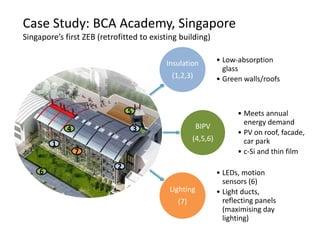

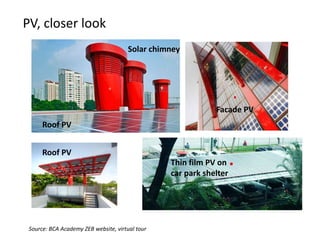

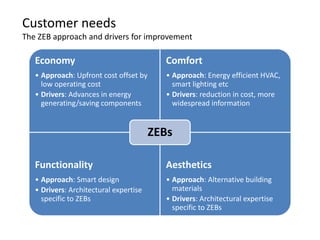

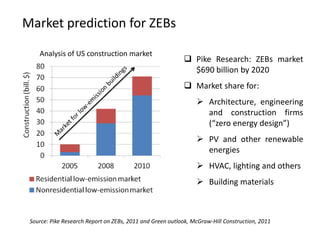

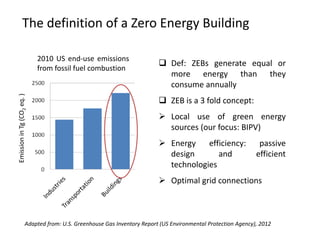

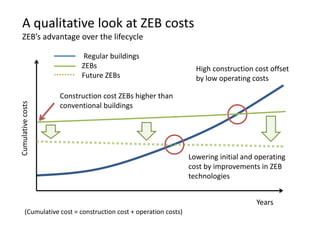

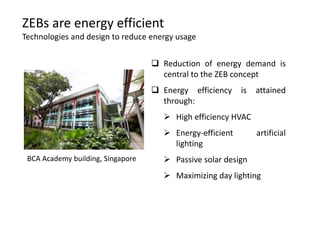

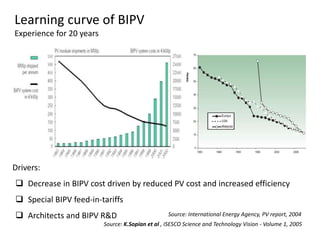

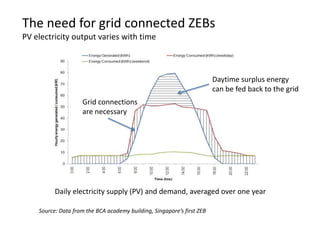

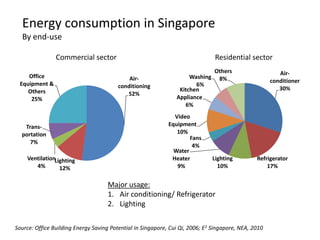

The document discusses zero energy buildings (ZEBs), which generate more energy than they consume annually and focus on local green energy sources, energy efficiency, and optimal grid connections. It highlights the benefits and costs of ZEBs compared to traditional buildings, emphasizing their high upfront costs that are offset by lower operational costs. The role of advanced technologies like building integrated photovoltaics (BIPV) and energy-efficient systems for heating, ventilation, and air conditioning (HVAC) is also examined, presenting insights into the future market potential for ZEBs.

![Grid parity in Singapore

a scenario under the assumption of net metering

0.40

+5%/a

0.35

Electricity costs/prices in [S$/kWh]

PV cost

0.30

0.25 0%/a

Utility price -7%/a

0.20

0.15 -13%/a

0.10

0.05

0.00

2011 2012 2013 2014 2015 2016 2017 2018 2019 2020

Calendar year

Source: Luther et. al., ICMAT, 2011](https://image.slidesharecdn.com/20120412zeroenergybuildingsfinal-120504044456-phpapp02/85/Zero-Energy-Buildings-7-320.jpg)

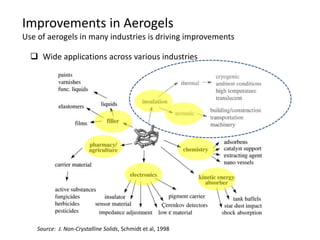

![Aerogels cost and performance

Commercially available building insulation materials

Insulating Material Thermal conductance Cost per ft3 (US$)

[W/m²·K]

Polystrene Foam 0.20 8.04

Rock Wool 0.36 1.64

Fiber Glass 0.32 1.63

Cellulose 0.29 1.81

Pure Silica Aerogel 0.05 2500

Clay Polymer Aerogel (Aeroclay) 0.05 8

Aerogels commercially available and used mainly in clothing and for

scientific applications (because of higher costs)

New startup Aeroclay (2010) is commercializing cheap aerogels made

of clay; scale up from R&D to manufacturing underway

Source: Evacuated Panels Utilizing Clay-Polymer Aerogel Composites for

Improved Housing Insulation, Dalton et. al., 2010](https://image.slidesharecdn.com/20120412zeroenergybuildingsfinal-120504044456-phpapp02/85/Zero-Energy-Buildings-24-320.jpg)