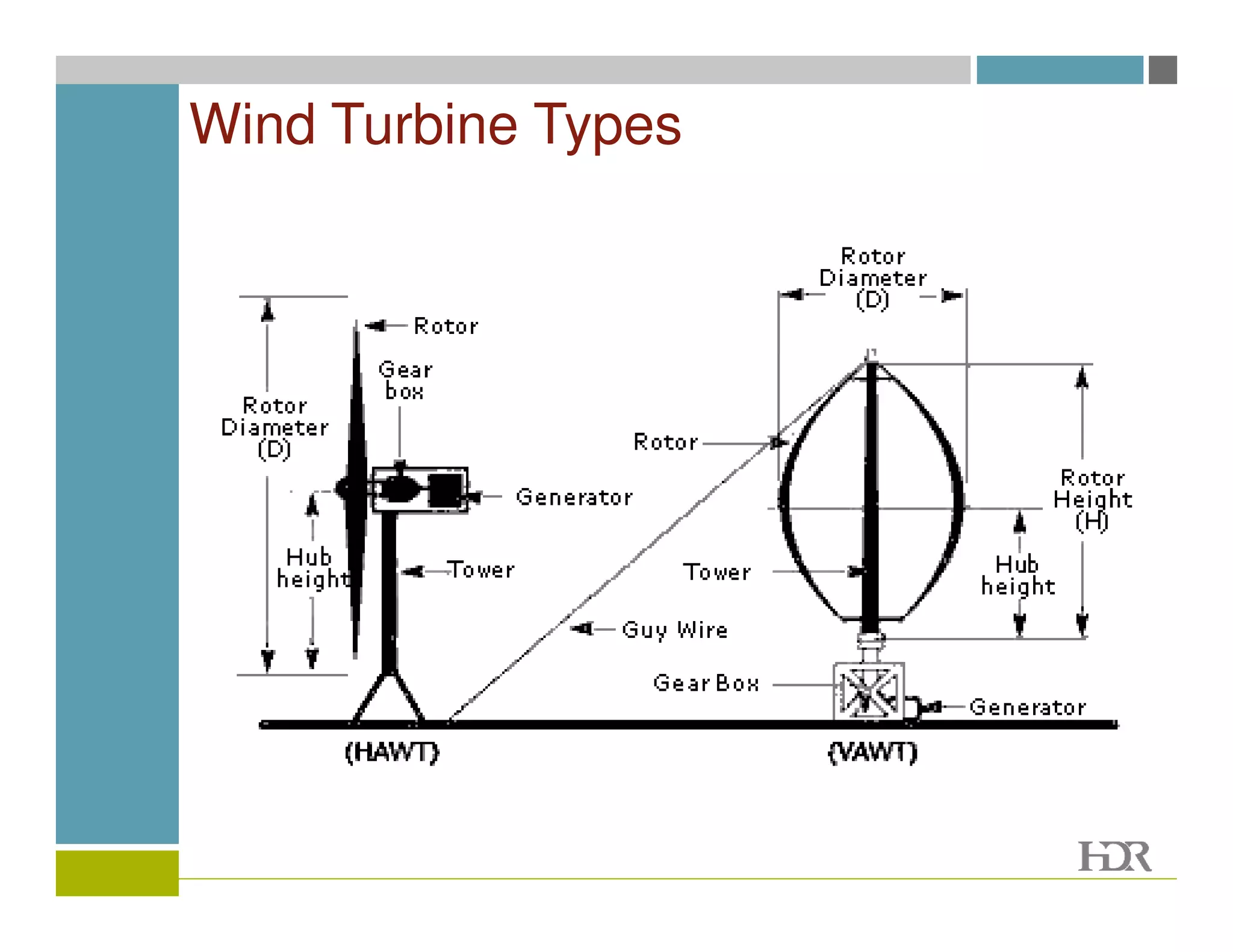

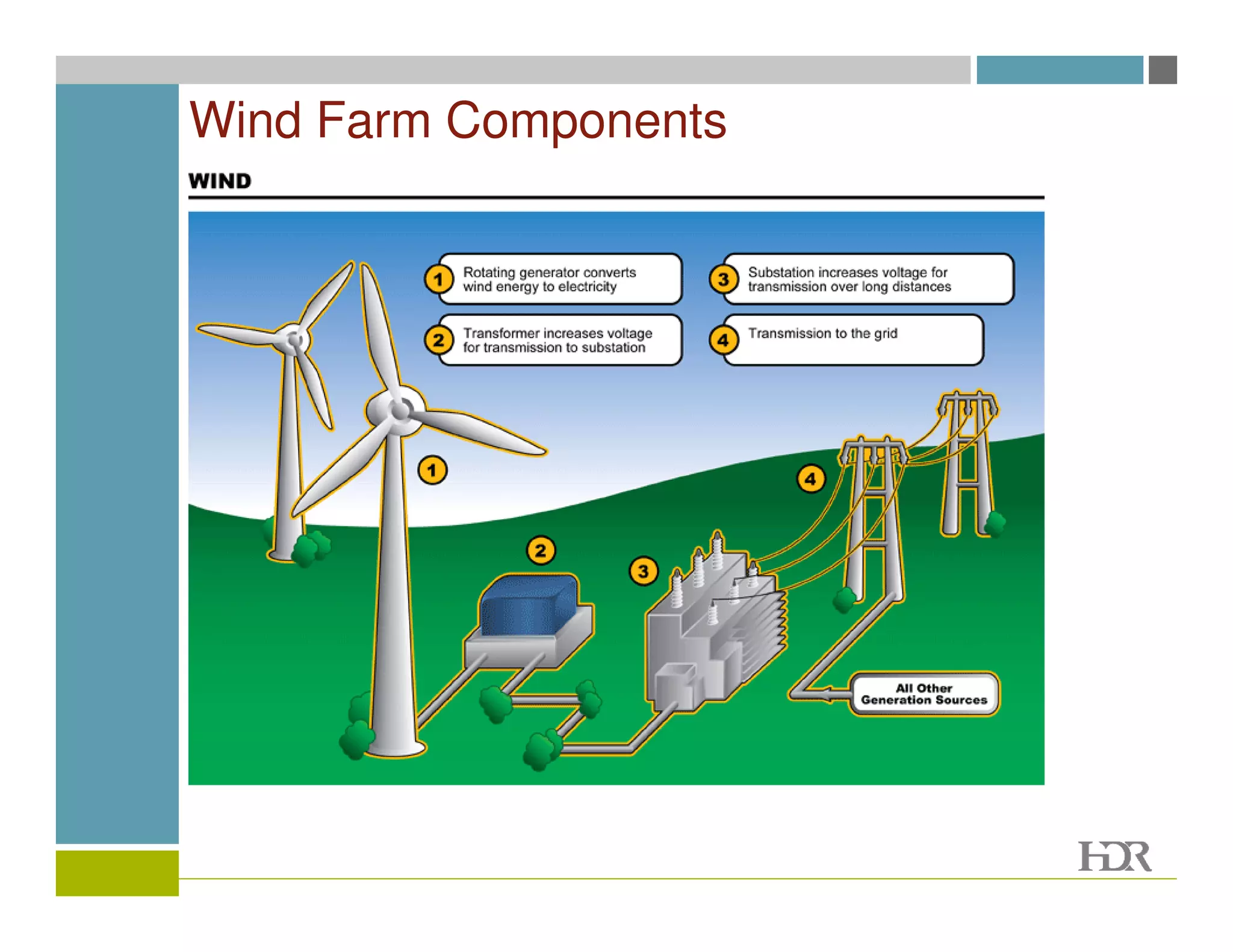

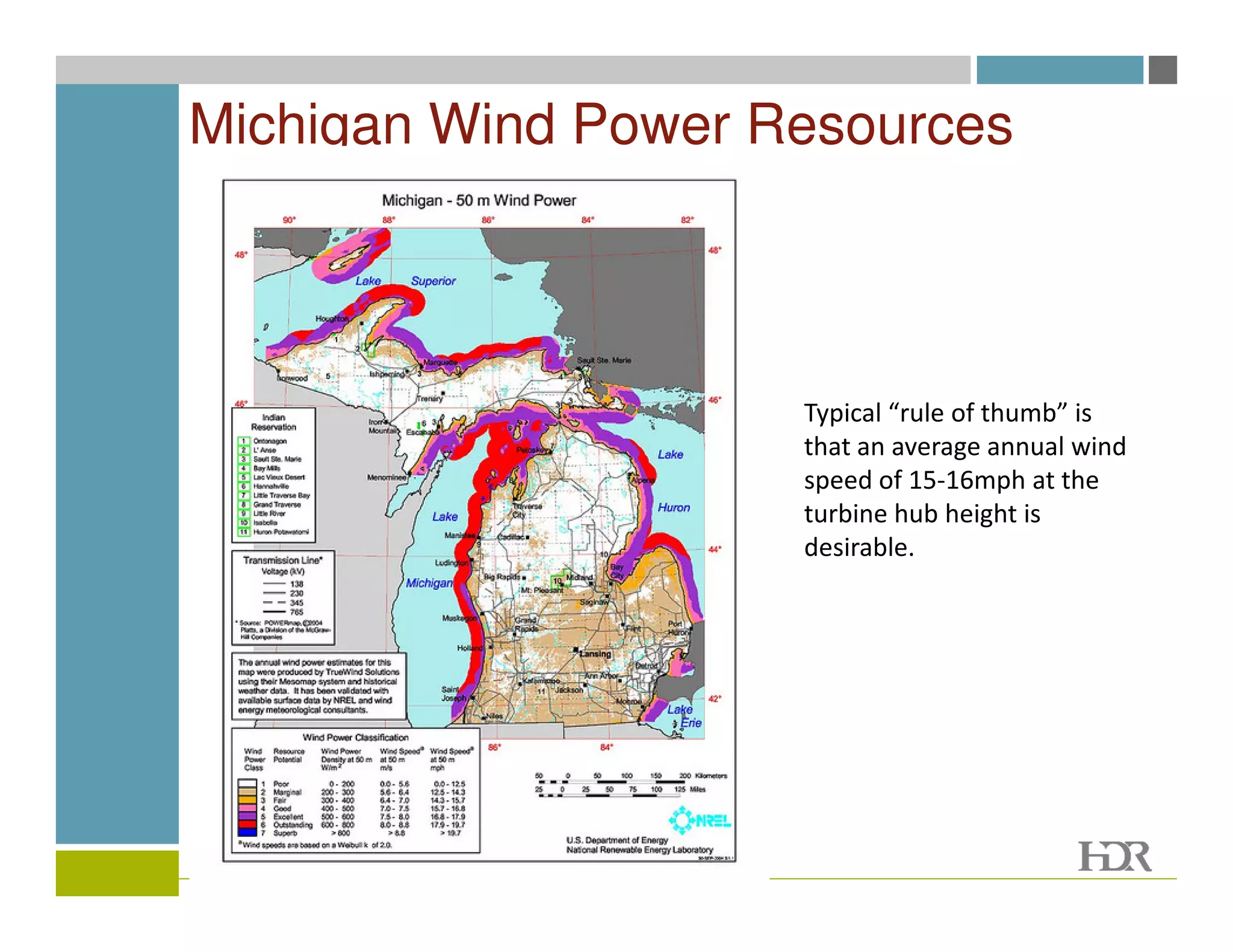

This document discusses various electric generation technologies including conventional steam power plants, combustion turbine power plants, combined cycle power plants, cogeneration/combined heat and power systems, wind power, and solar power. It provides an overview of how each technology works at a high level, typical efficiencies, advantages, and disadvantages. Key points covered include the Rankine cycle for steam plants, Brayton cycle for gas turbines, increased efficiency of combined cycle plants, utilizing otherwise wasted heat for cogeneration, intermittent nature of wind but no emissions, and different solar photovoltaic and concentrated solar technologies.