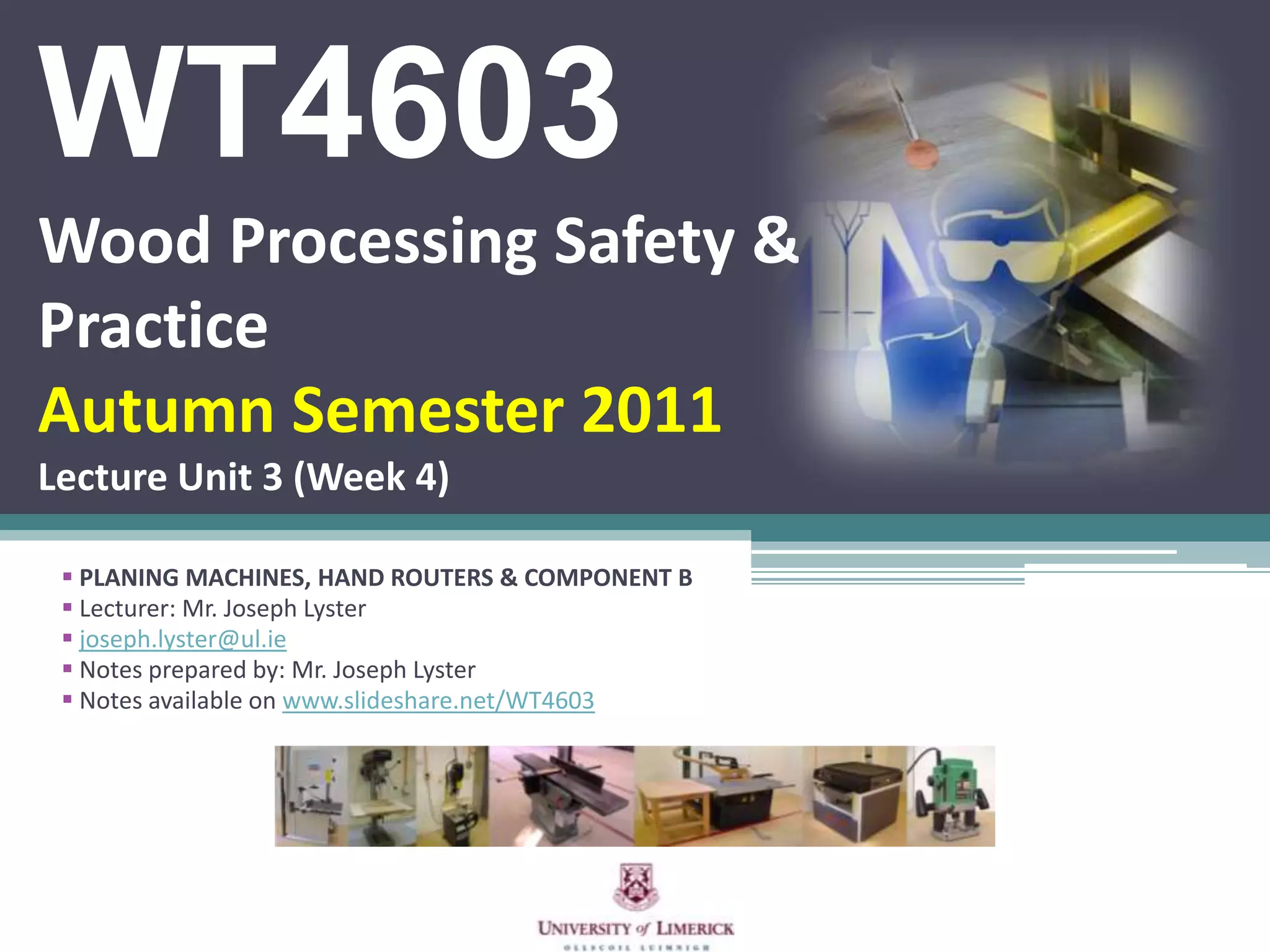

