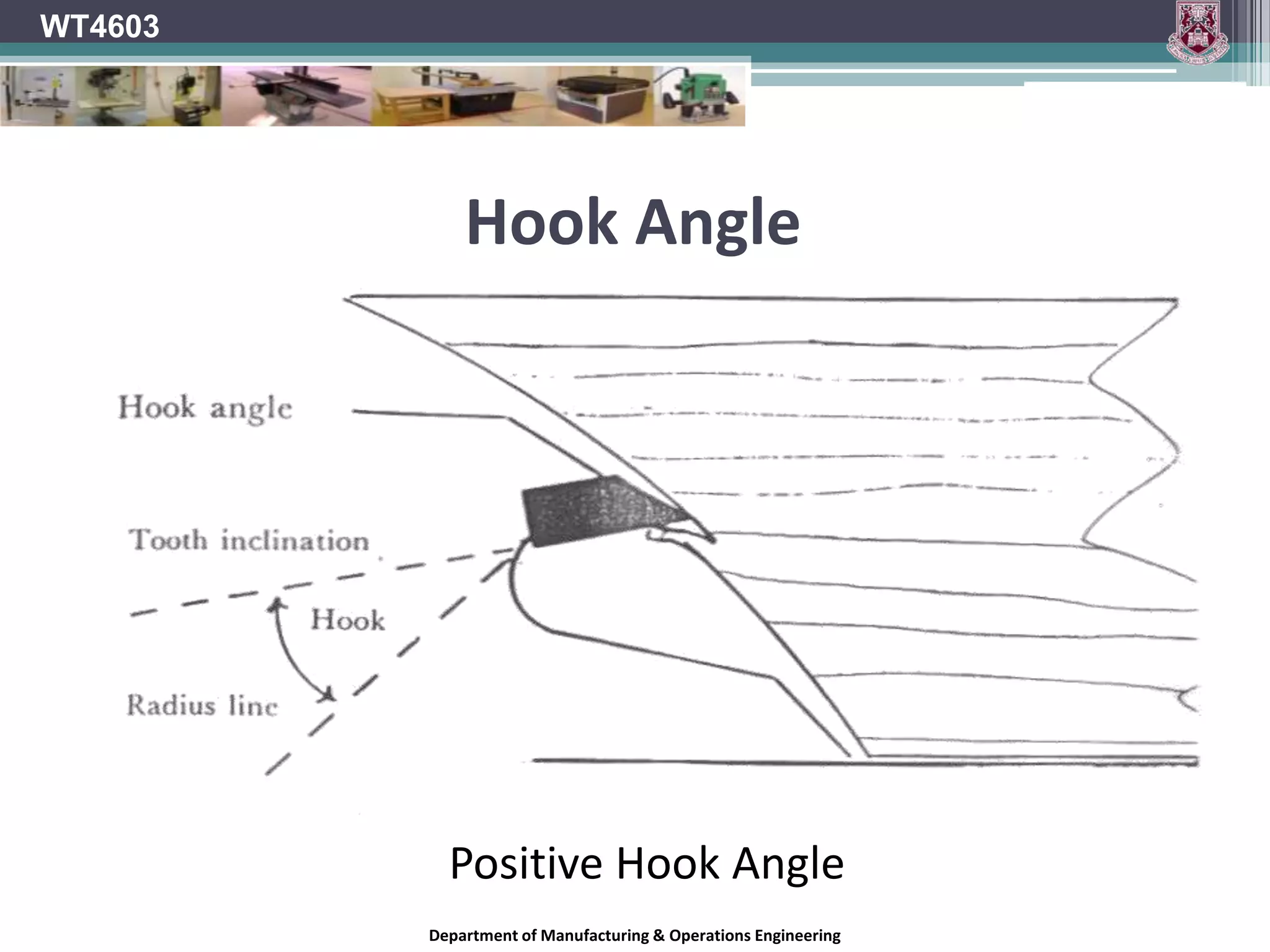

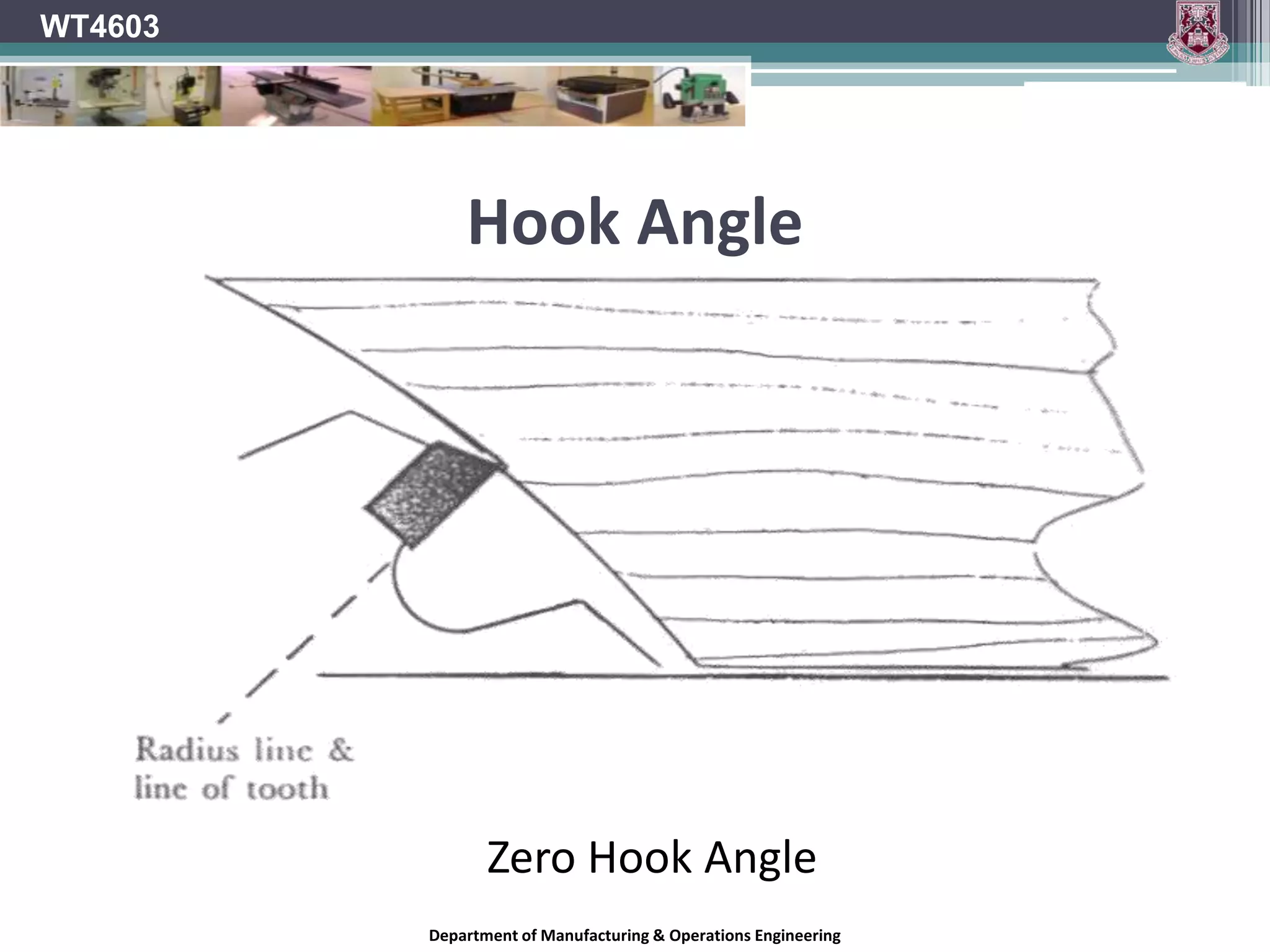

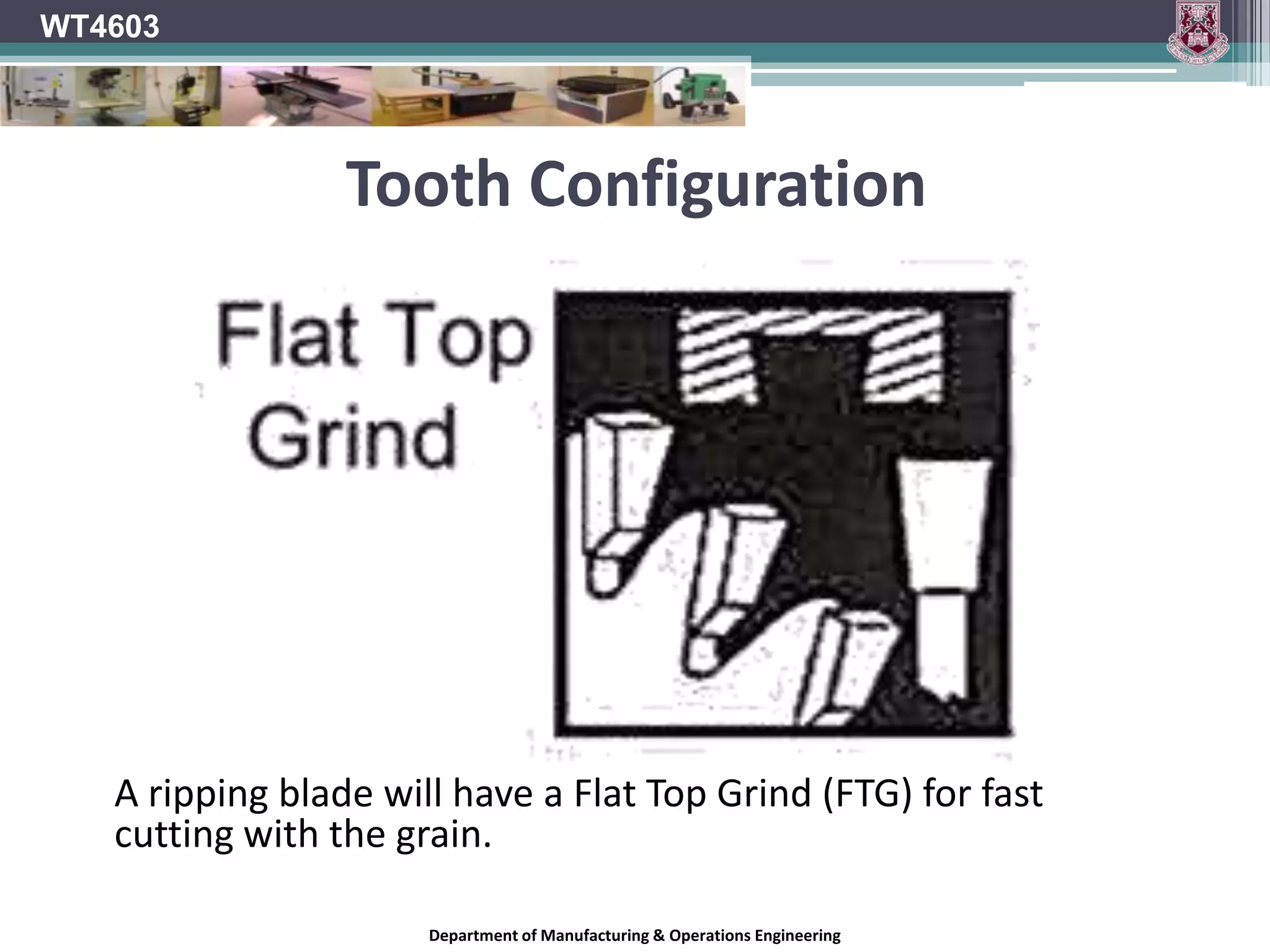

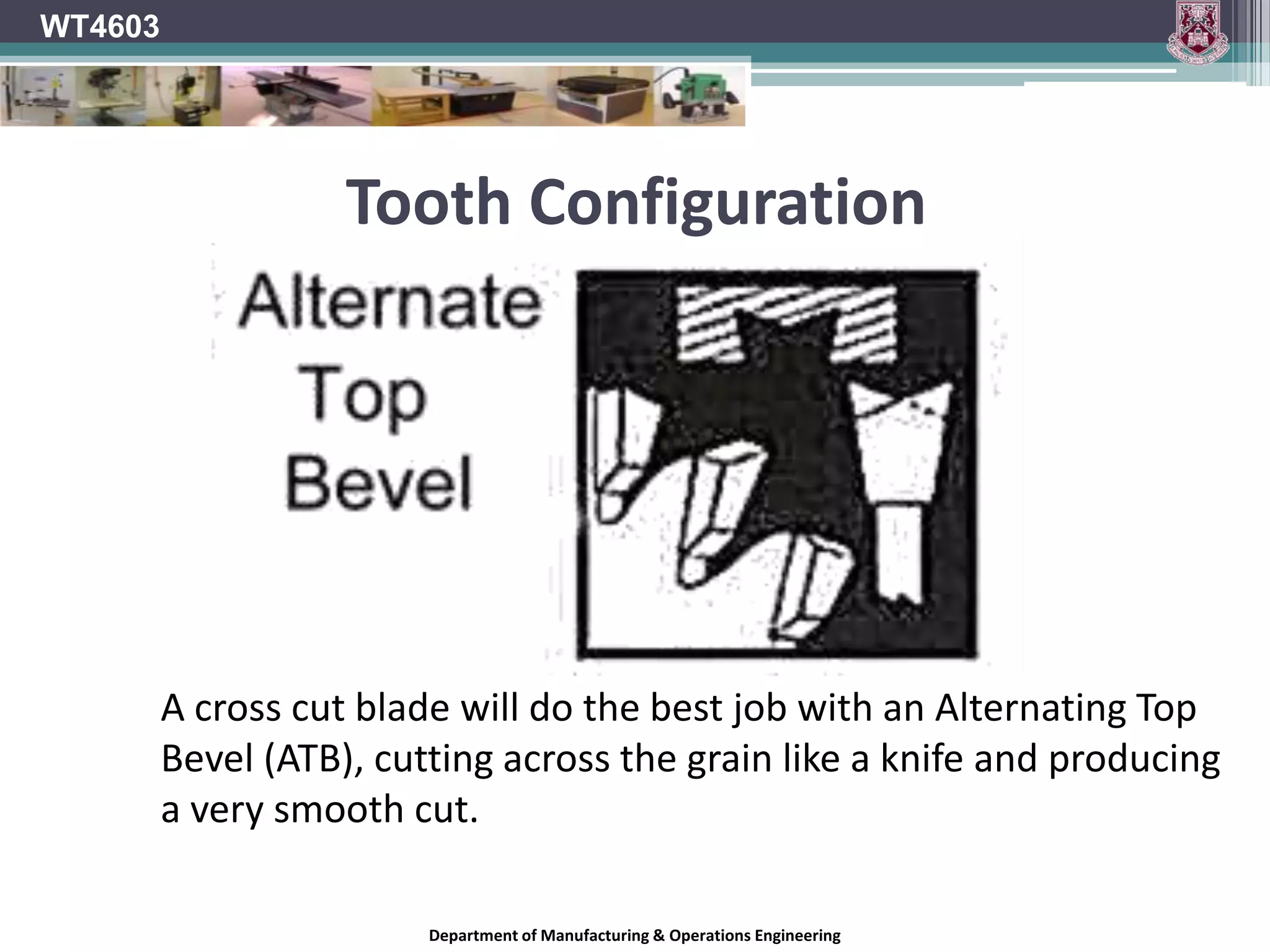

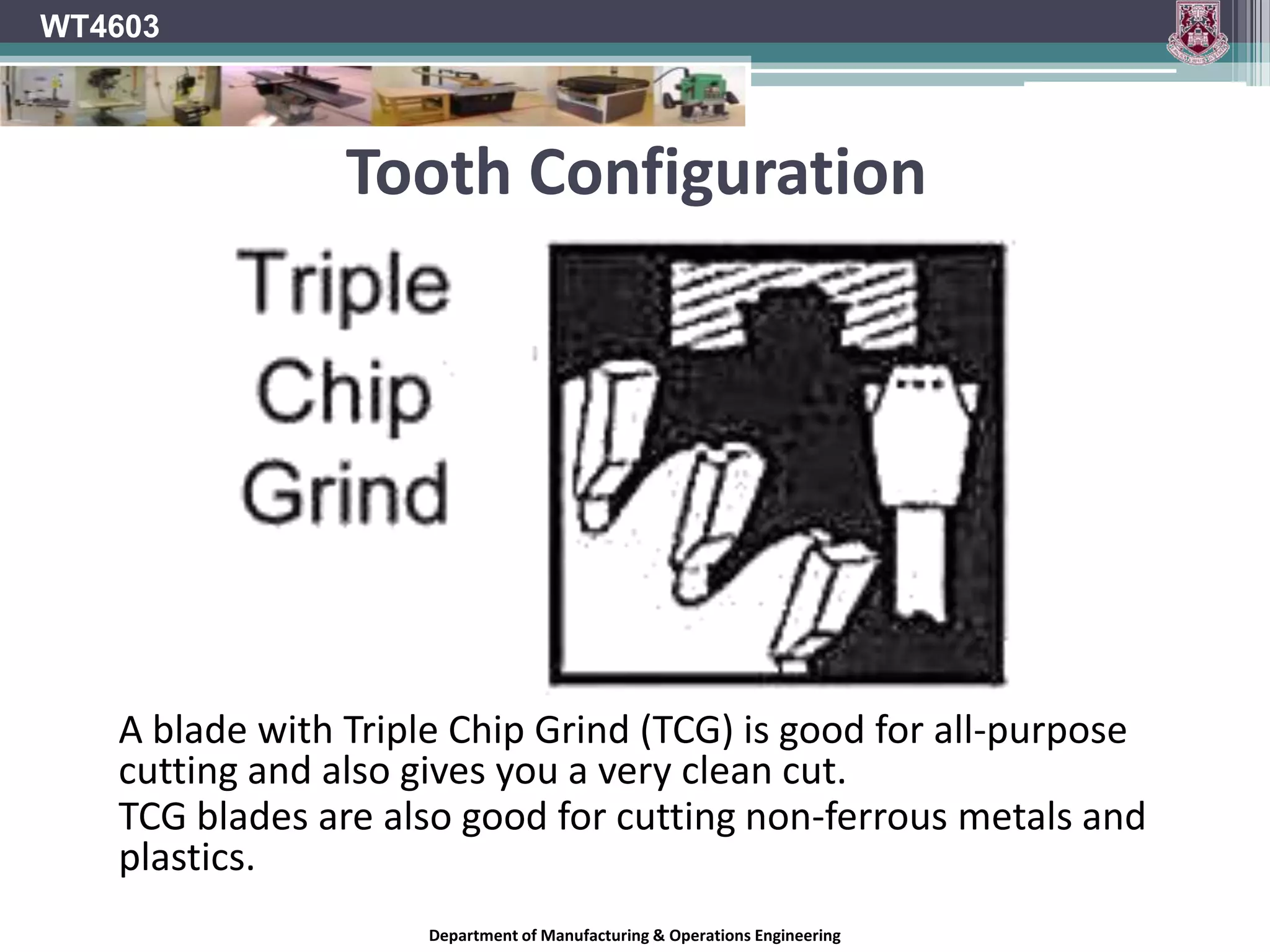

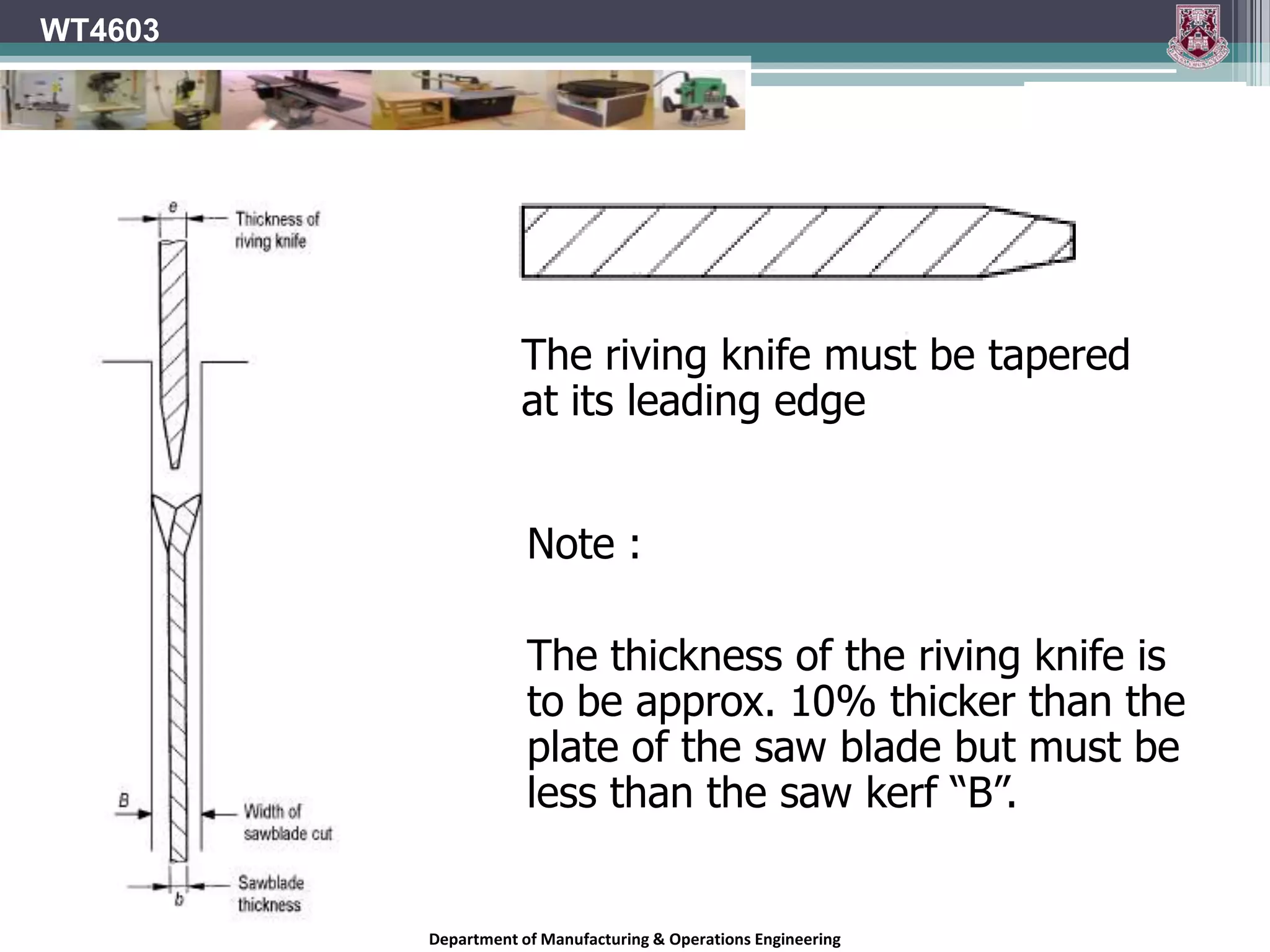

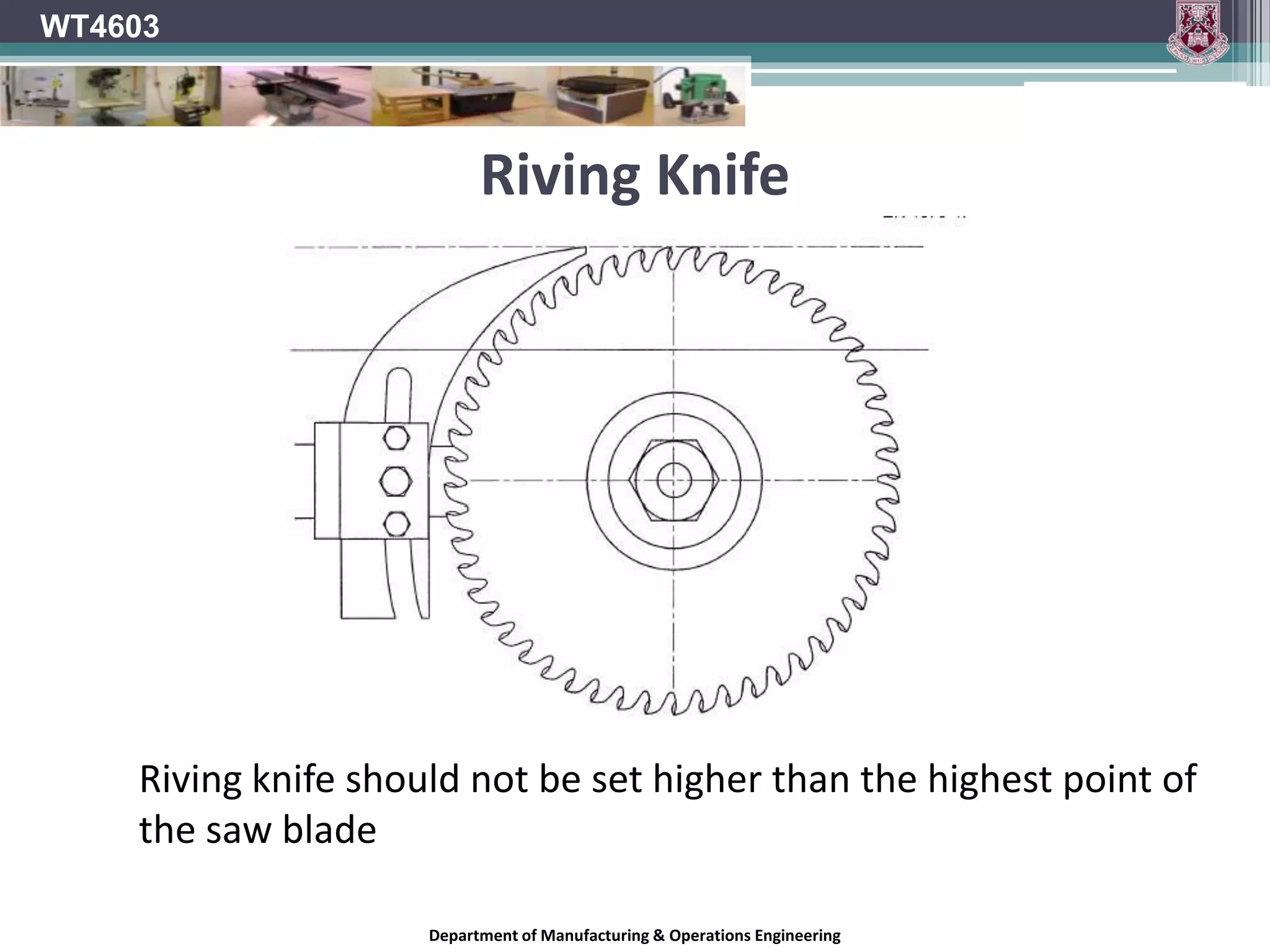

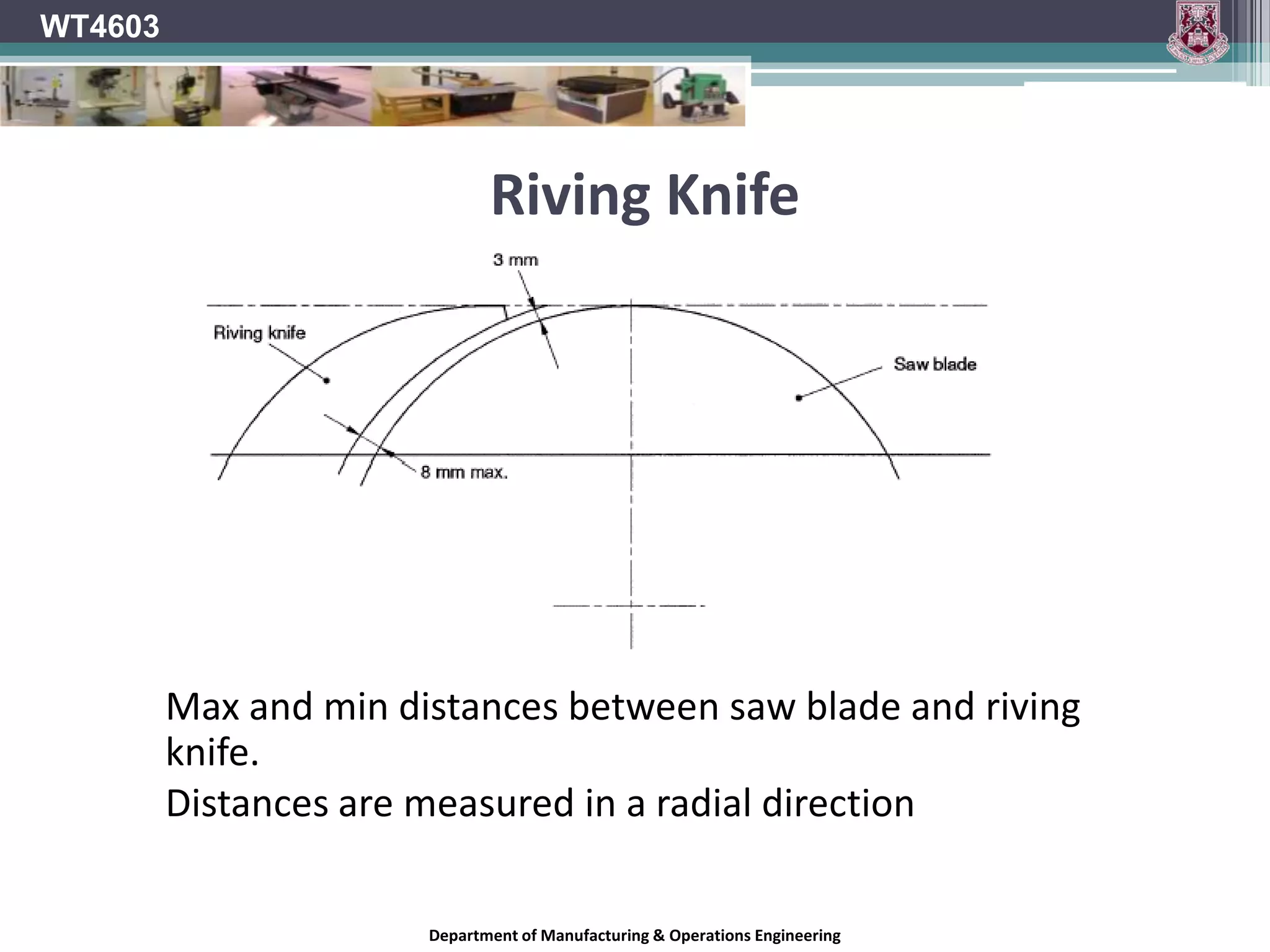

