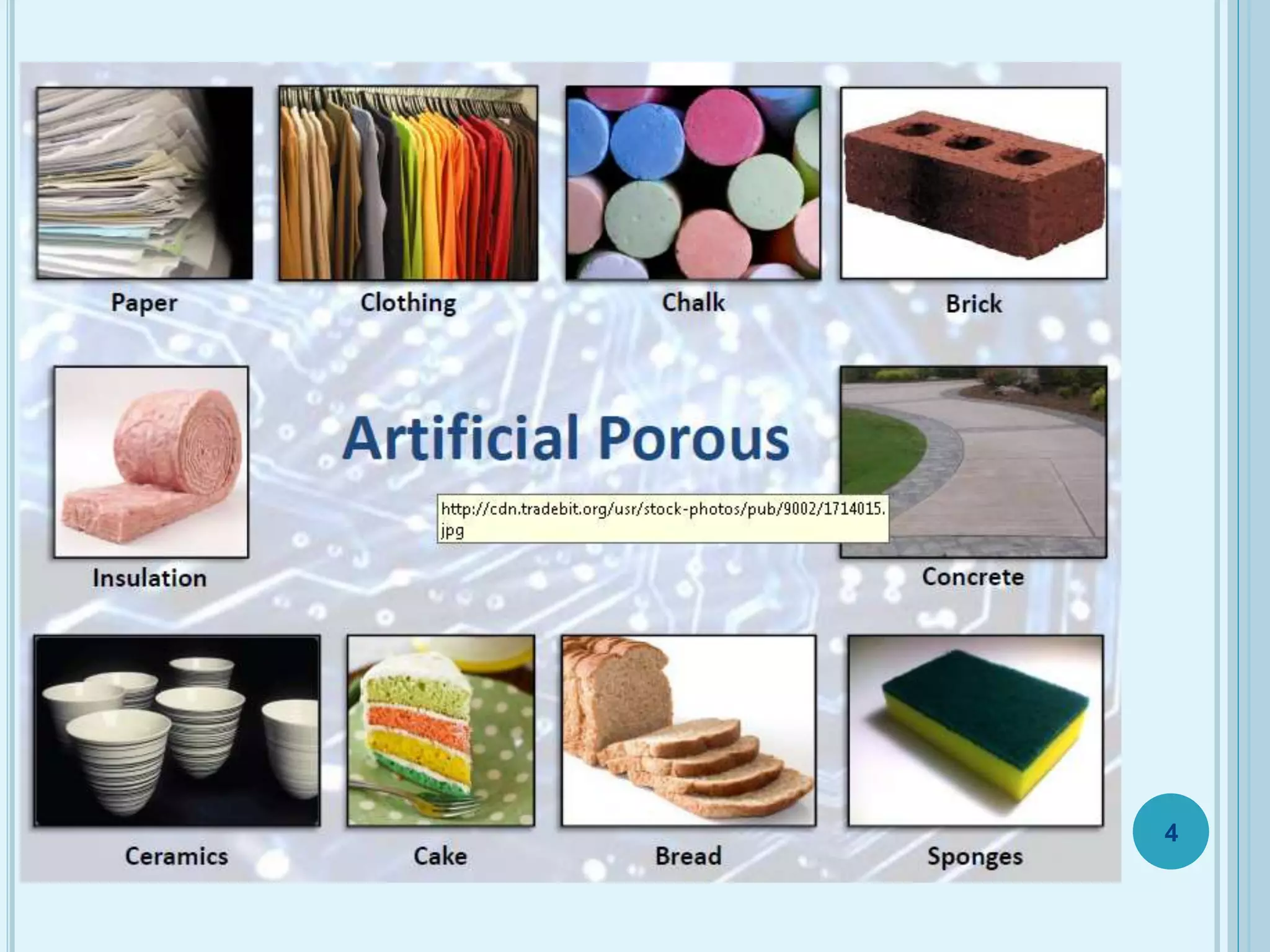

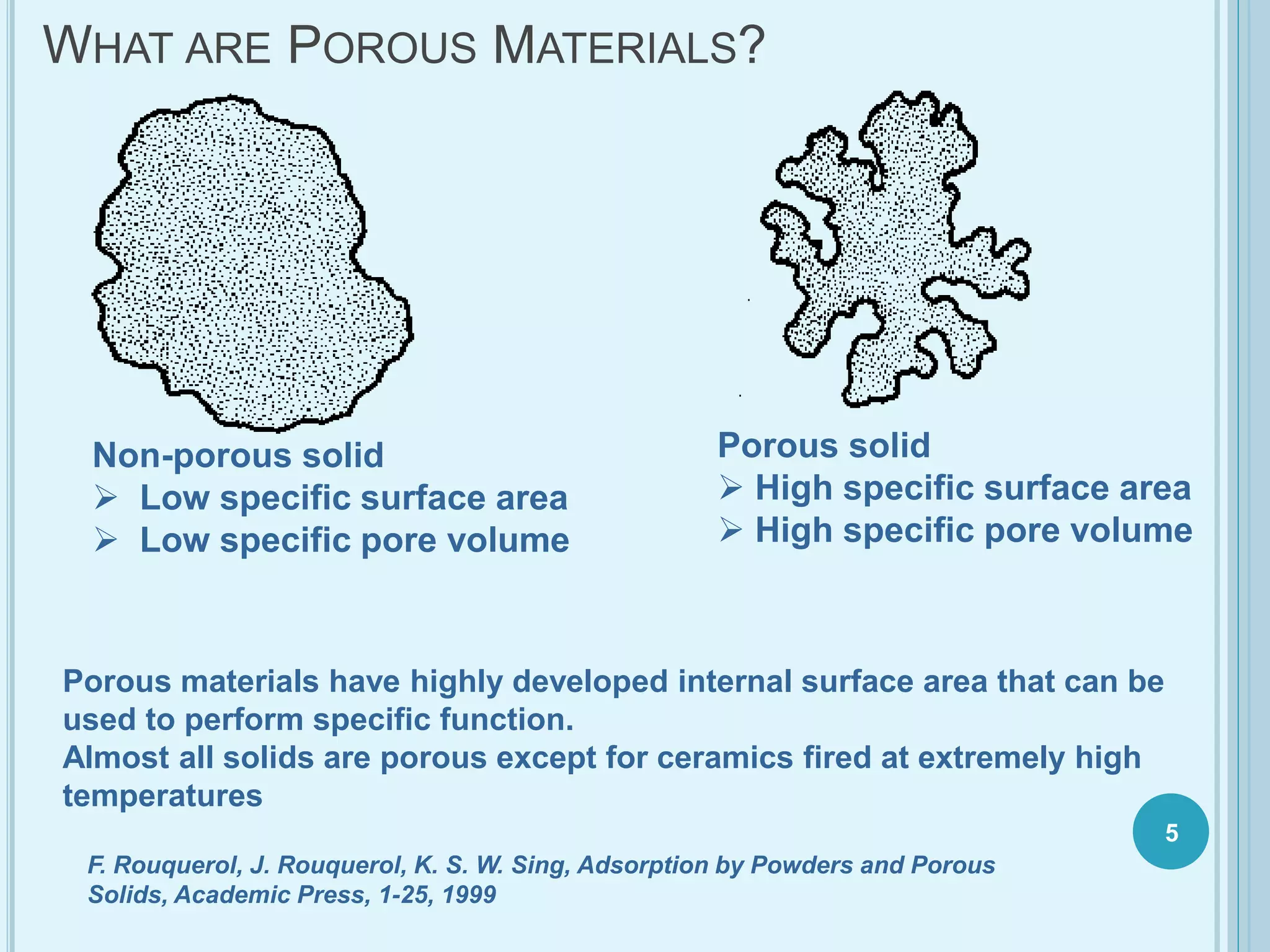

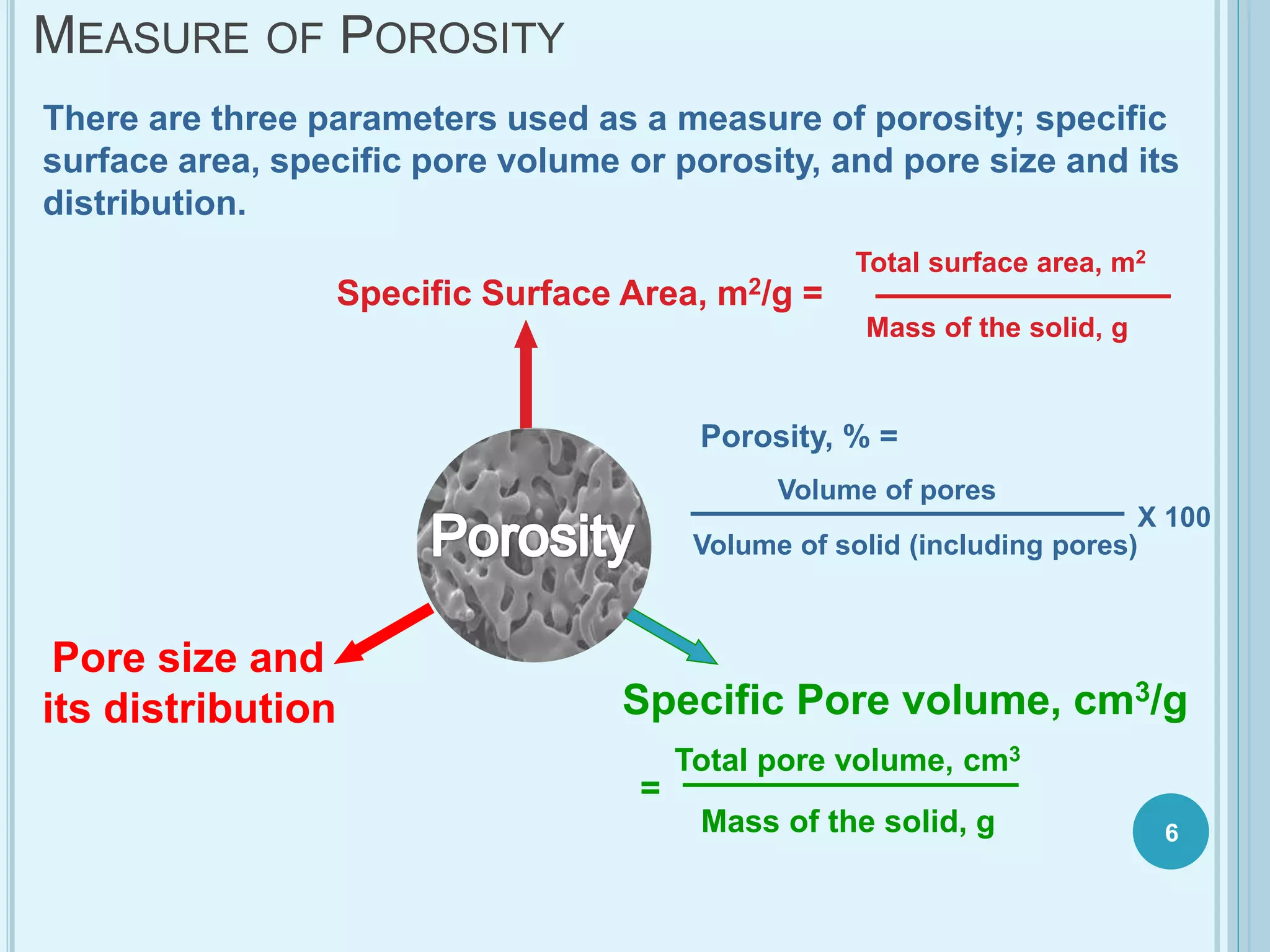

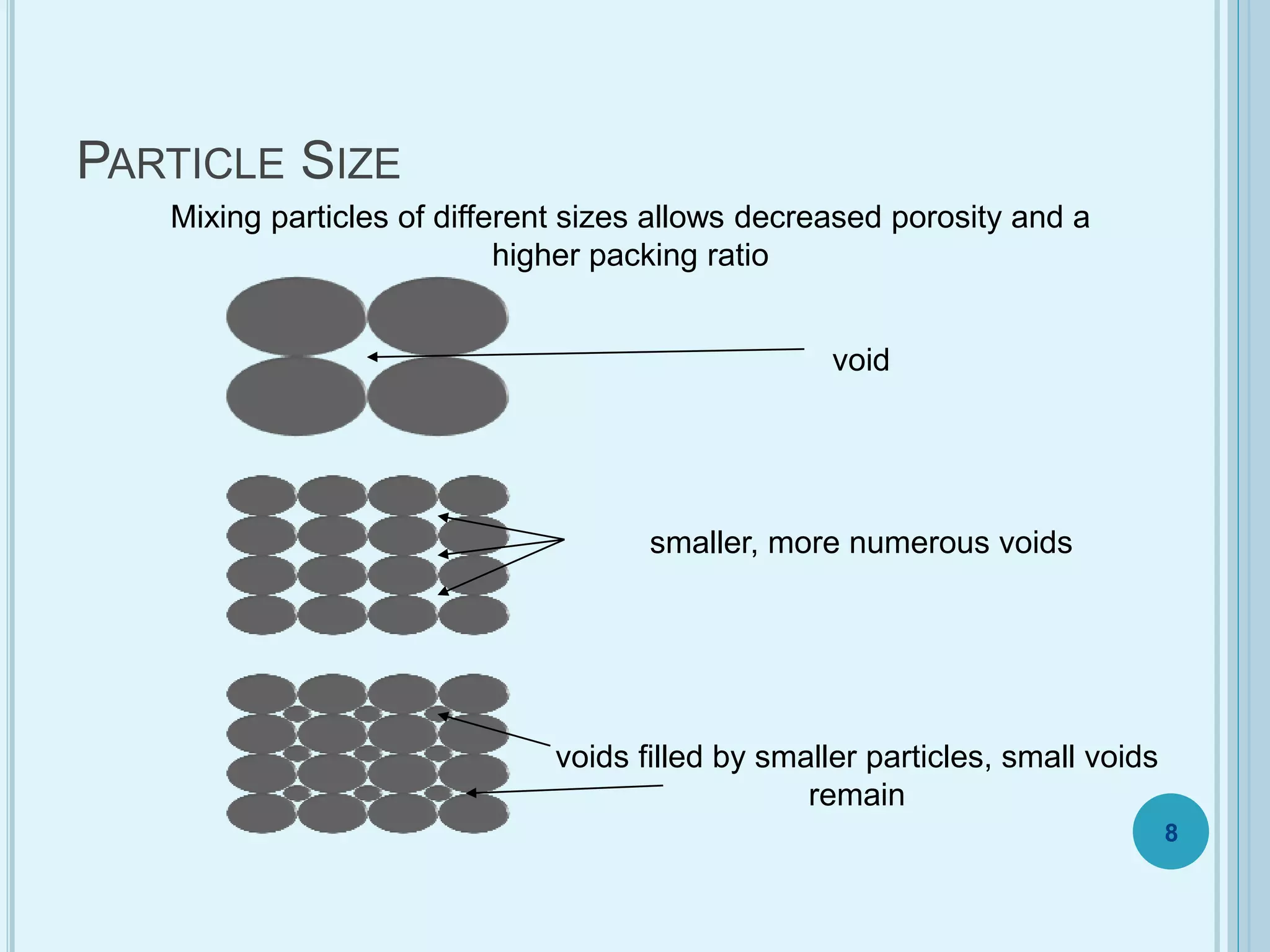

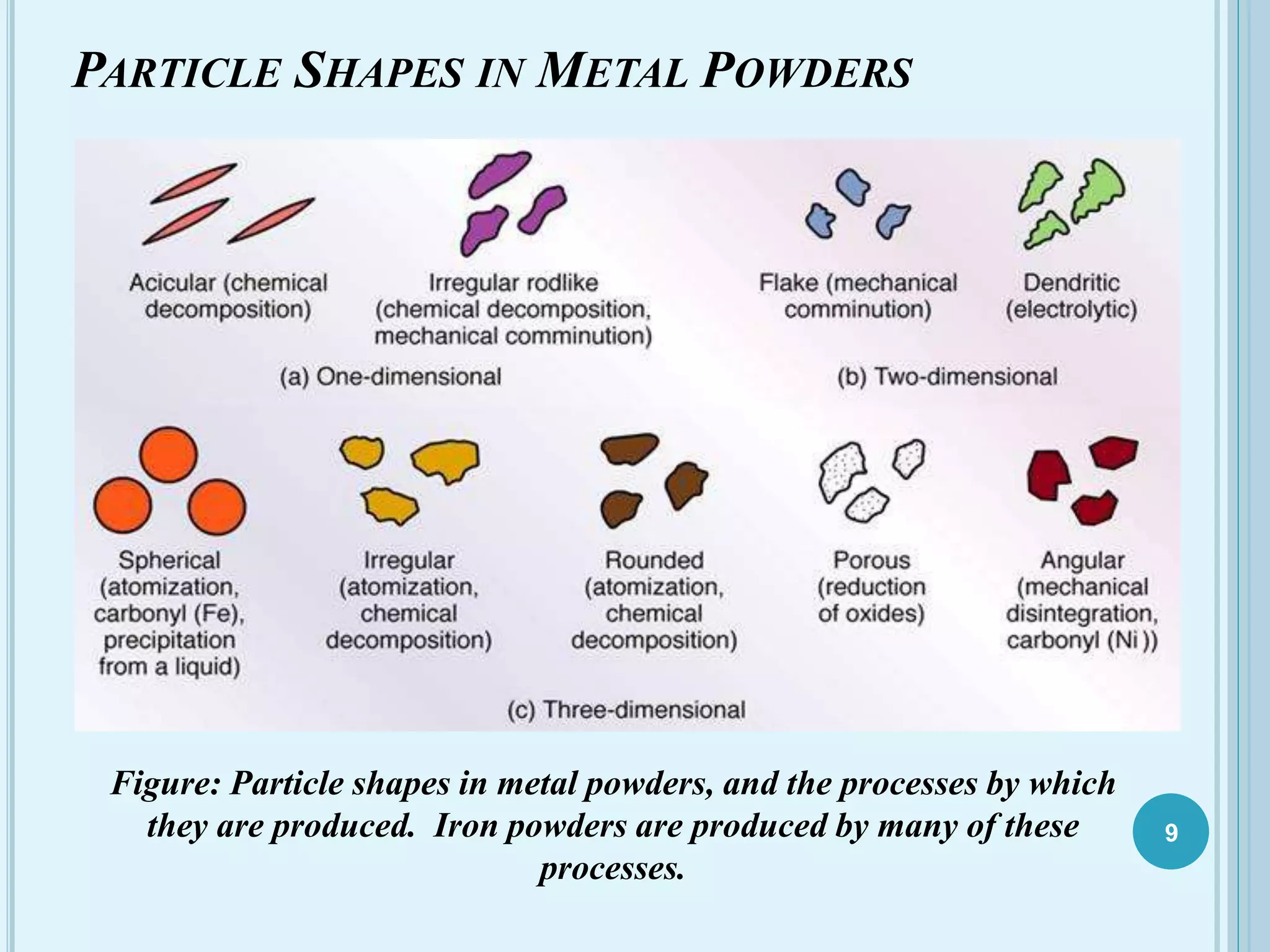

