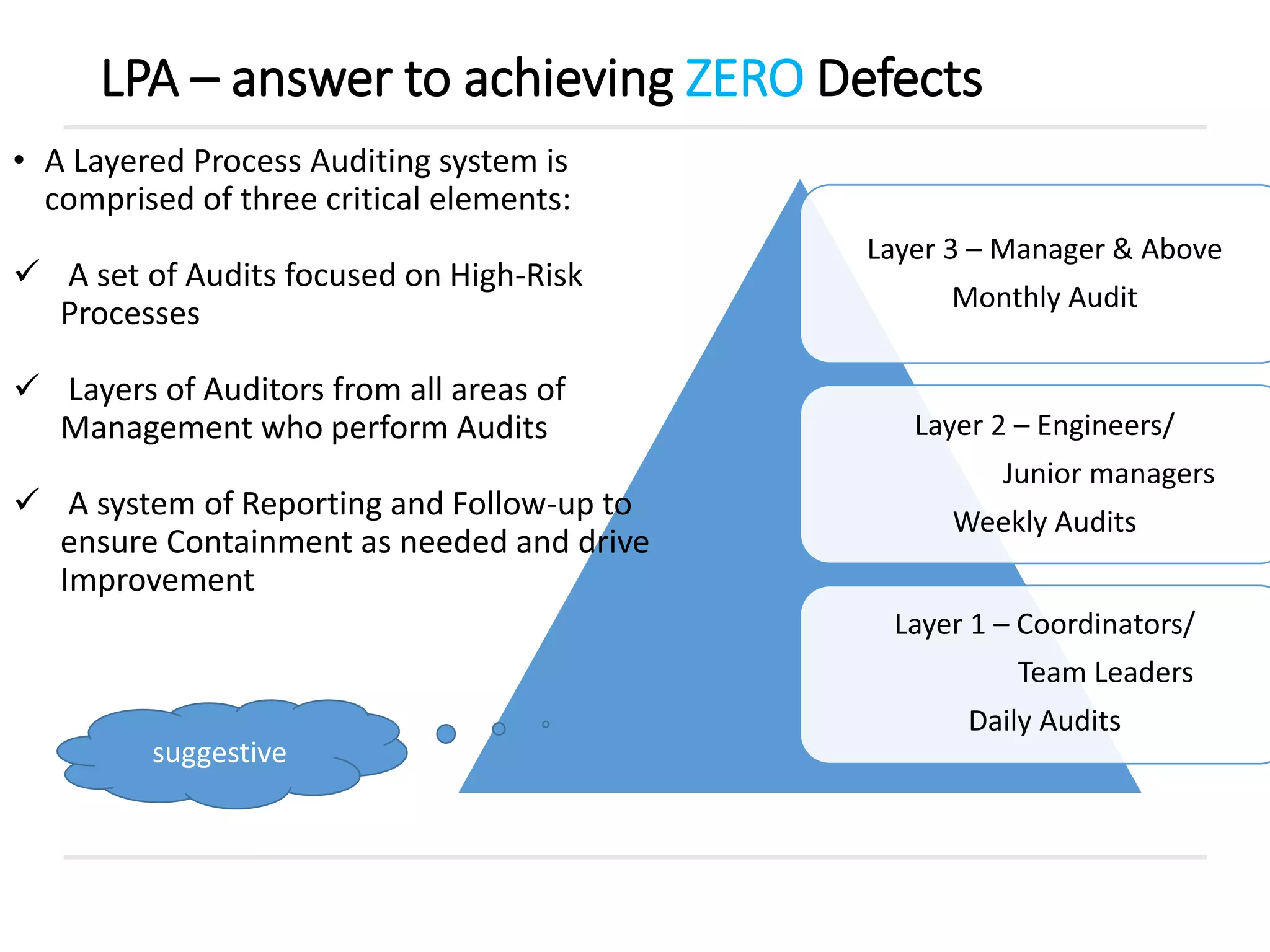

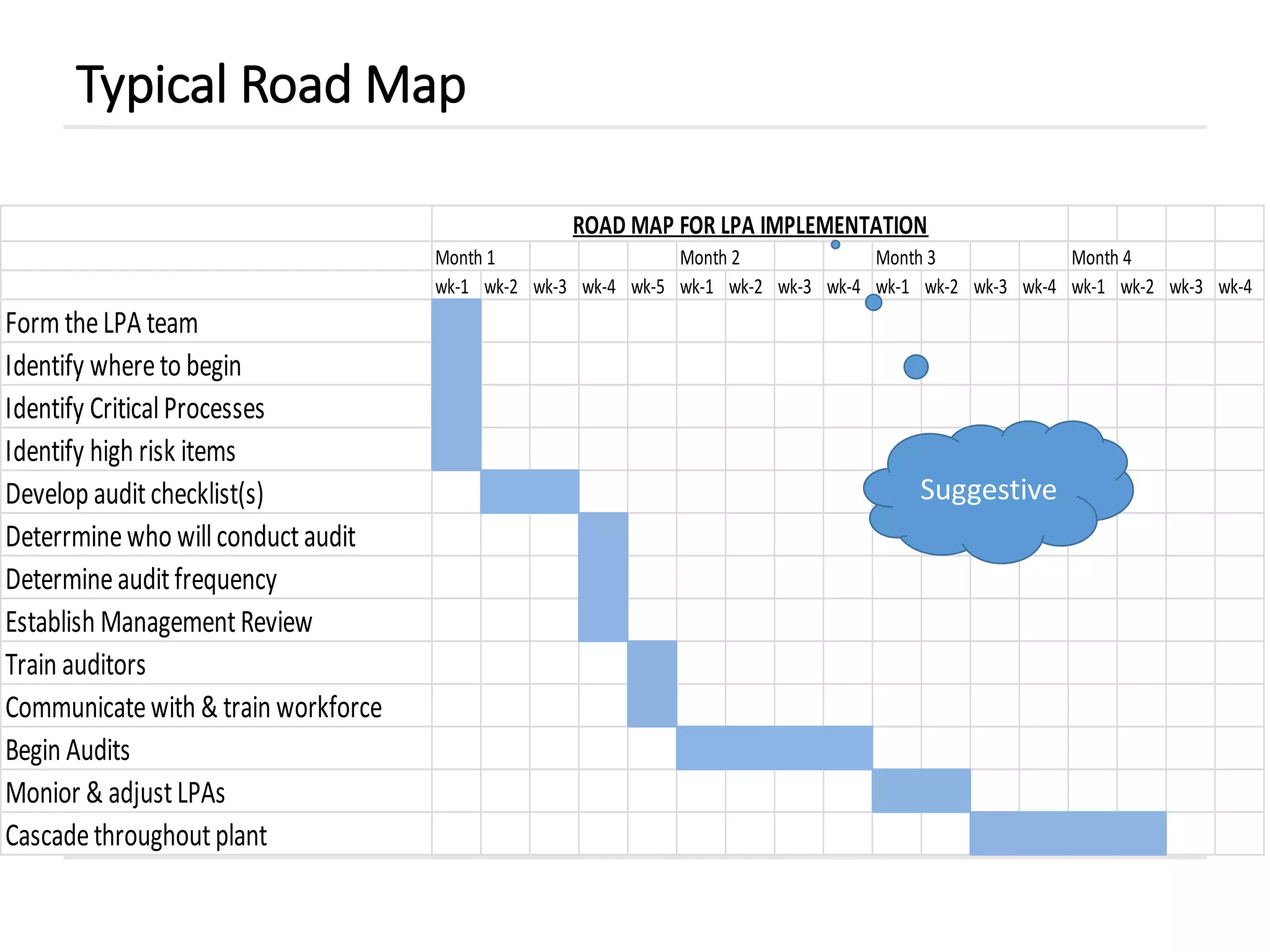

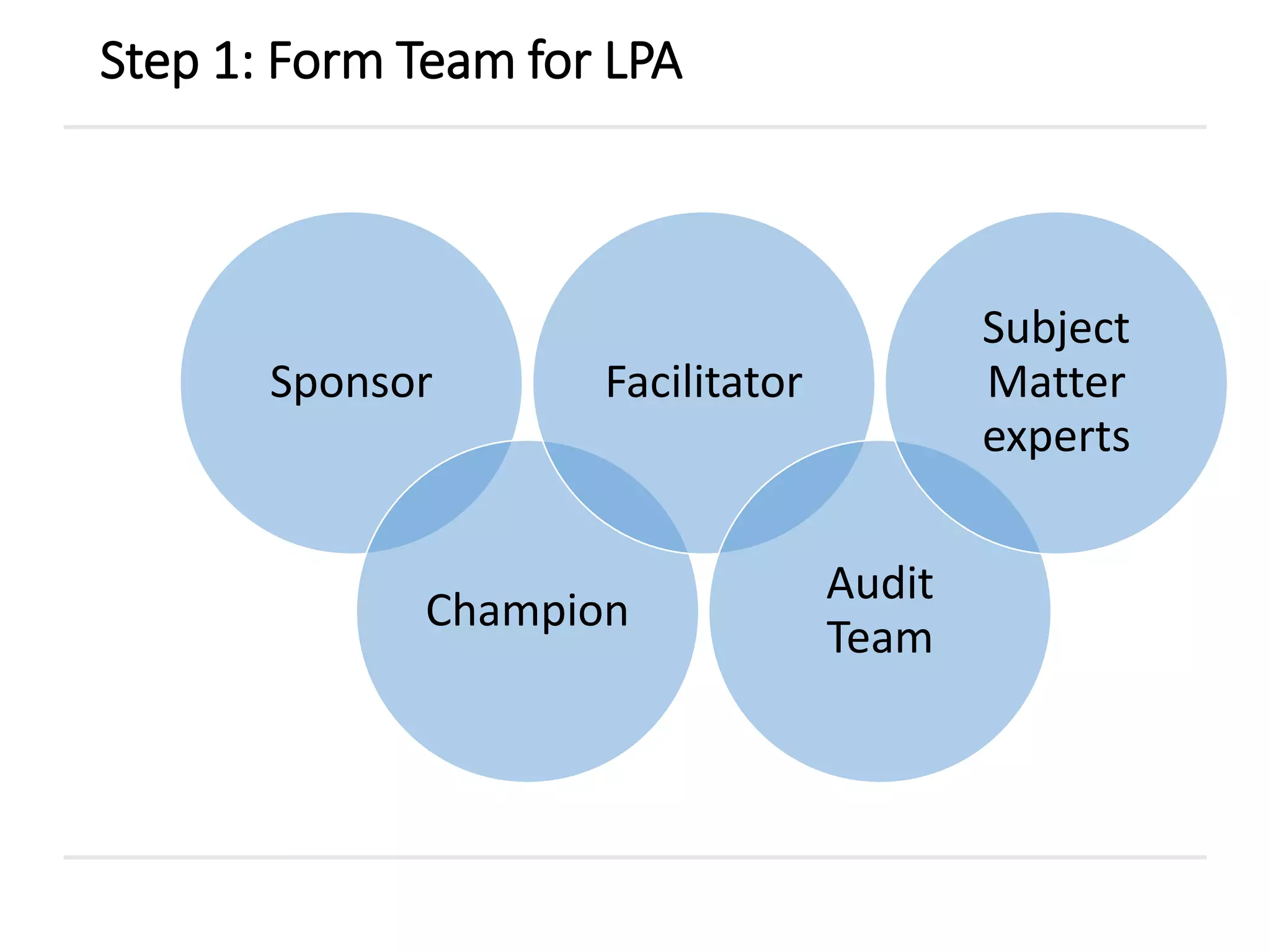

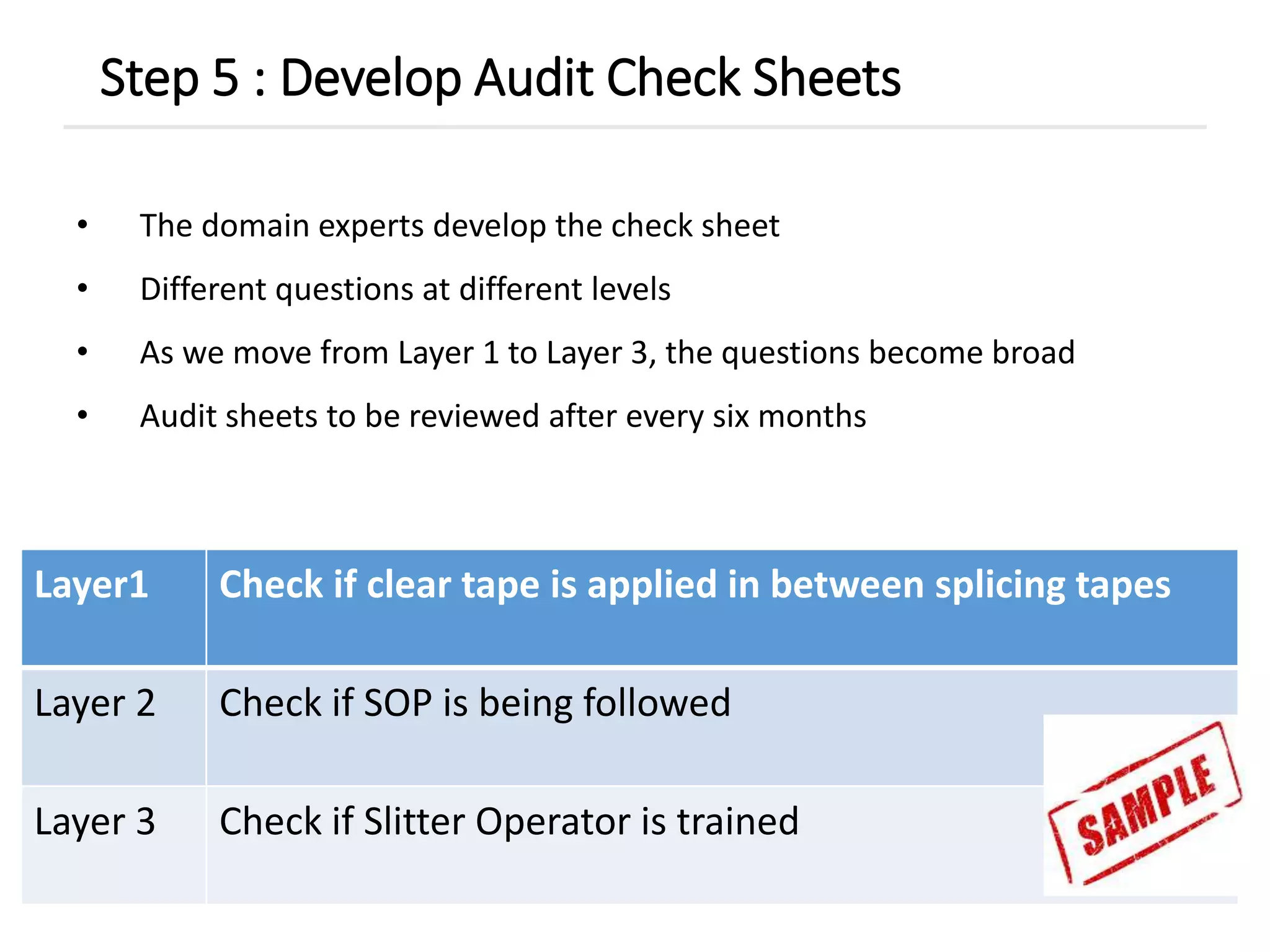