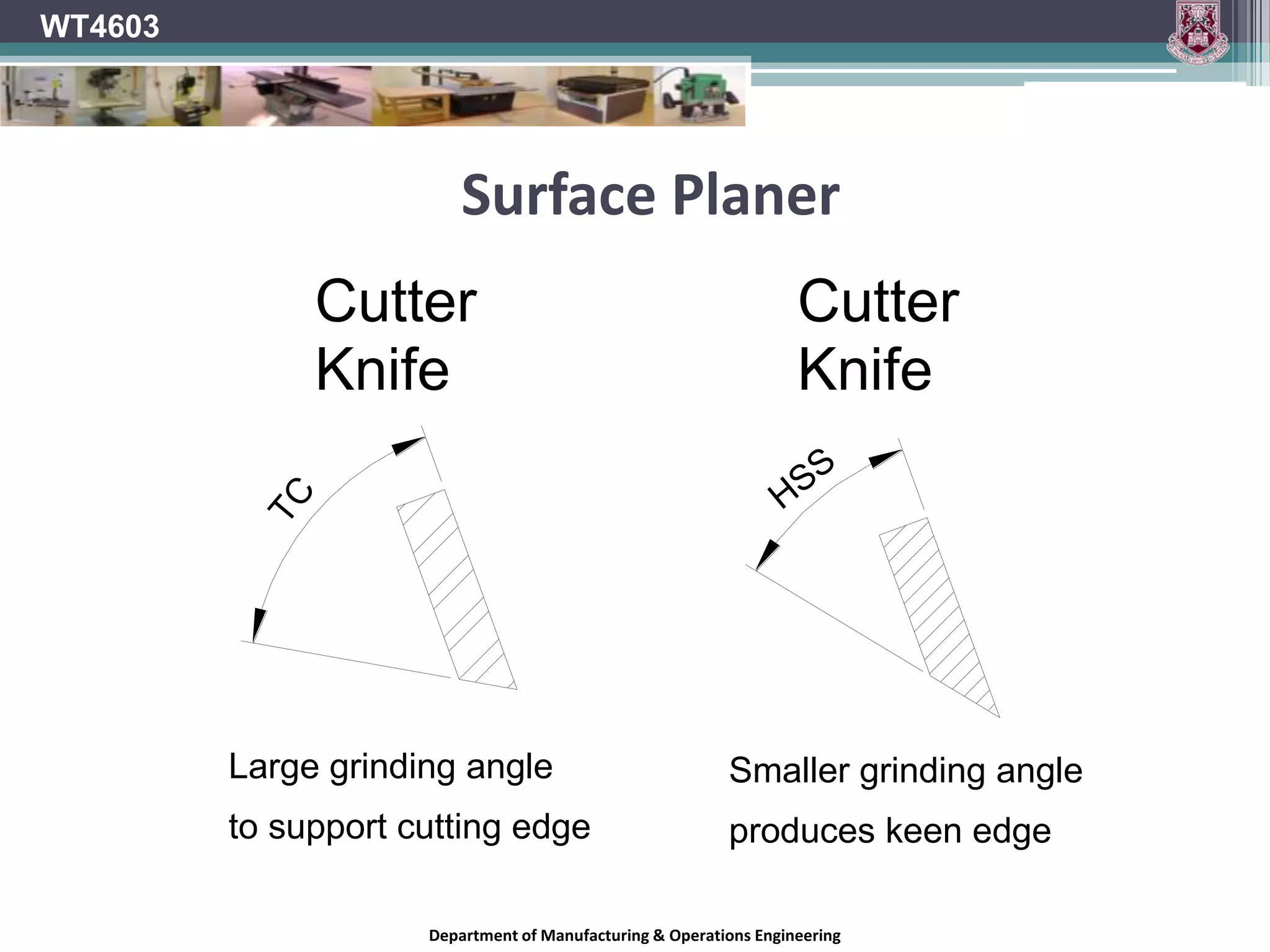

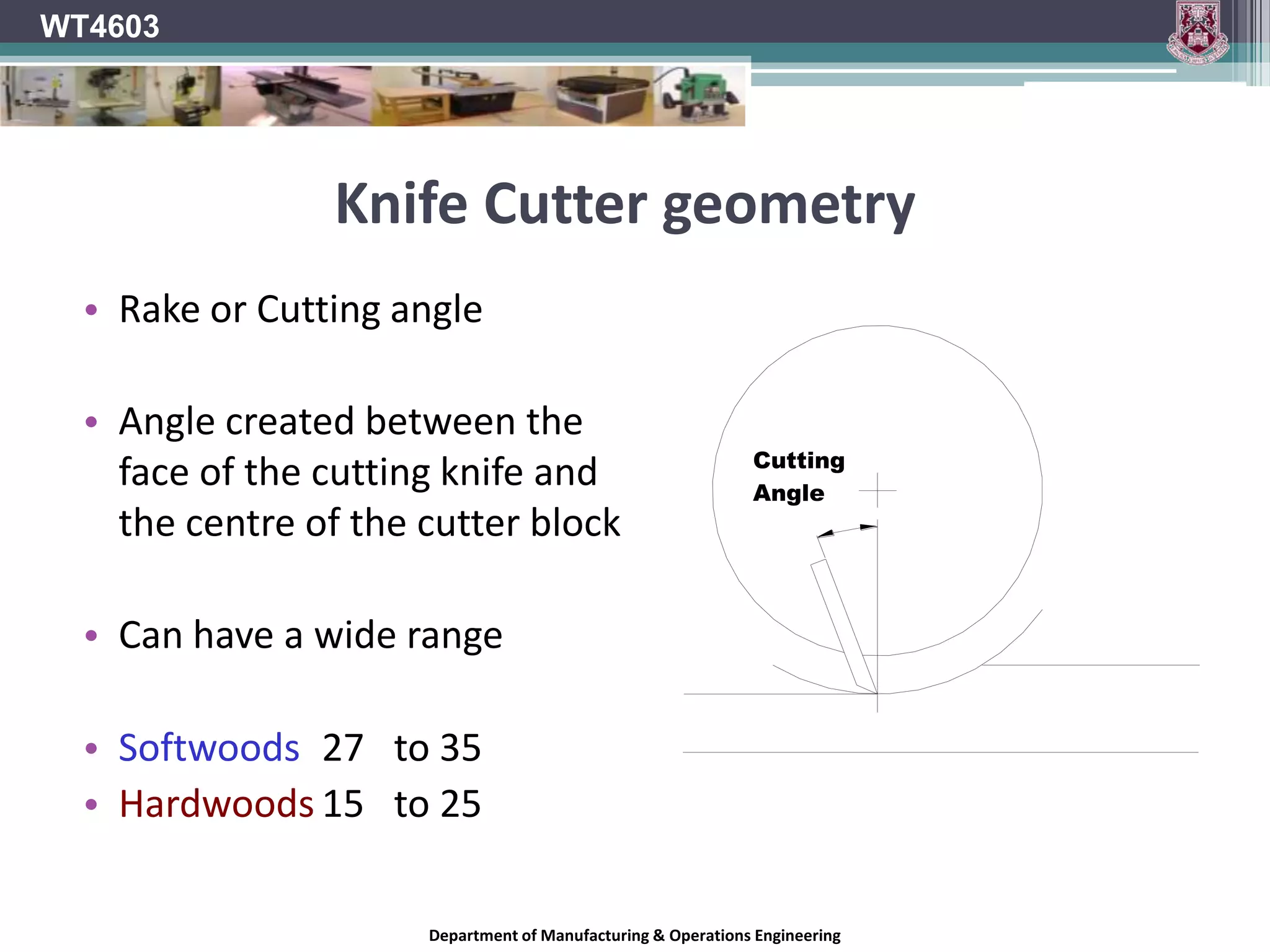