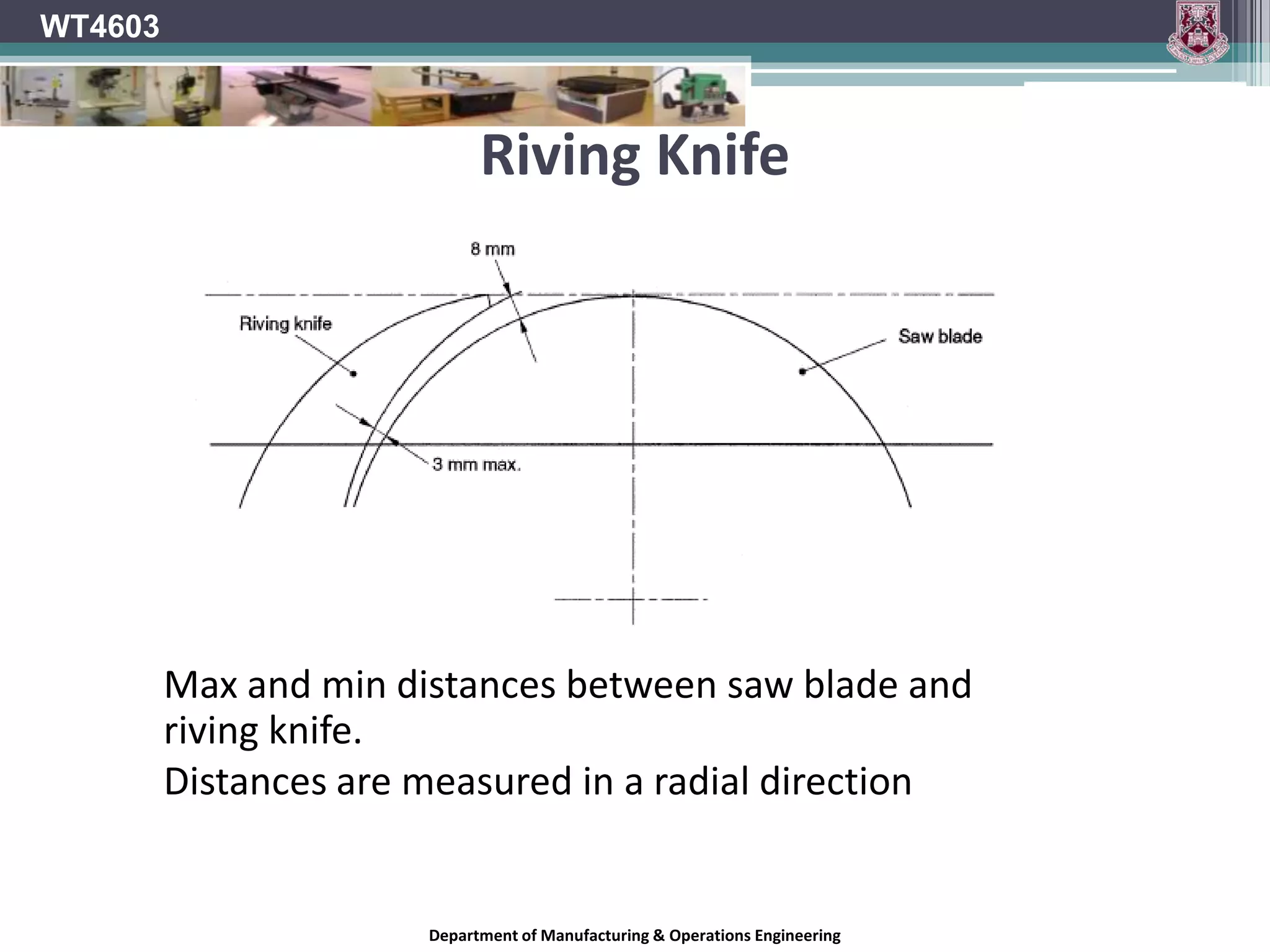

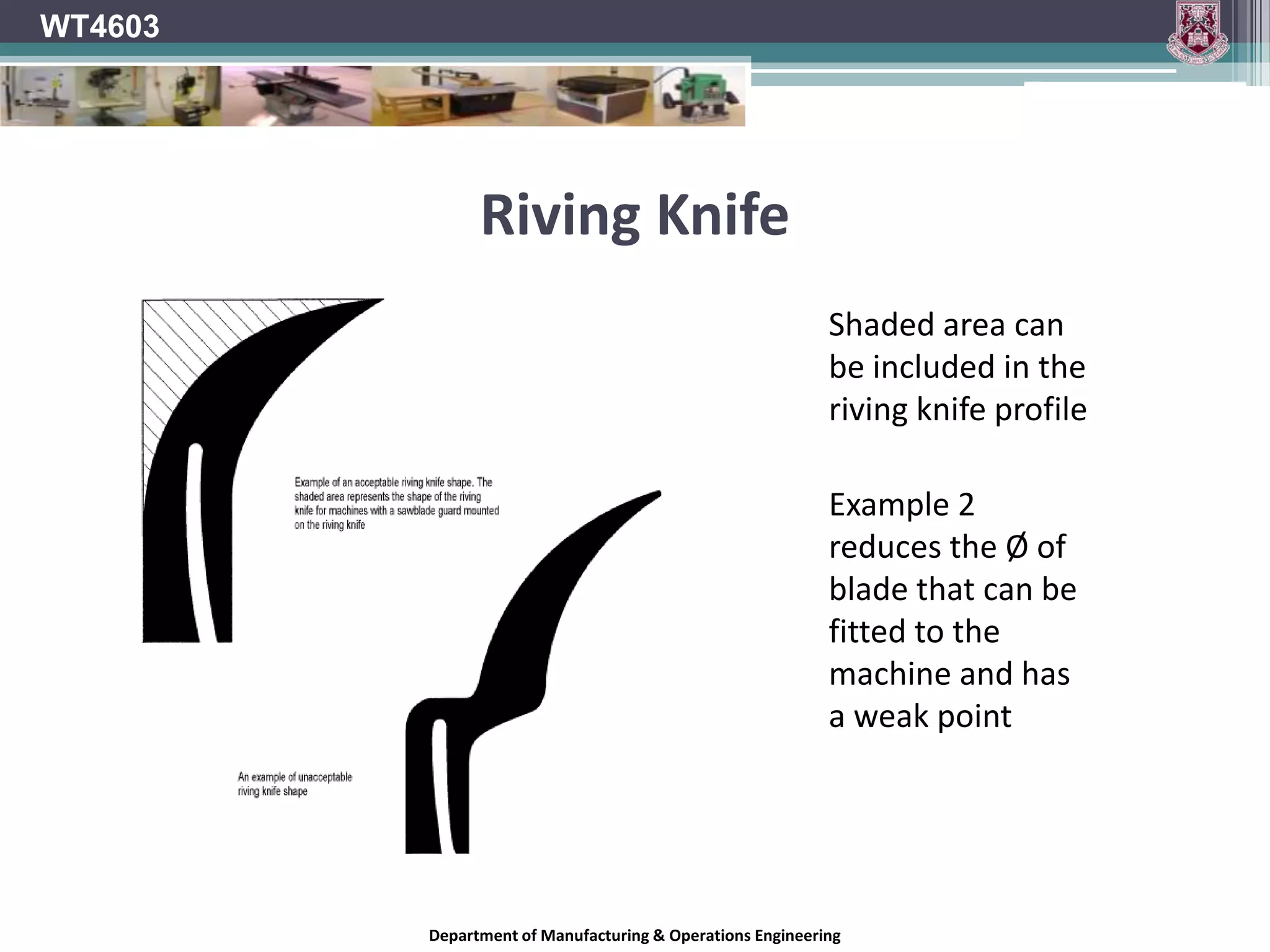

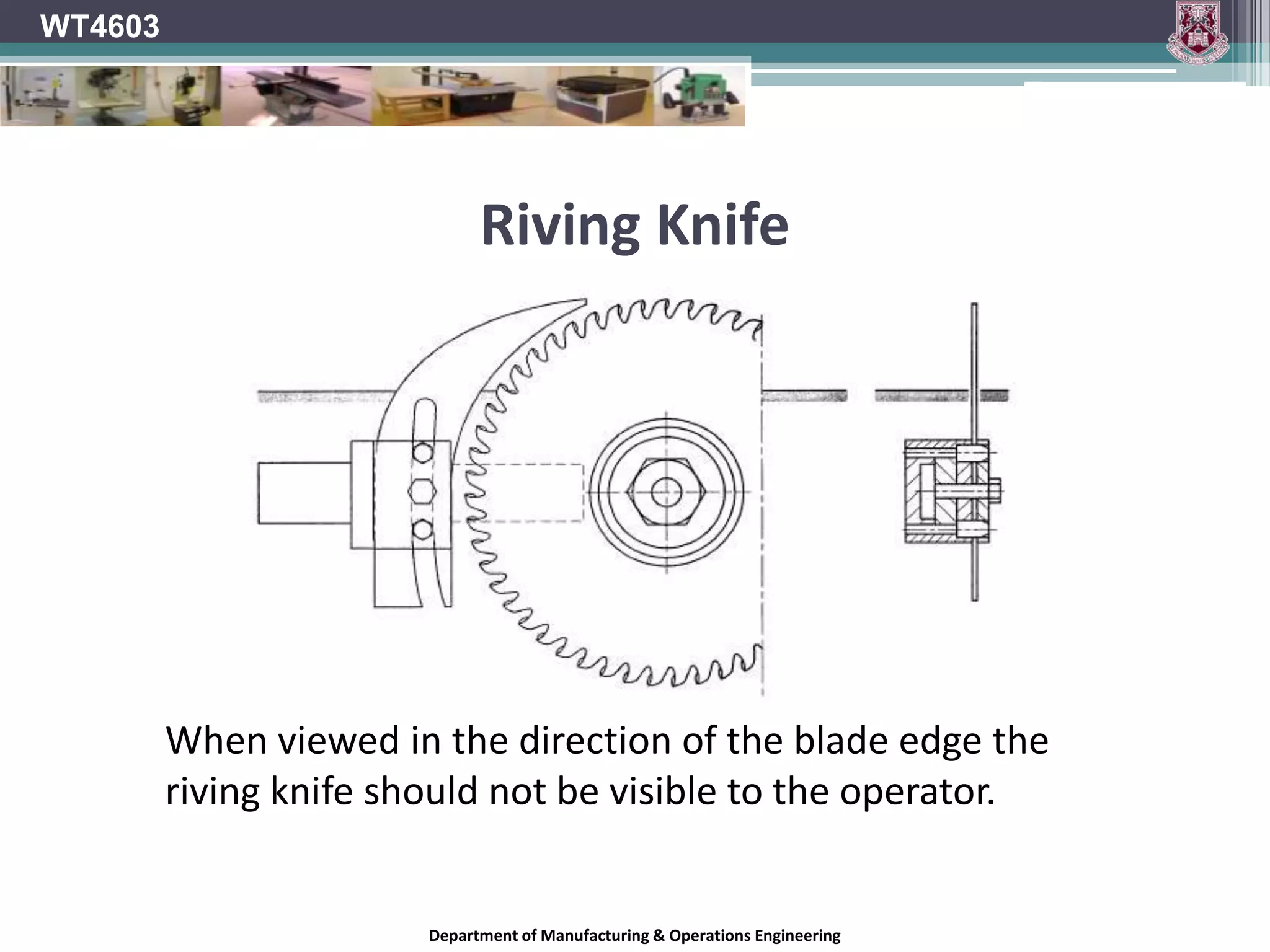

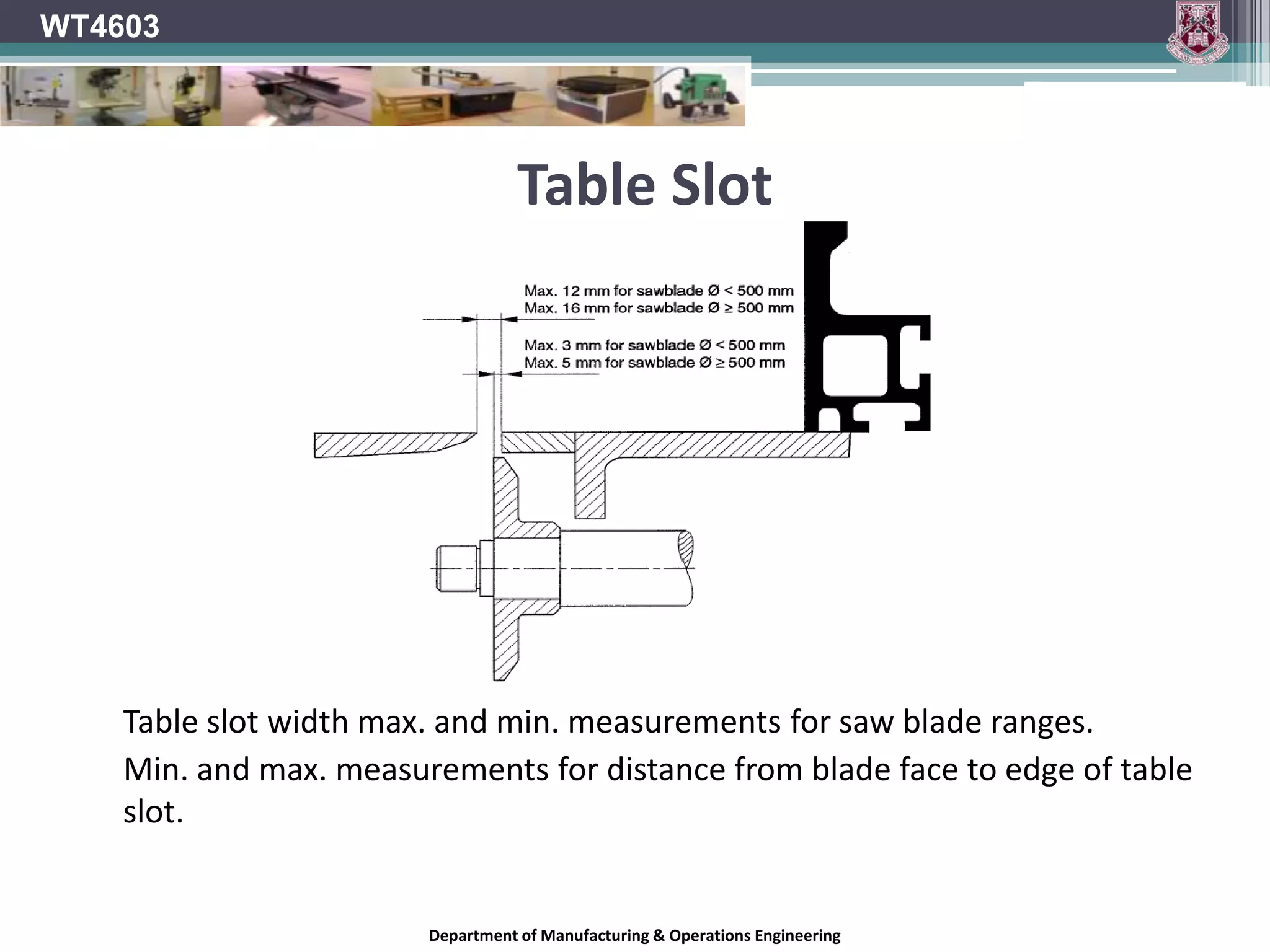

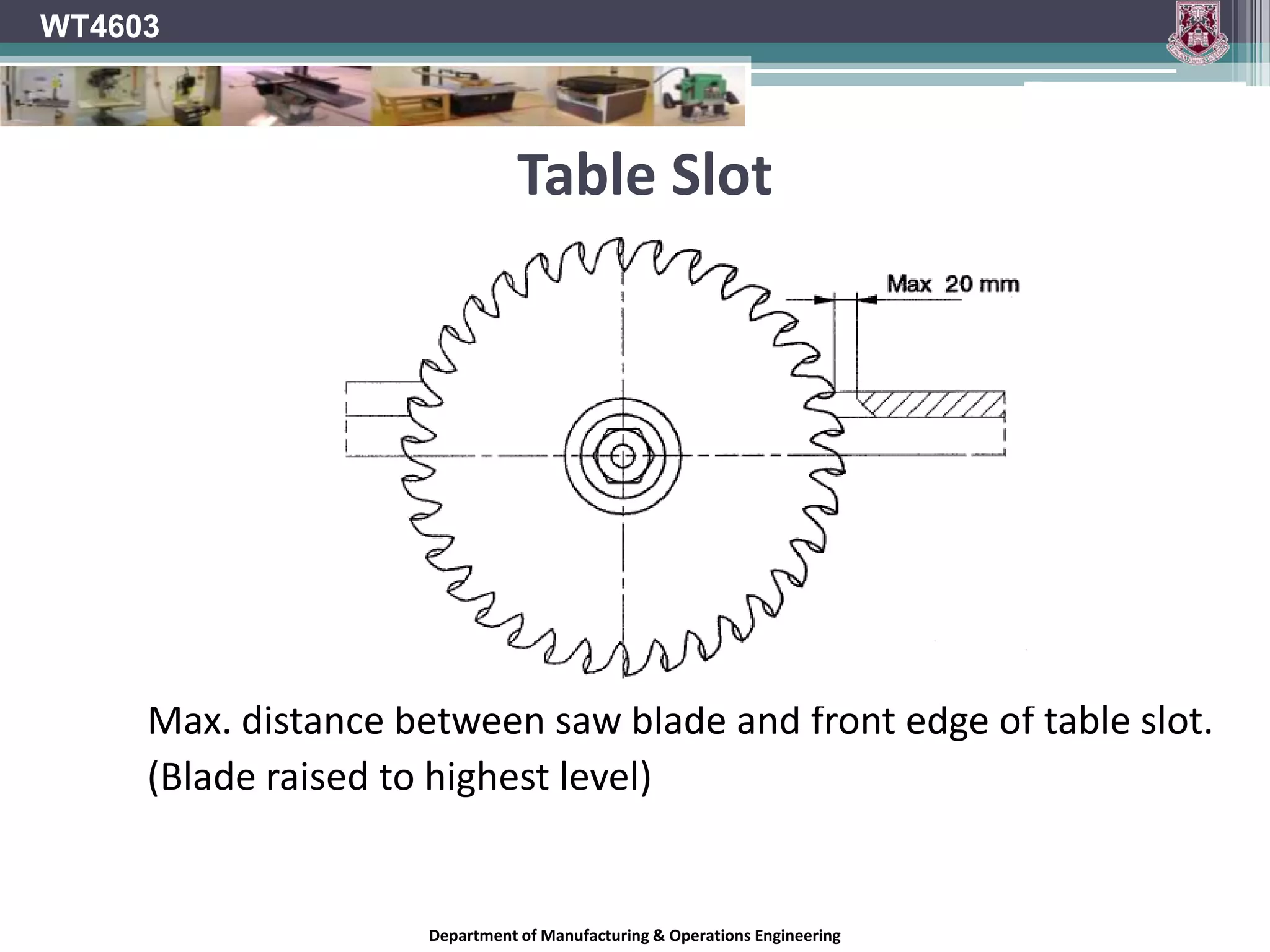

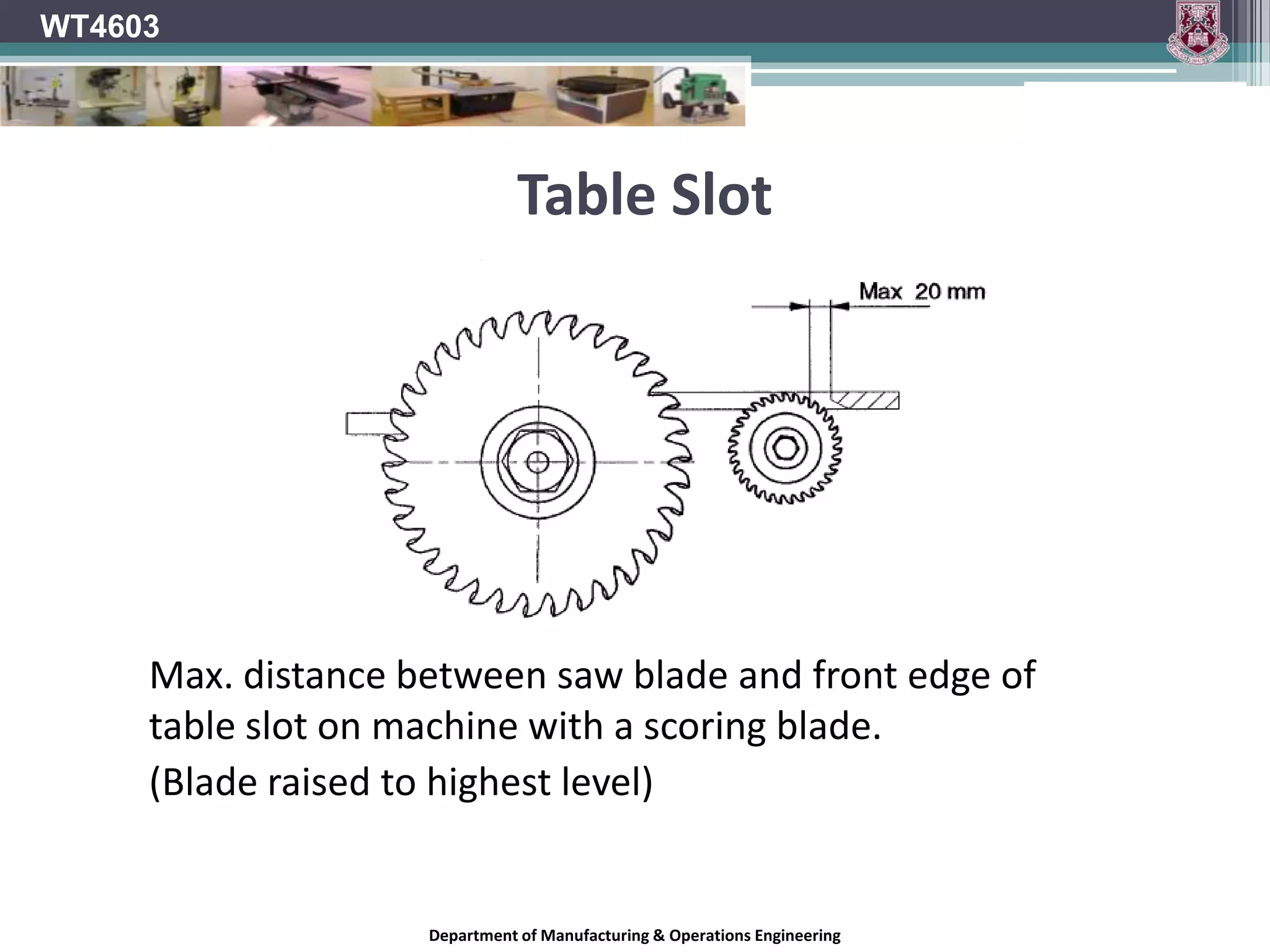

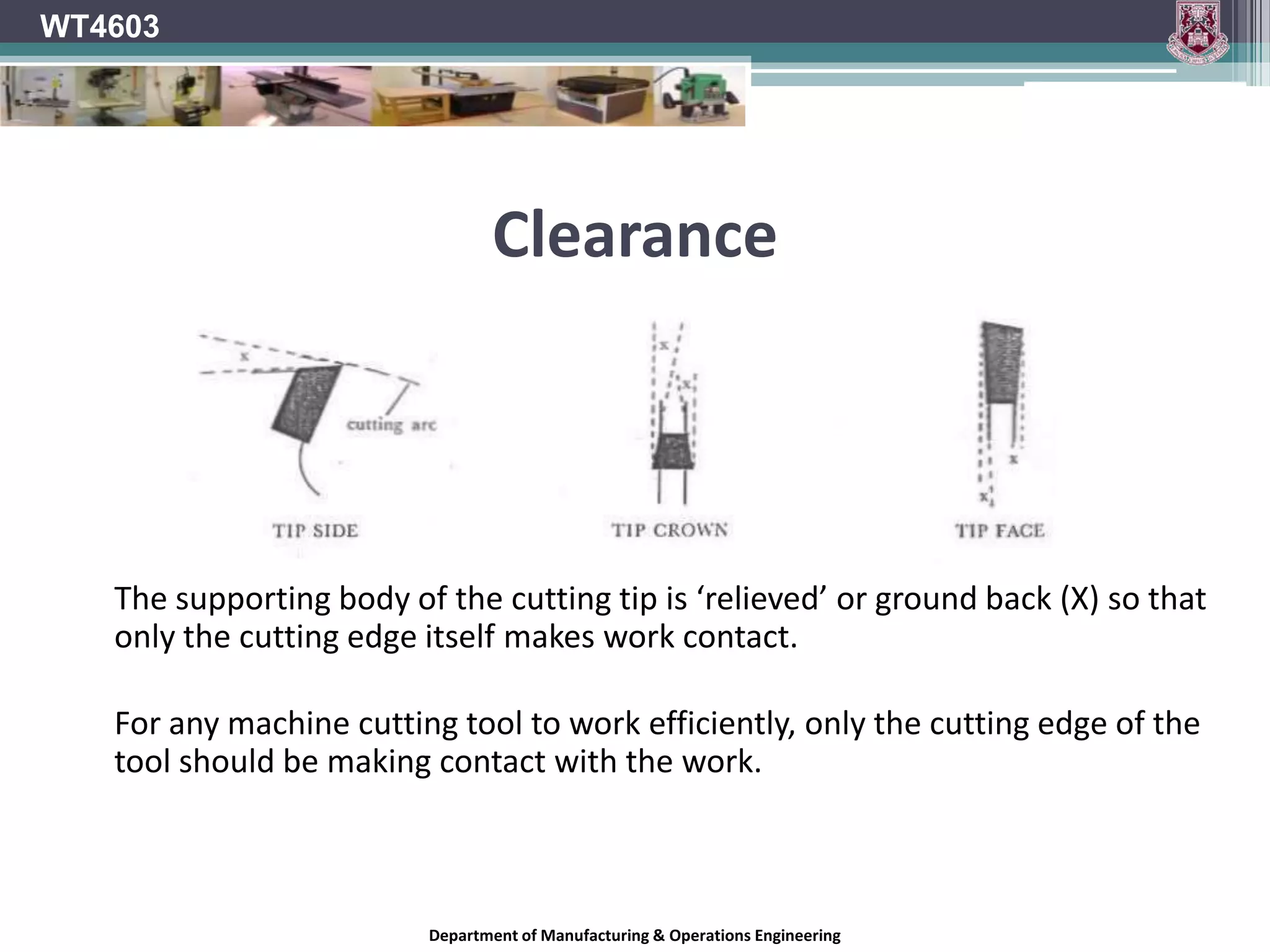

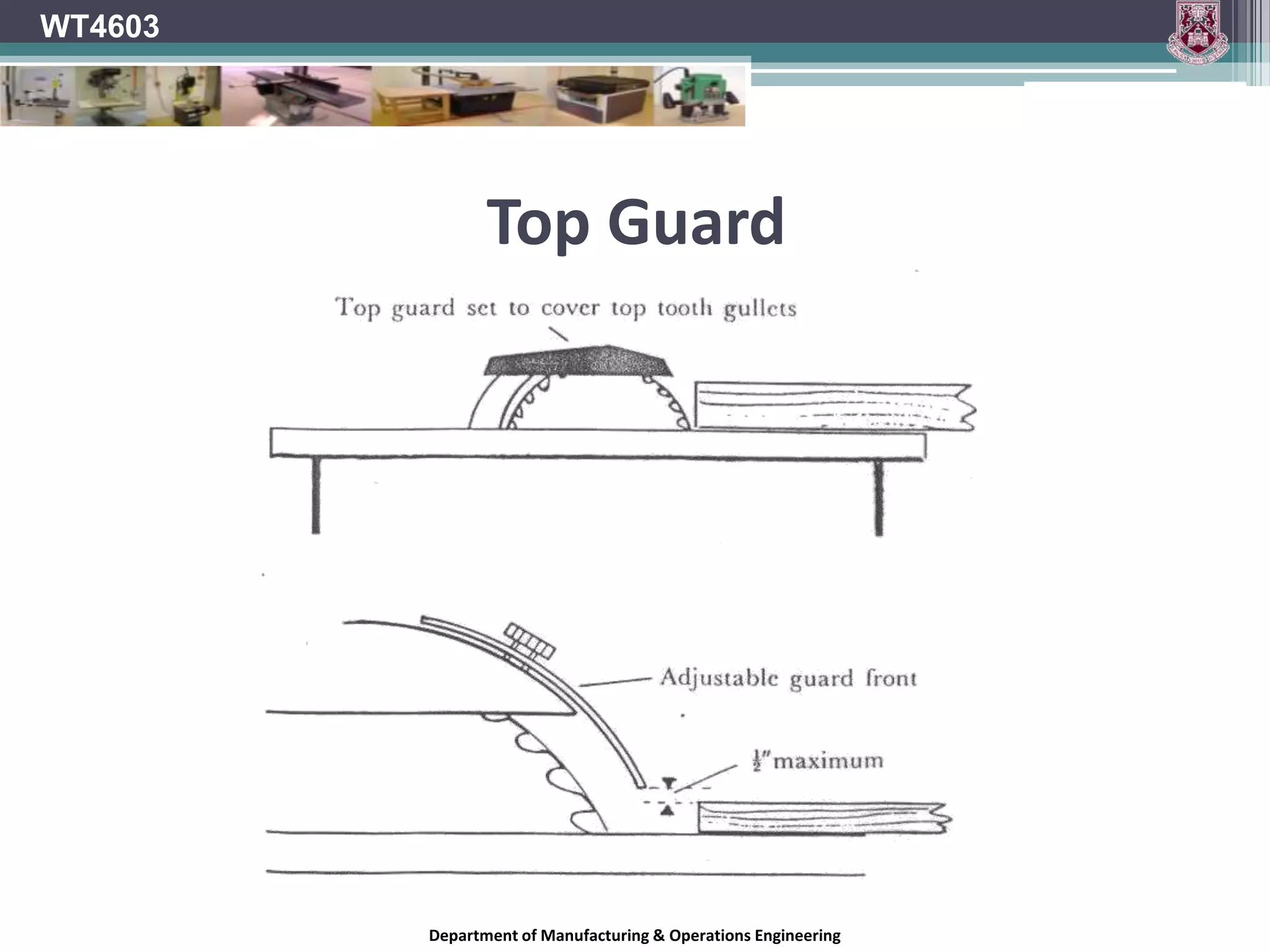

