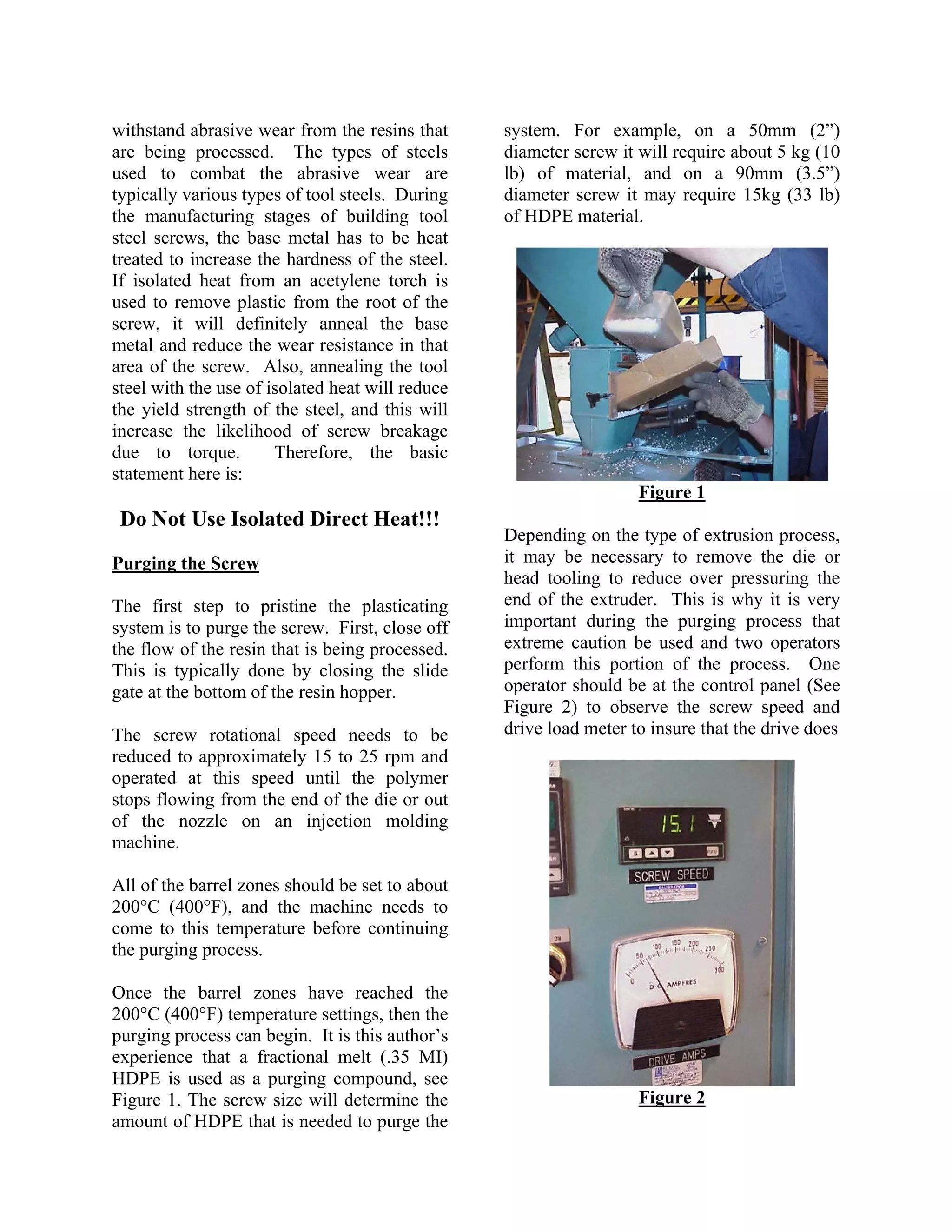

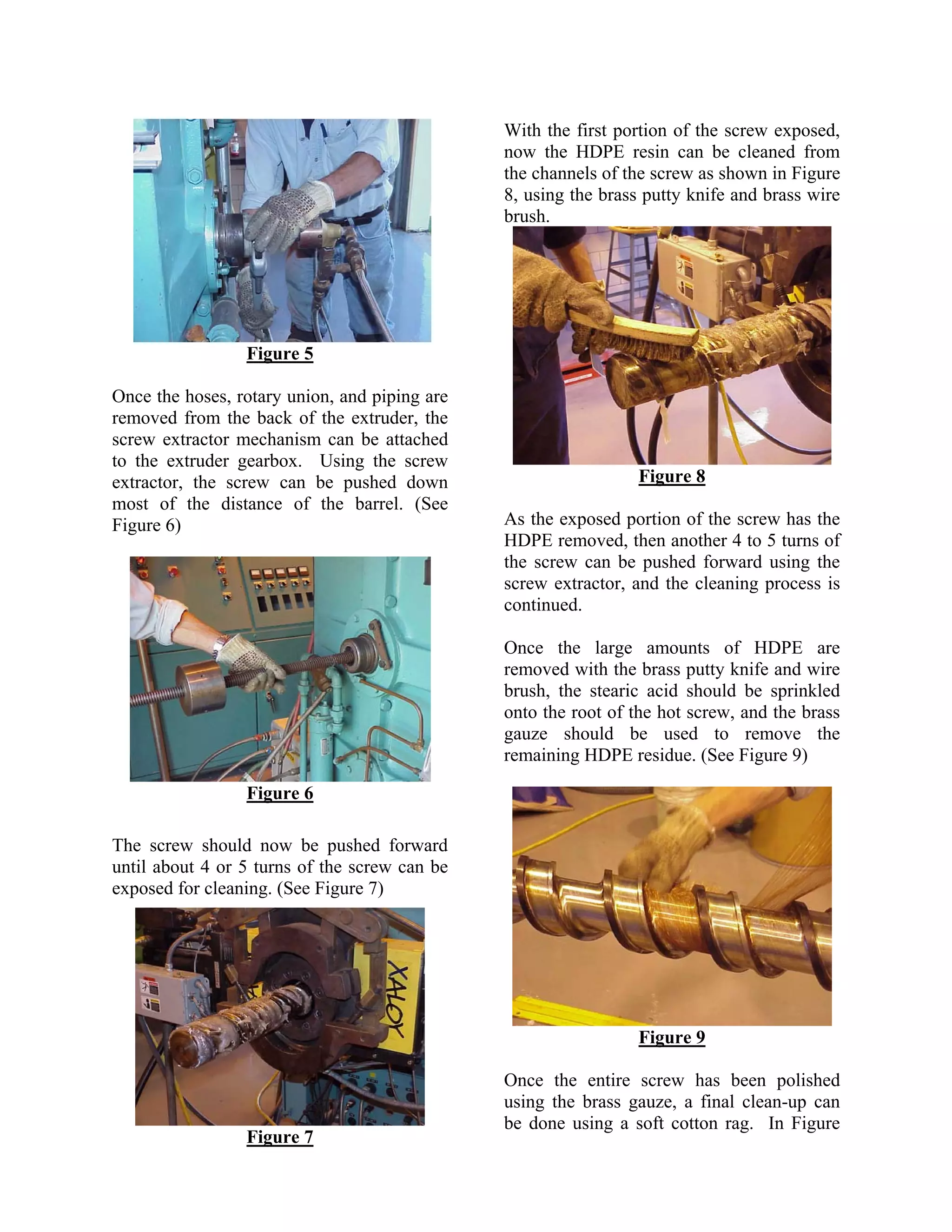

This document provides guidance on properly purging and cleaning screws and barrels for extrusion and injection molding machines. It recommends using HDPE as a purging compound and rotating the screw at 15-20 rpm to purge the system. Direct heat from an acetylene torch should never be used, as it can damage screw tolerances and properties. Instead, simple hand tools like brass brushes and putty knives should be used to manually clean screws once removed from the machine. The document aims to help companies improve changeover and maintenance procedures in a safe and cost-effective manner.