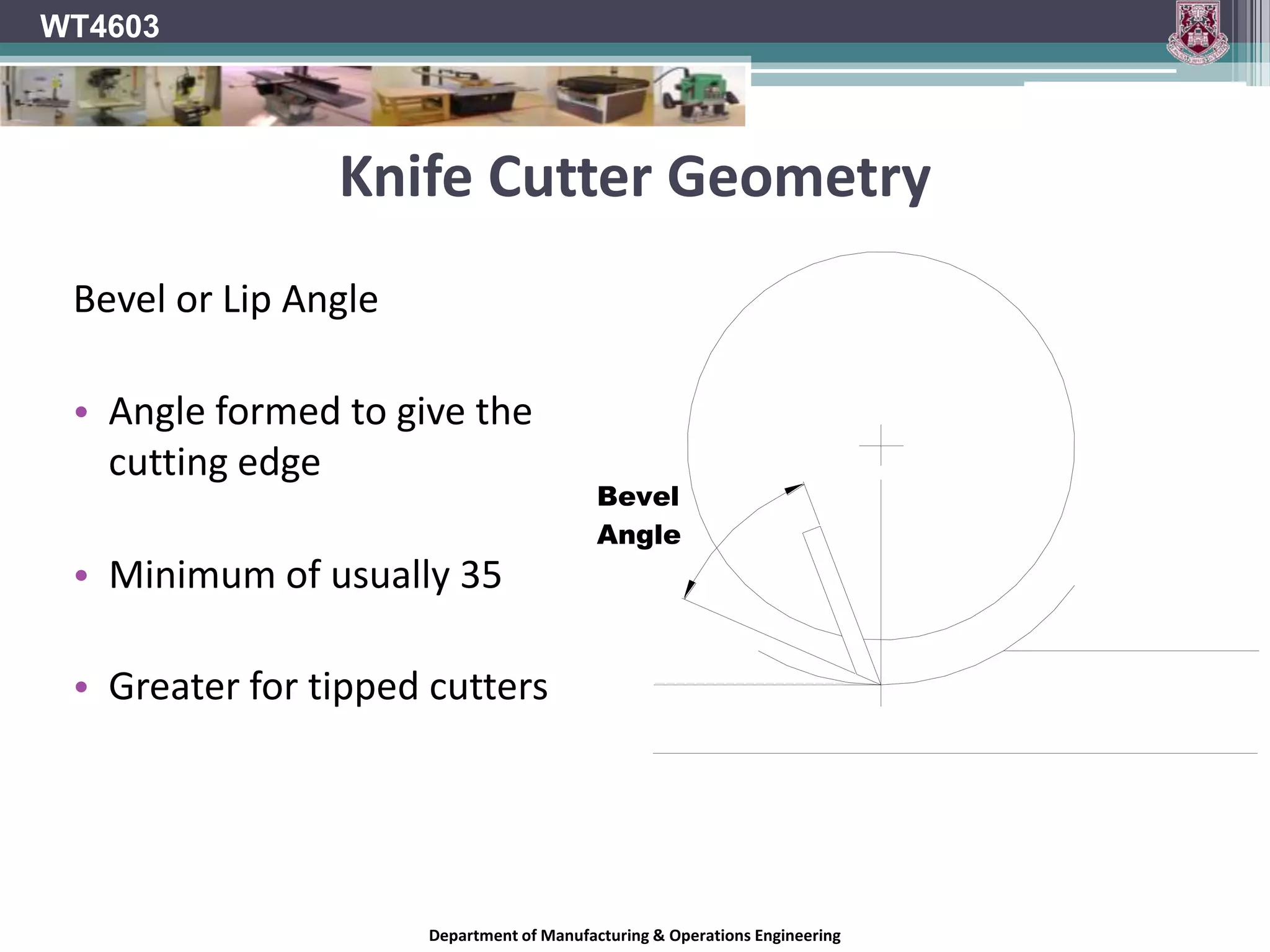