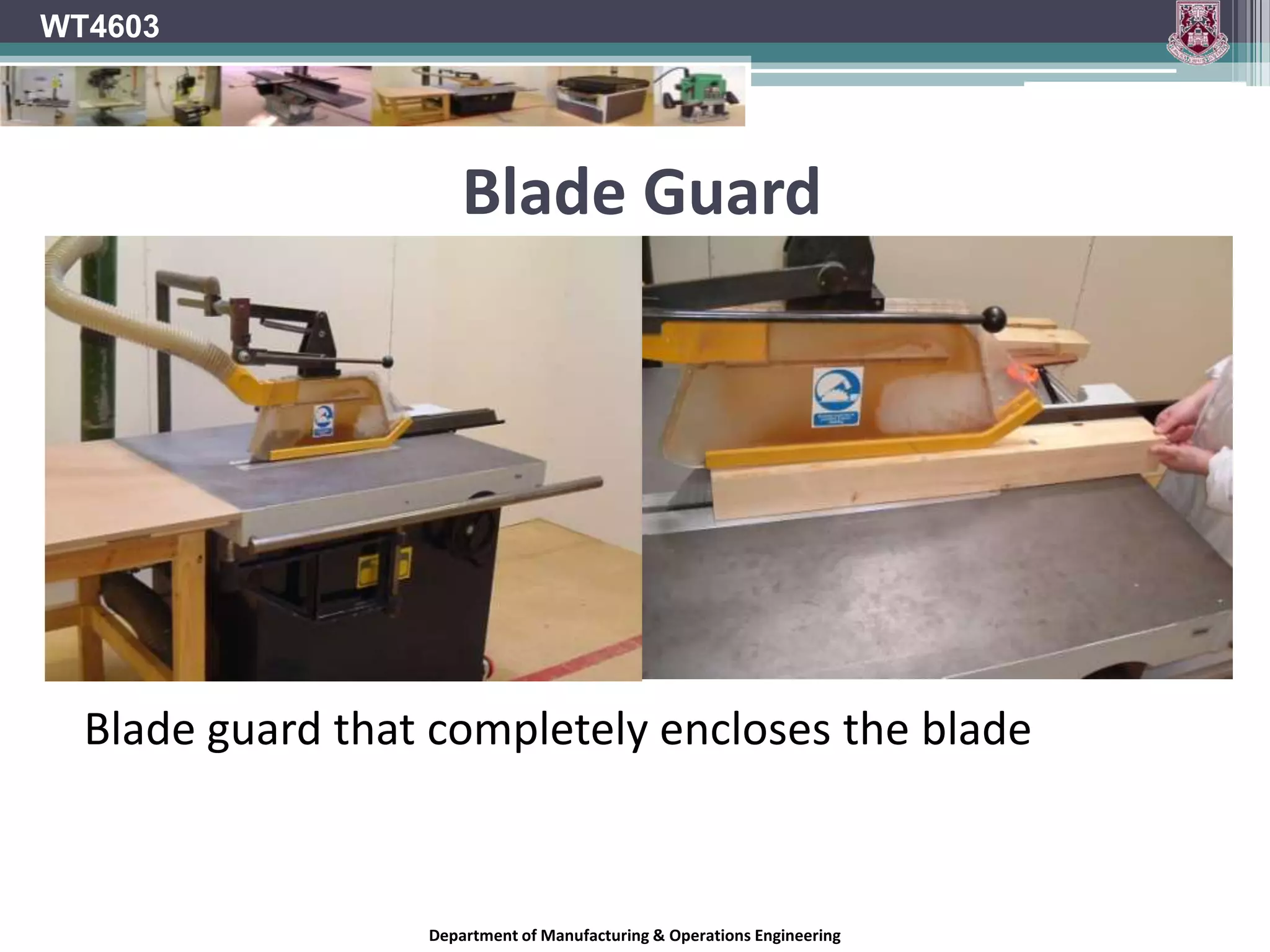

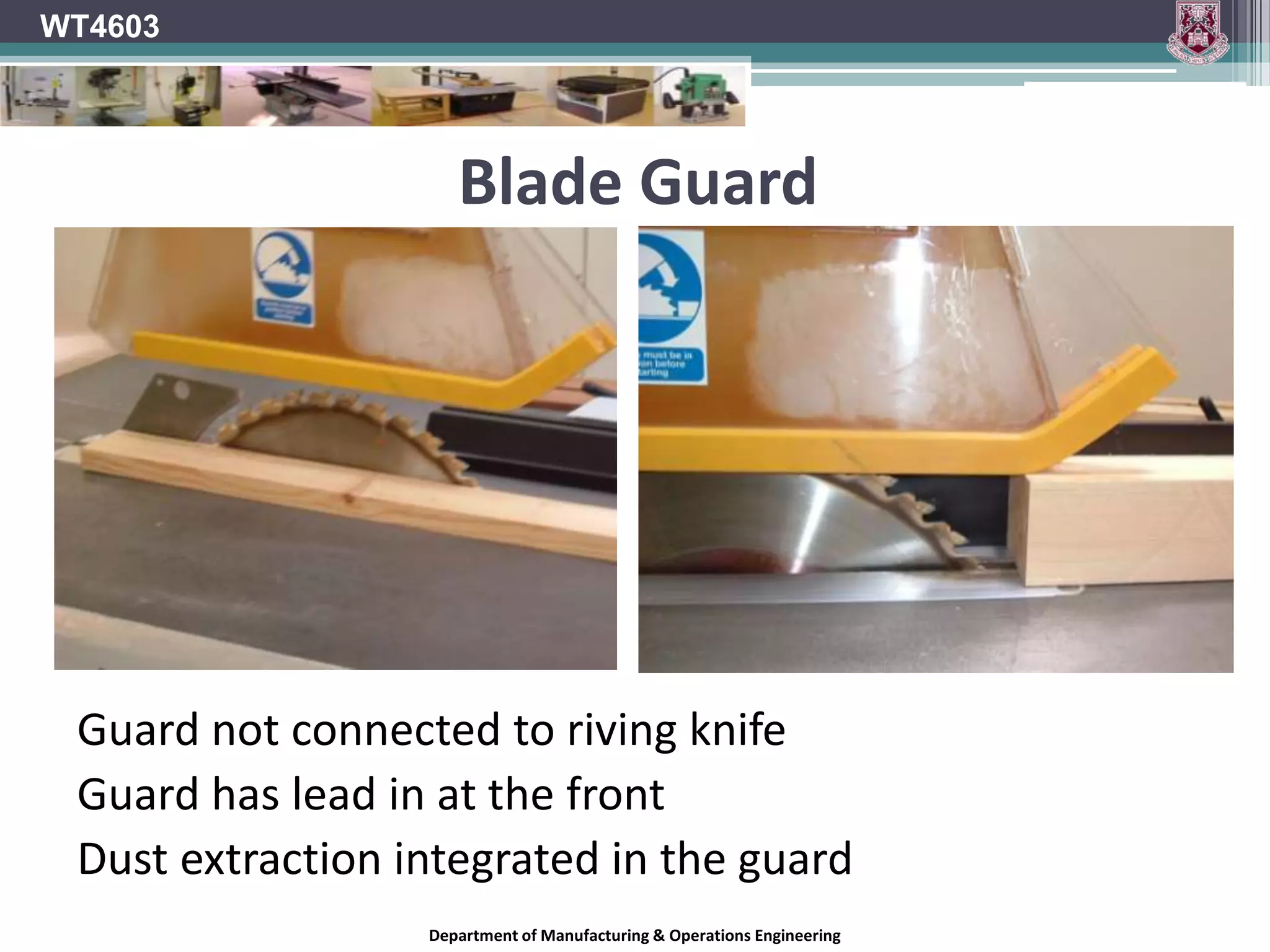

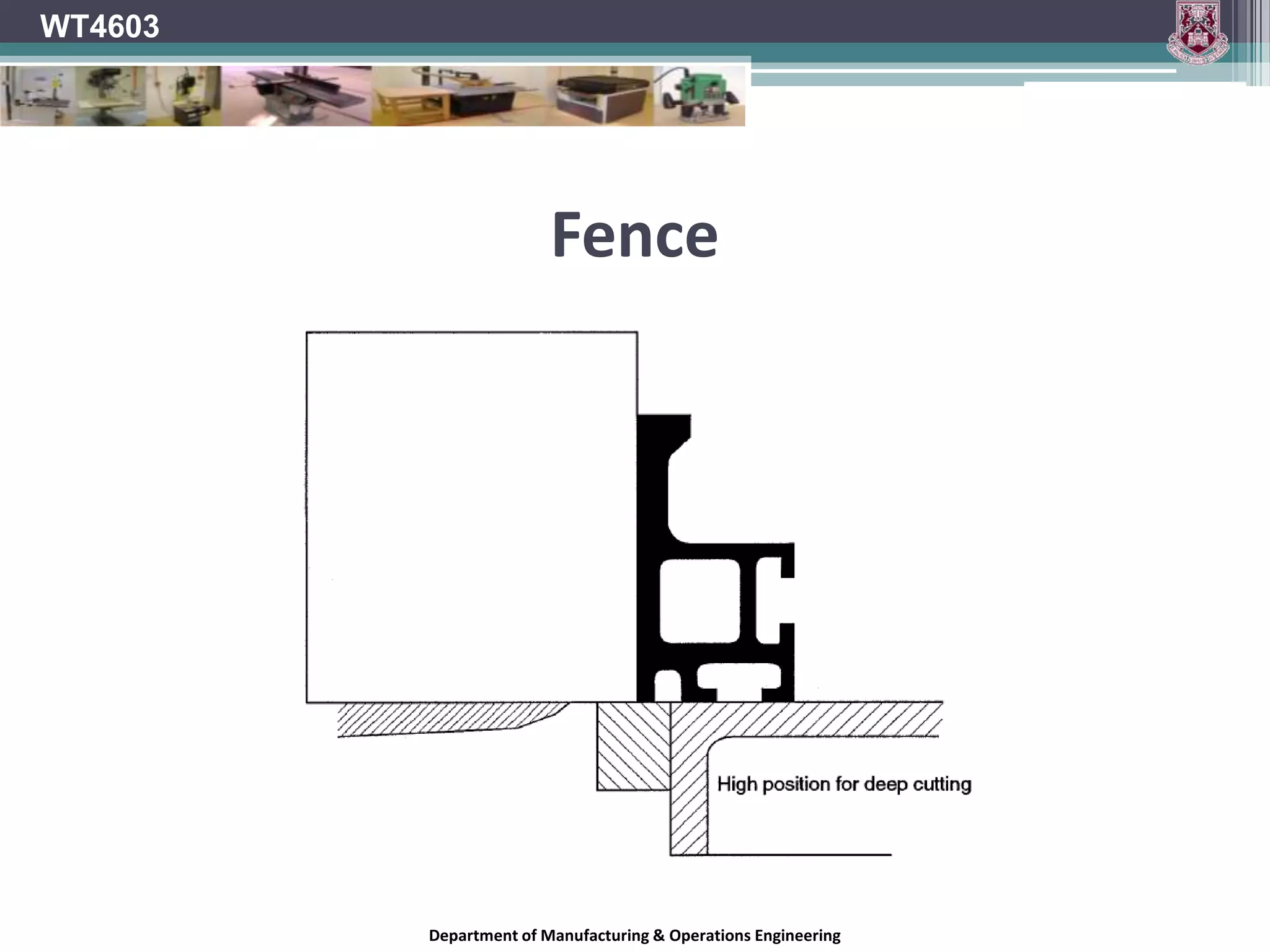

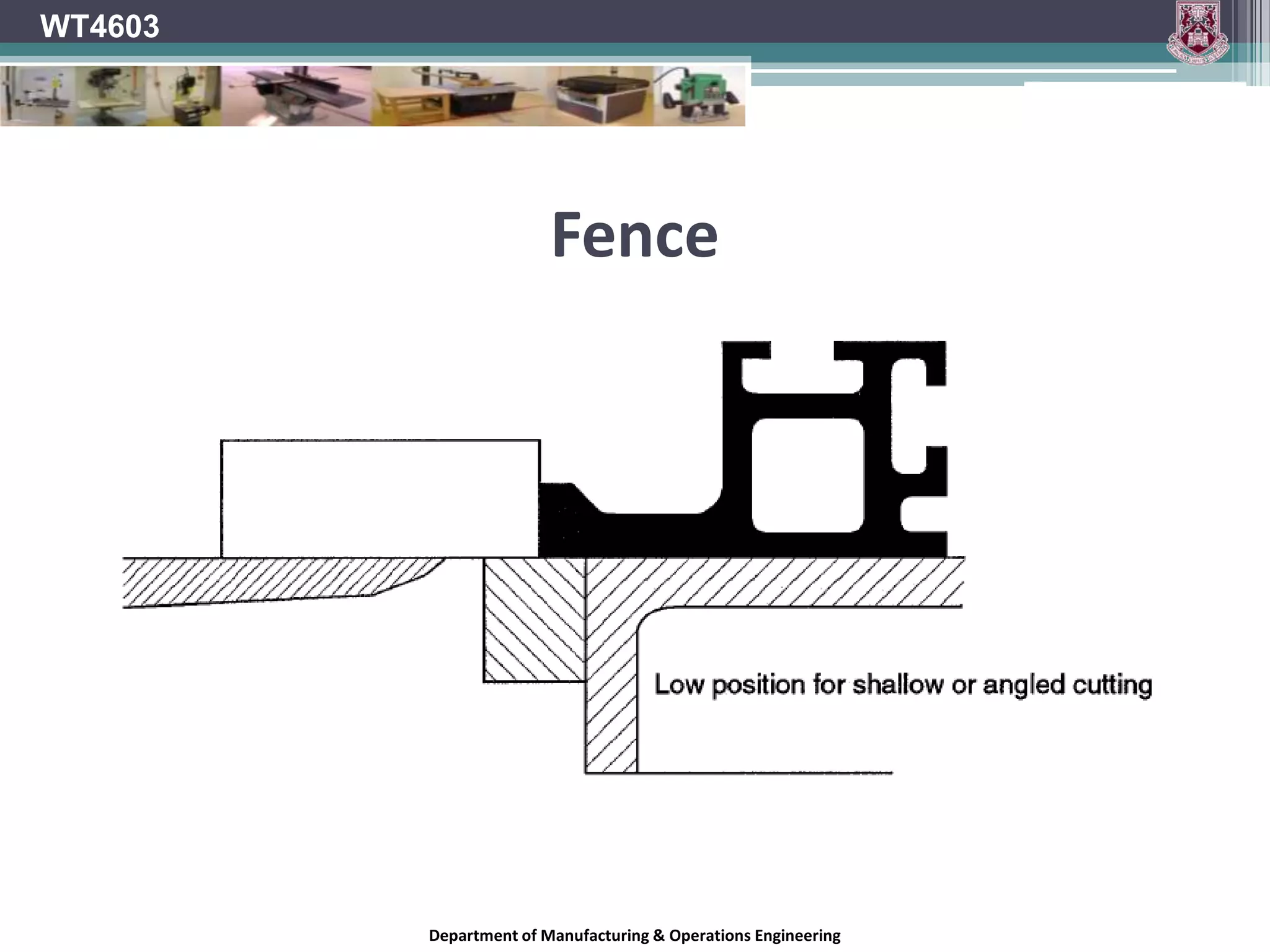

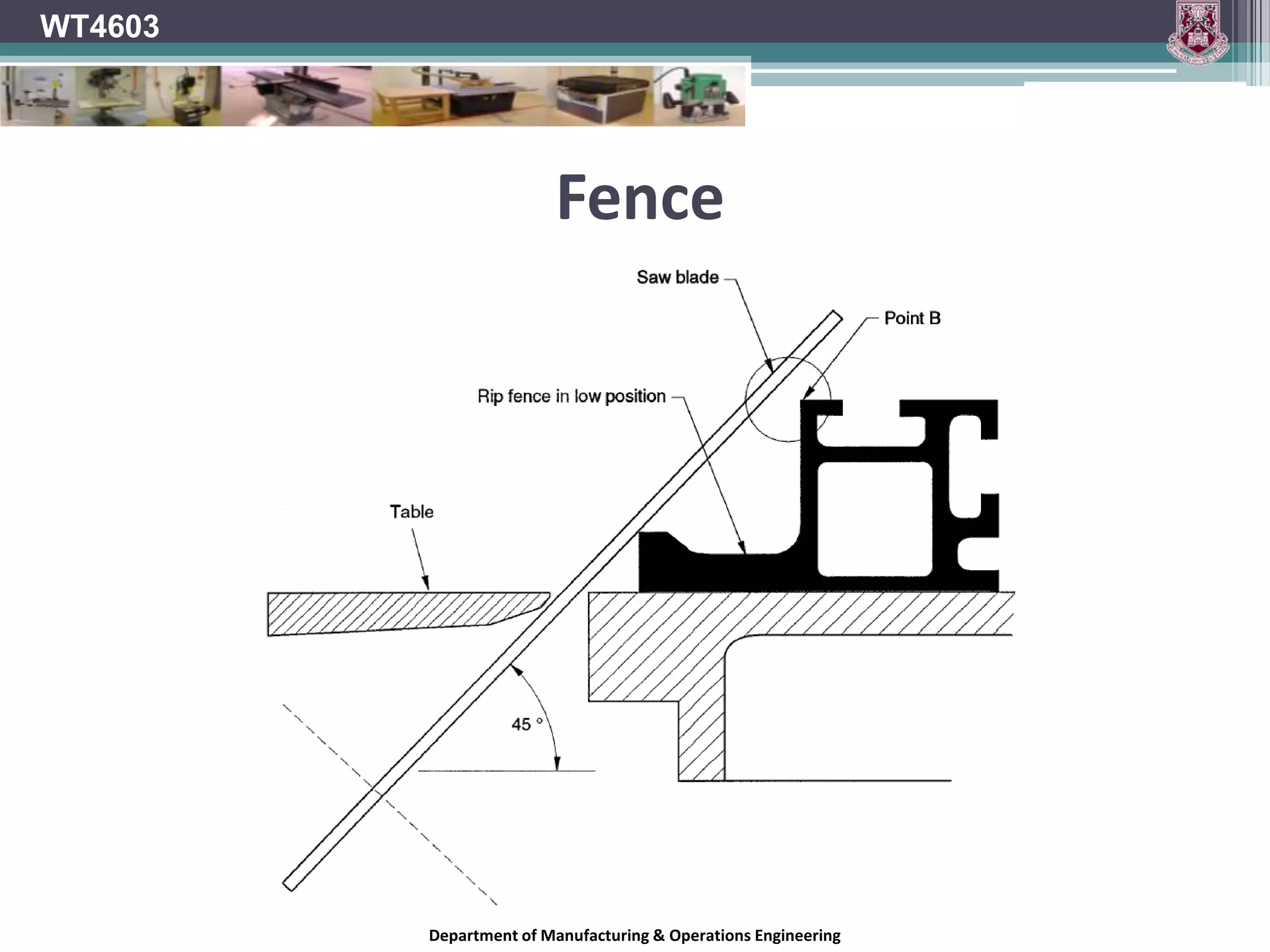

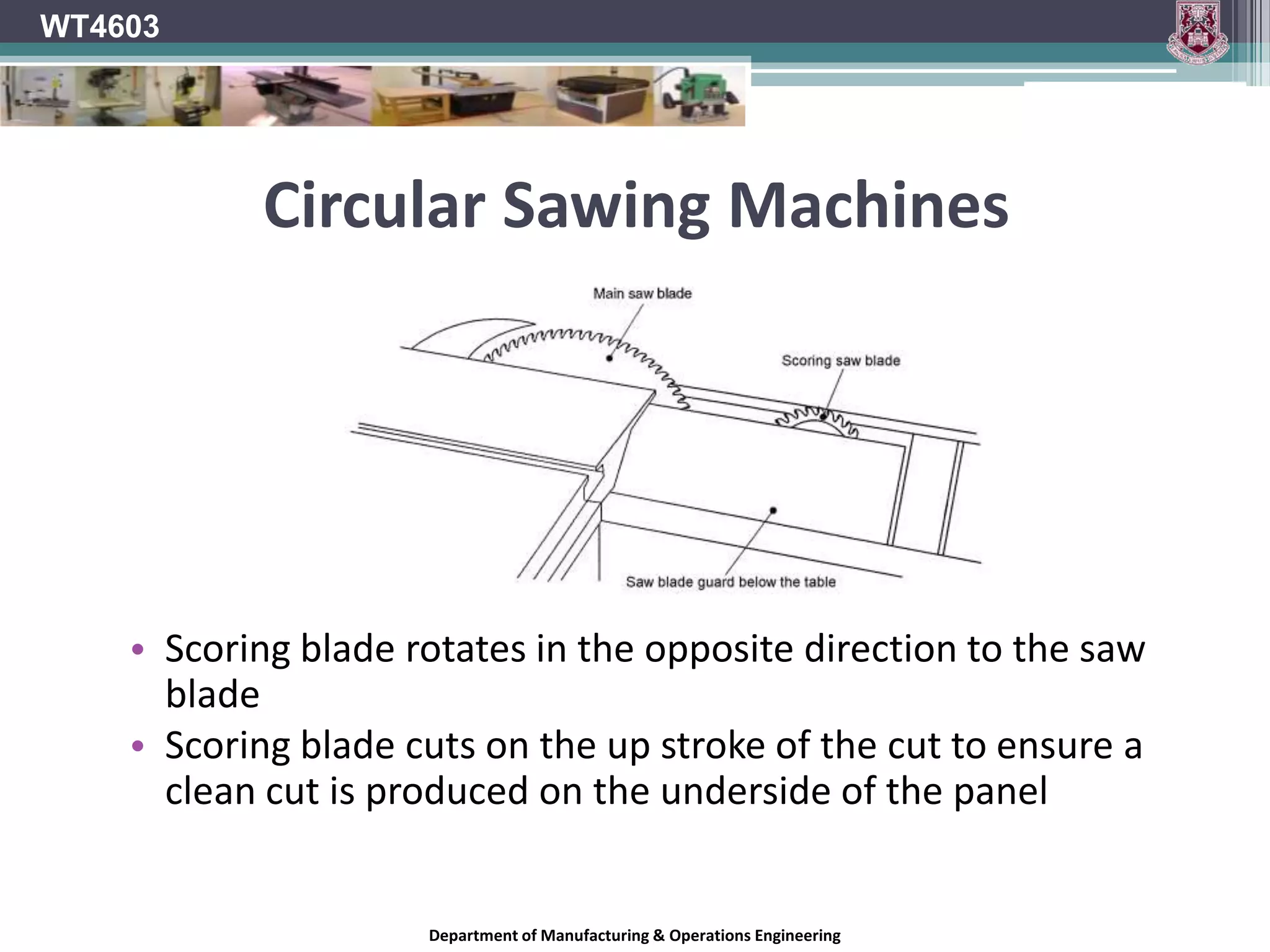

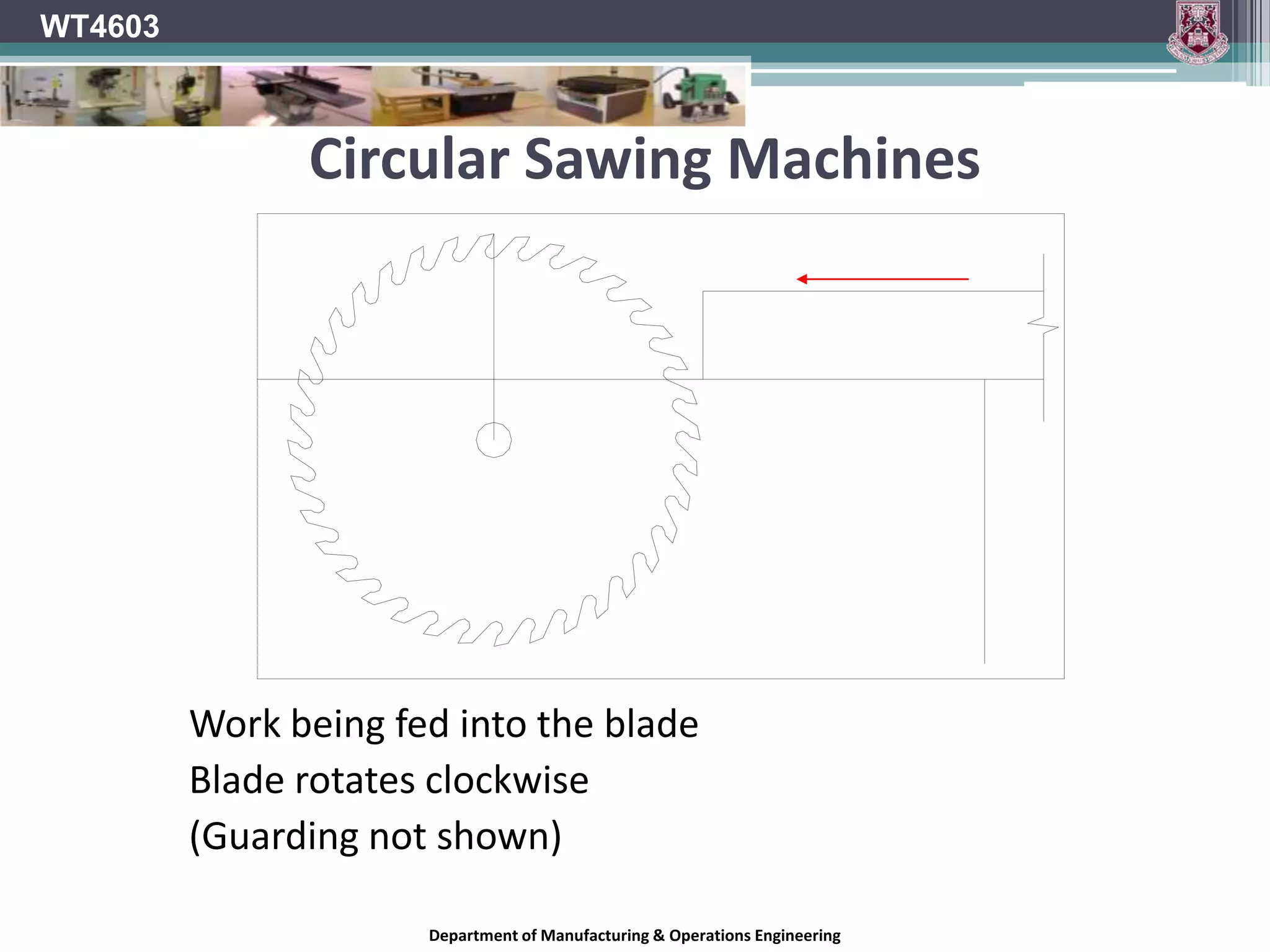

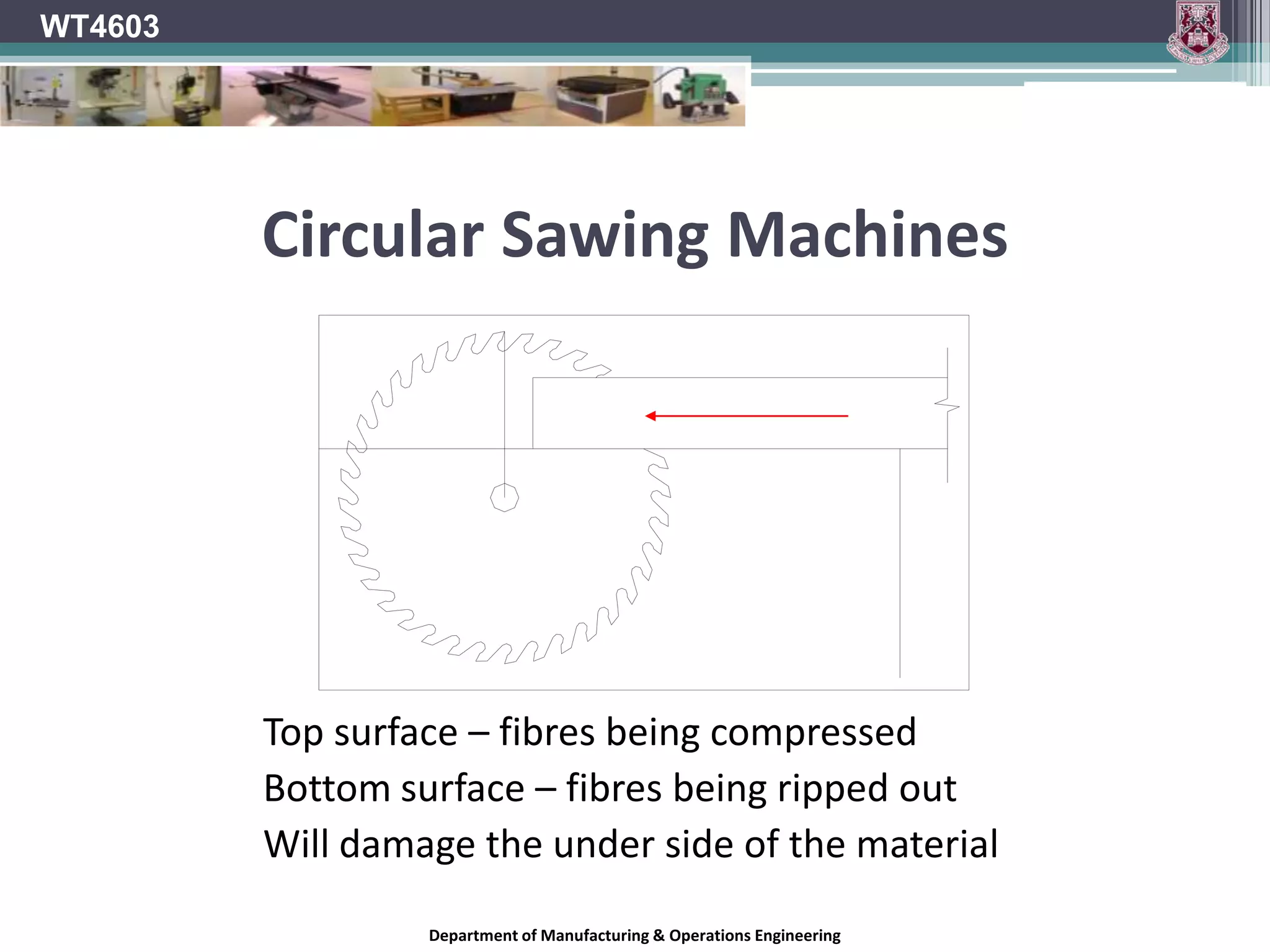

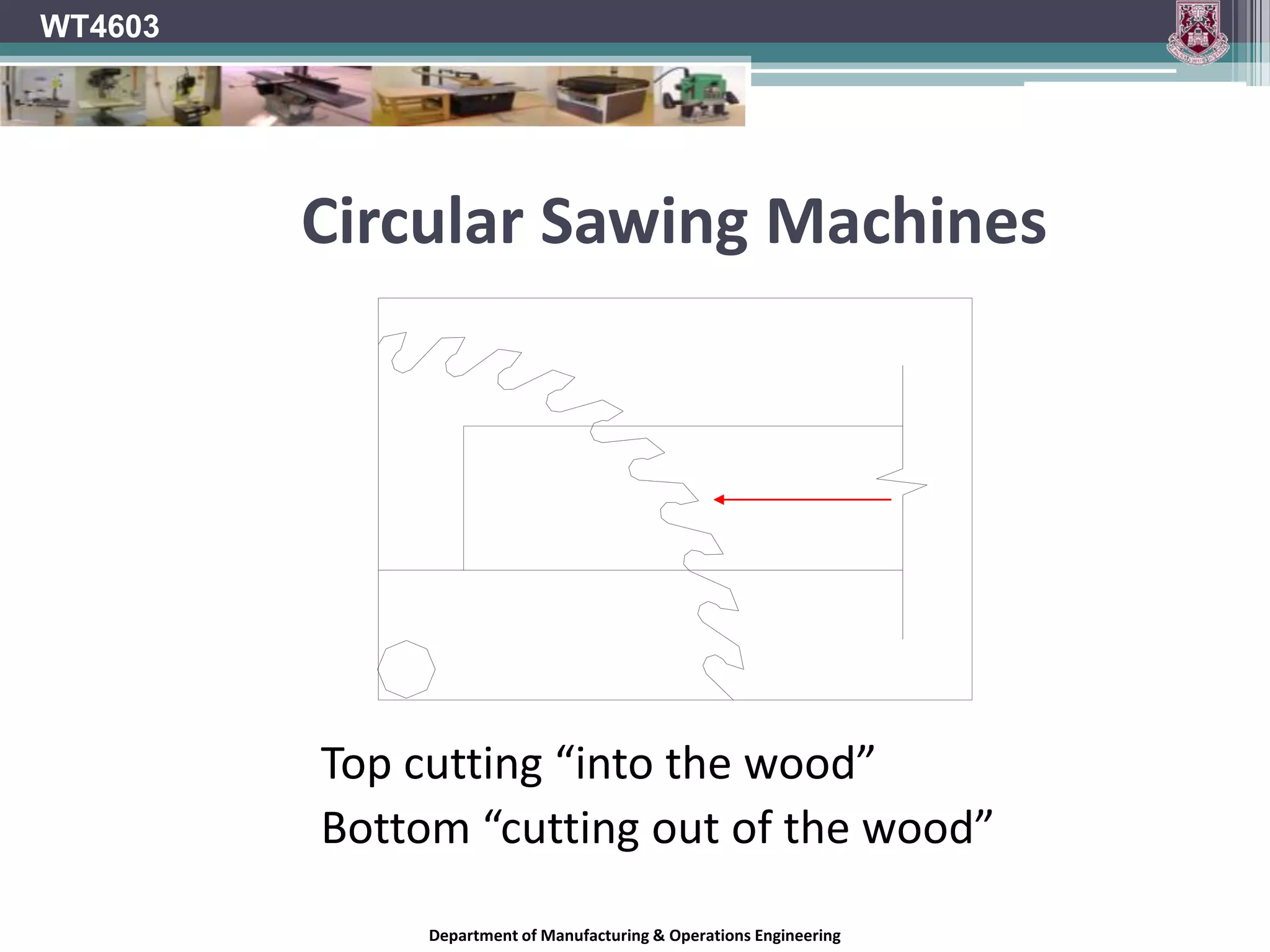

