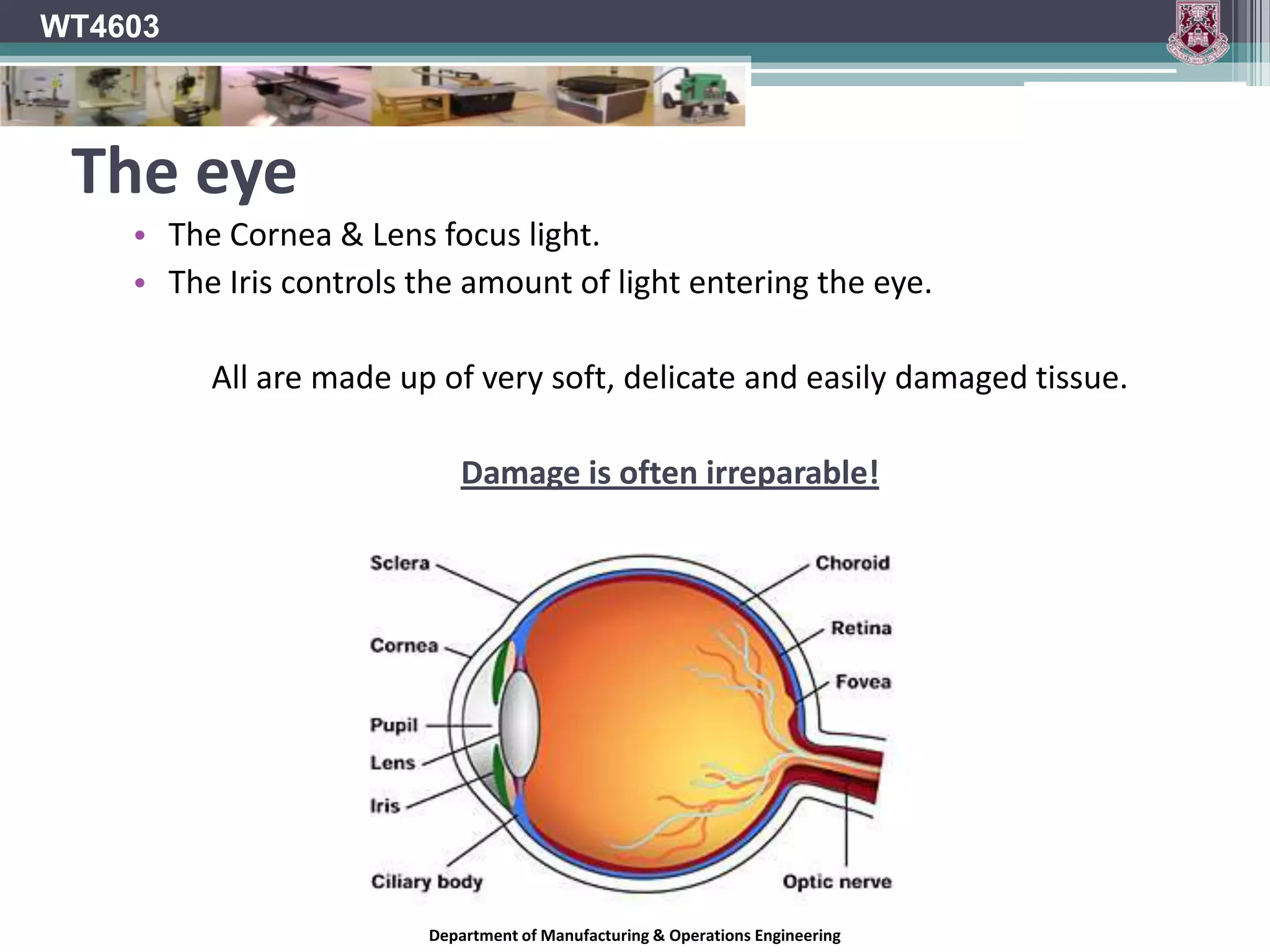

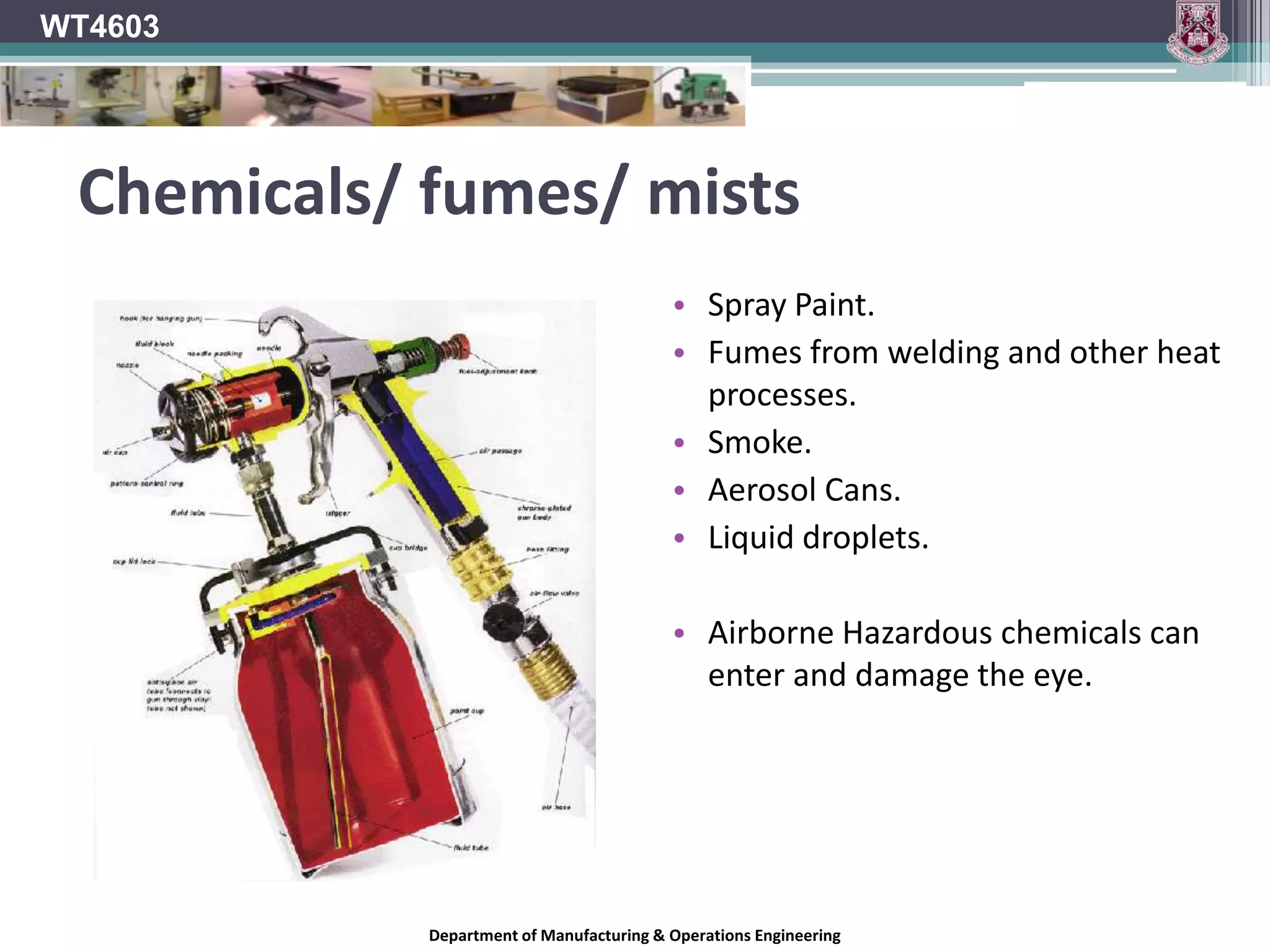

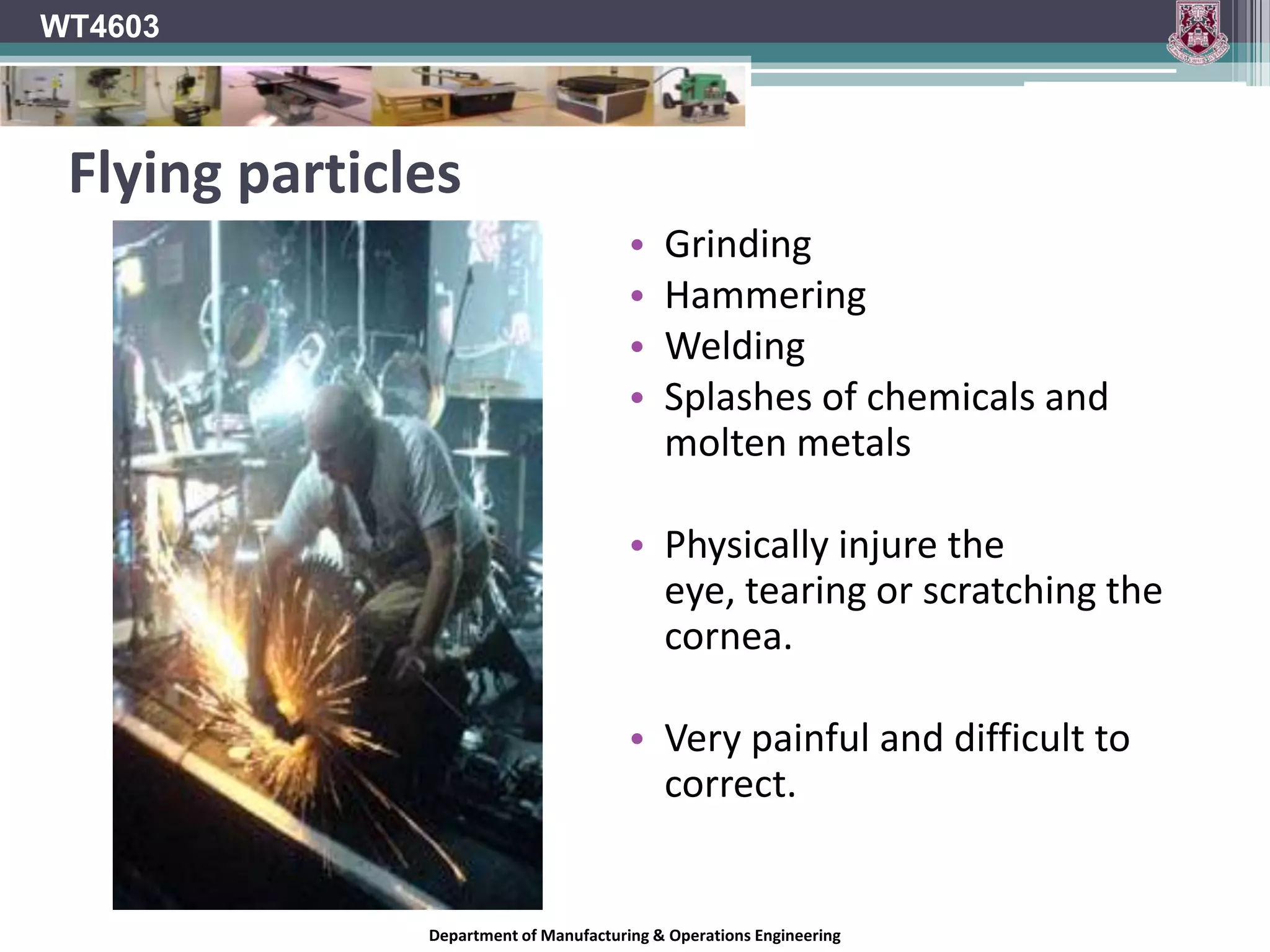