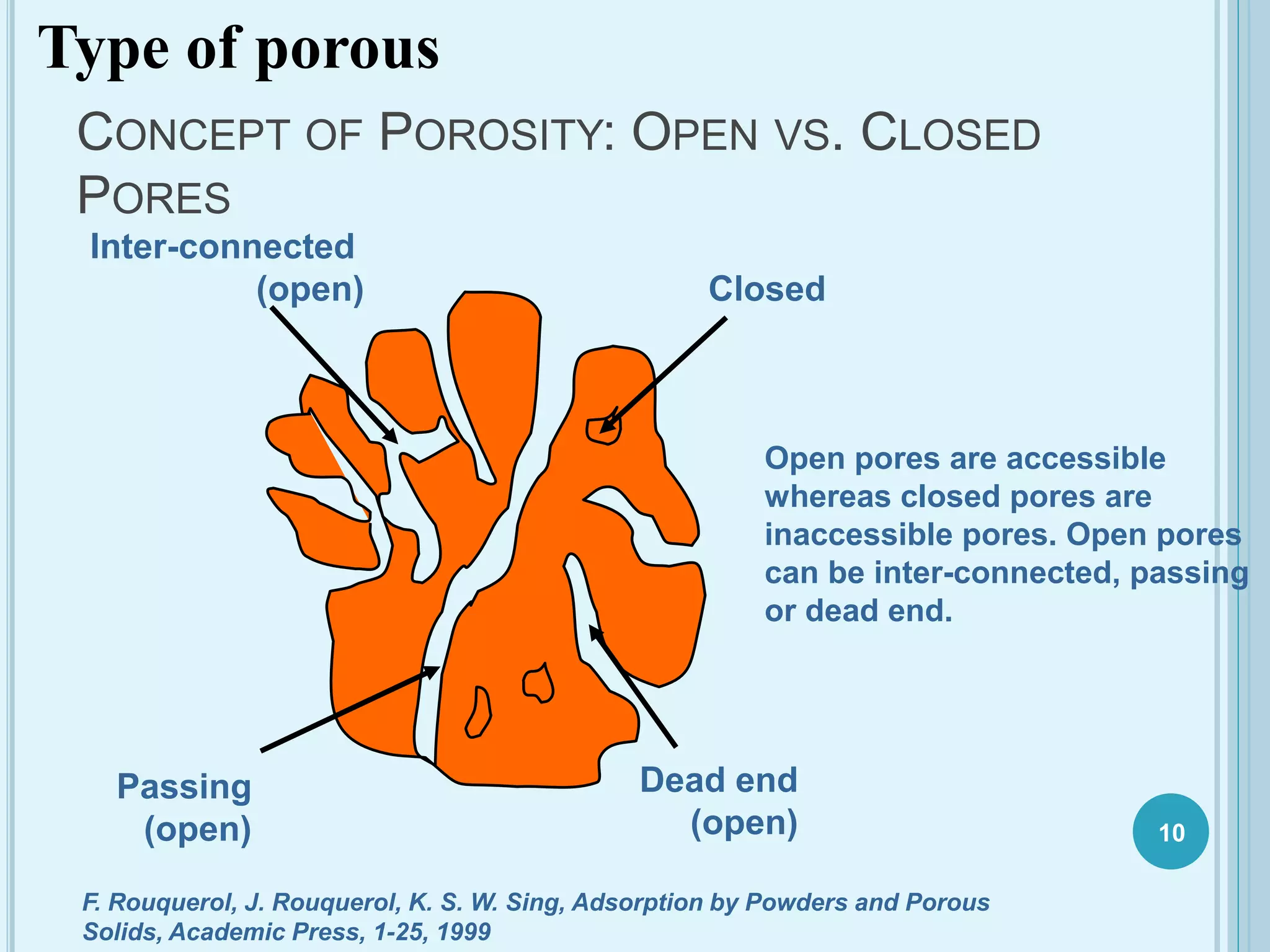

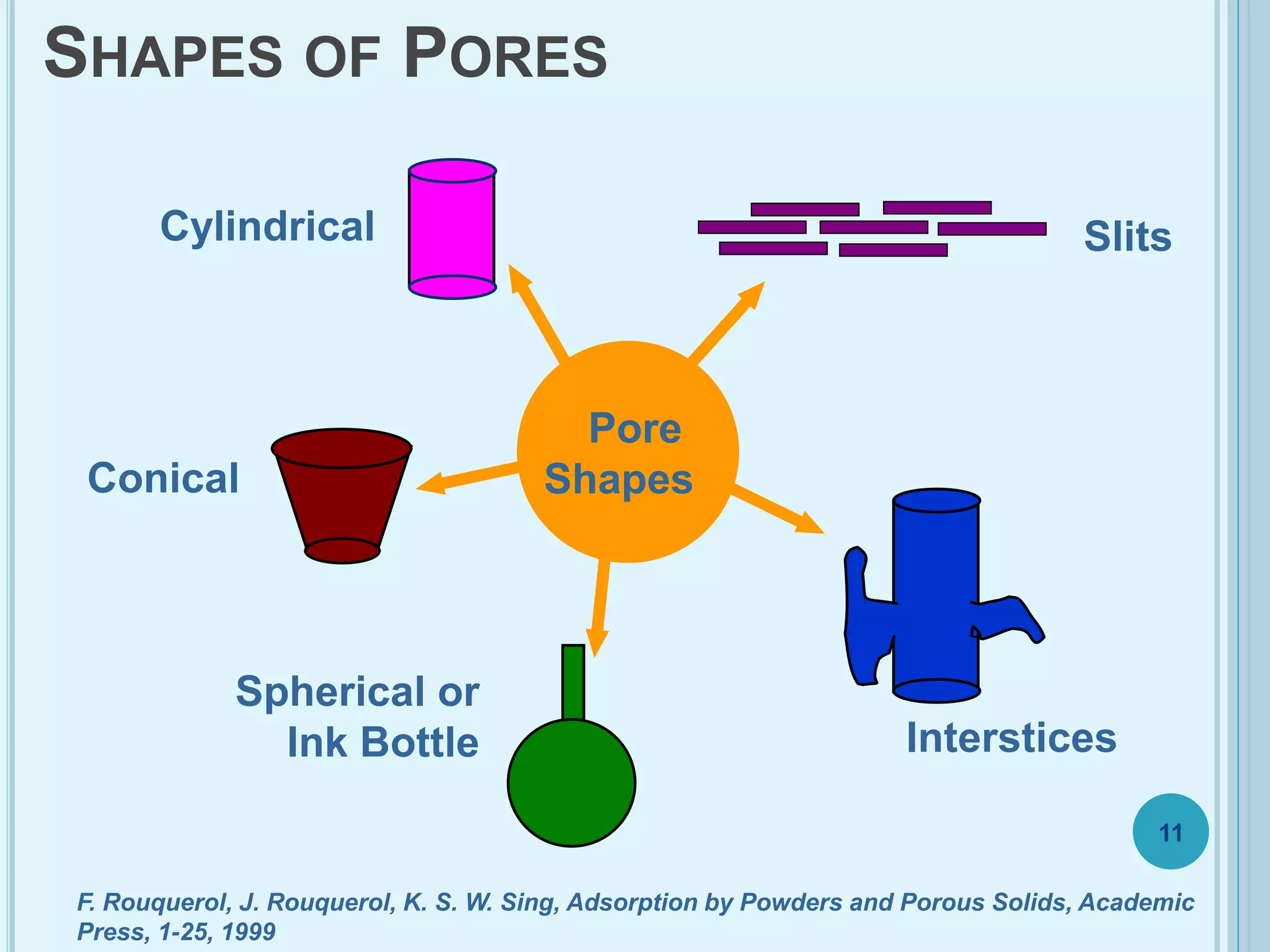

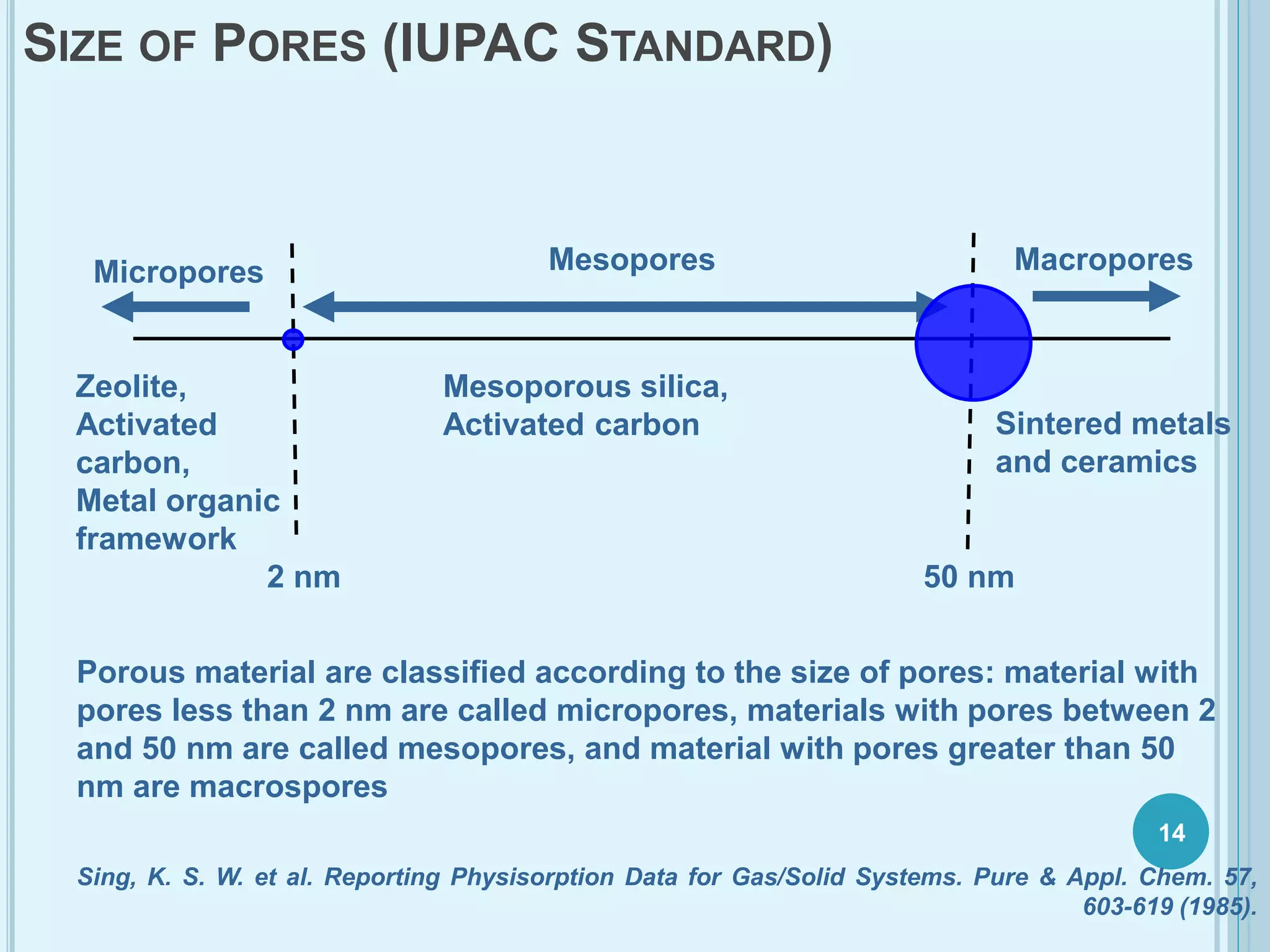

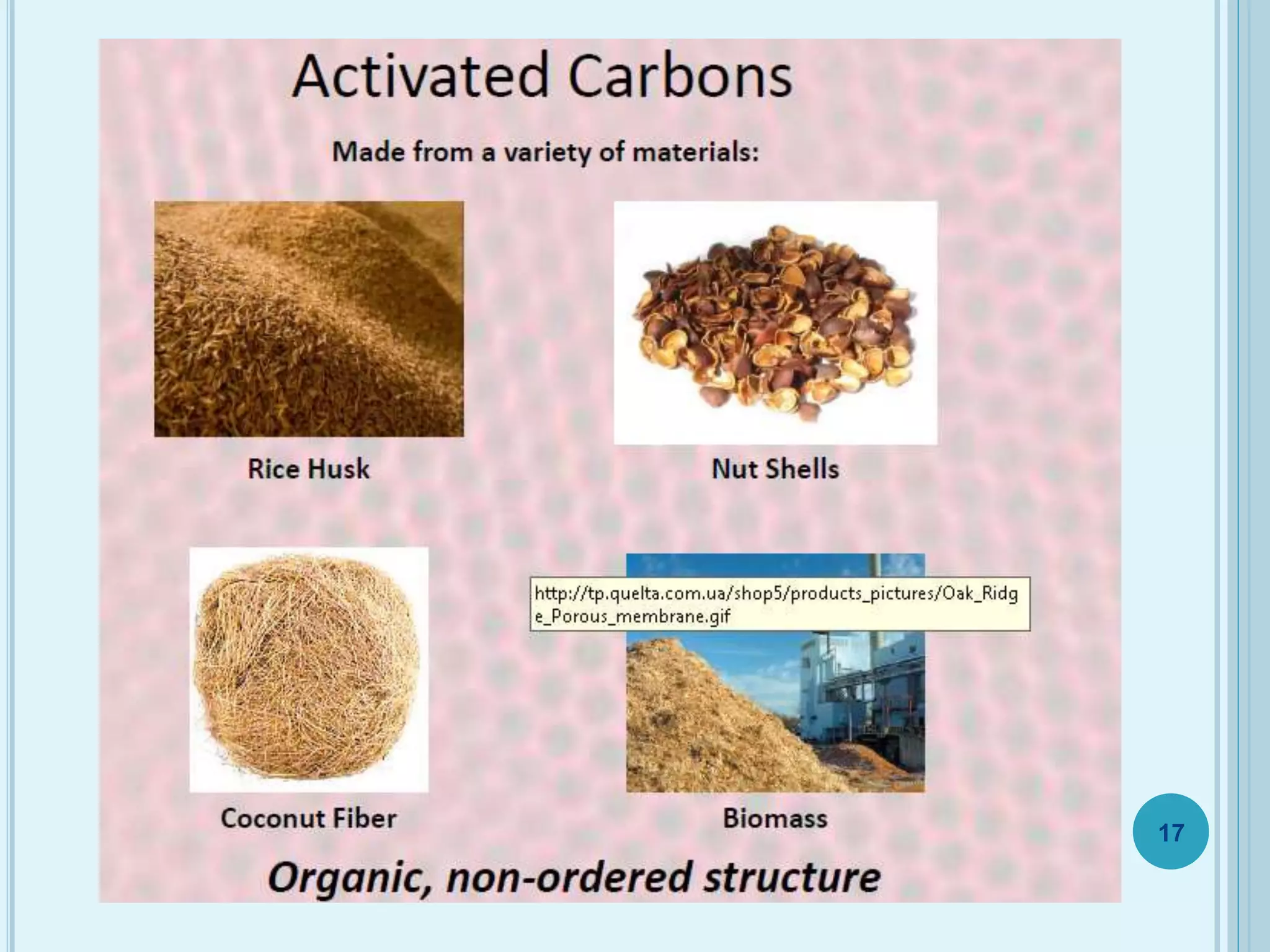

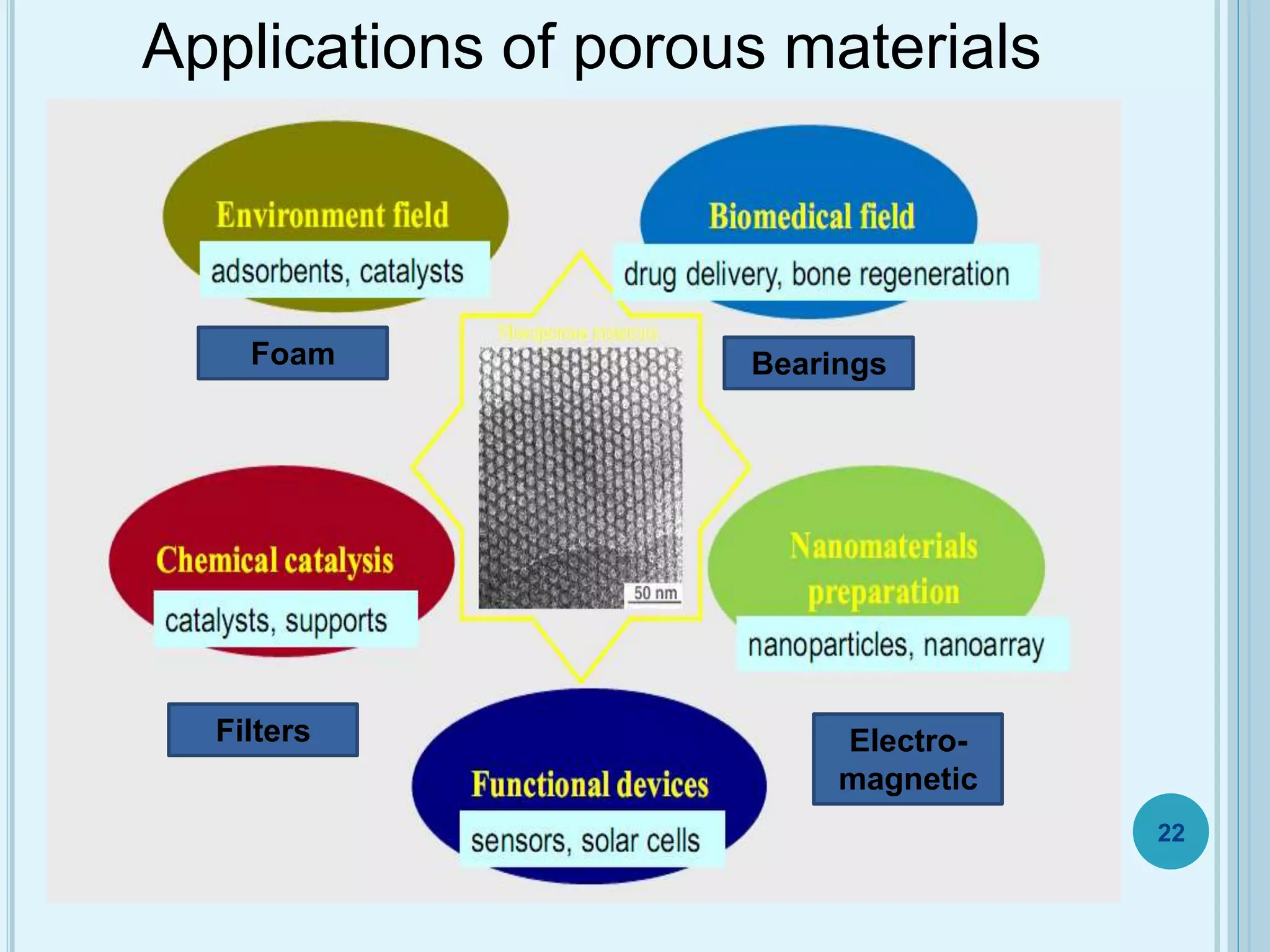

