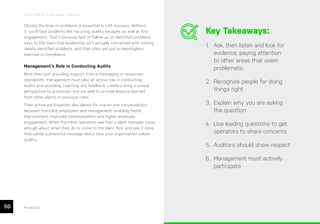

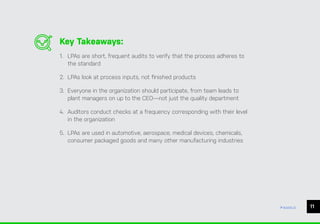

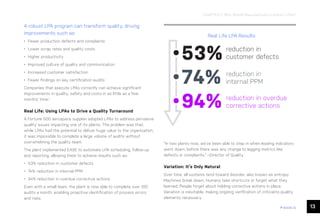

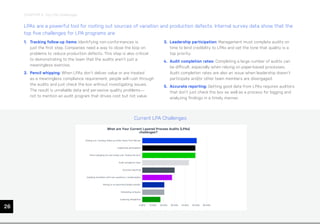

Layered process audits (LPAs) are short, frequent audits conducted by all levels of an organization to verify critical process parameters and prevent defects. LPAs can drive significant improvements in quality by reducing production defects, complaints and costs through early identification of process variation issues. Regular LPAs improve communication and build a culture of quality by respecting operators and providing recognition of efforts.

![27

ease.io

CHAPTER #: Chapter Title

It’s a staggering comparison

going from seven [audits]

per year to 100 every month.

Of all our indicators, auditing

is one of the metrics that

correlates most strongly

with quality.

–Director of Quality, Aerospace Manufacturer](https://image.slidesharecdn.com/lpas-230702181138-6fbe8e6d/85/LPAs-pdf-27-320.jpg)