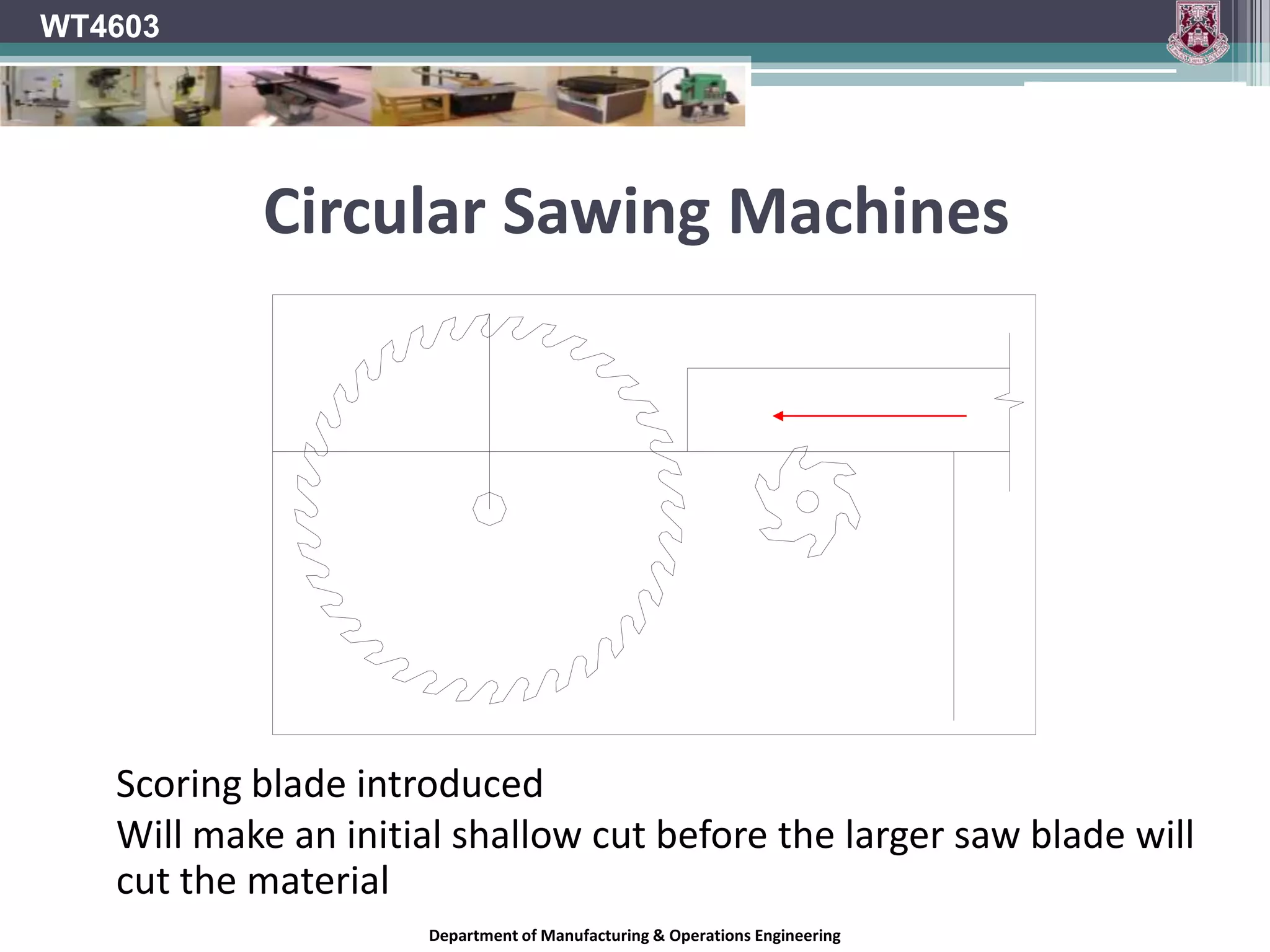

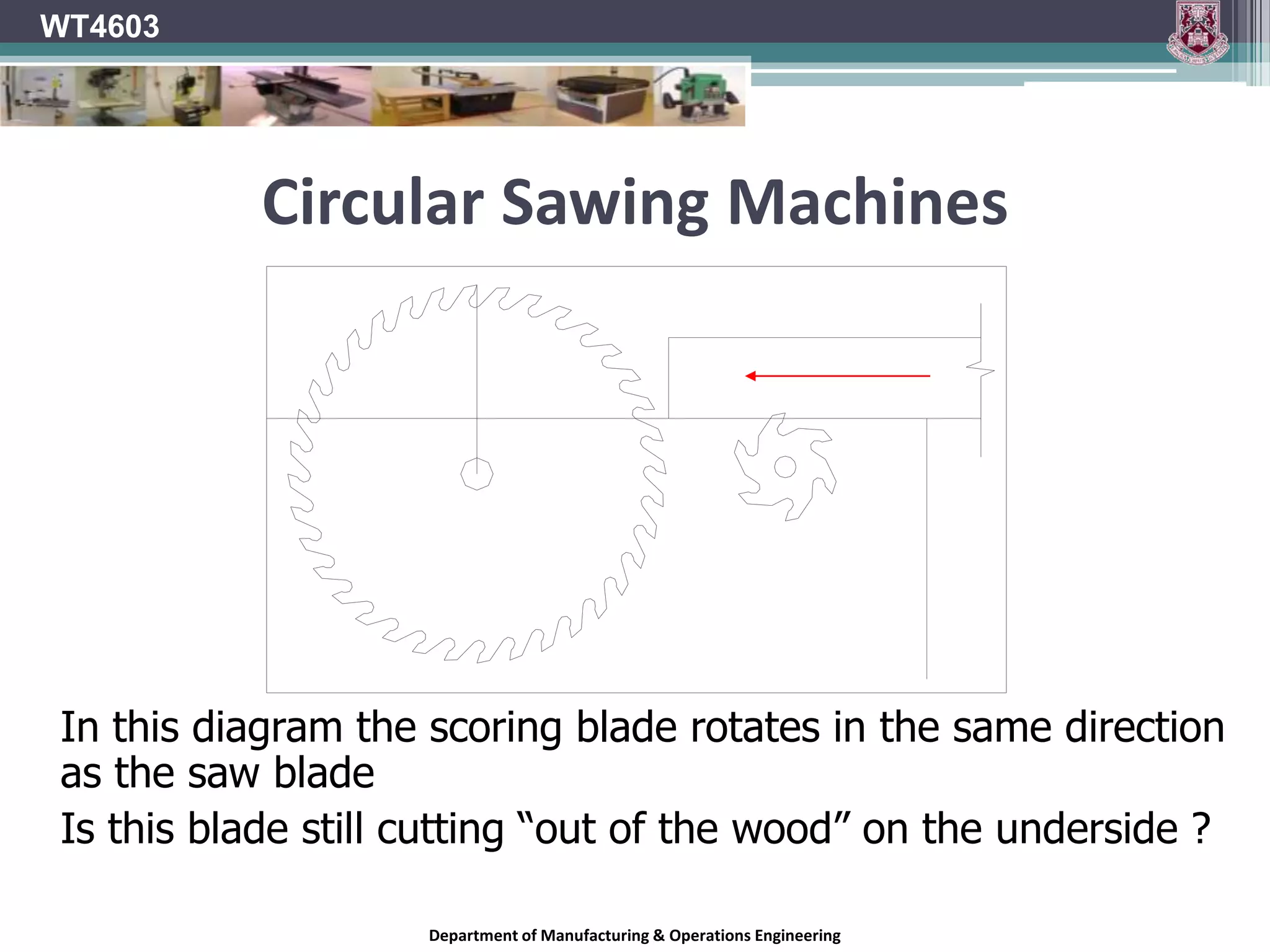

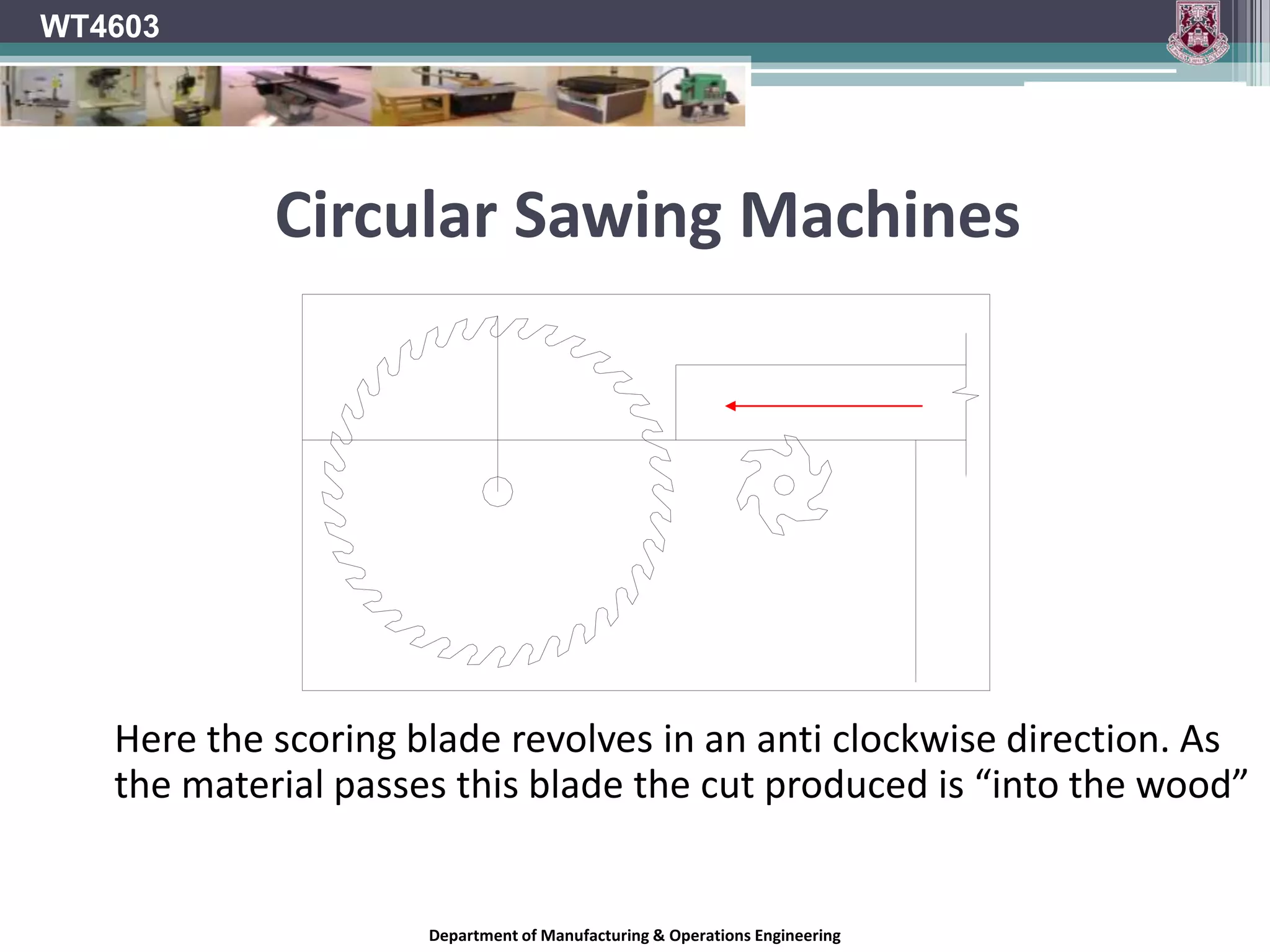

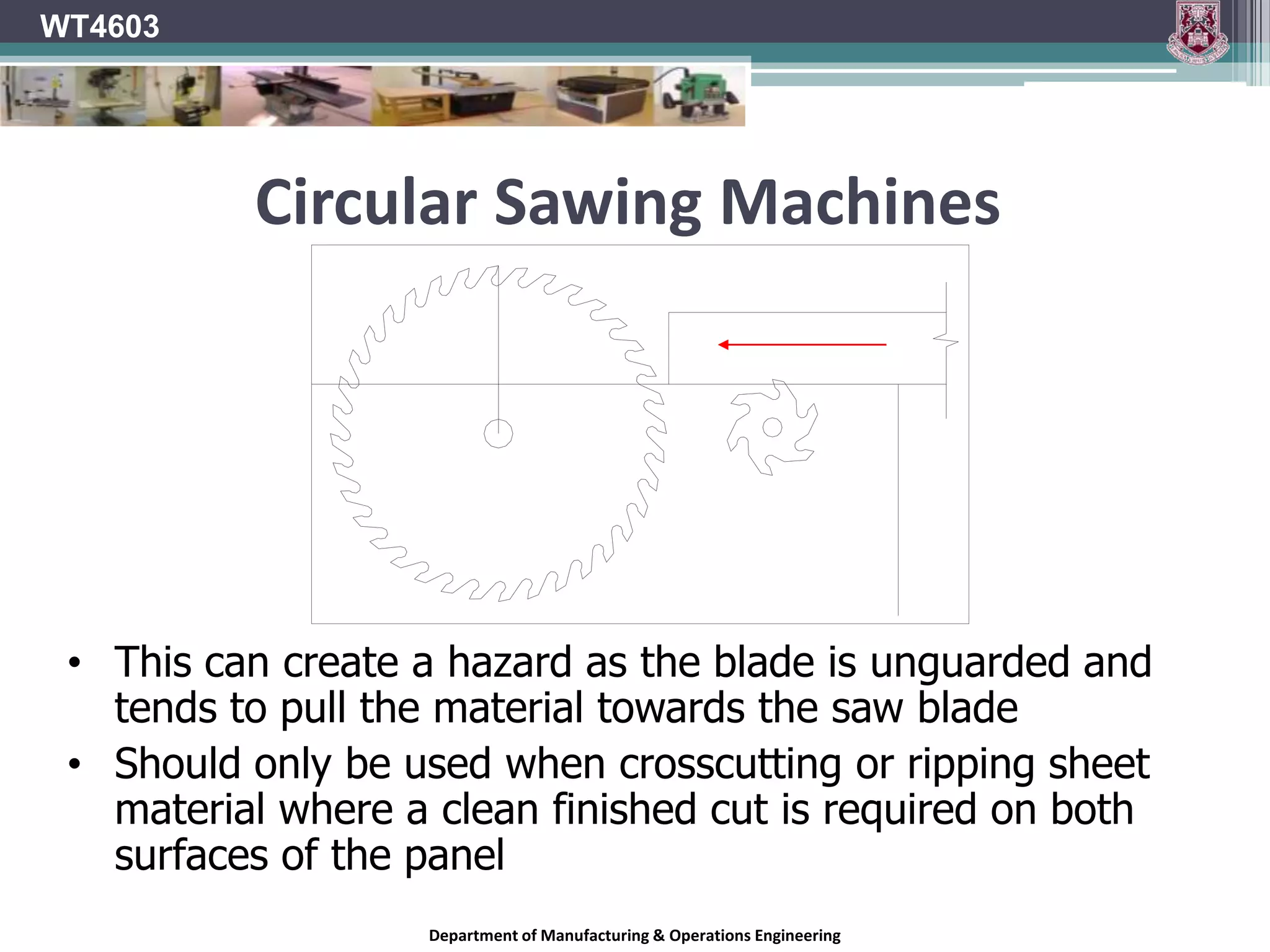

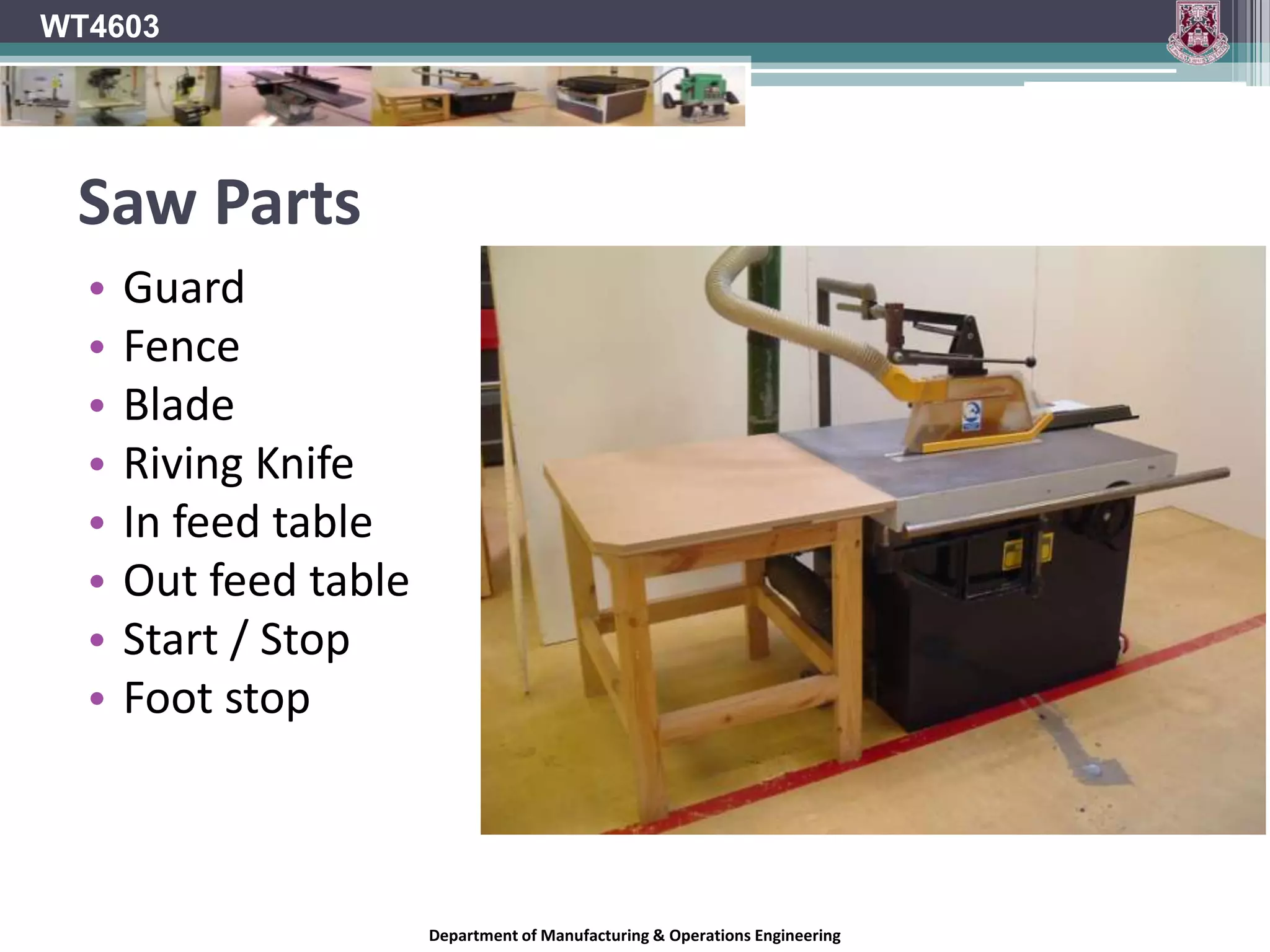

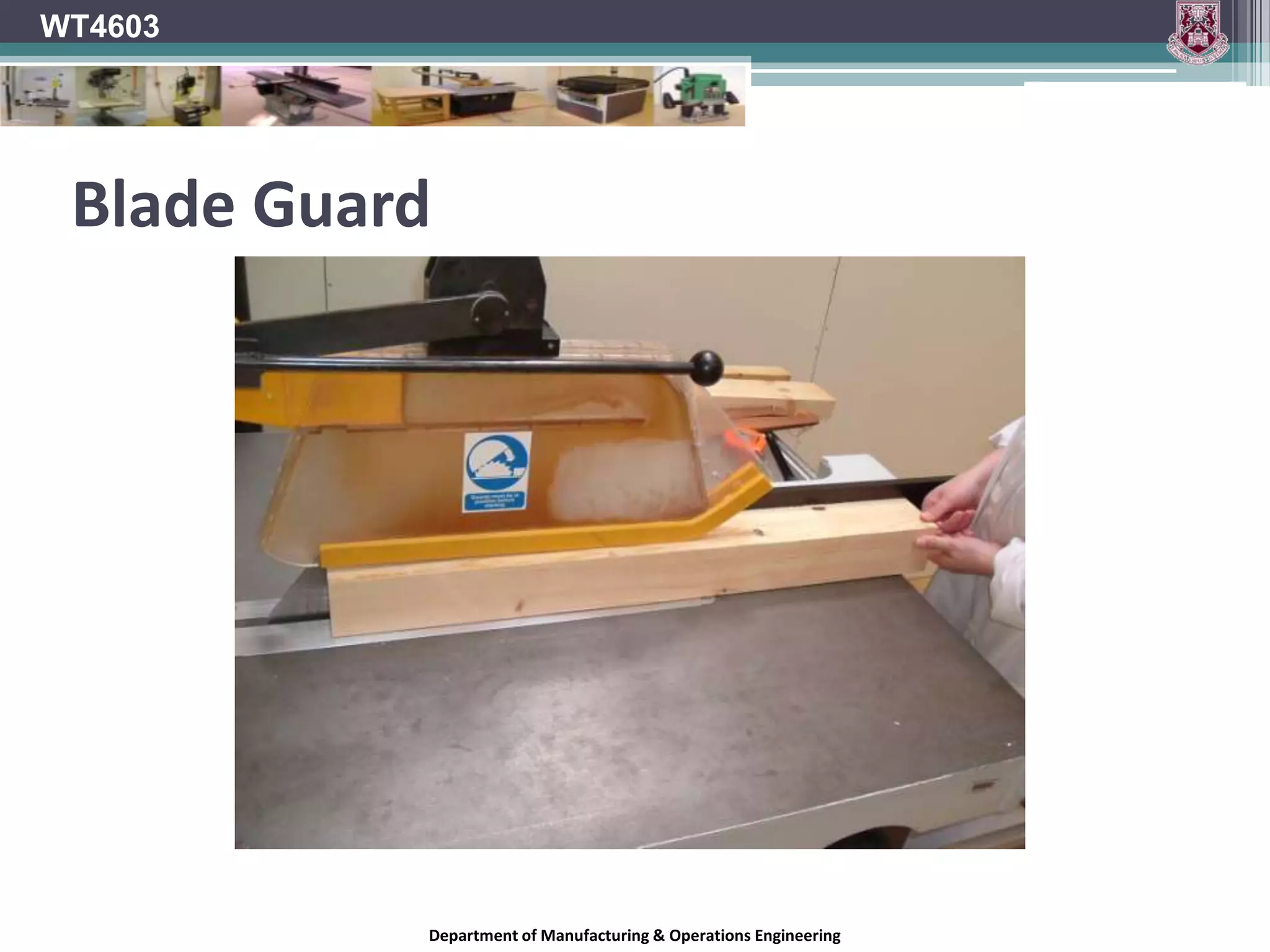

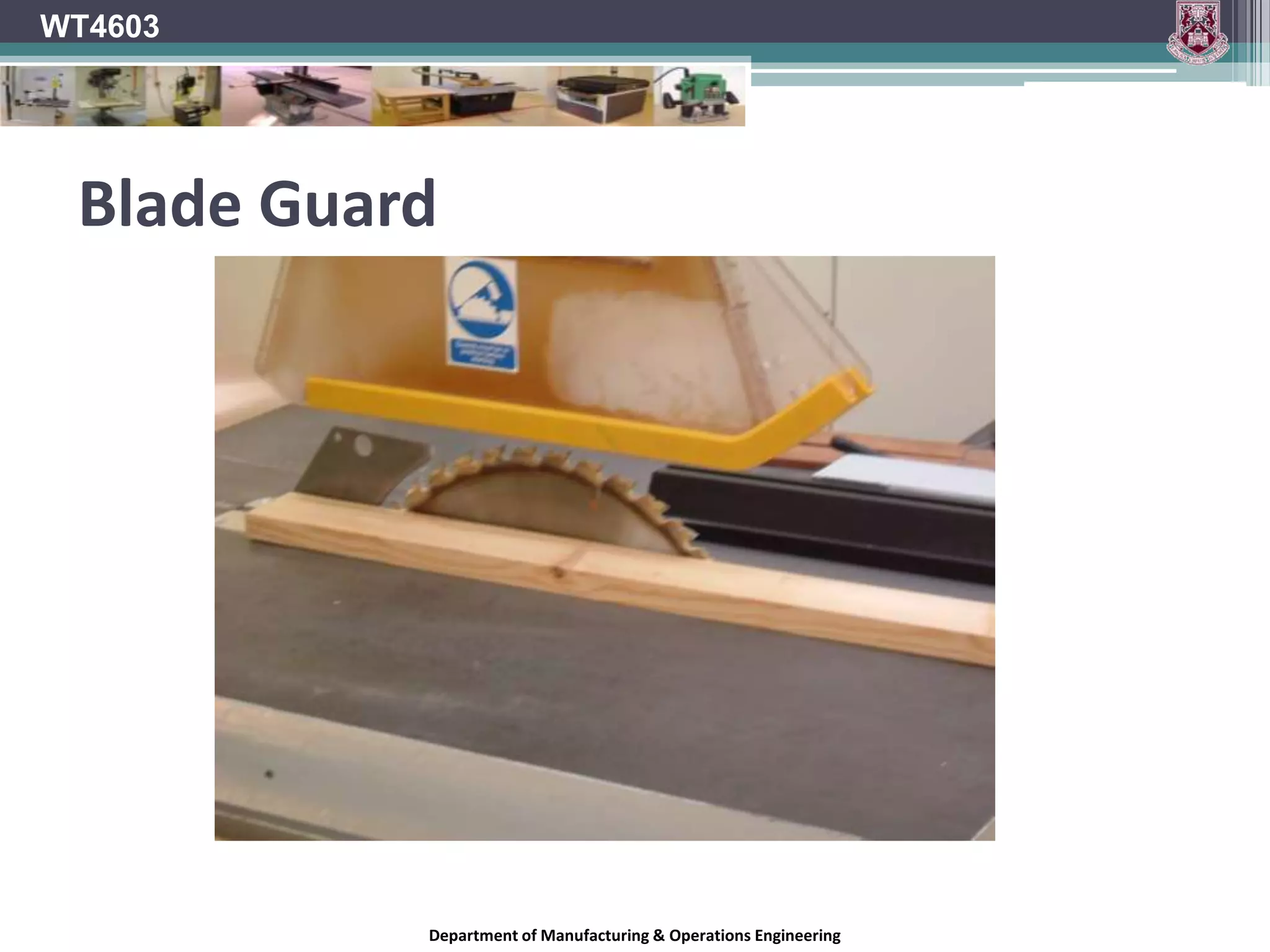

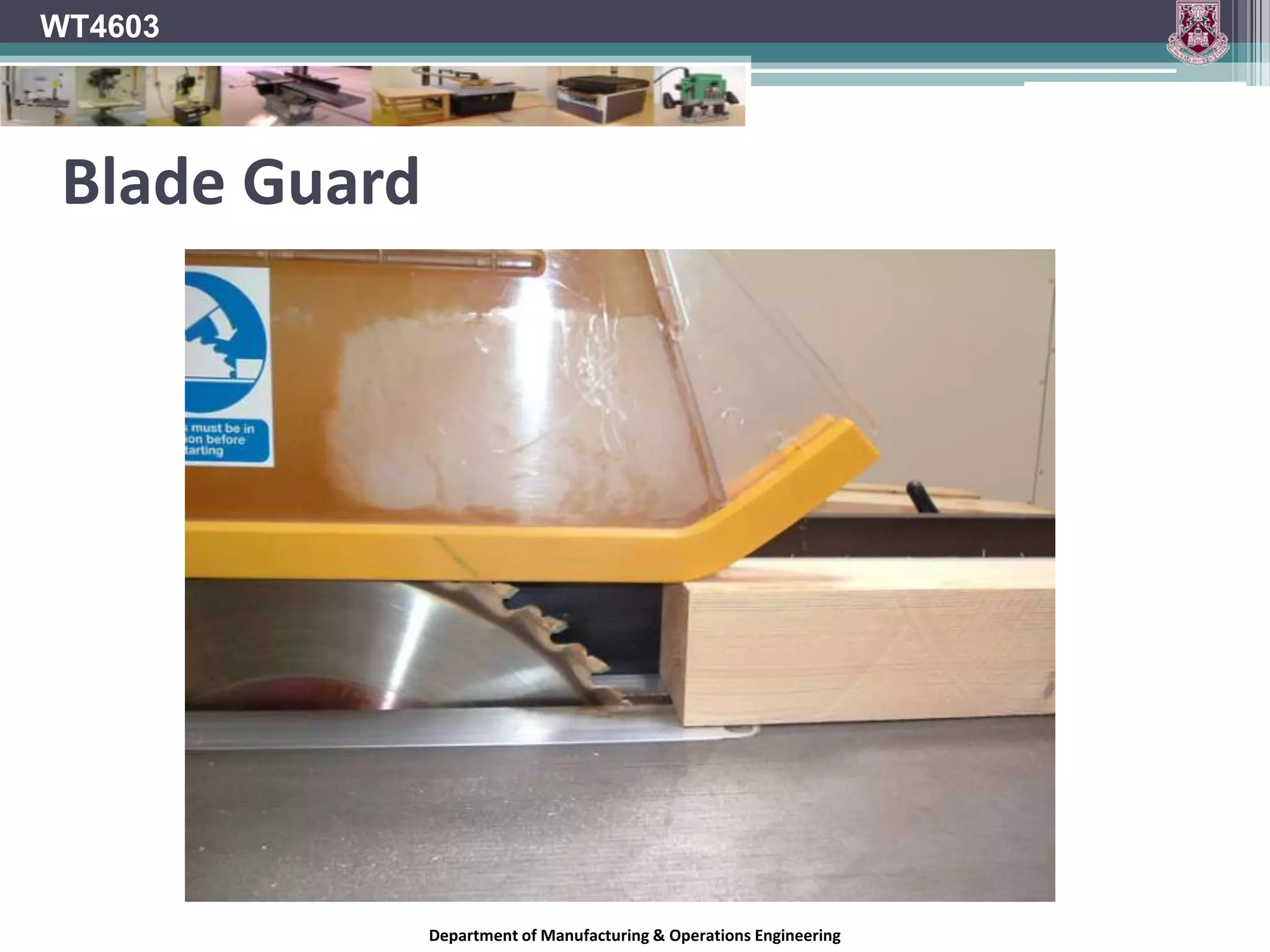

