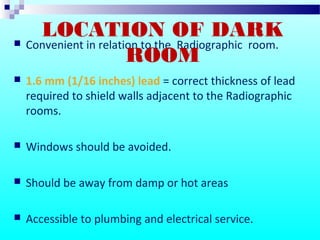

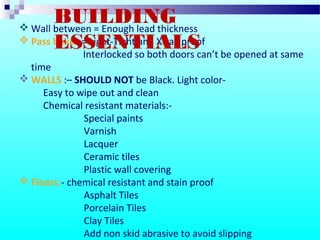

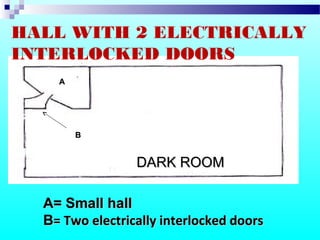

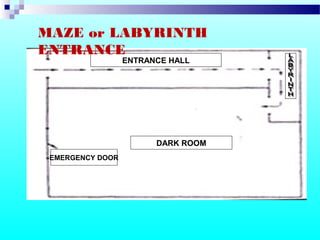

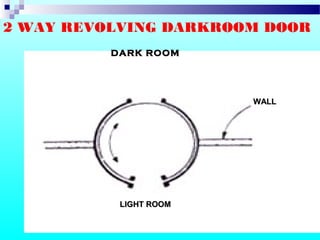

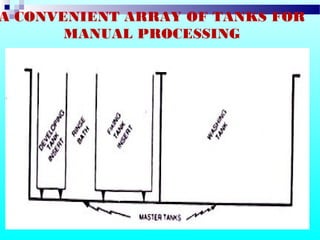

This document provides guidelines for setting up a dark room for radiographic use. It recommends locating the dark room conveniently near the radiographic room with 1.6mm lead shielding on walls. The dark room should be away from damp or hot areas and accessible to plumbing and electrical service. It describes building essentials like single light-tight doors, interlocked double doors, and revolving doors. Proper ventilation, illumination, and apparatus are also discussed for maintaining film quality and working conditions.