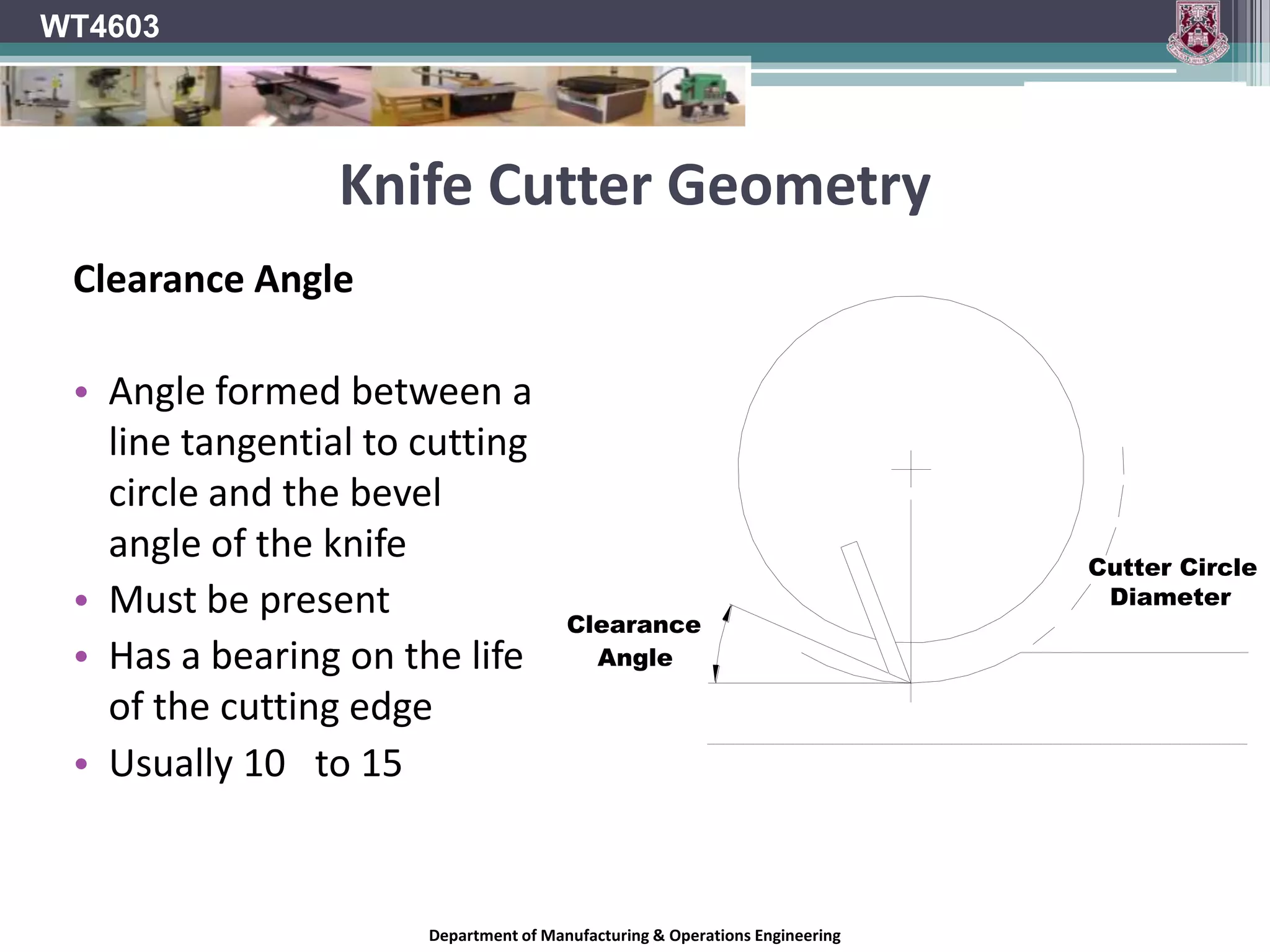

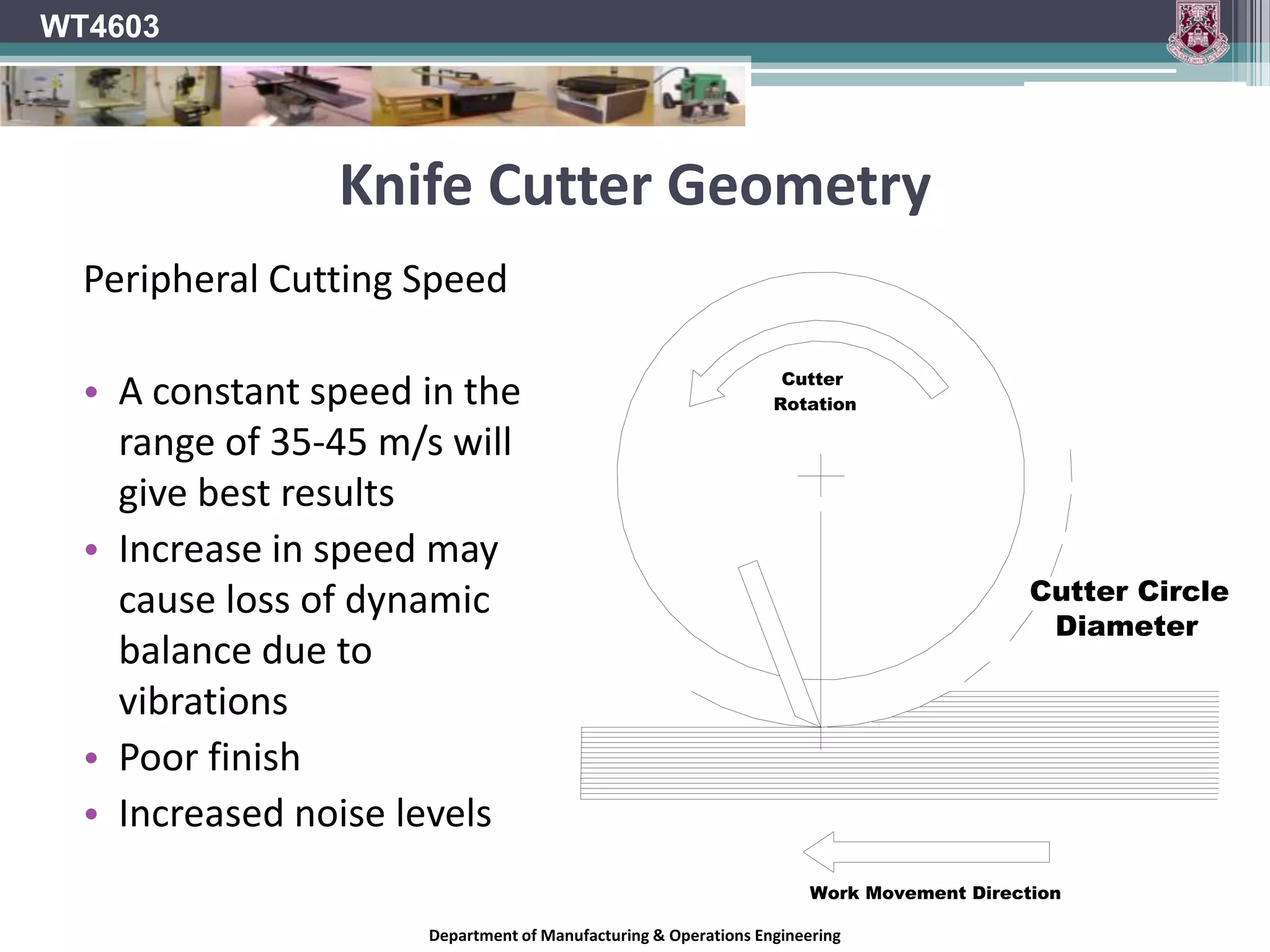