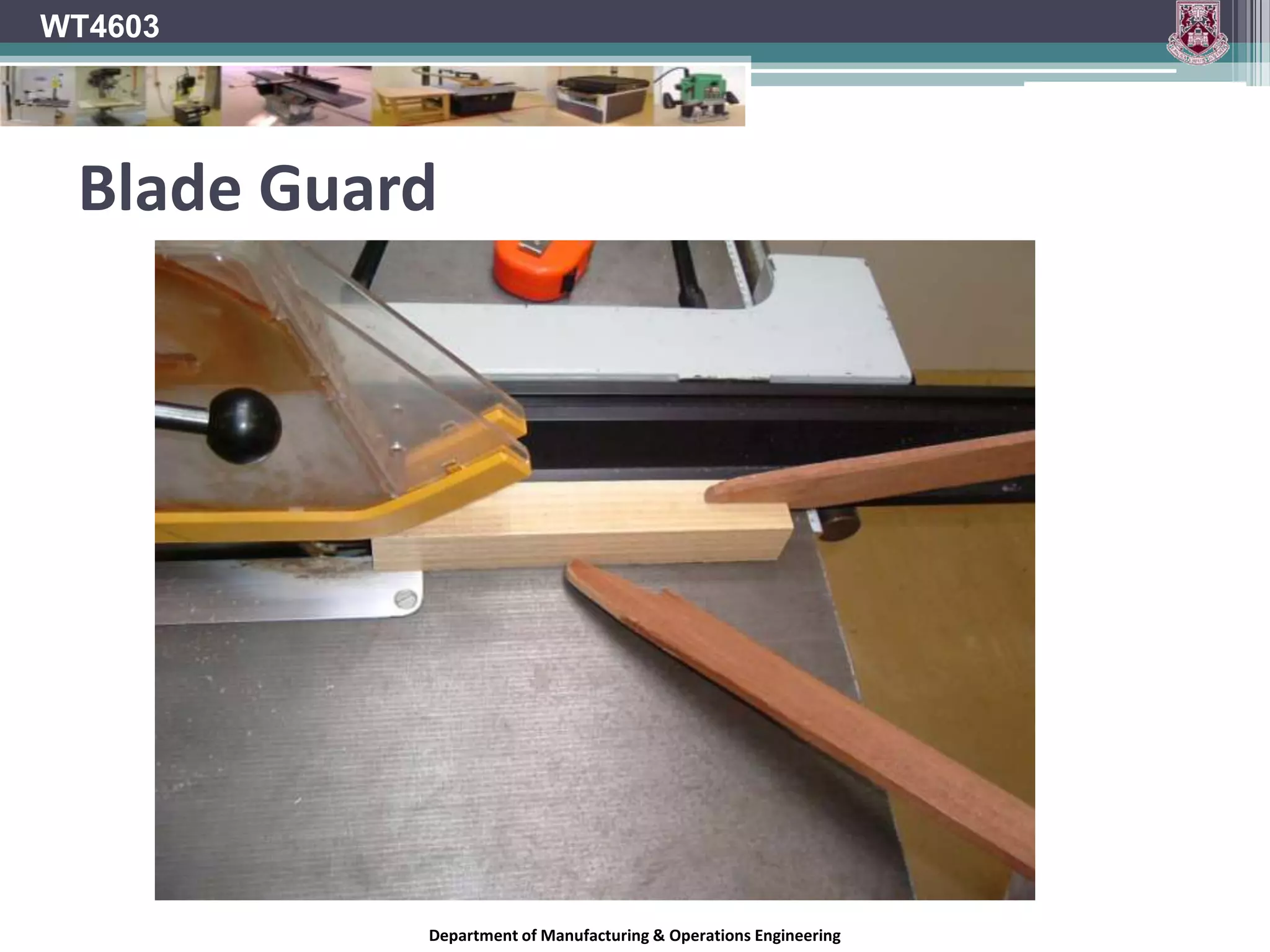

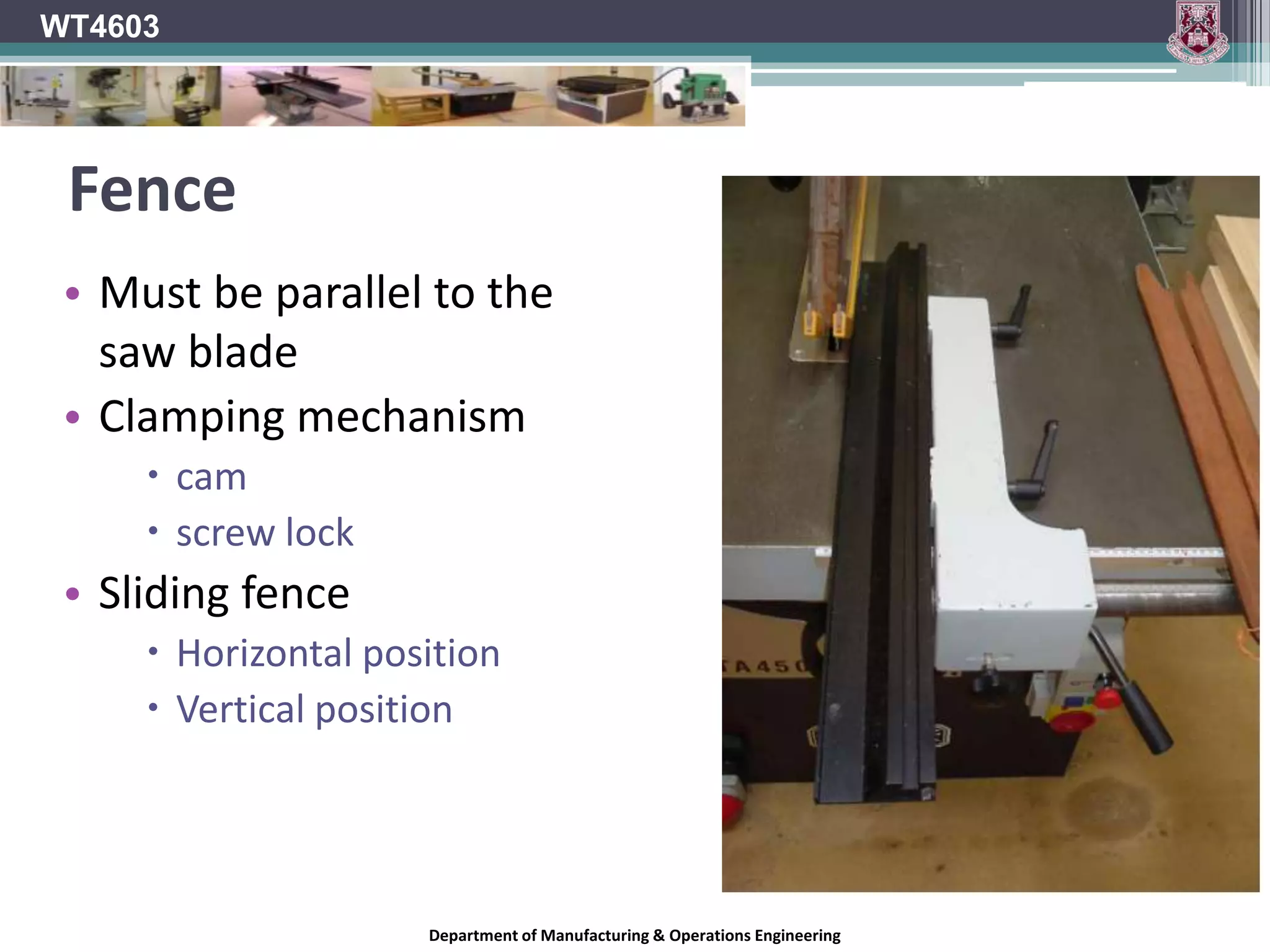

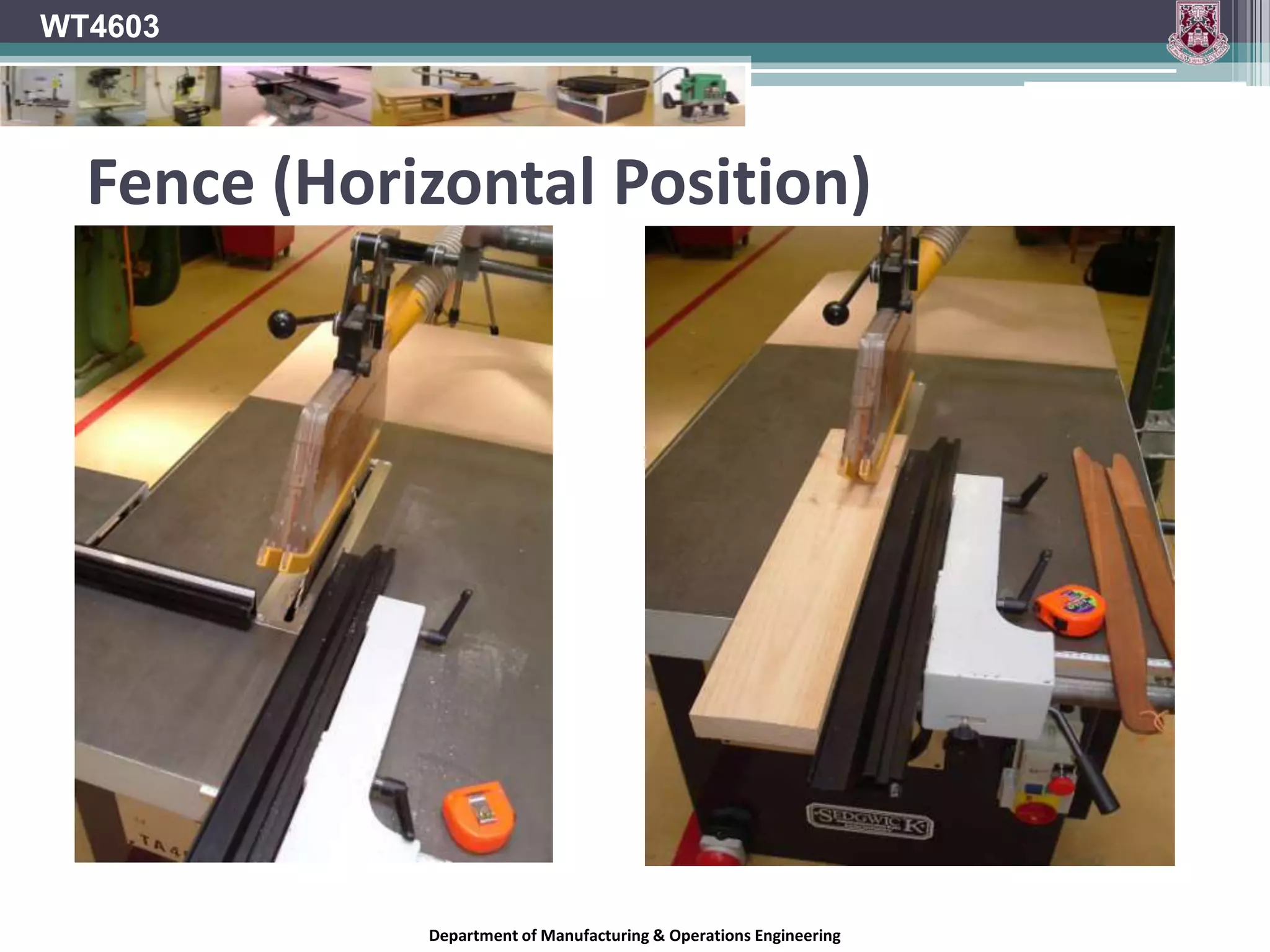

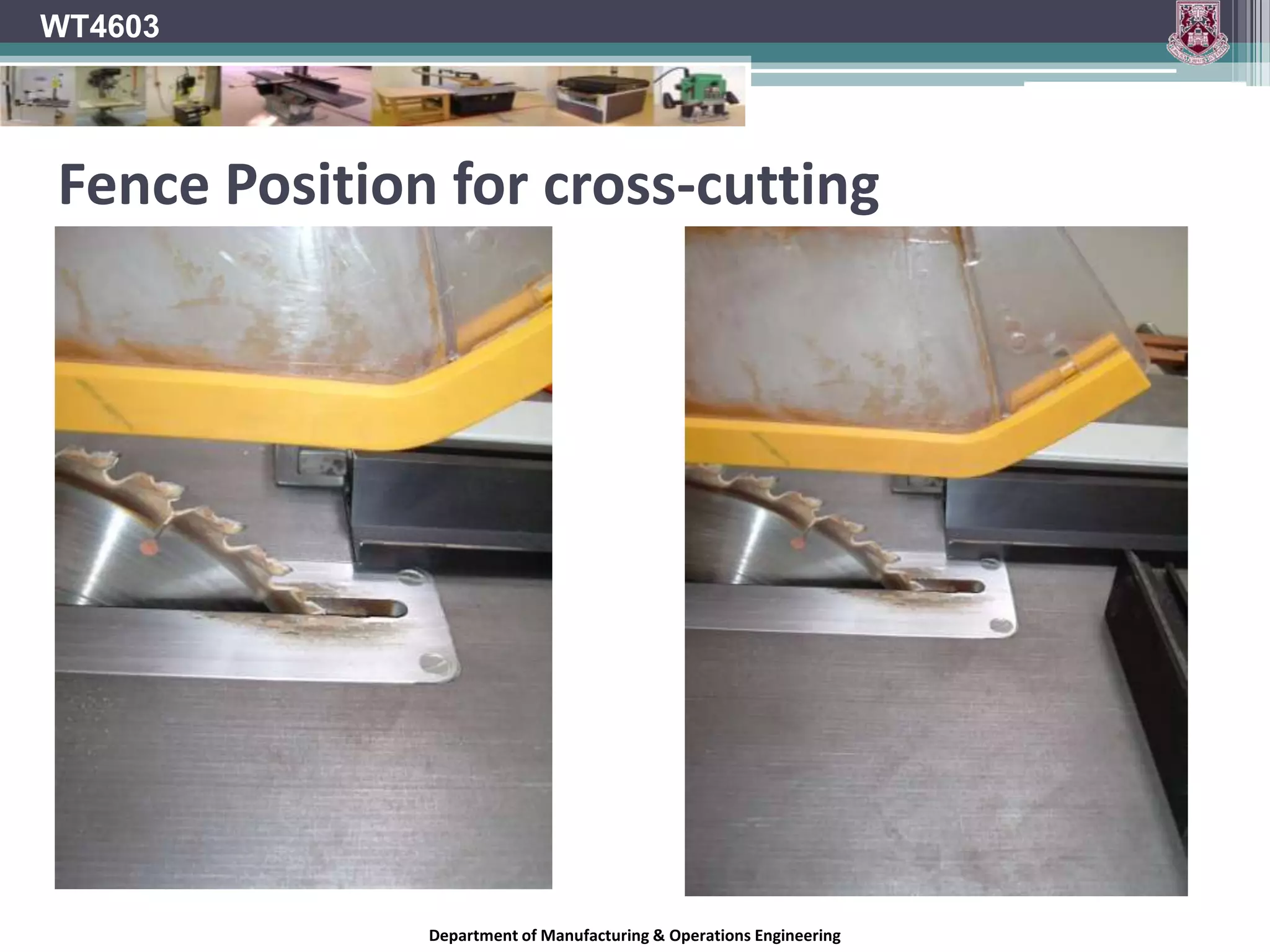

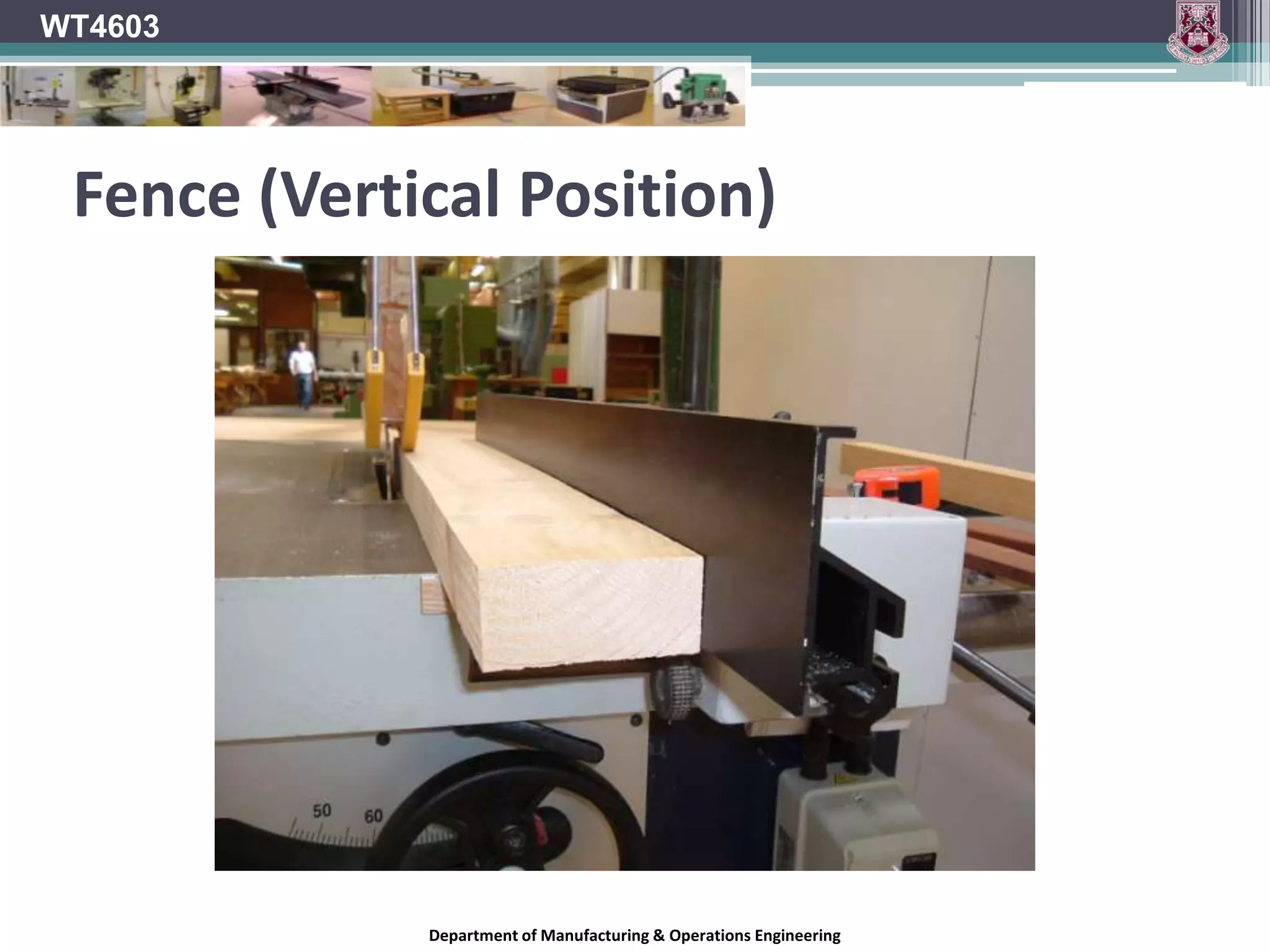

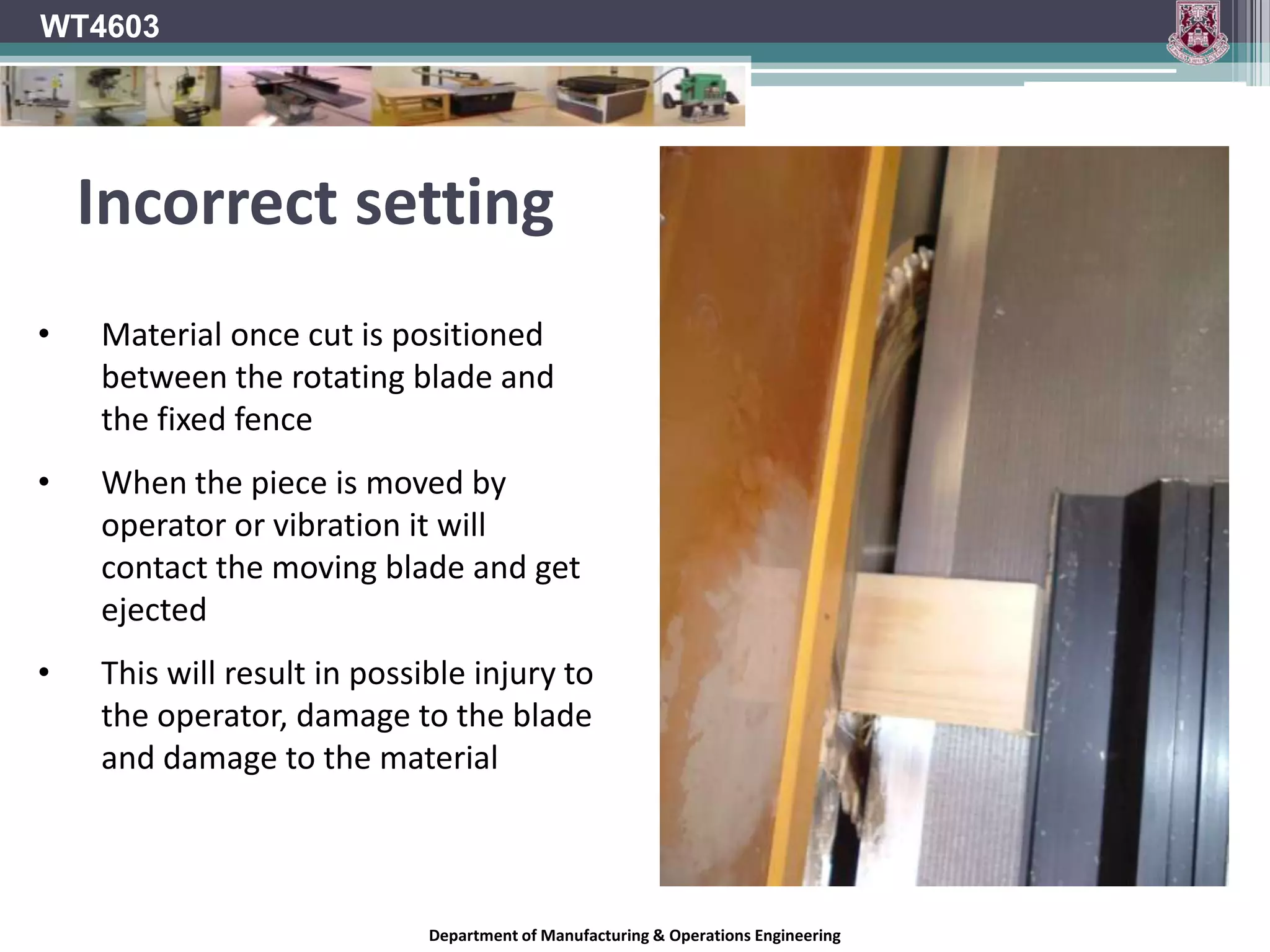

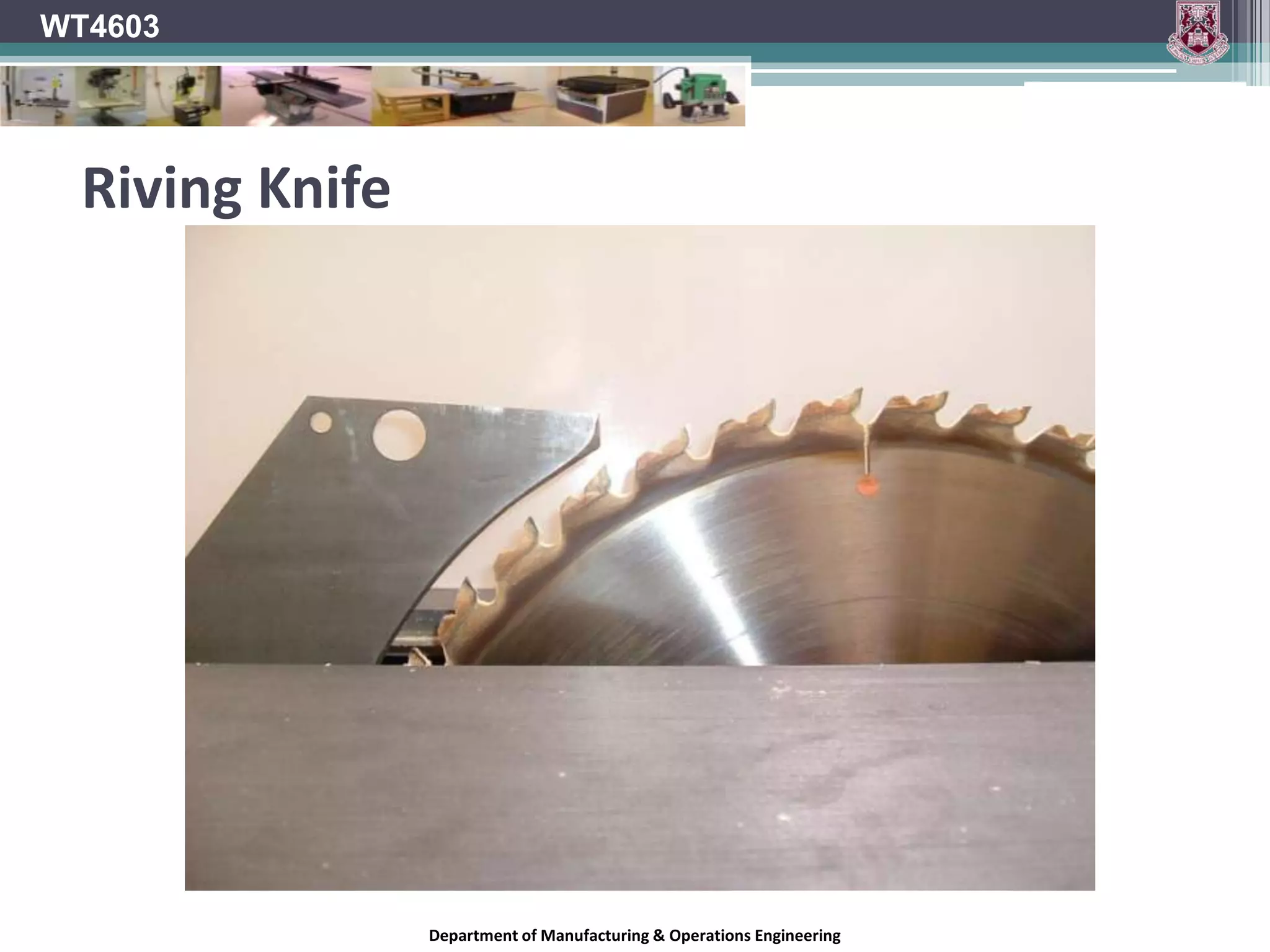

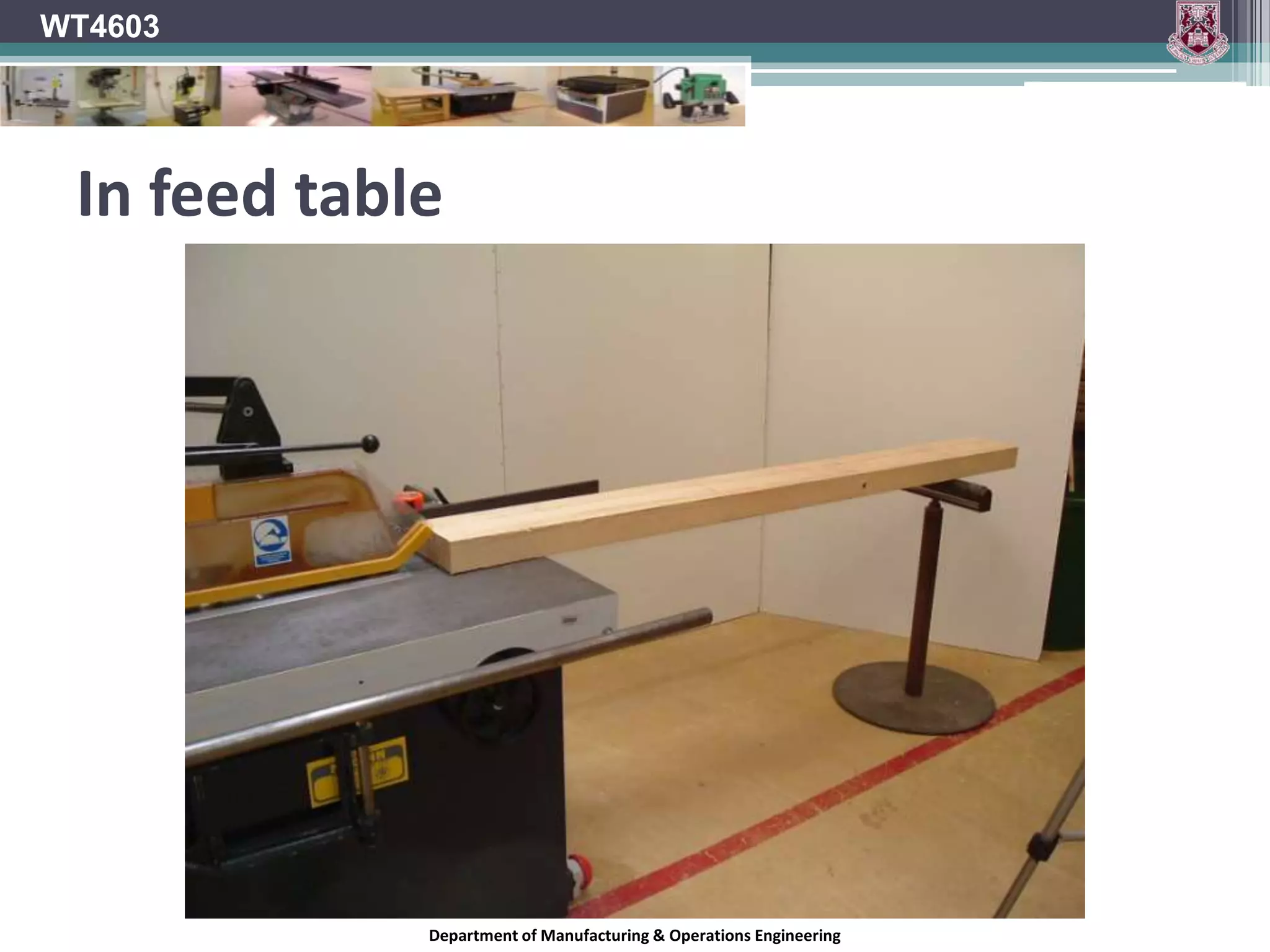

