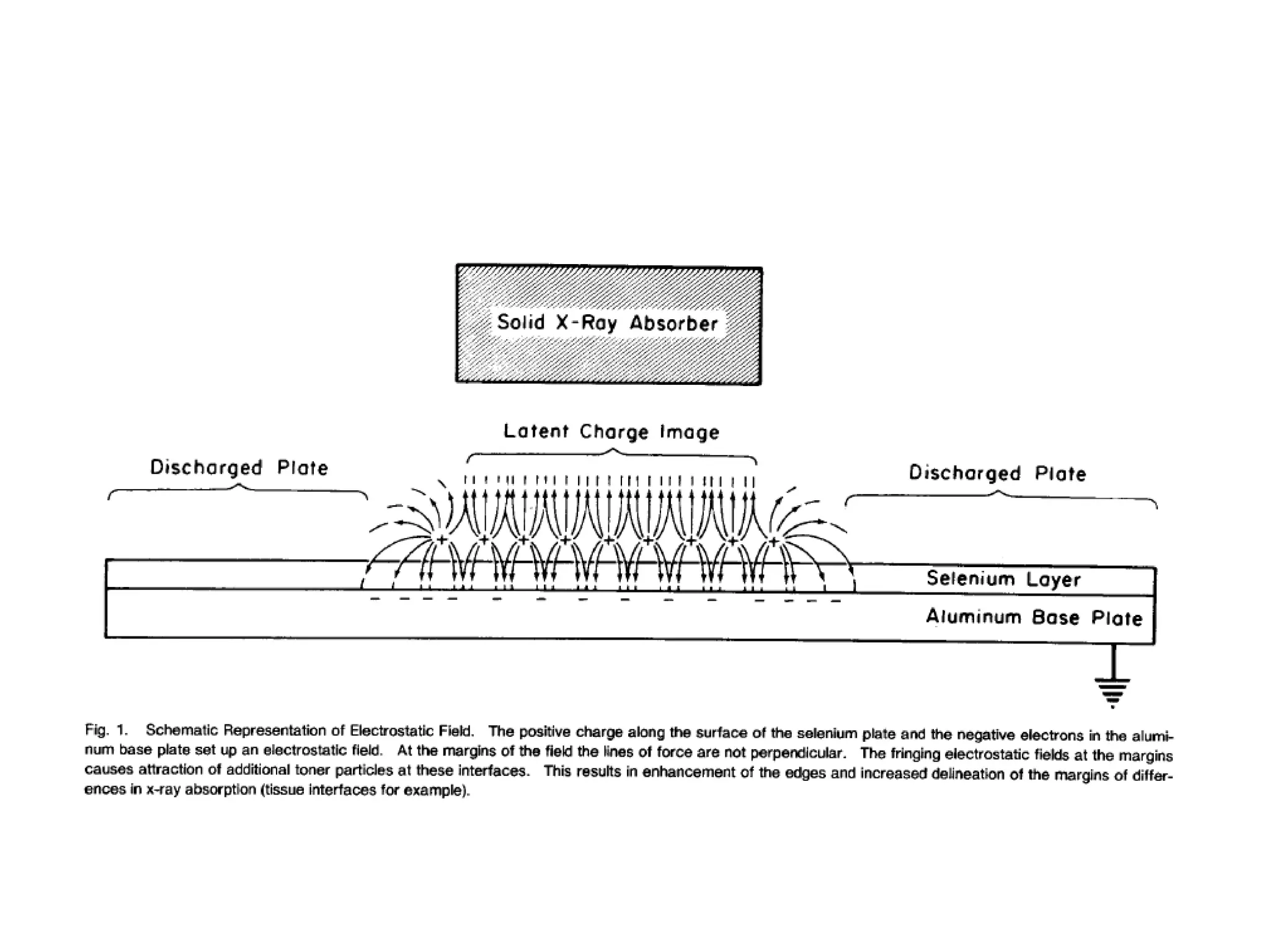

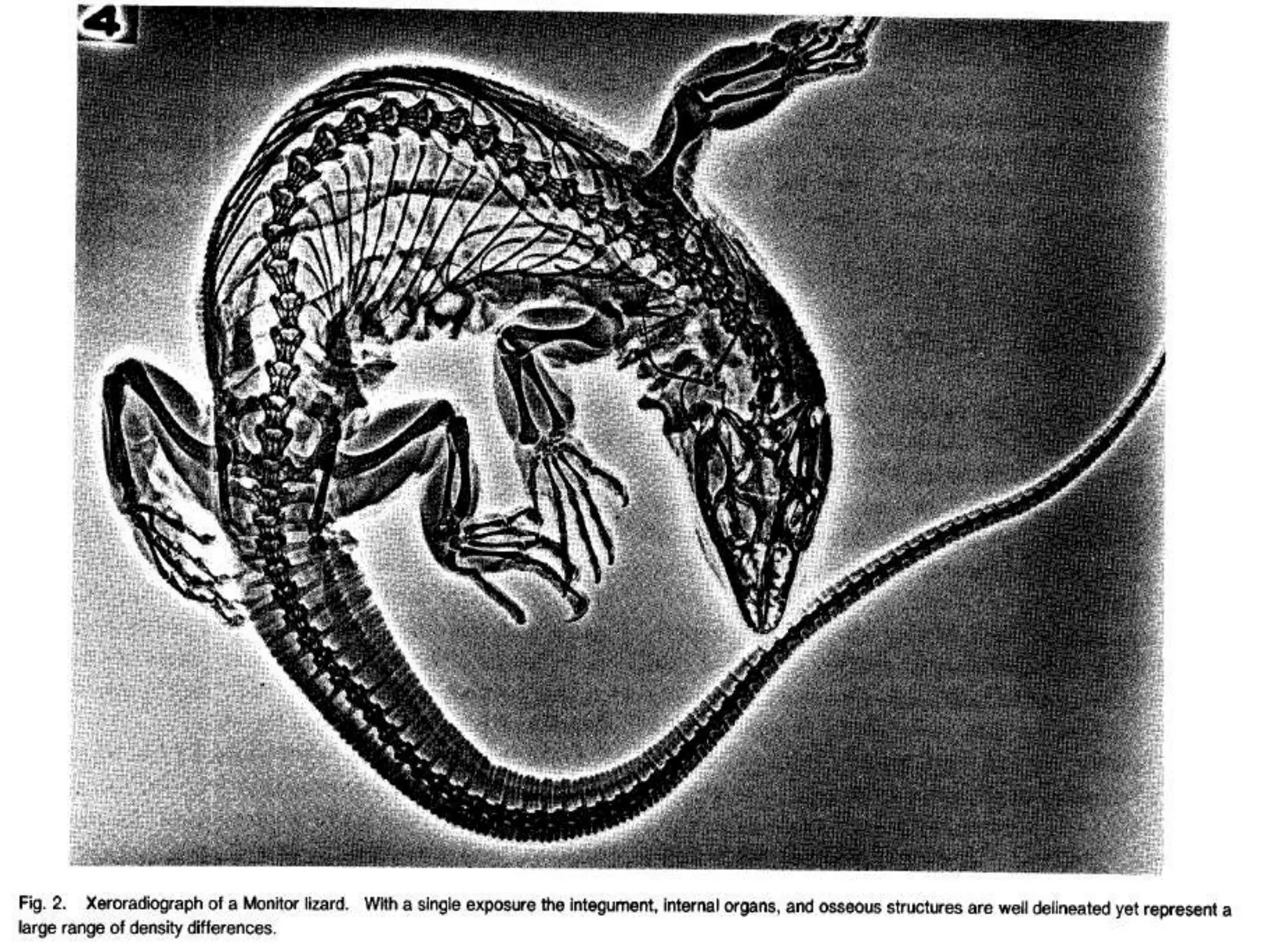

Xeroradiography is a method of medical imaging that uses the xerographic copying process to produce images from diagnostic x-rays. It involves charging a photoconductive plate, typically made of selenium, then exposing it to x-rays to create a latent electrostatic image. This image is developed using charged toner powder and transferred to paper, producing a visible x-ray image. Key advantages are eliminating accidental film exposure, providing high resolution and the ability to simultaneously evaluate multiple tissues. However, it also has disadvantages like being unable to image very thick body parts and having fragile selenium coatings.