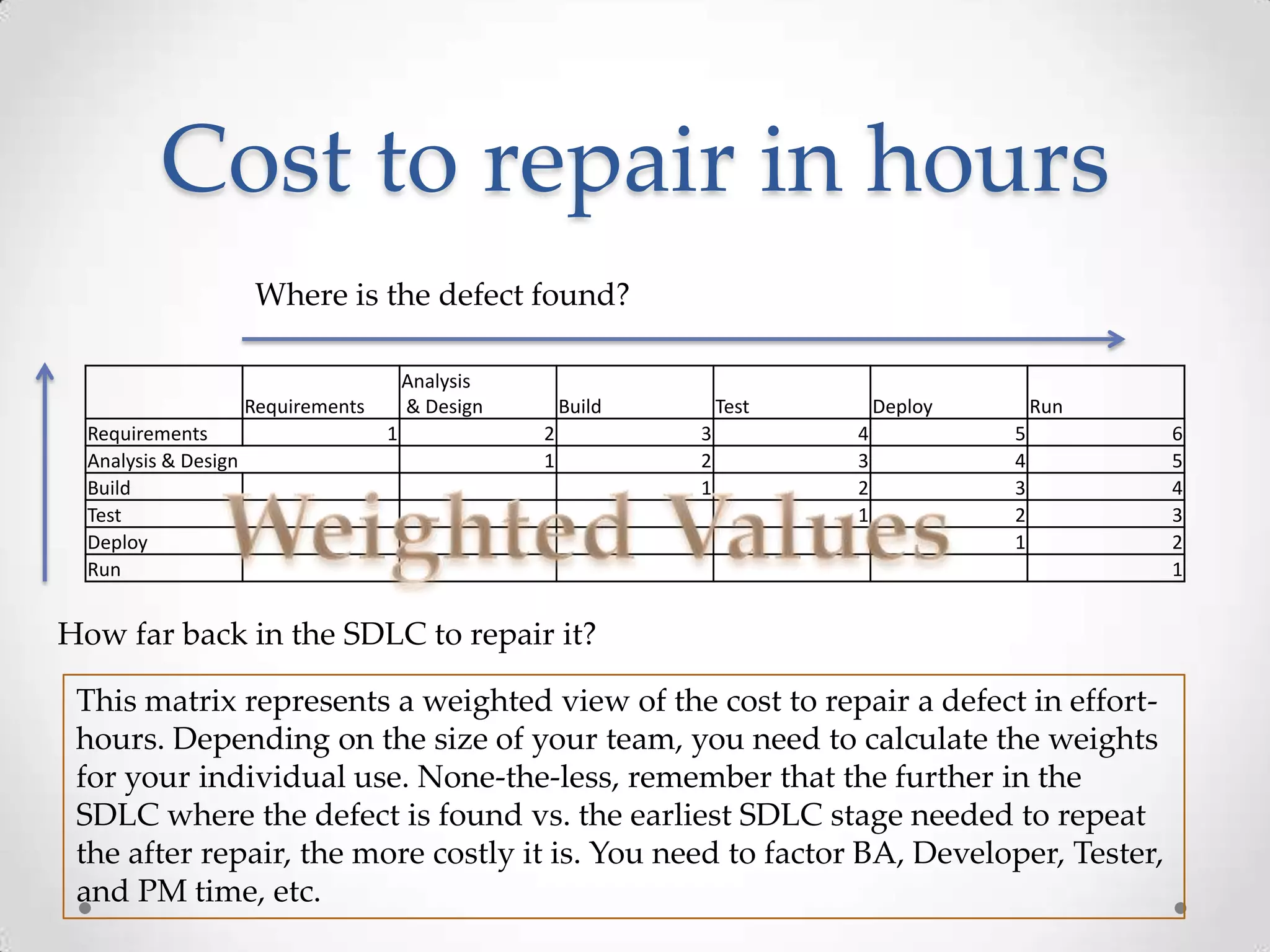

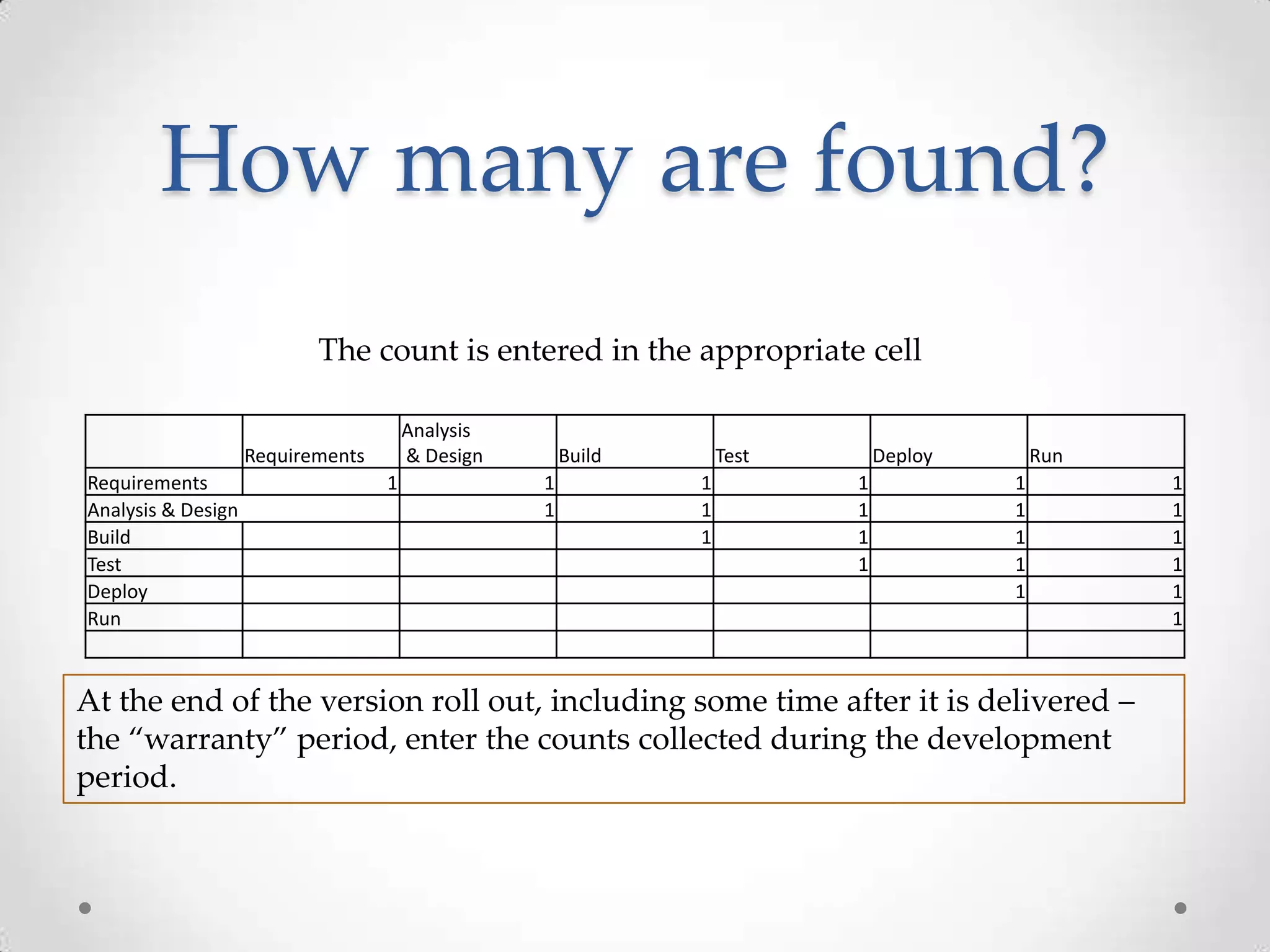

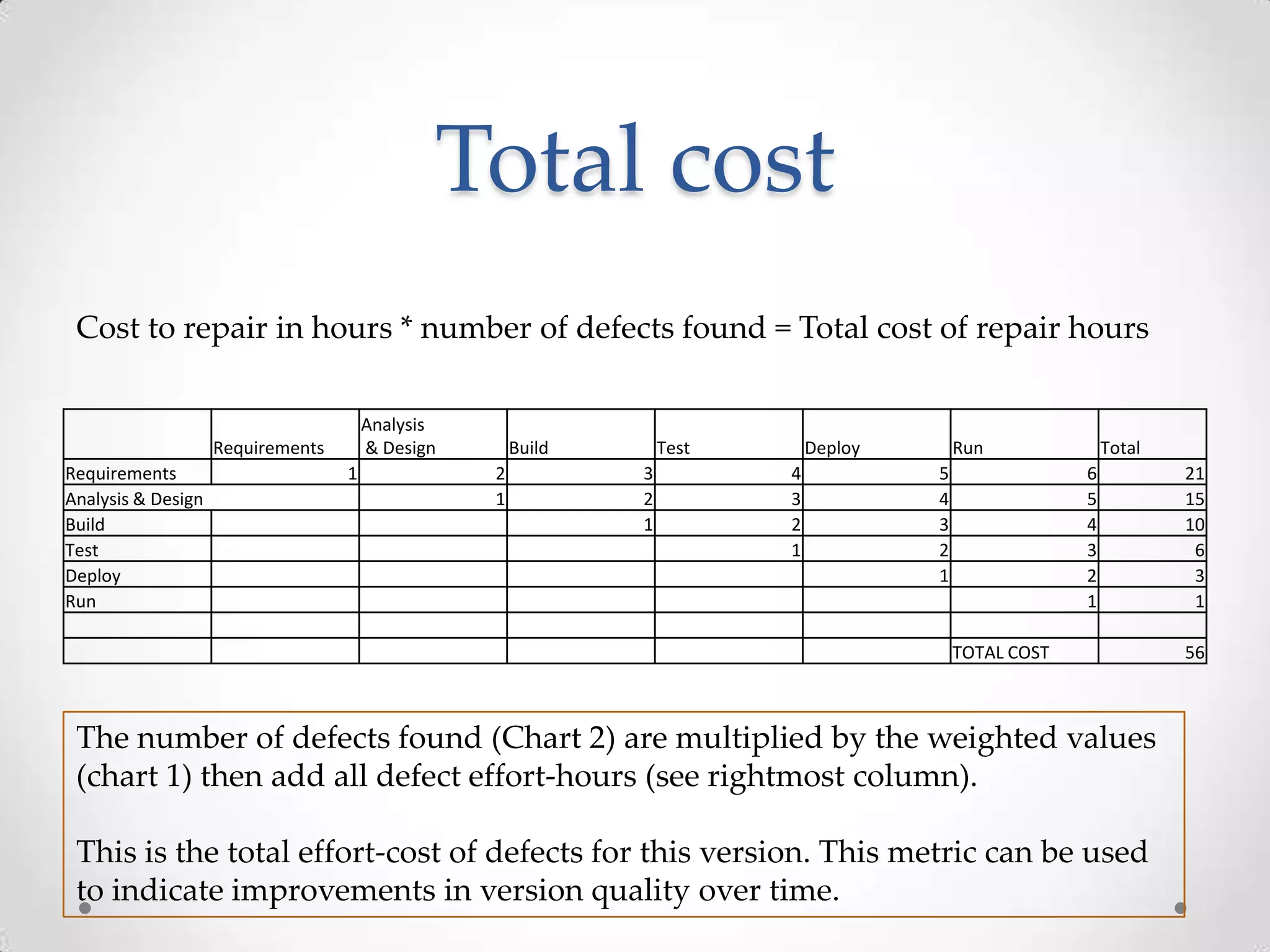

The document discusses the varying costs of defects based on their timing in the Software Development Life Cycle (SDLC) and the factors influencing these costs, such as the scope of the initiative and team size. It describes a scoring process for logging defects by type and stage, and highlights the total cost of repair based on the effort required to fix the defects. The analysis emphasizes the importance of early defect detection to minimize repair costs, suggesting a calculated approach to monitor version quality over time.