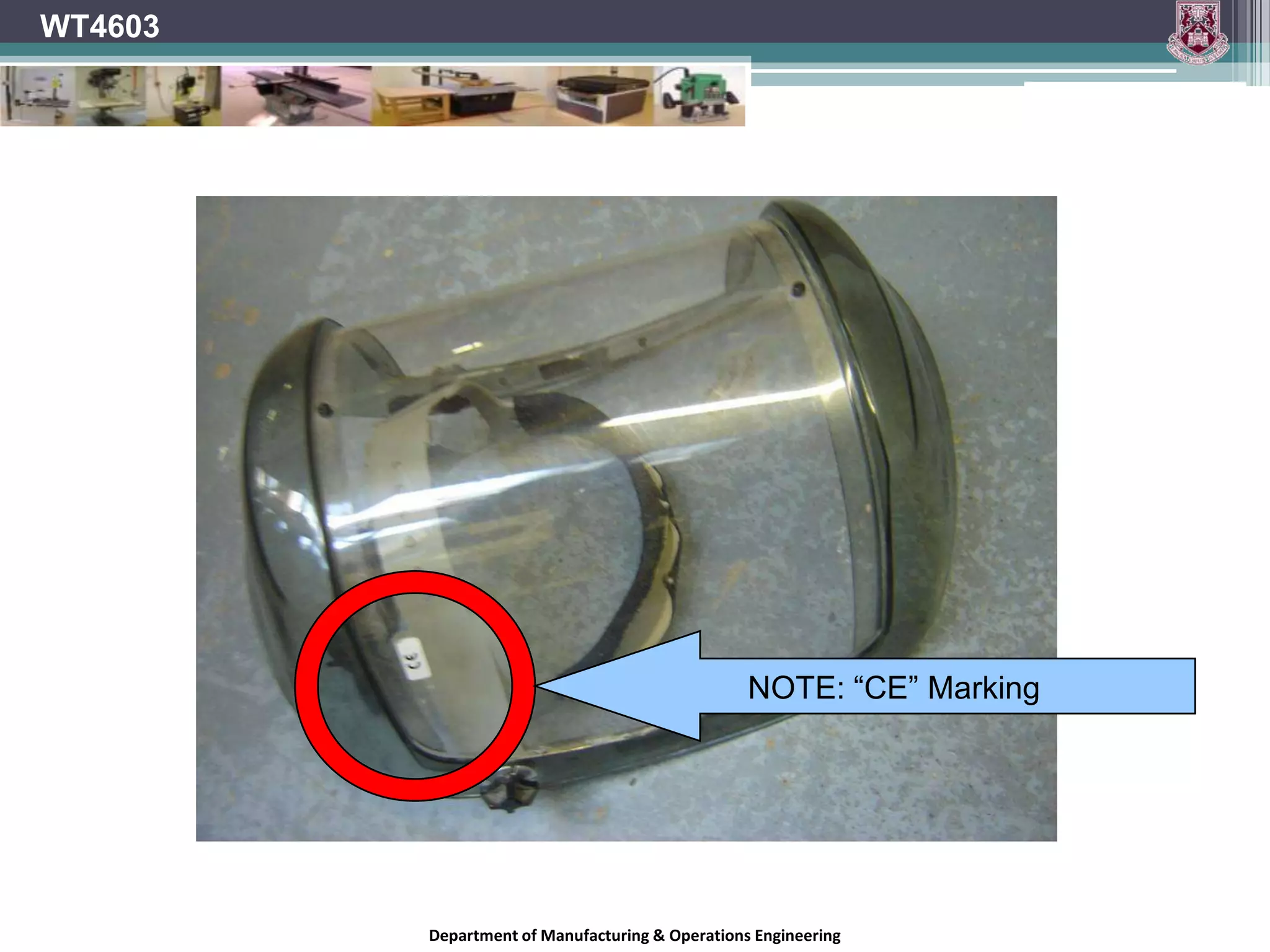

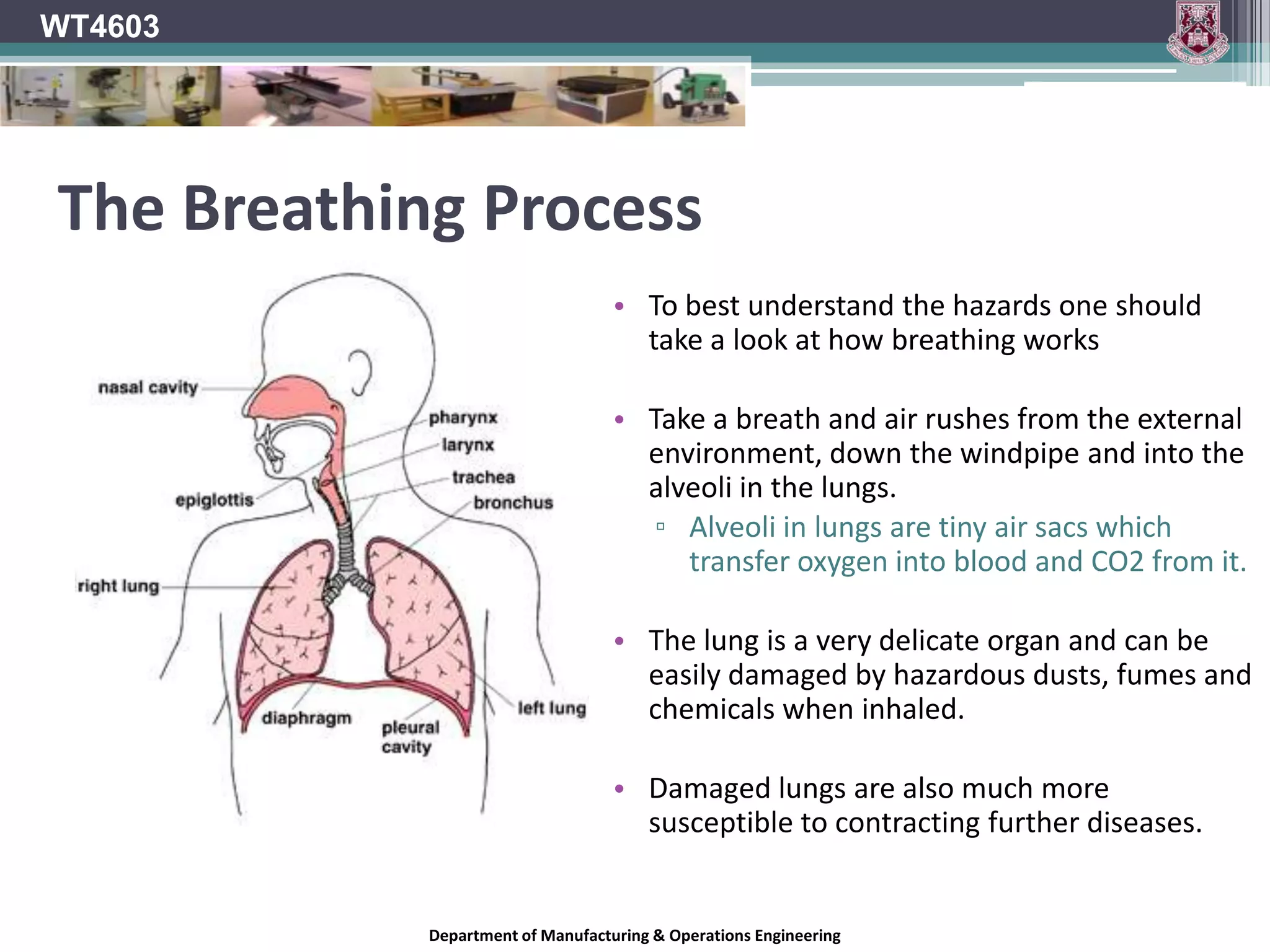

This document discusses personal protective equipment (PPE) and its importance in wood processing safety. It notes that PPE should only be used as a last resort after all other hazard controls have failed. The document outlines the responsibilities of employers and employees to assess hazards, provide appropriate PPE, train workers on PPE use, and care for PPE. It emphasizes the importance of proper eye protection during wood processing due to the risk of impact or airborne hazards like sawdust.