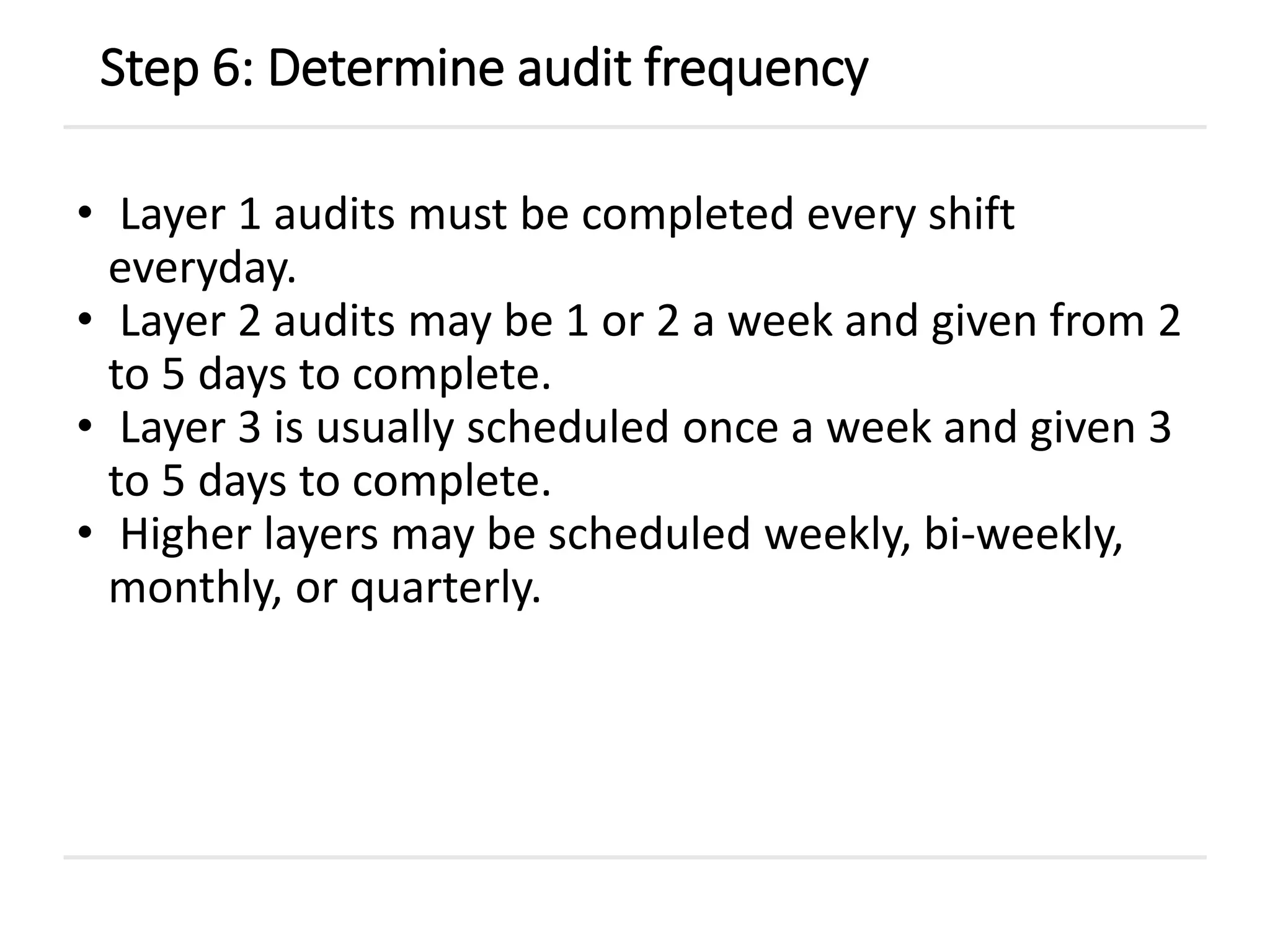

Layered Process Auditing (LPA) is a quality improvement tool for manufacturing that involves three layers of auditors - daily audits by coordinators, weekly audits by engineers/managers, and monthly audits by senior managers. The audits focus on high-risk processes and ensure key work steps are performed properly. Benefits include preventing errors, reducing rework and waste, and improving quality and customer satisfaction. Implementing LPA involves forming an audit team, identifying critical processes, developing audit checklists, training auditors, conducting audits, and establishing management review and follow-up processes to drive continuous improvement.