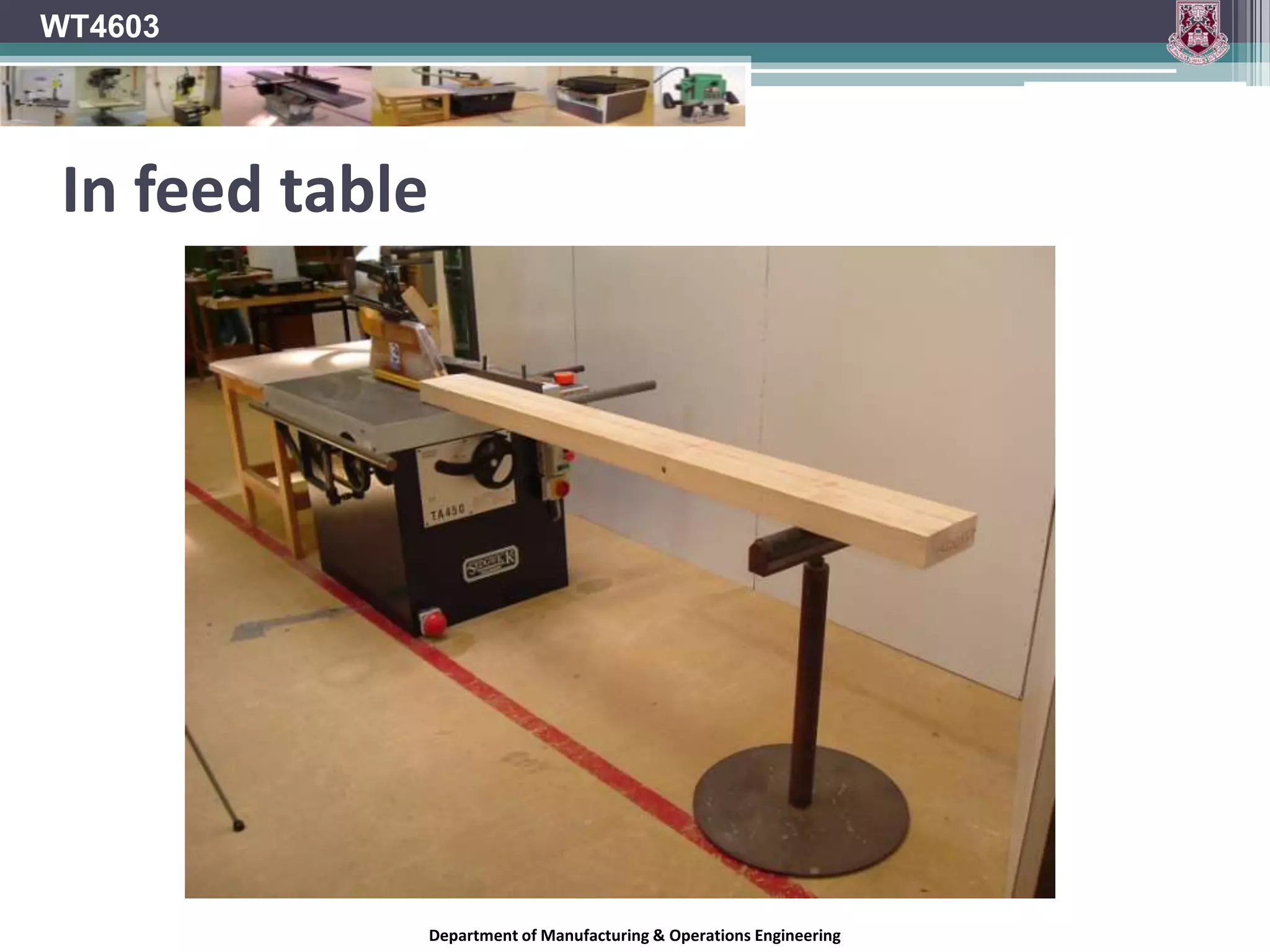

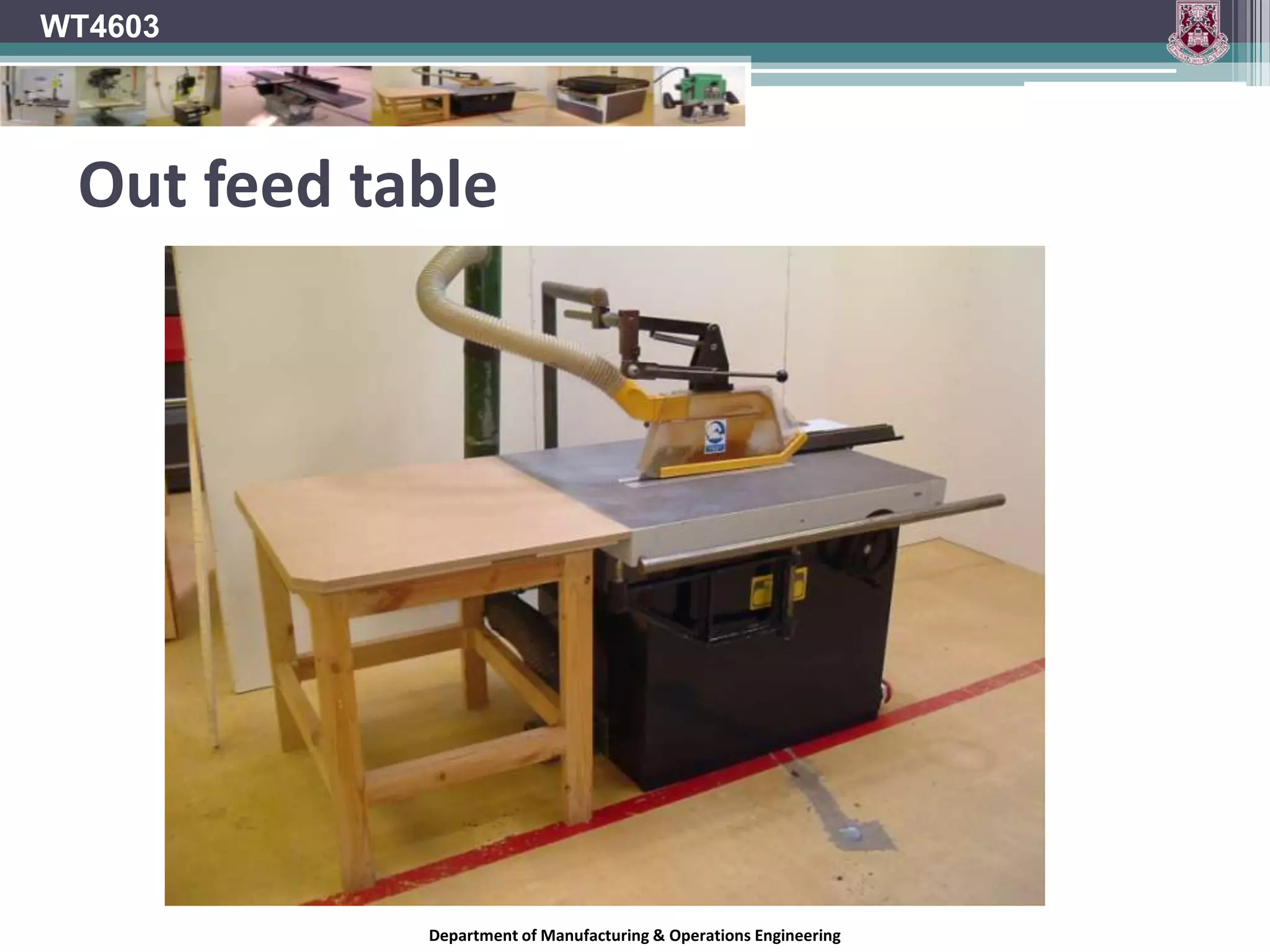

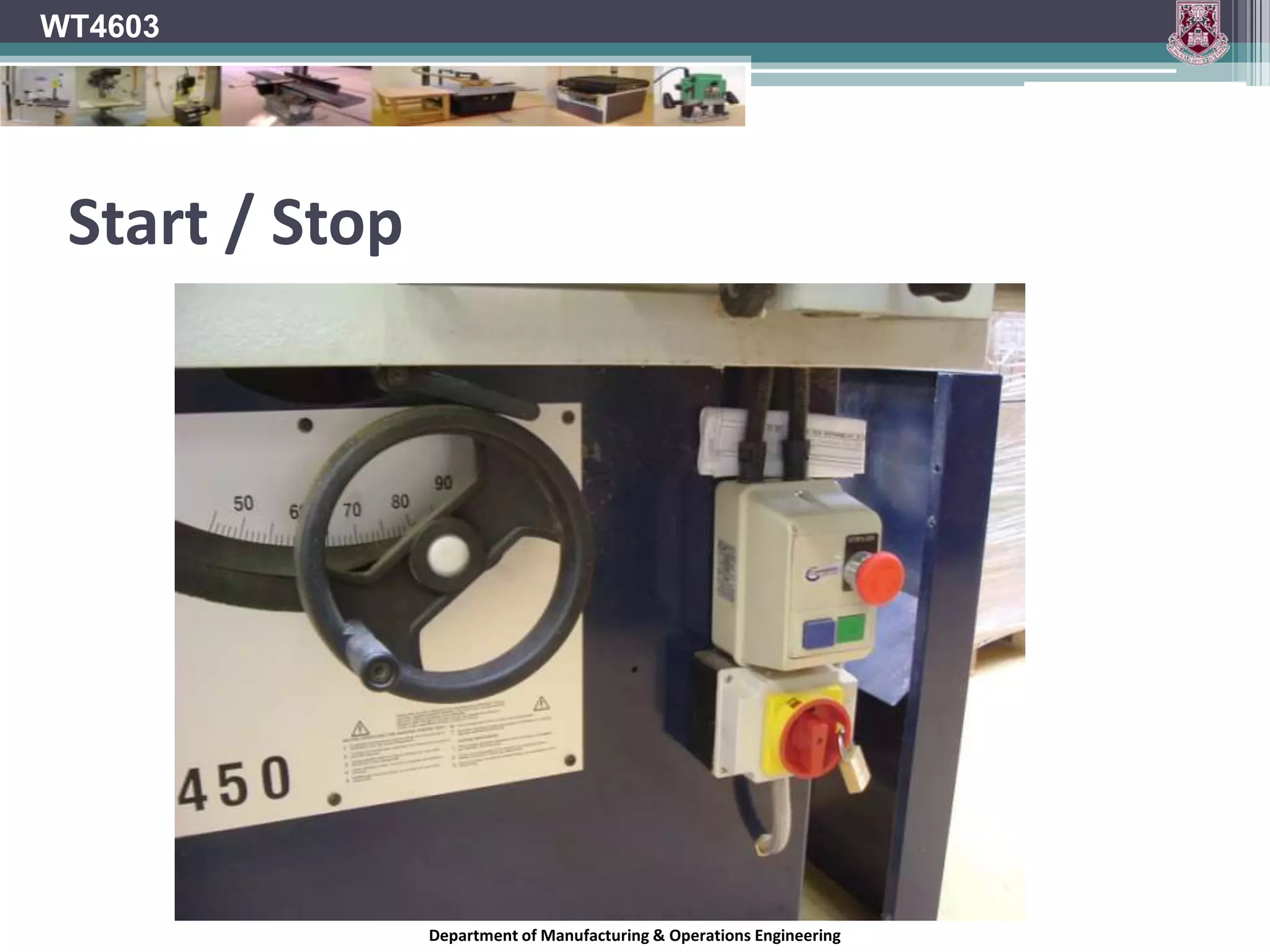

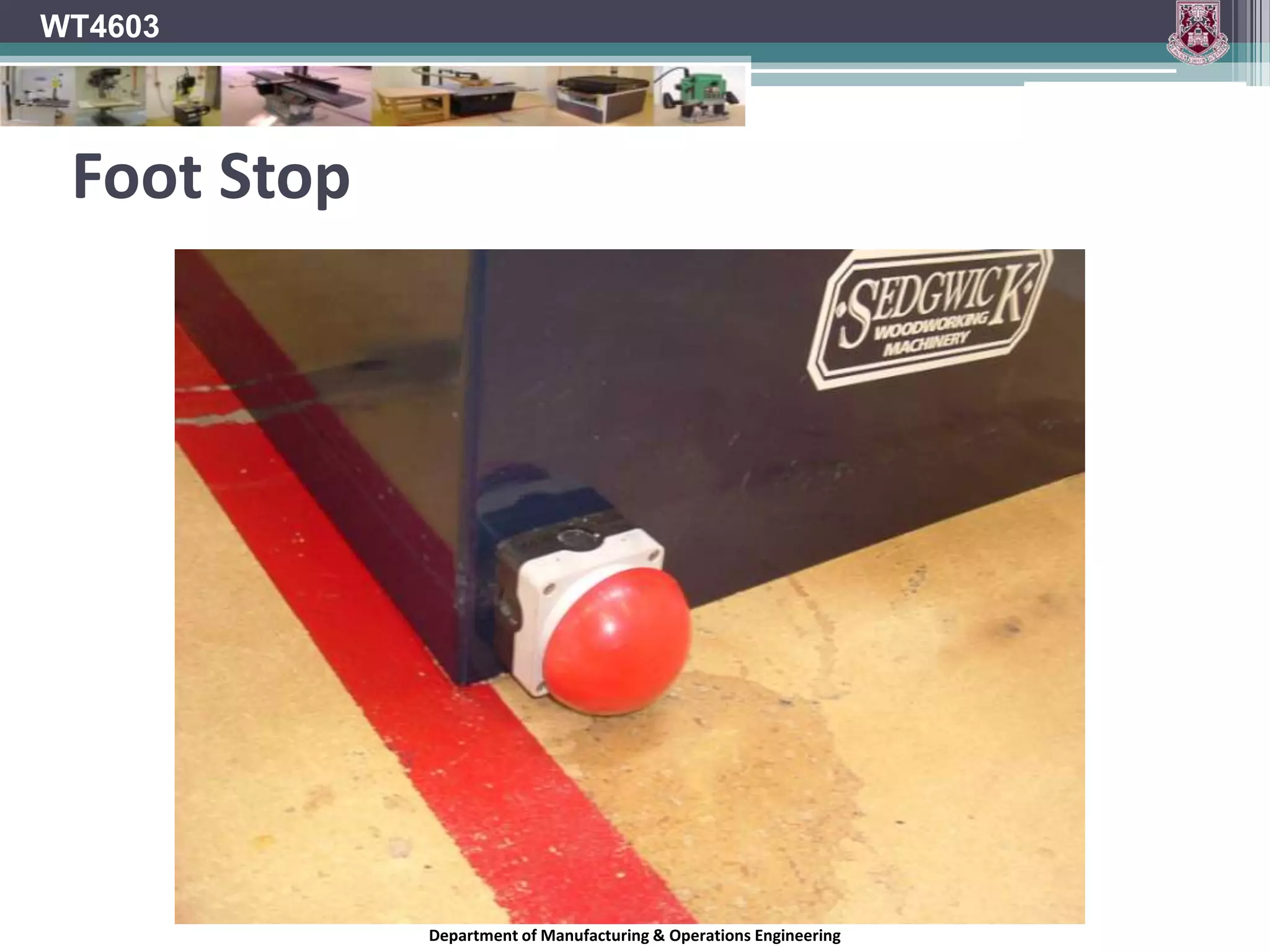

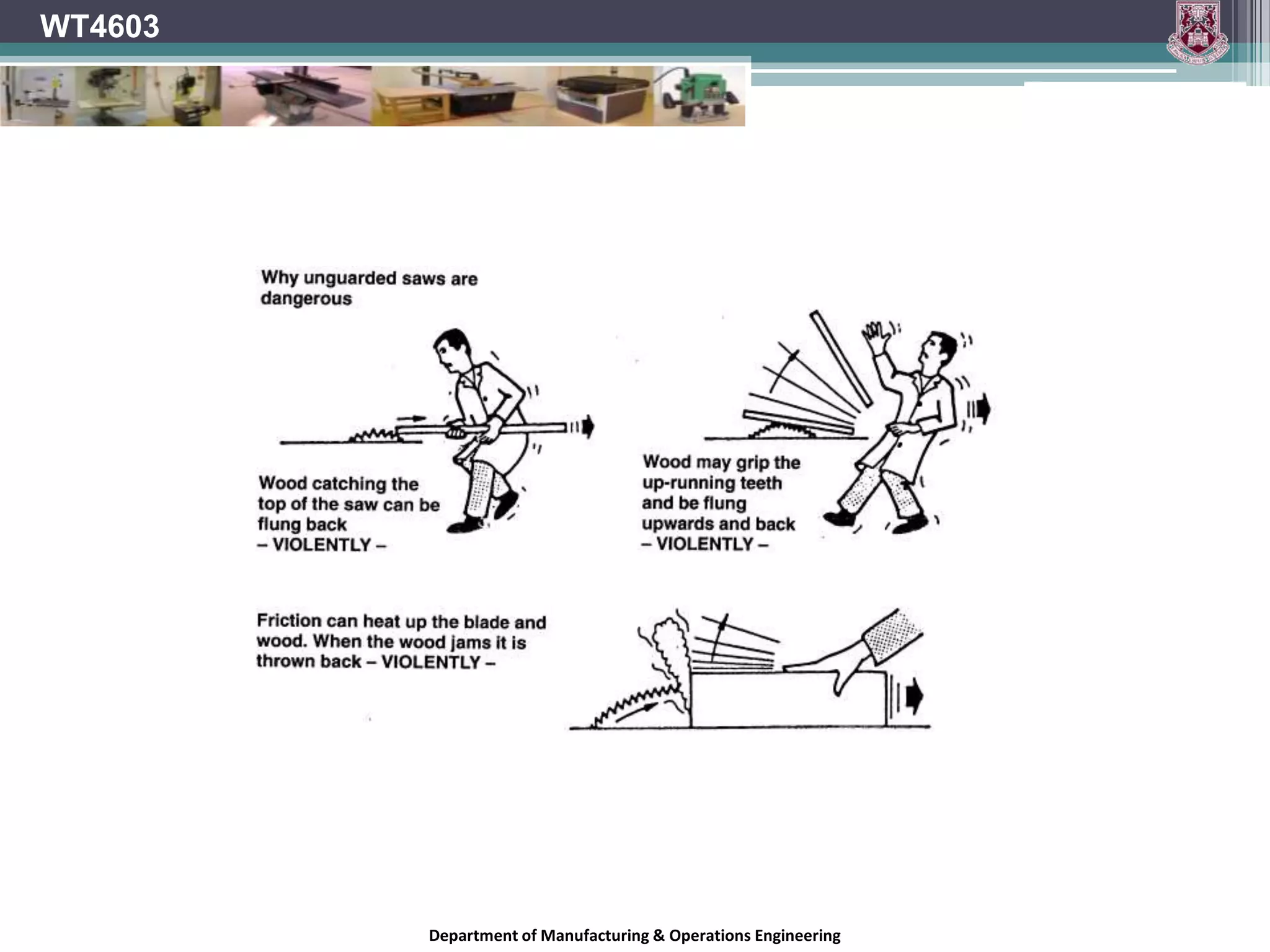

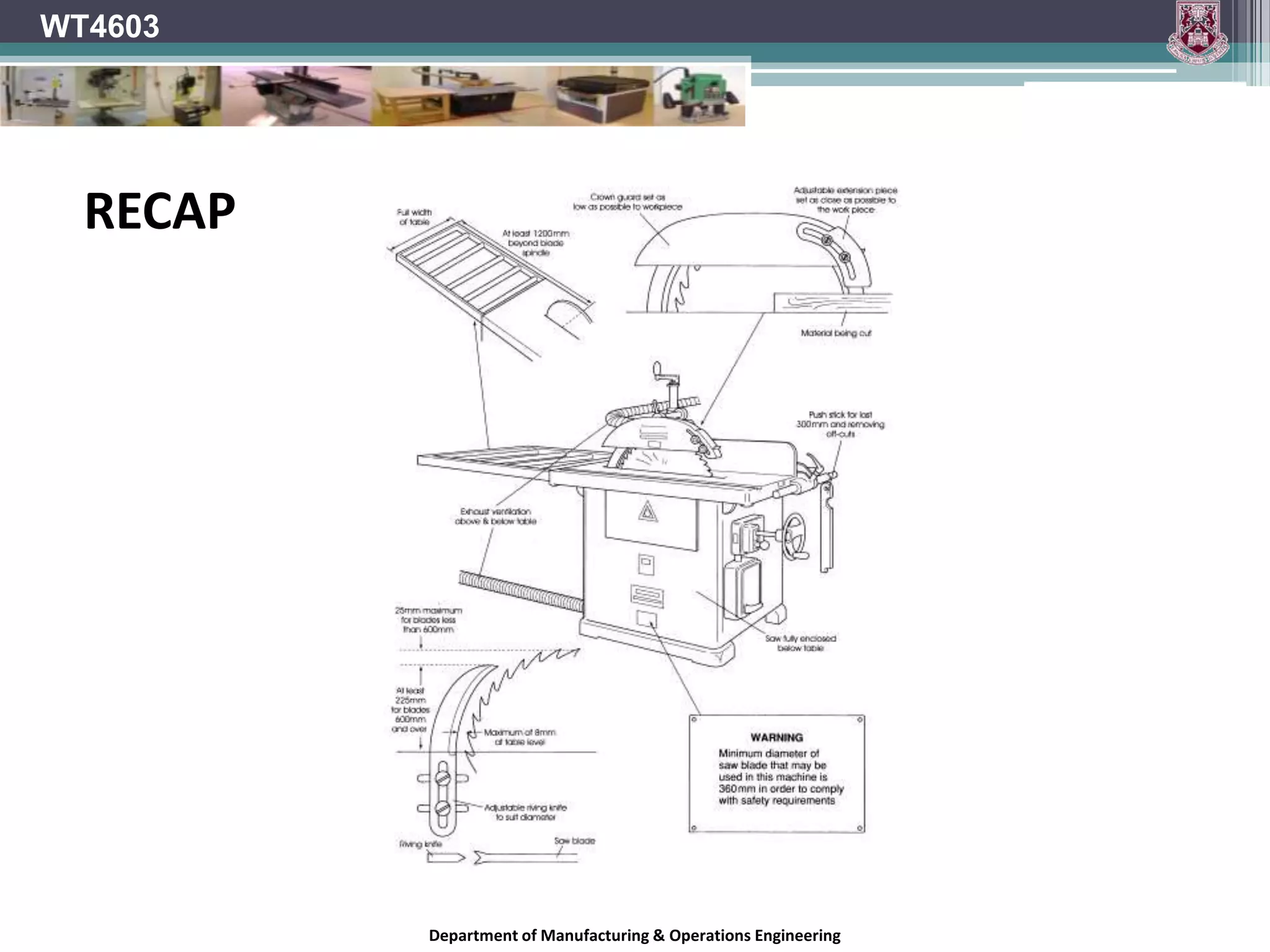

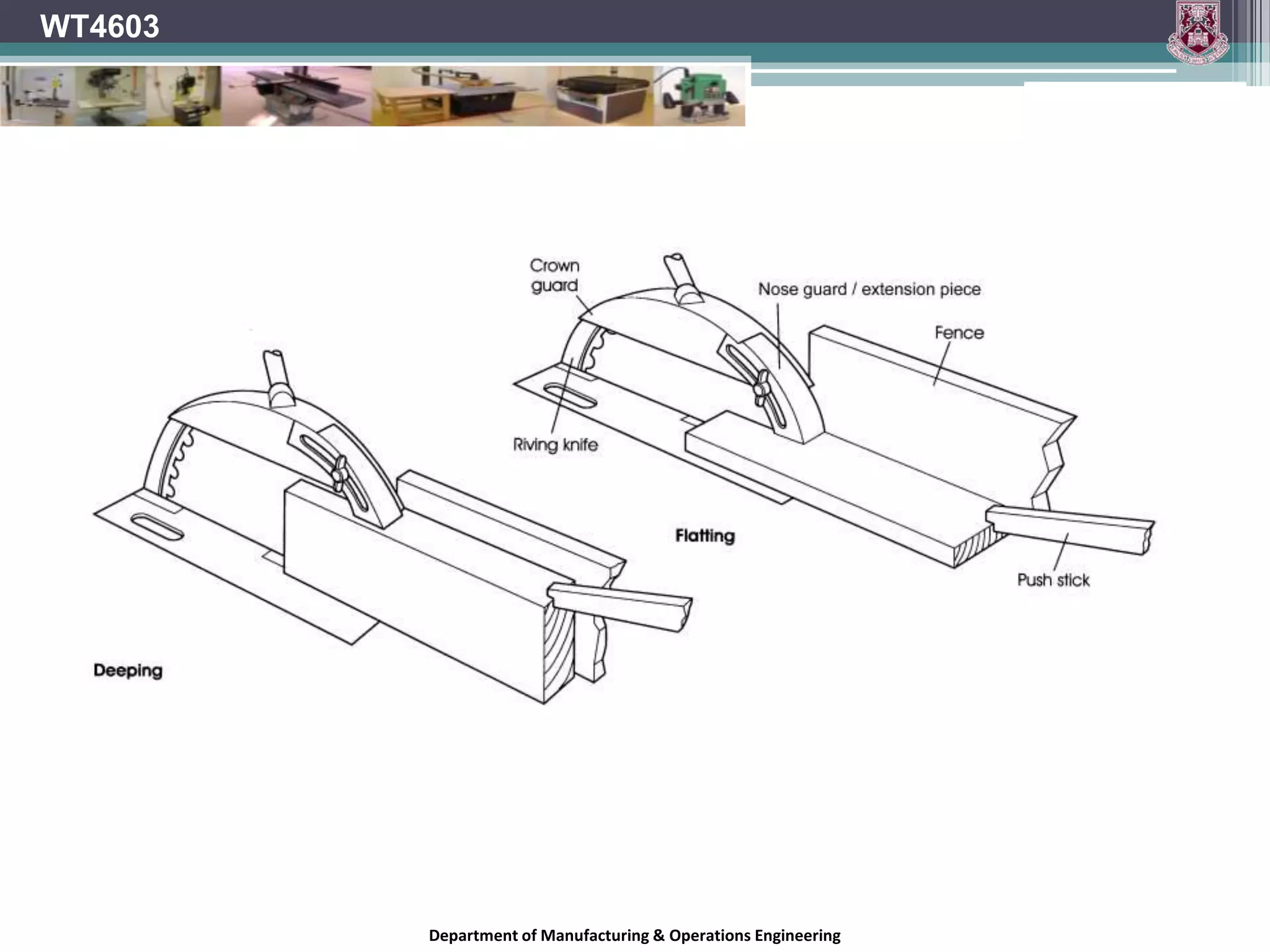

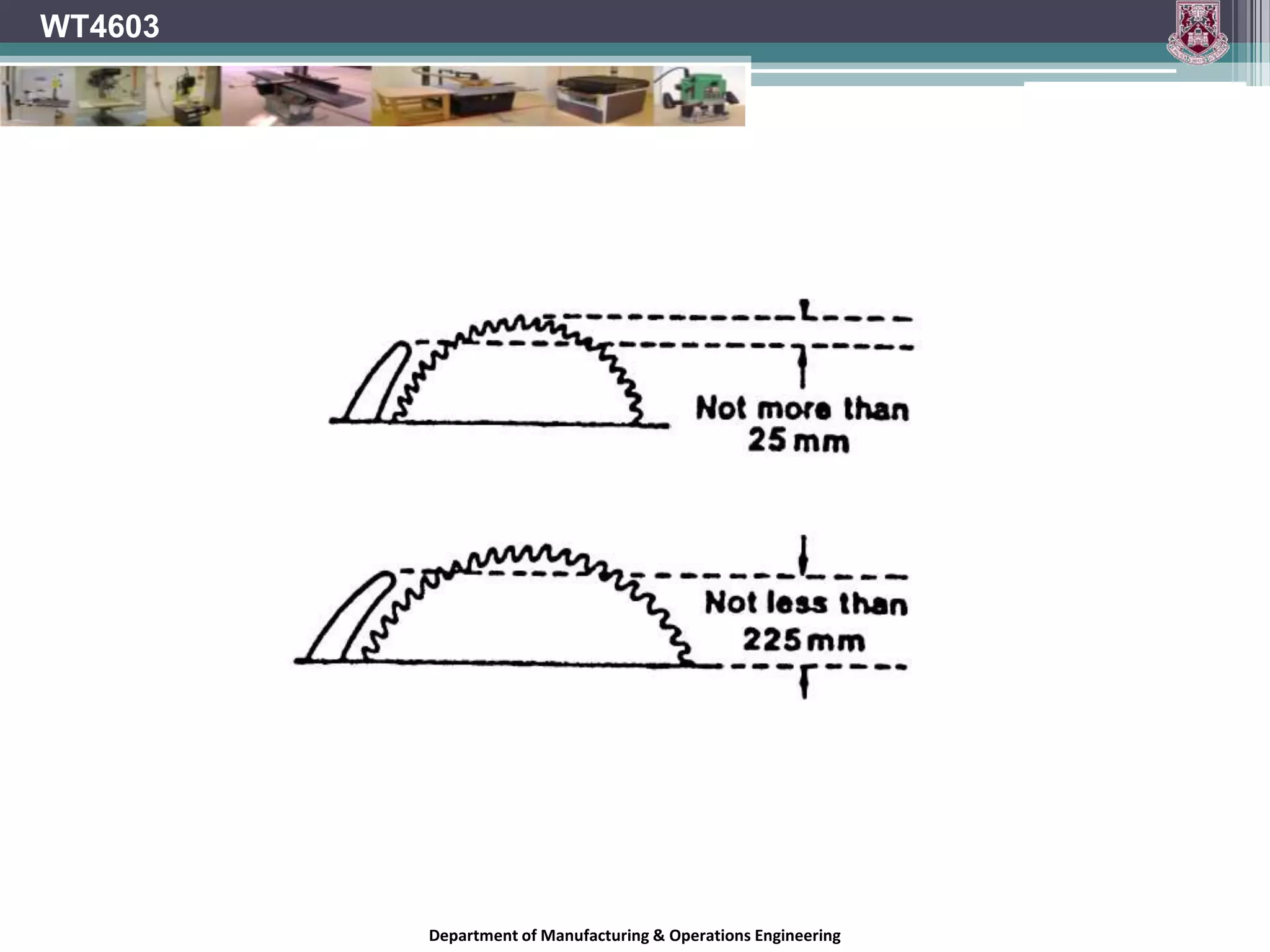