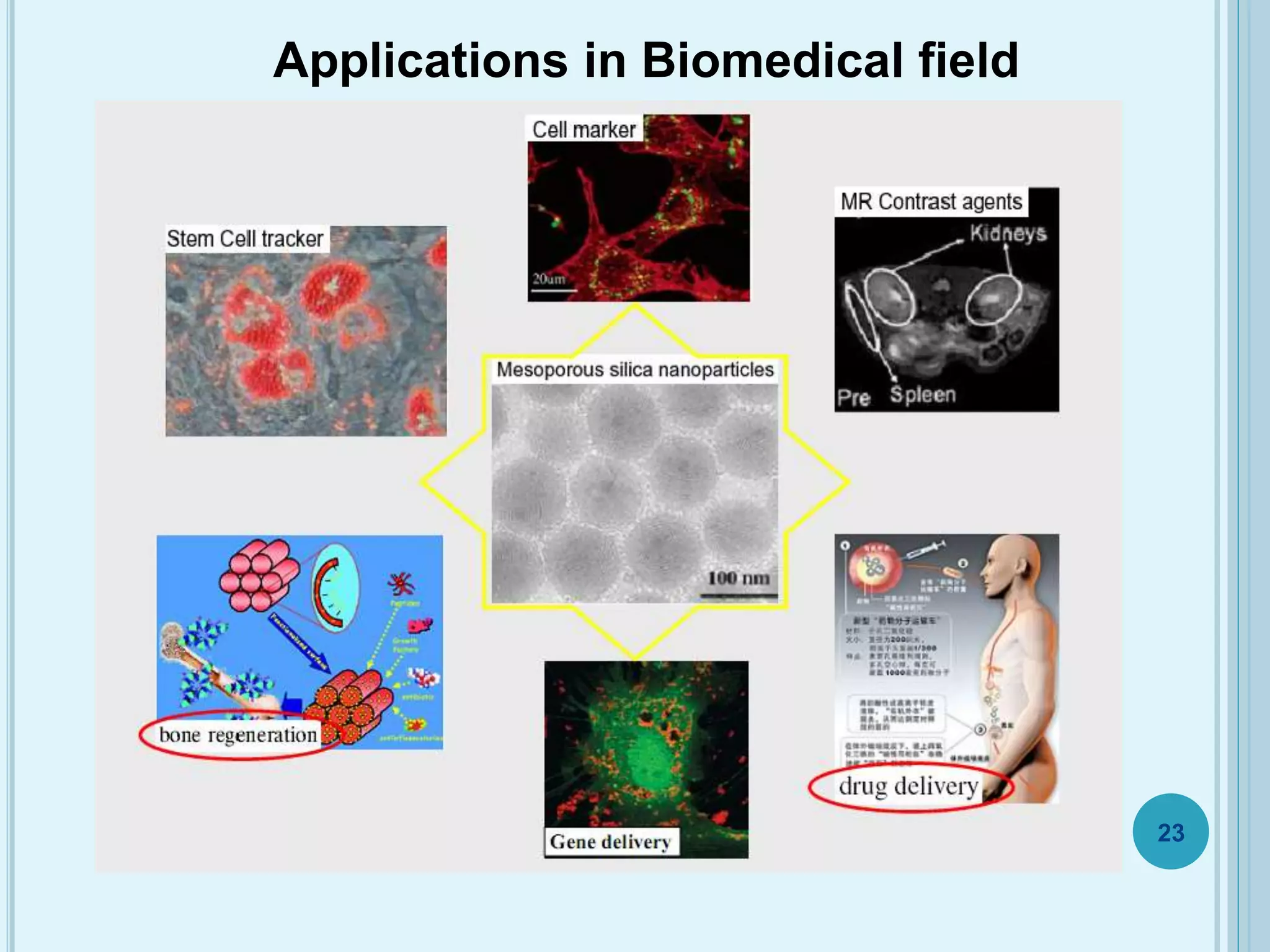

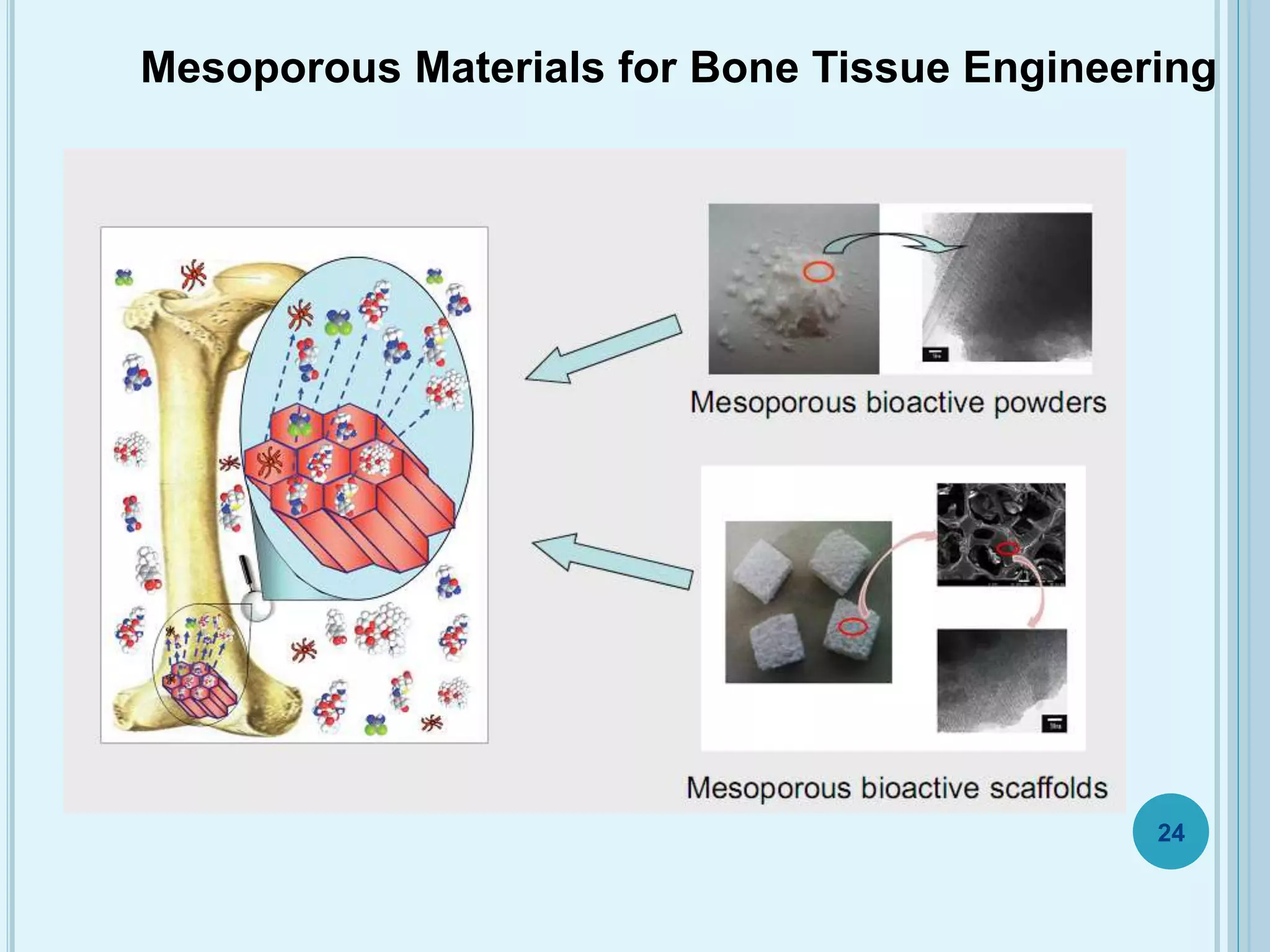

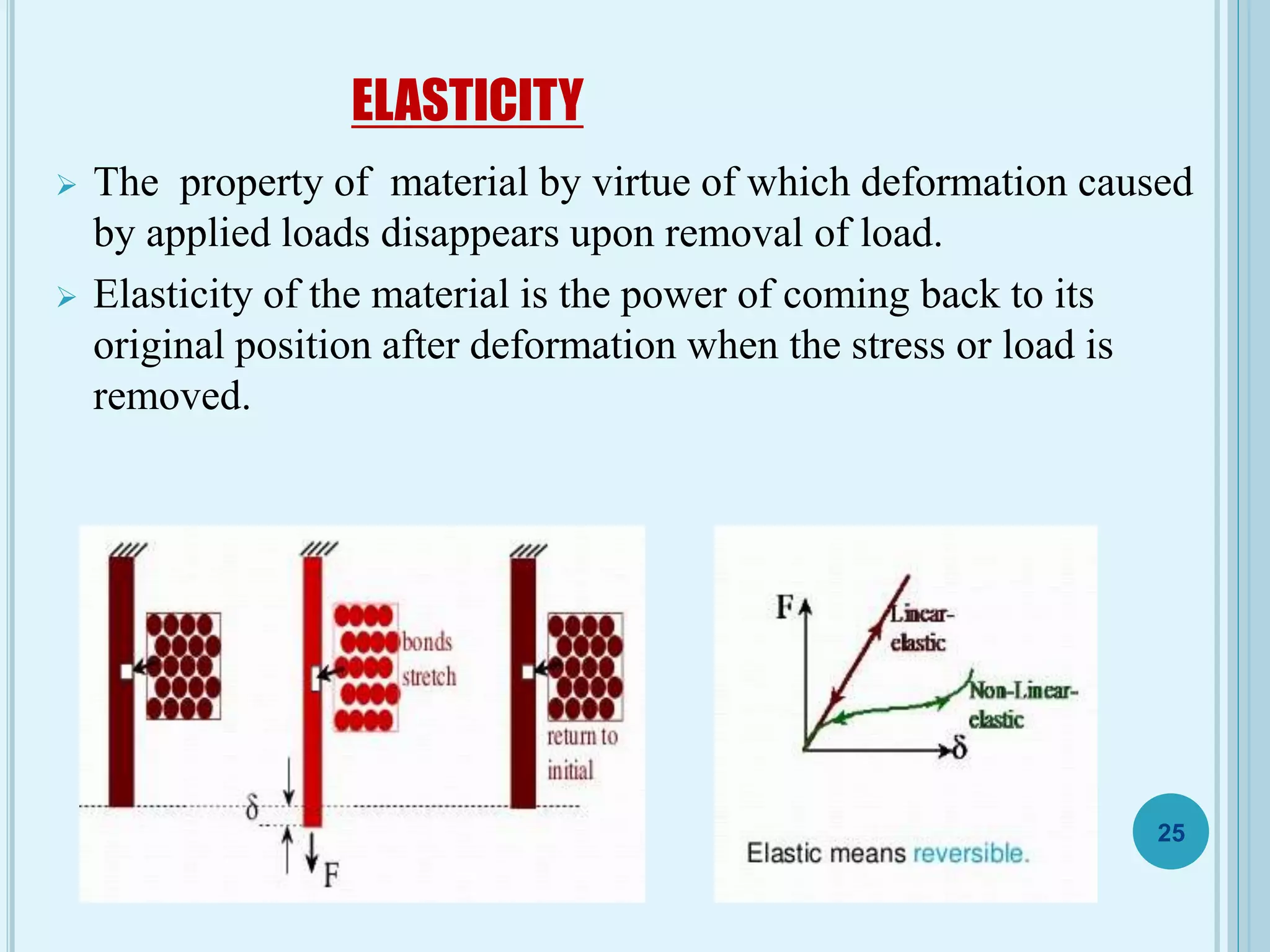

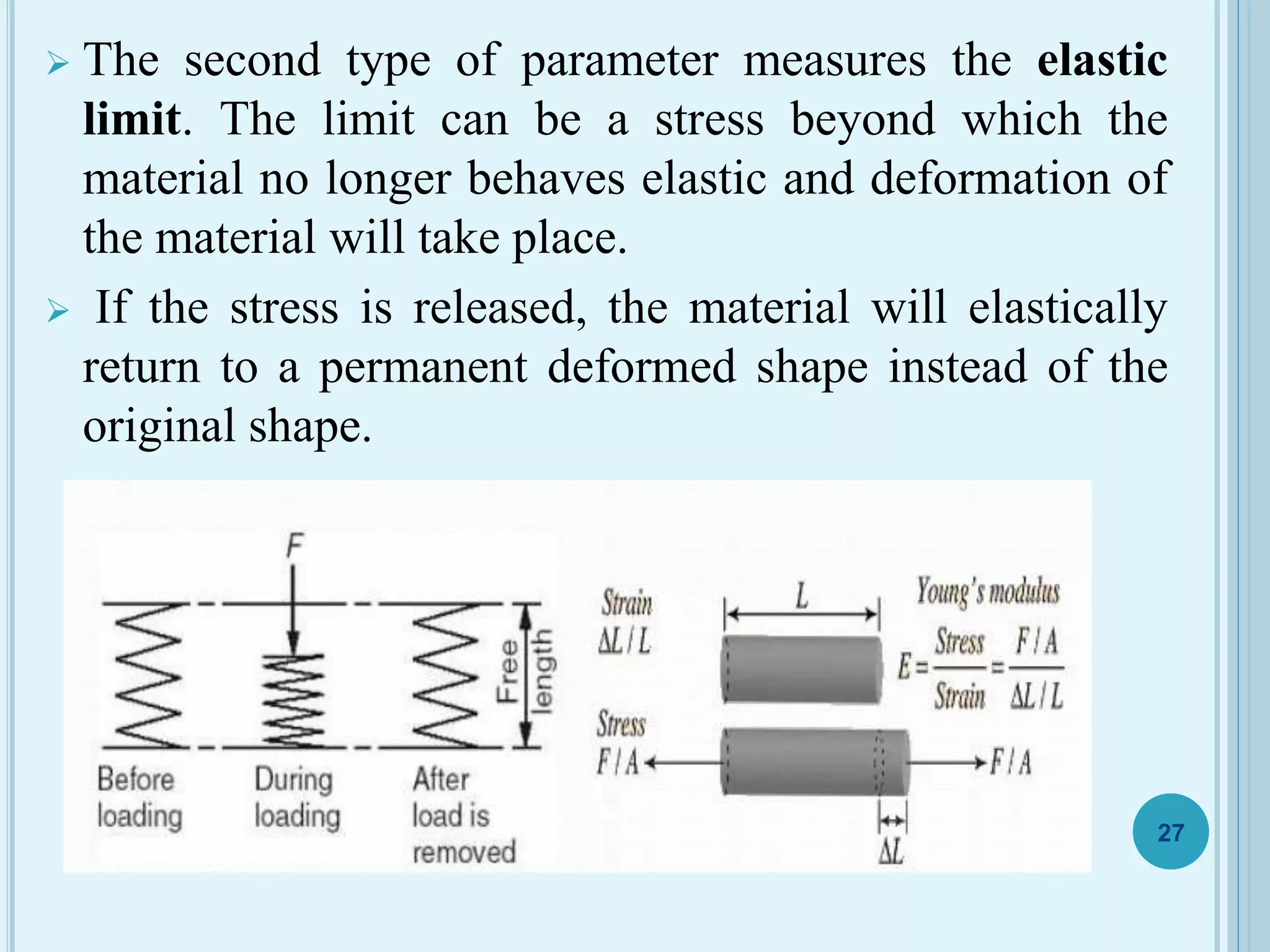

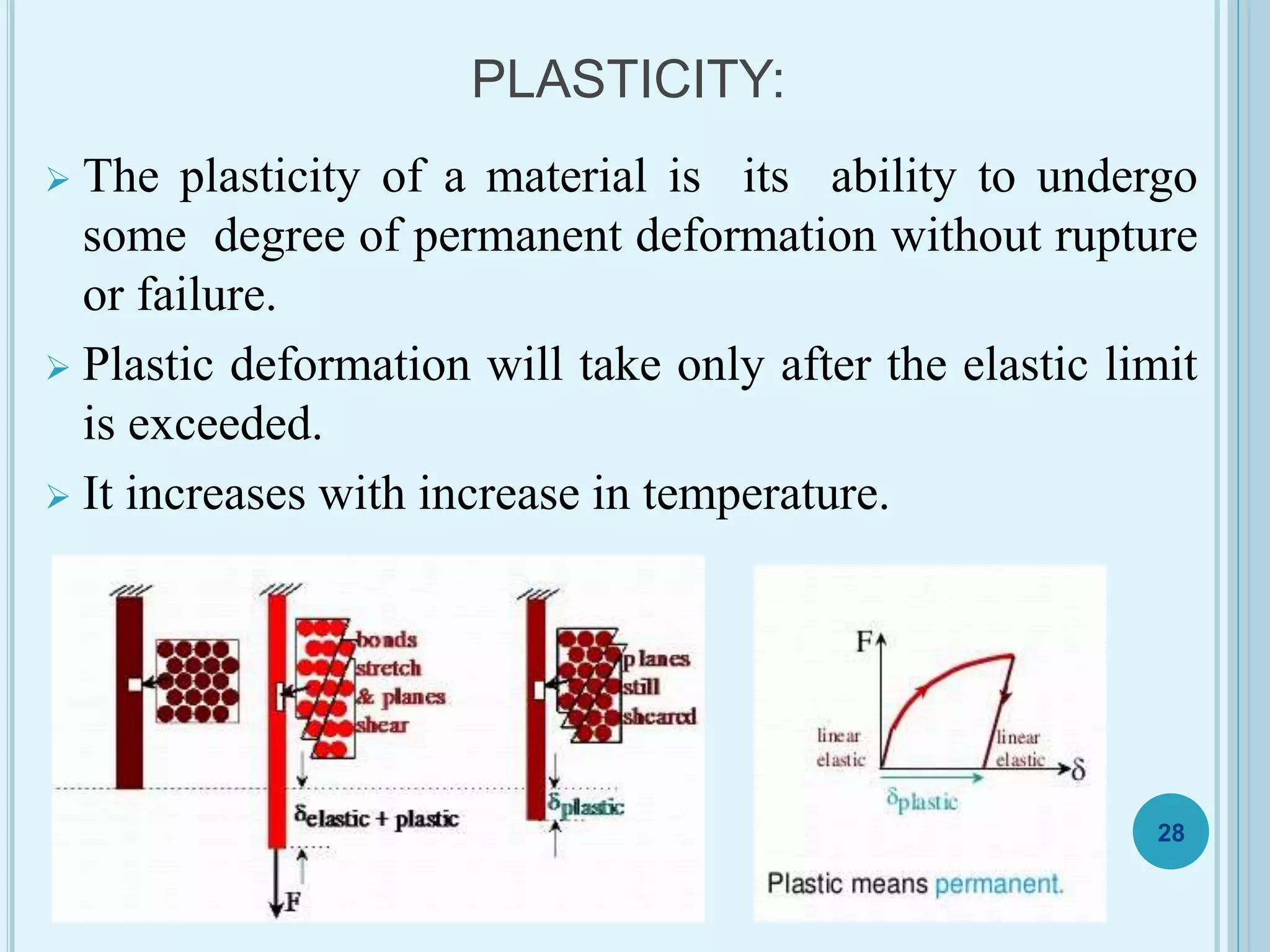