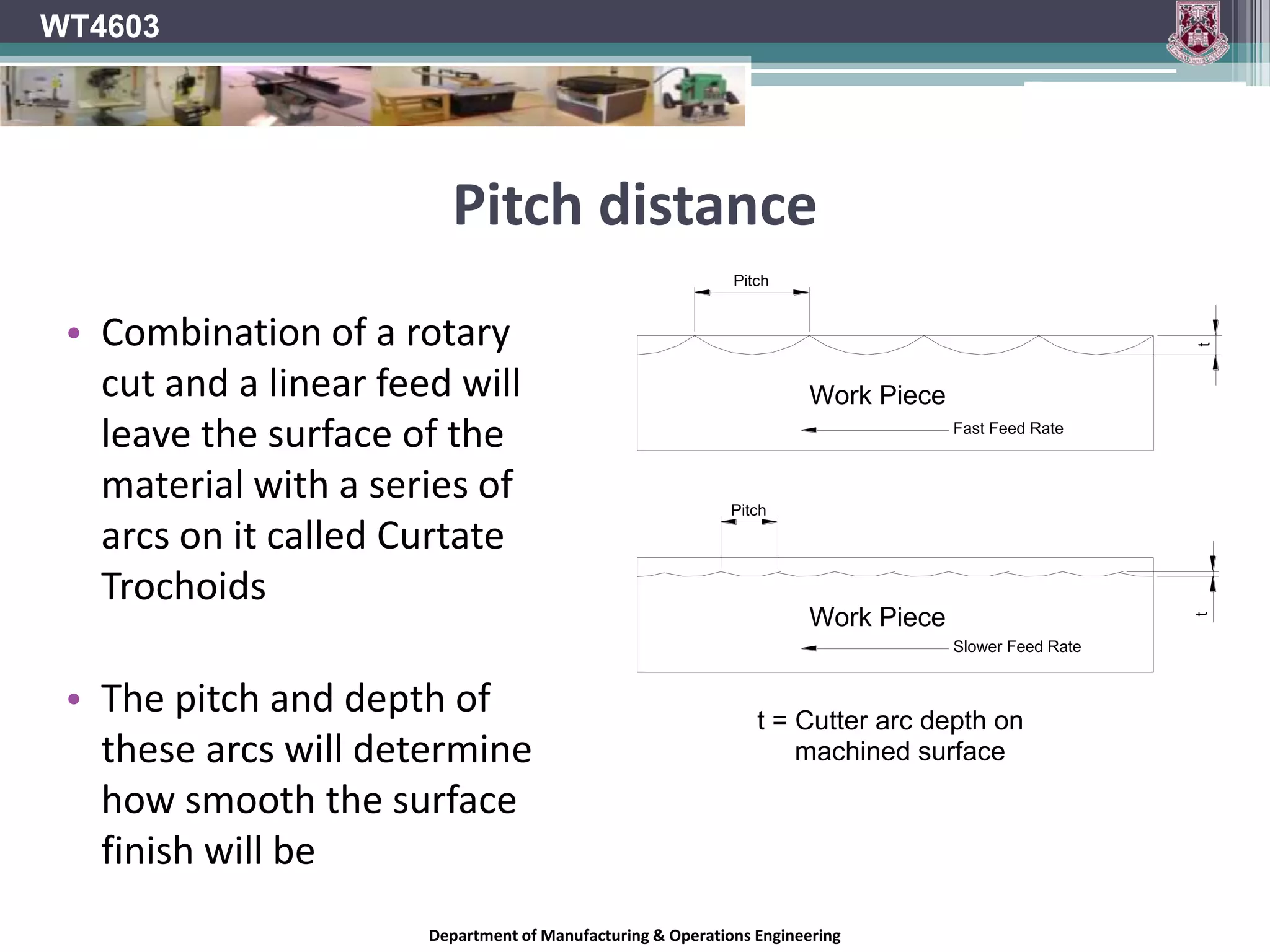