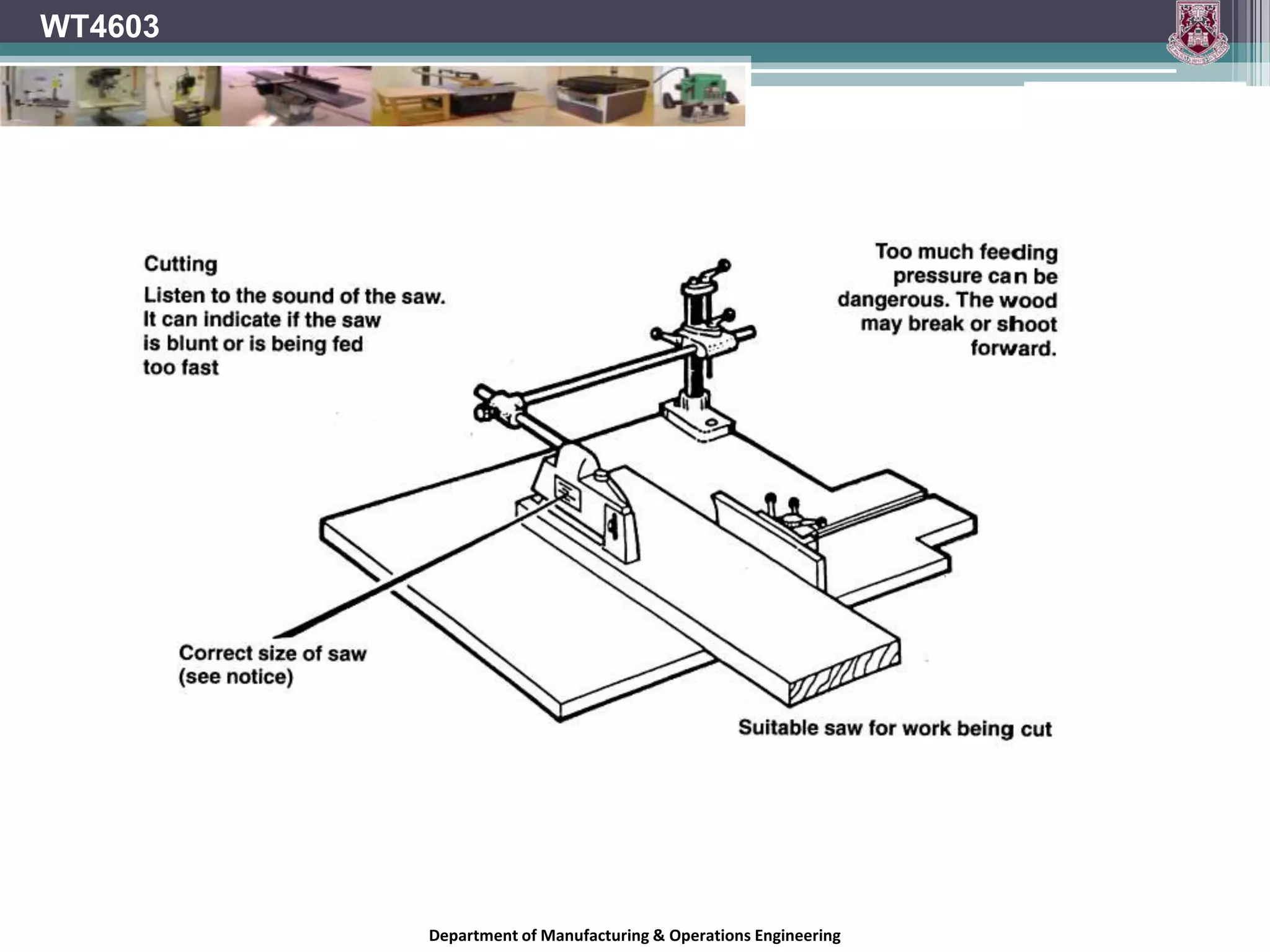

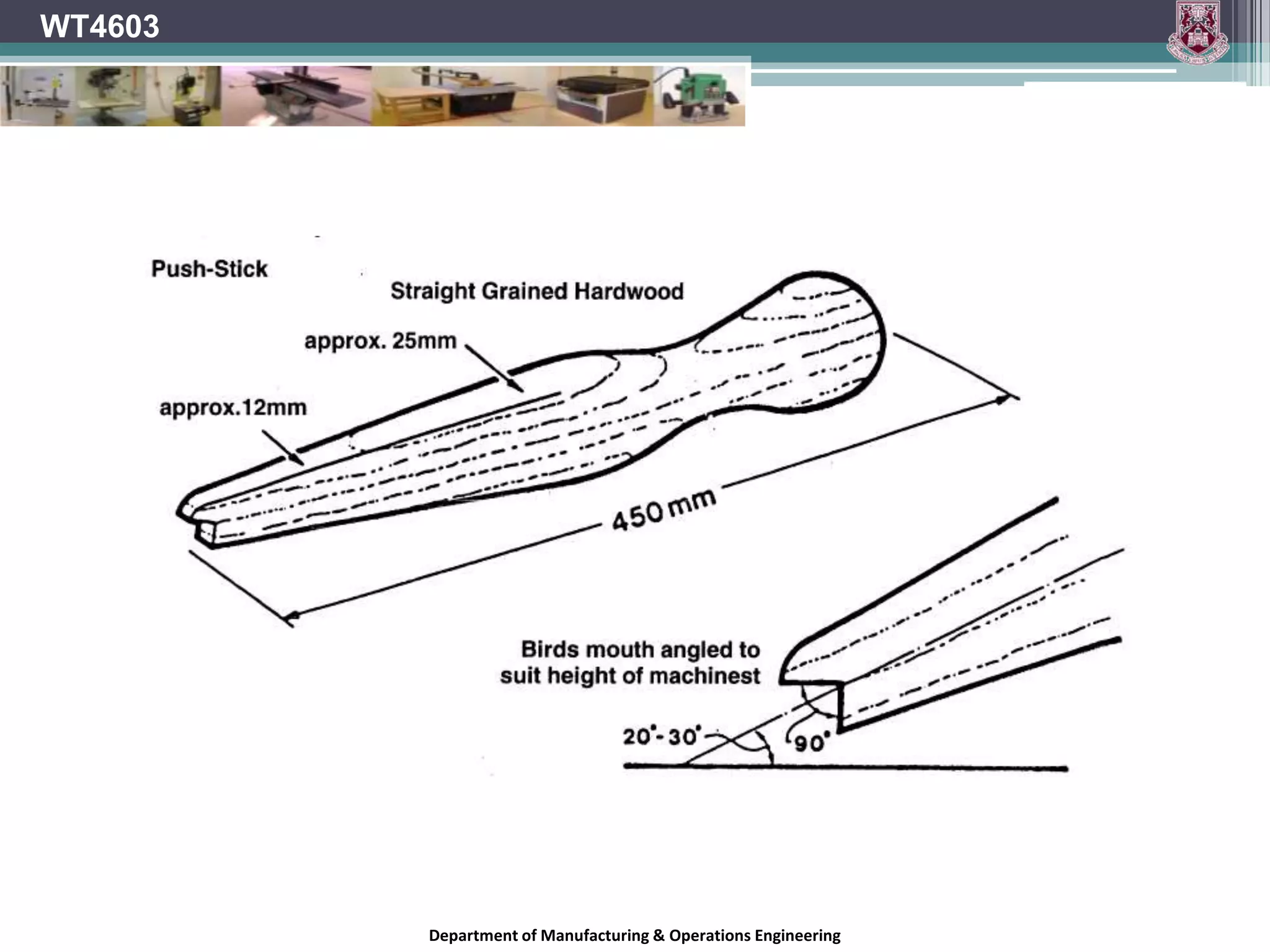

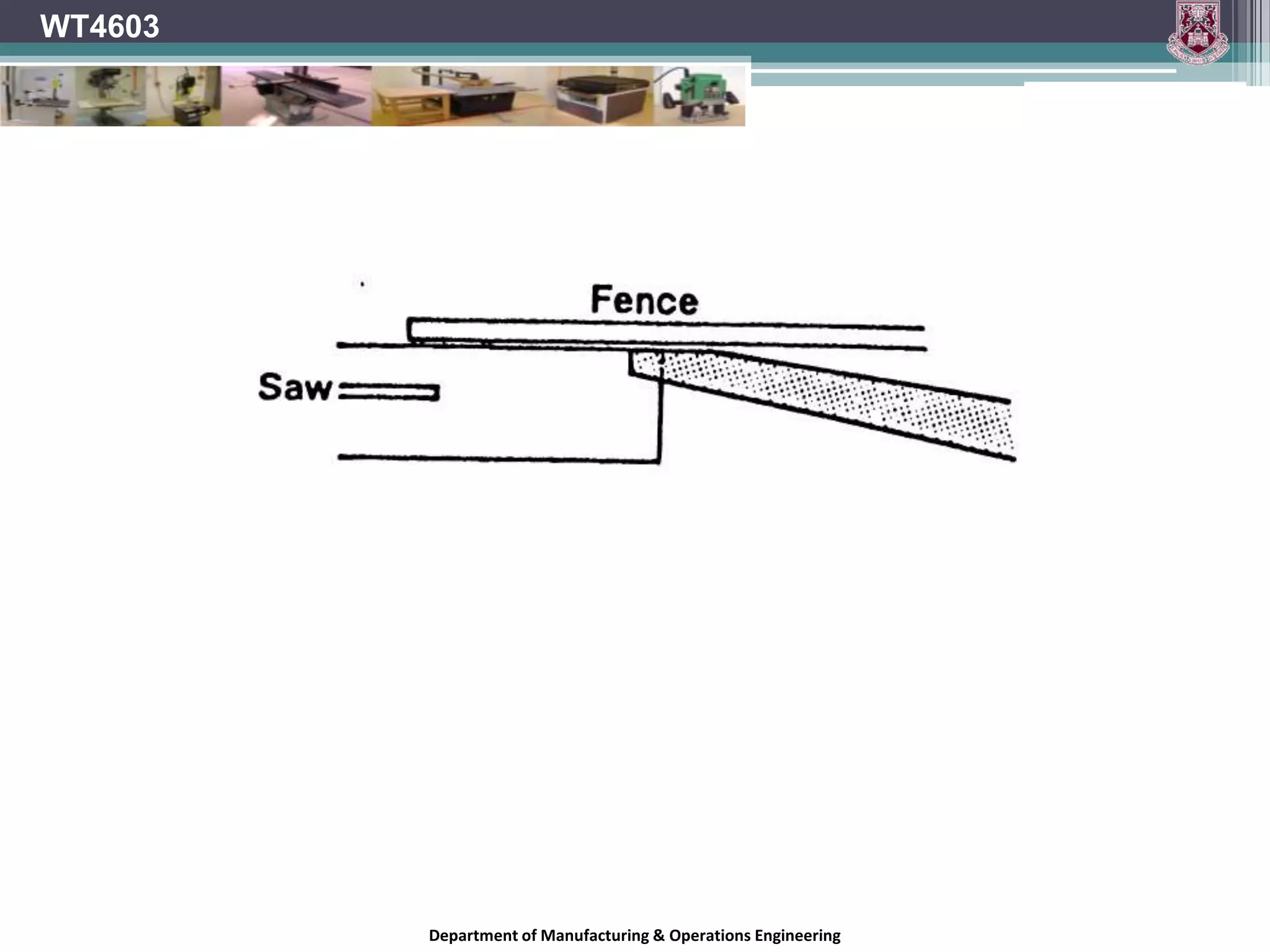

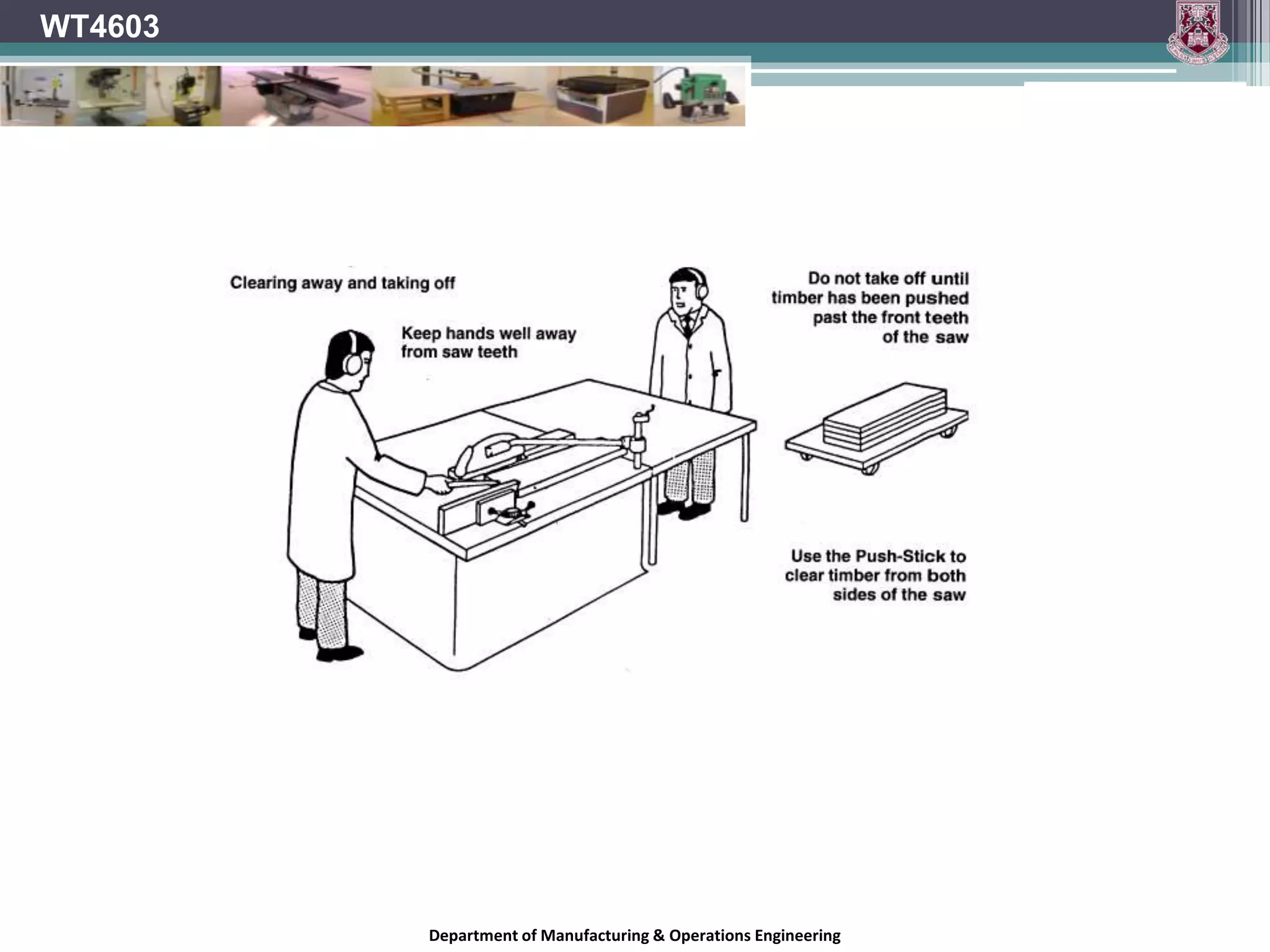

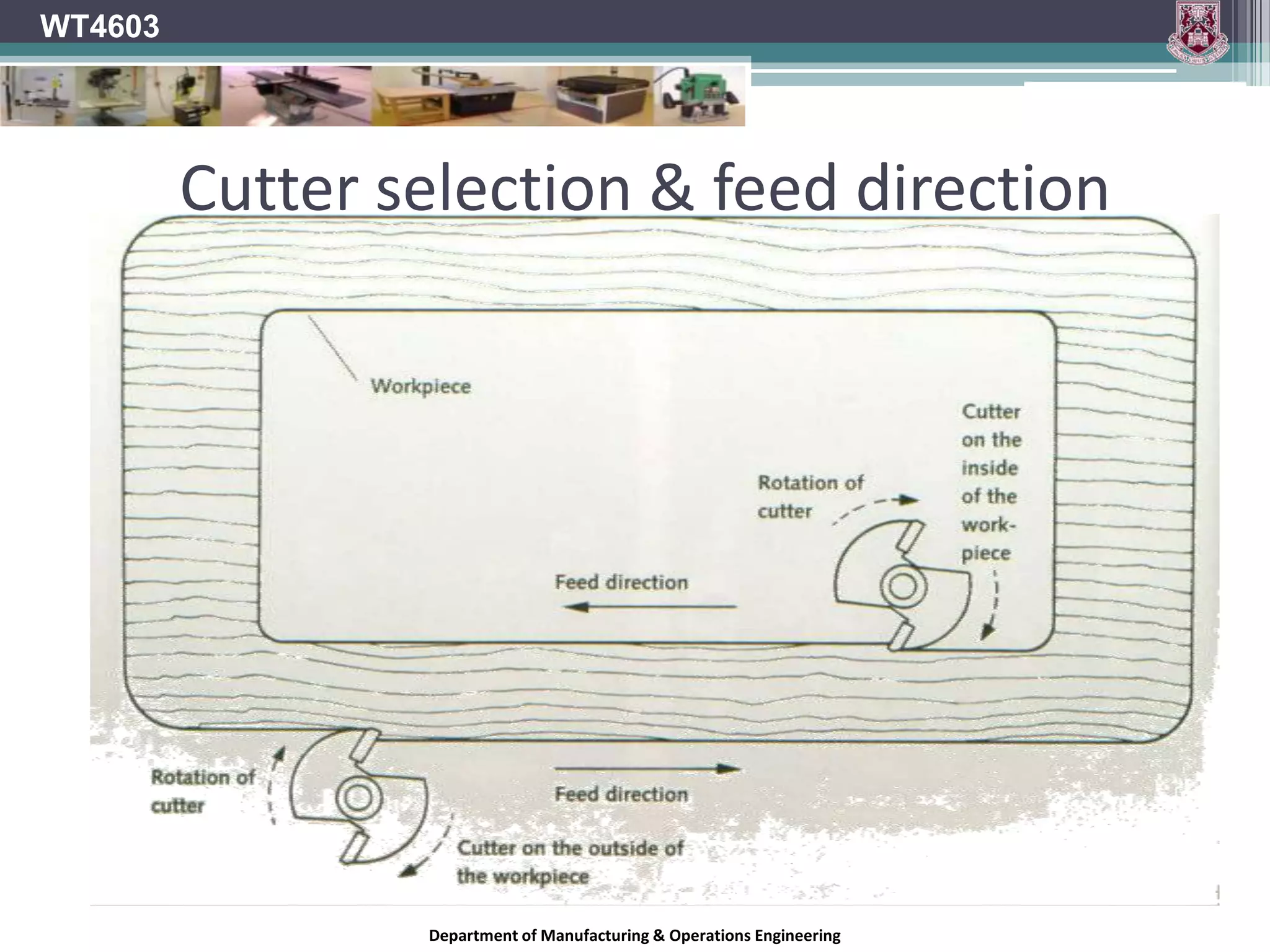

This document provides information on safety practices and equipment for circular saws and routers. It discusses hazards associated with these machines and risk control measures. Specific topics covered include circular saw machine maintenance, saw blade terminology such as hook angle and tooth configuration, riving knife specifications, and table slot dimensions. The notes were prepared by Mr. Joseph Lyster for his WT4603 Wood Processing Safety & Practice course at UL and are available online.