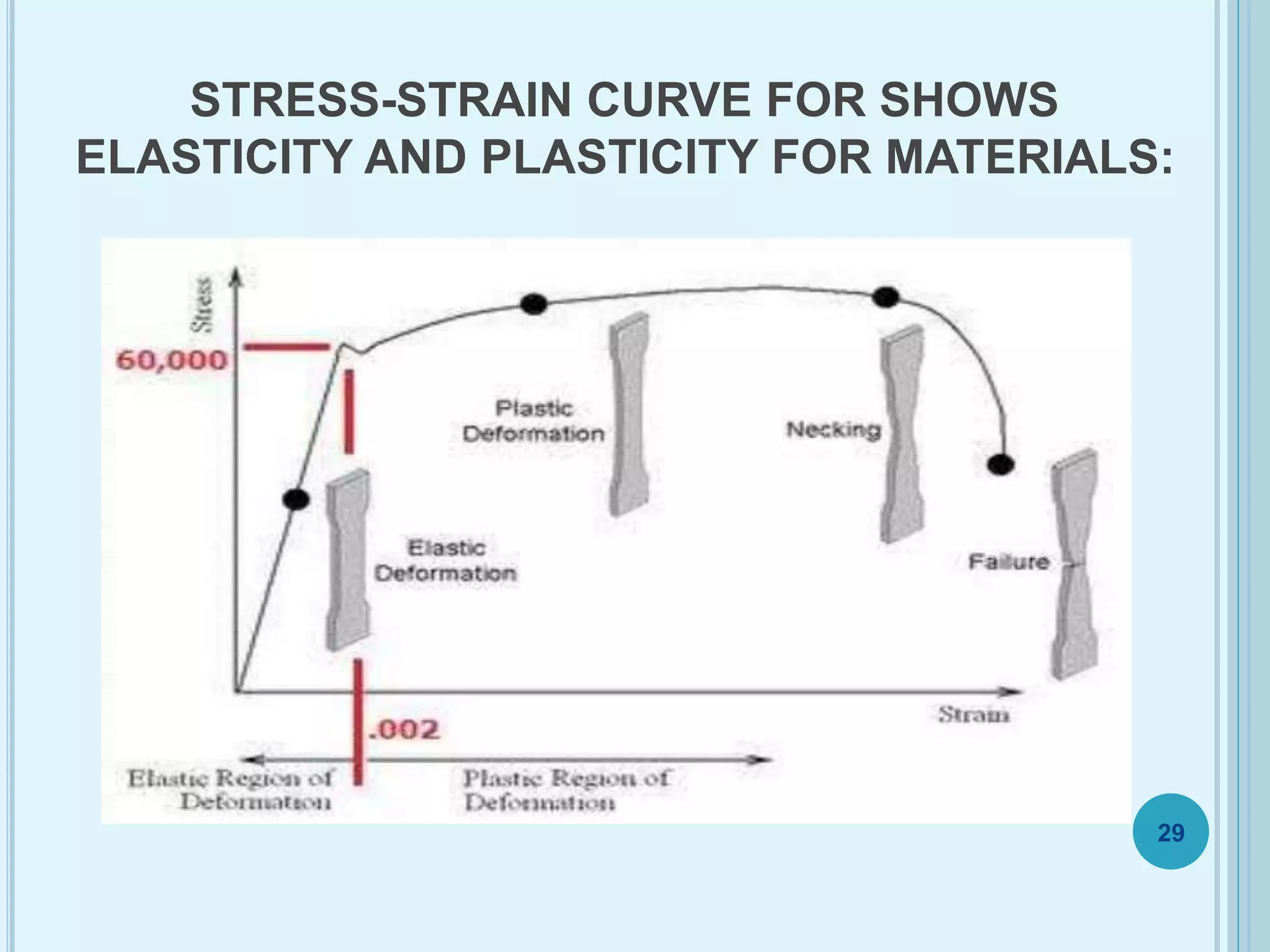

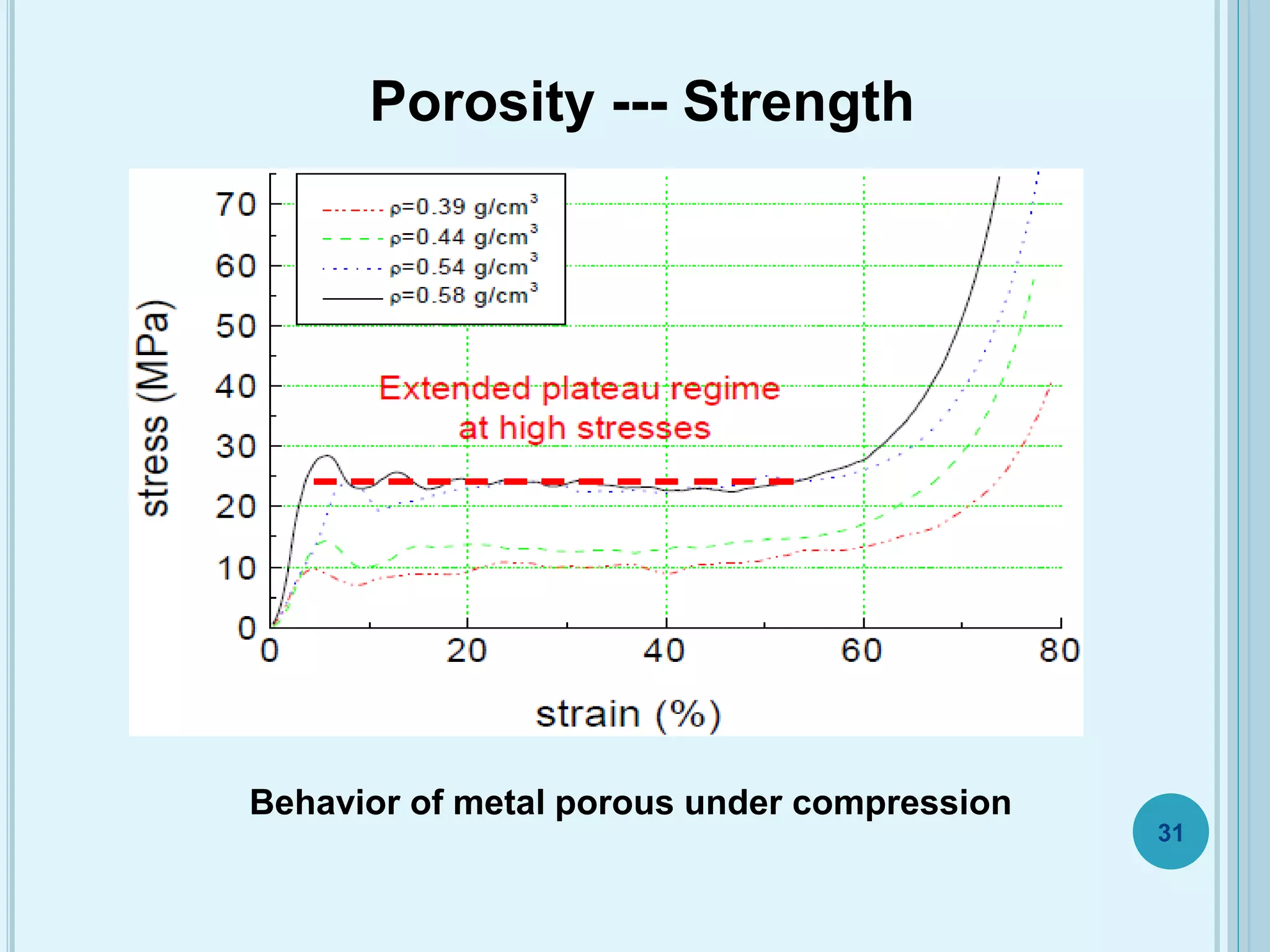

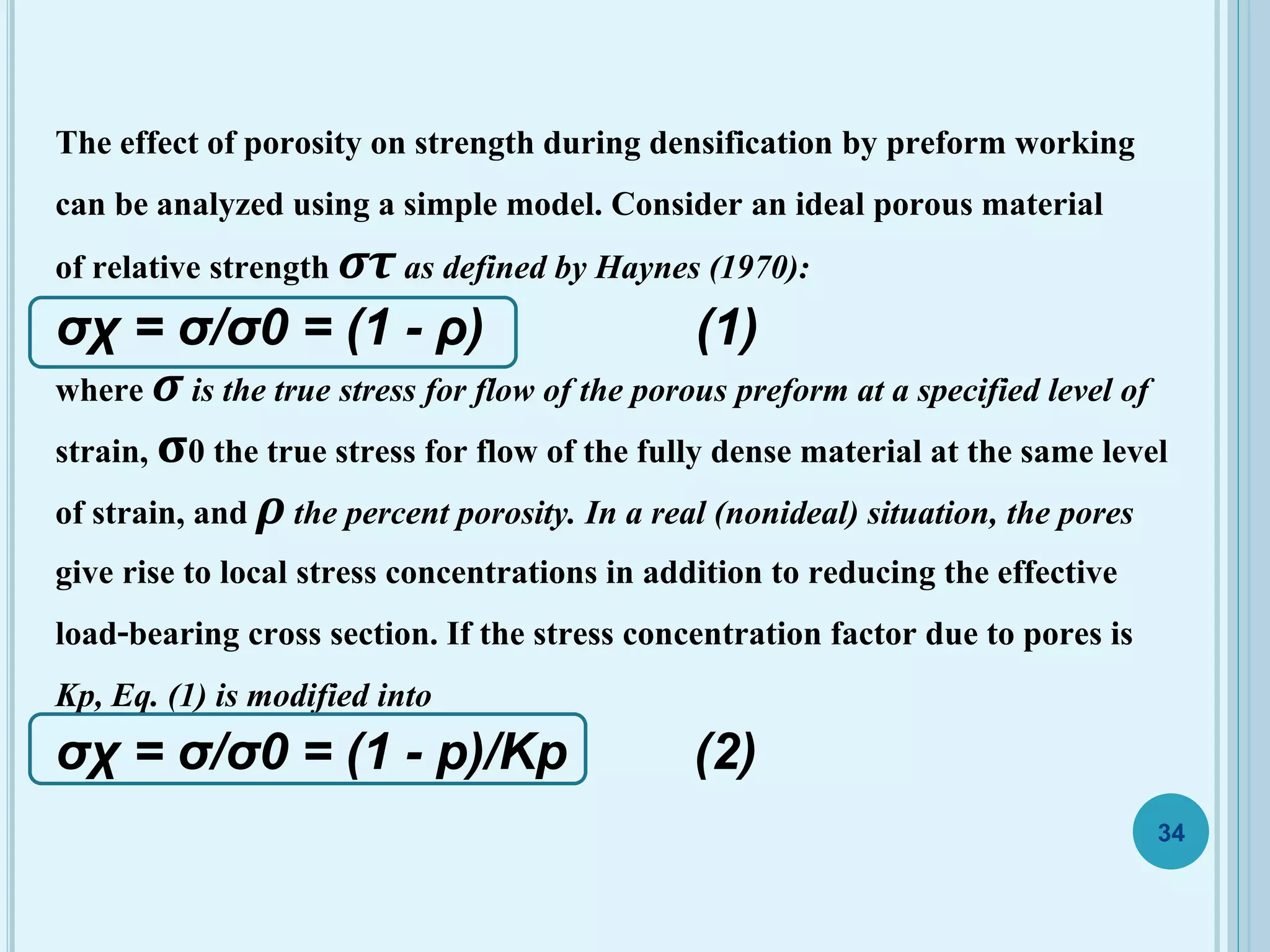

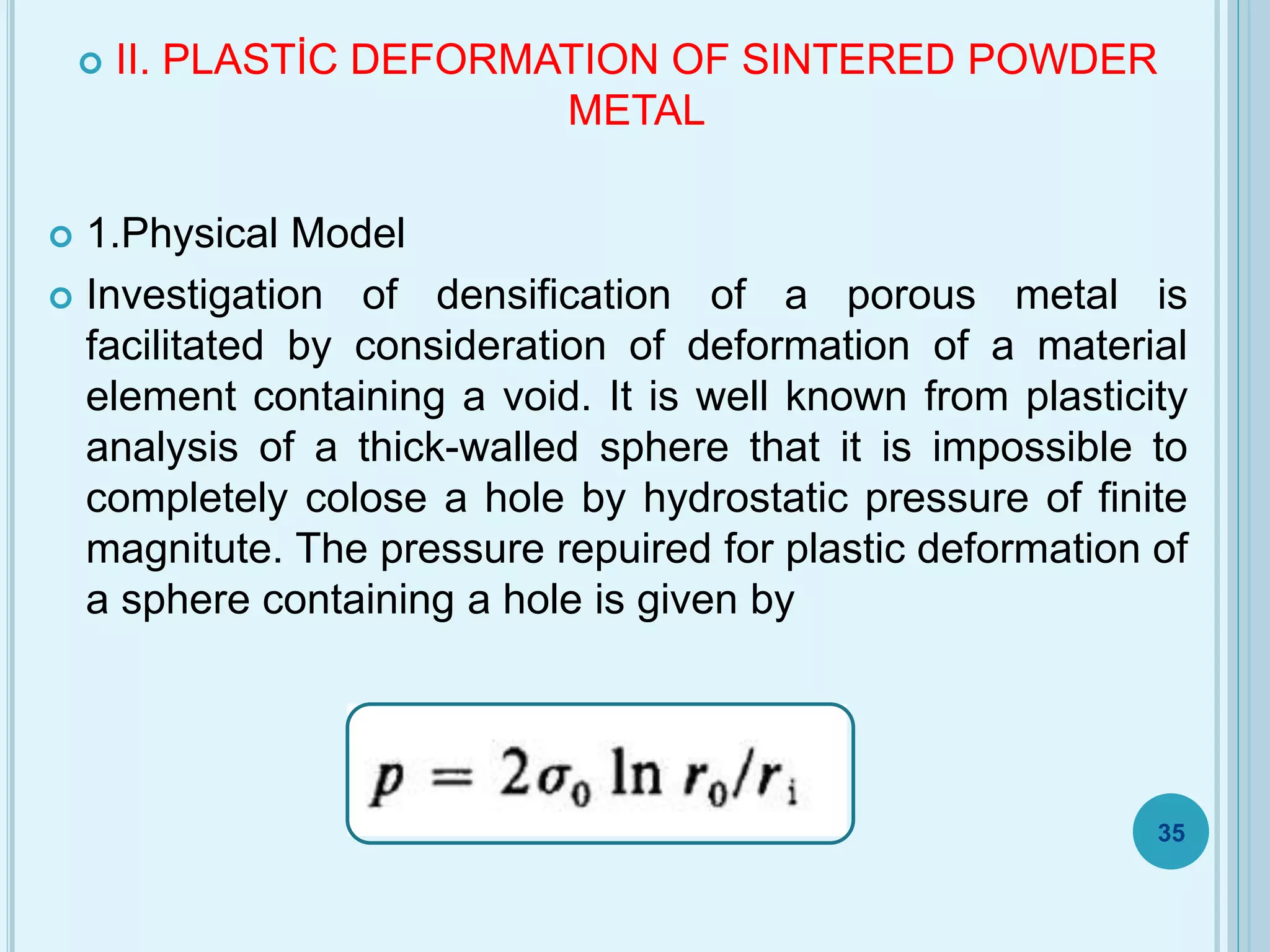

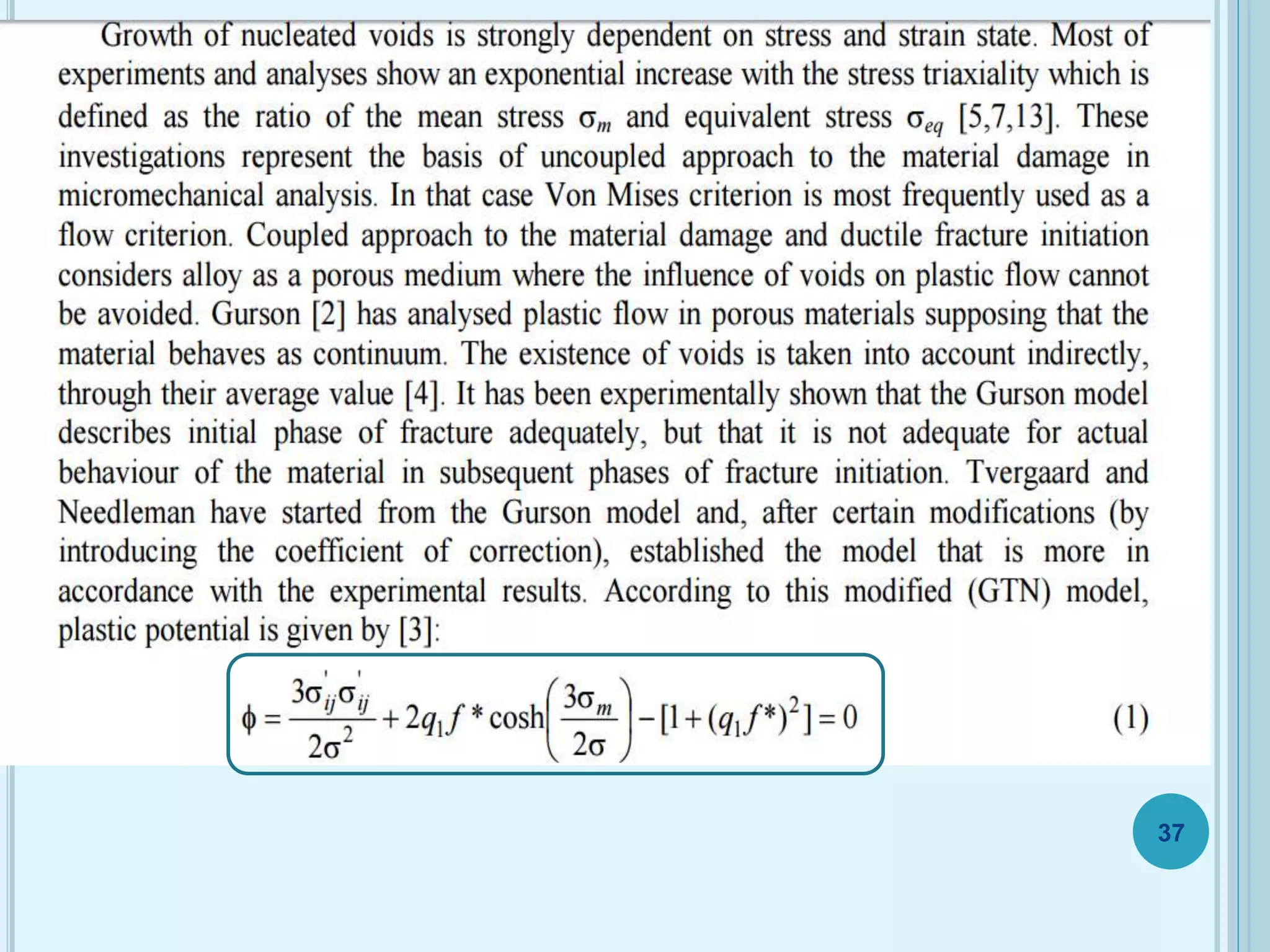