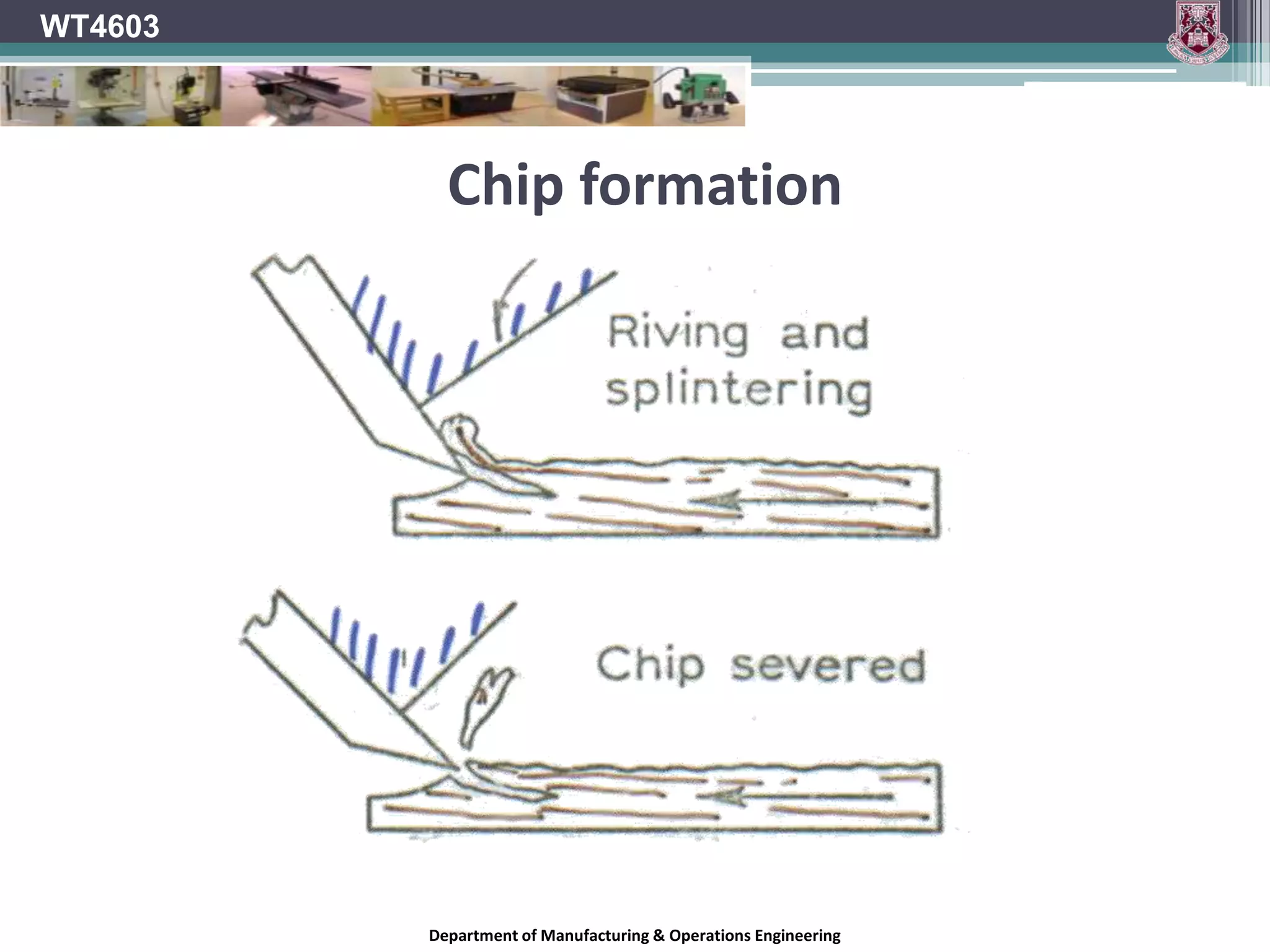

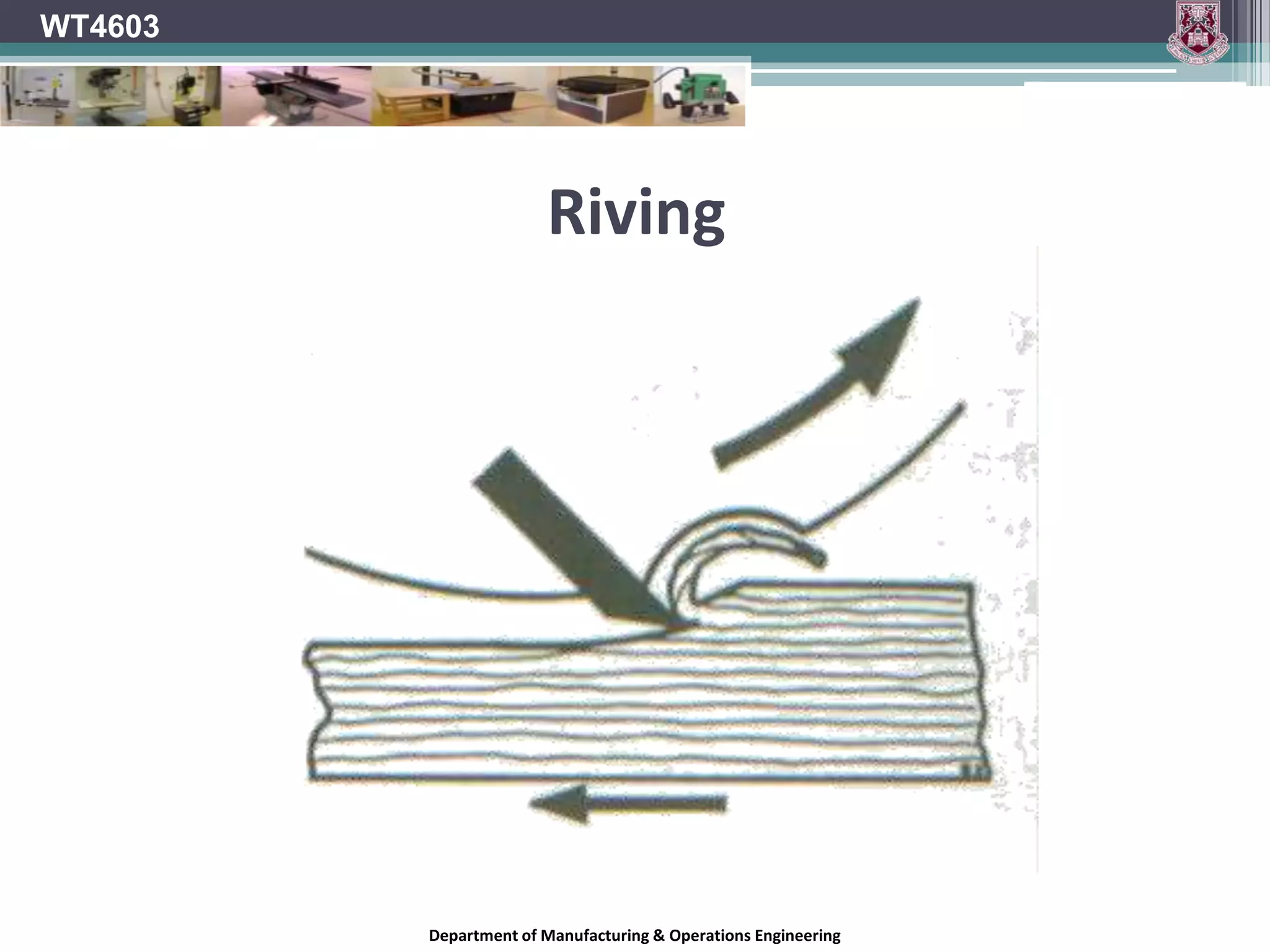

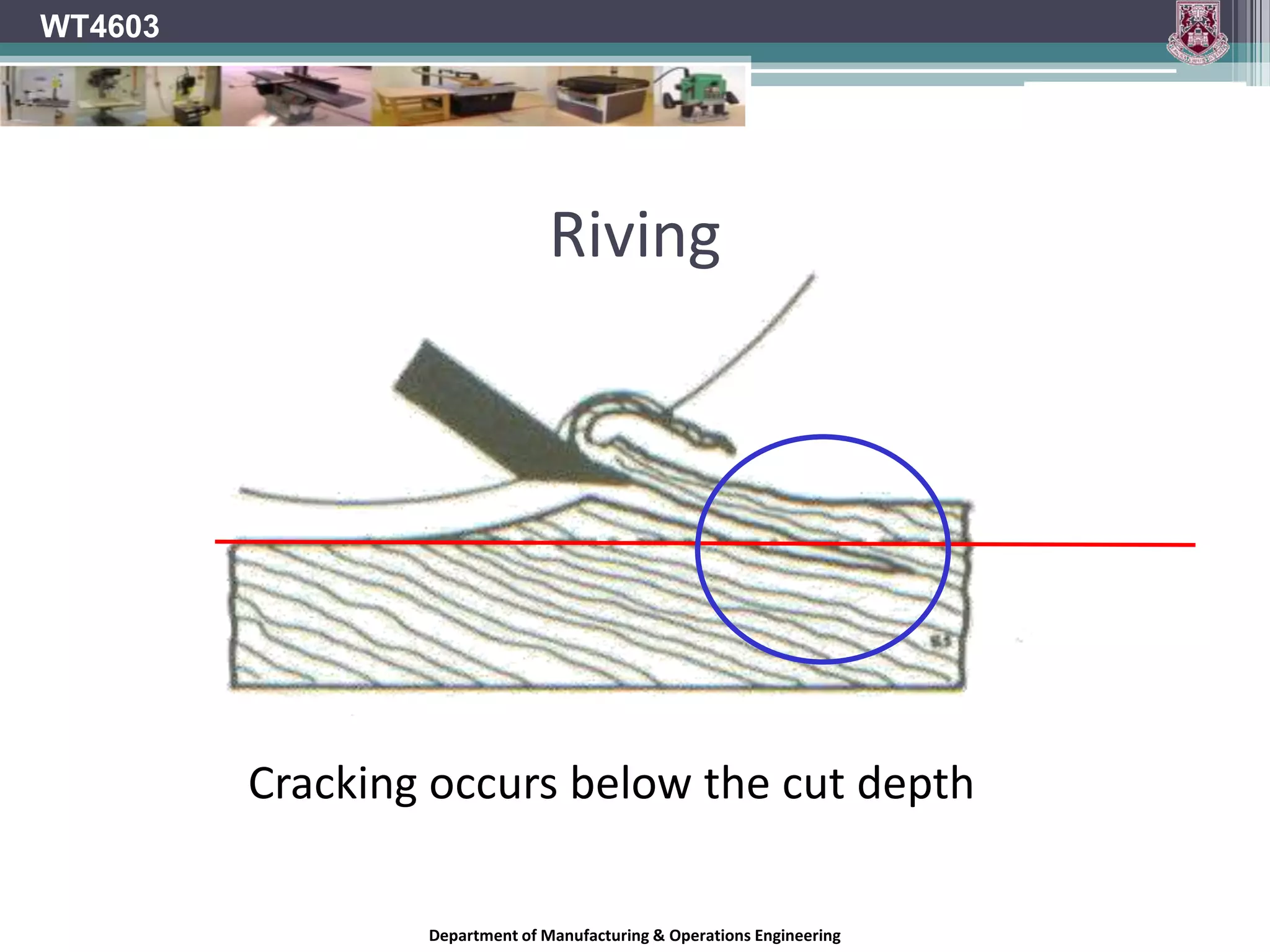