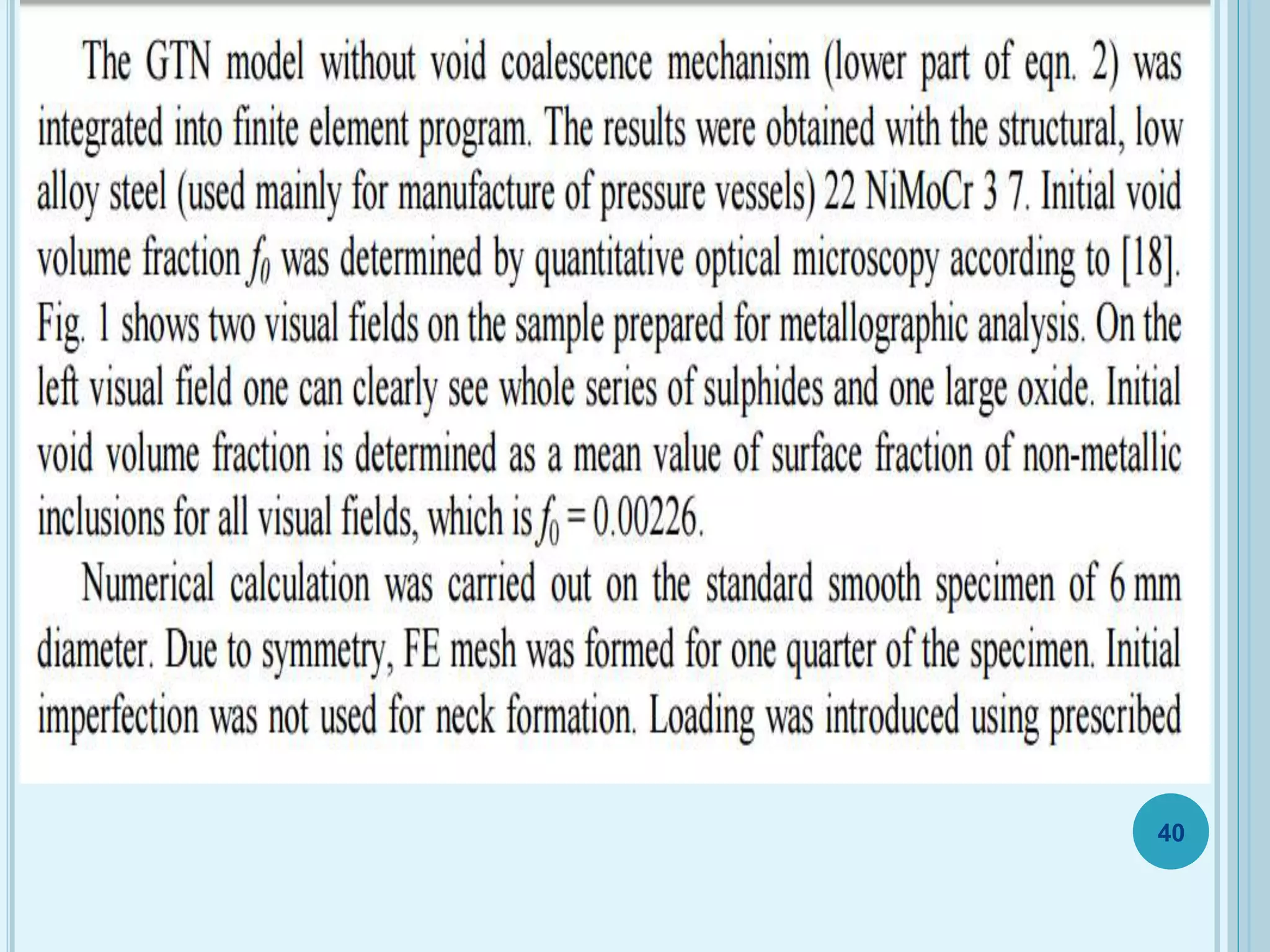

This document discusses plasticity theory related to porous materials. It begins with an introduction to porous materials, defining them as solids with high specific surface area and pore volume. Porosity is measured using specific surface area, specific pore volume, and pore size/distribution. Particle size, shape, and distribution affect porosity, with smaller, irregularly-shaped particles allowing for reduced porosity. Pores are classified as open or closed. Elasticity and plasticity in materials is also introduced, with plasticity defined as the ability to deform without failure. Porous metal plasticity models are discussed, intended for metals with over 90% density, based on void nucleation and failure. The effect of porosity on material strength is analyzed