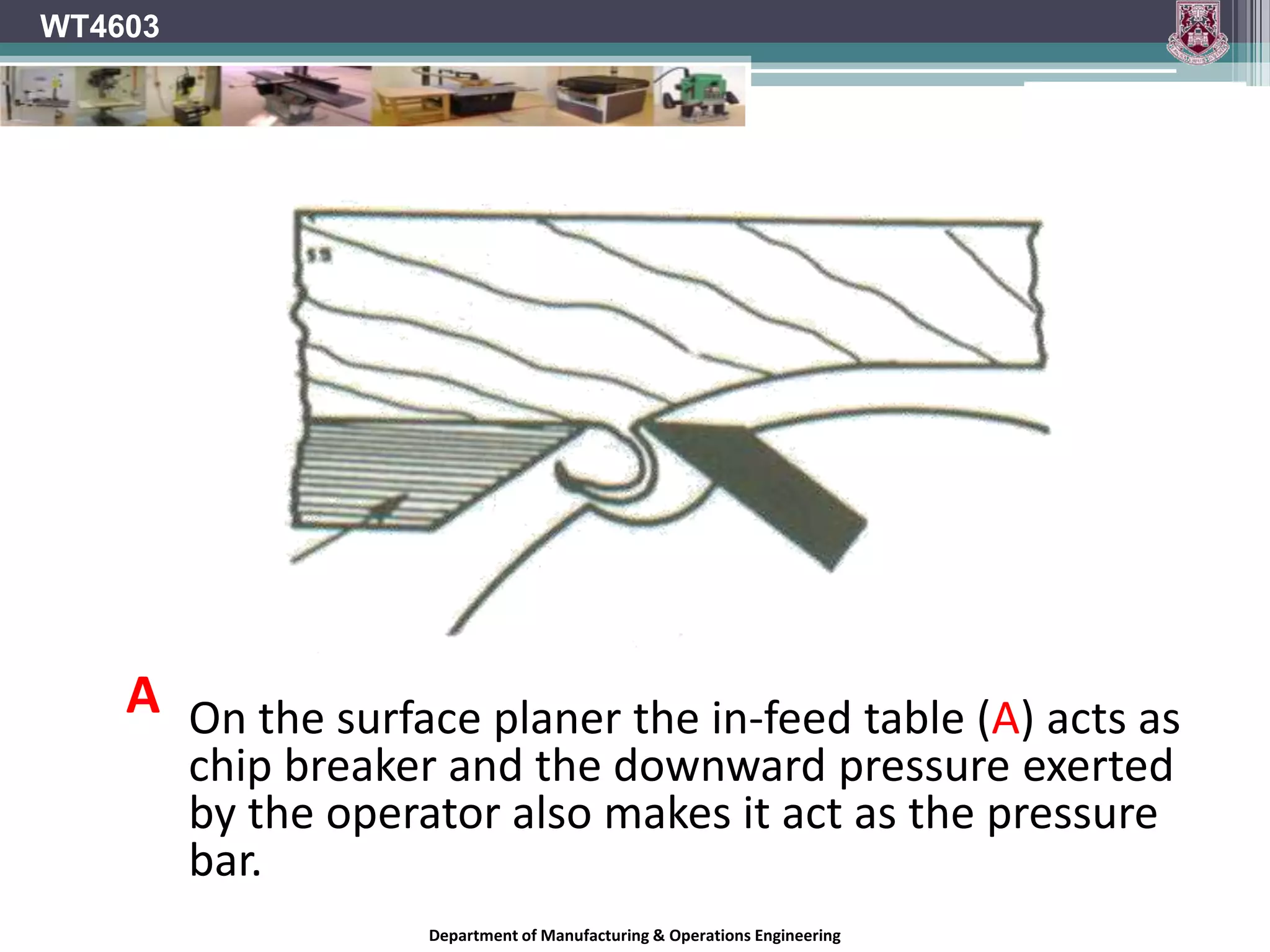

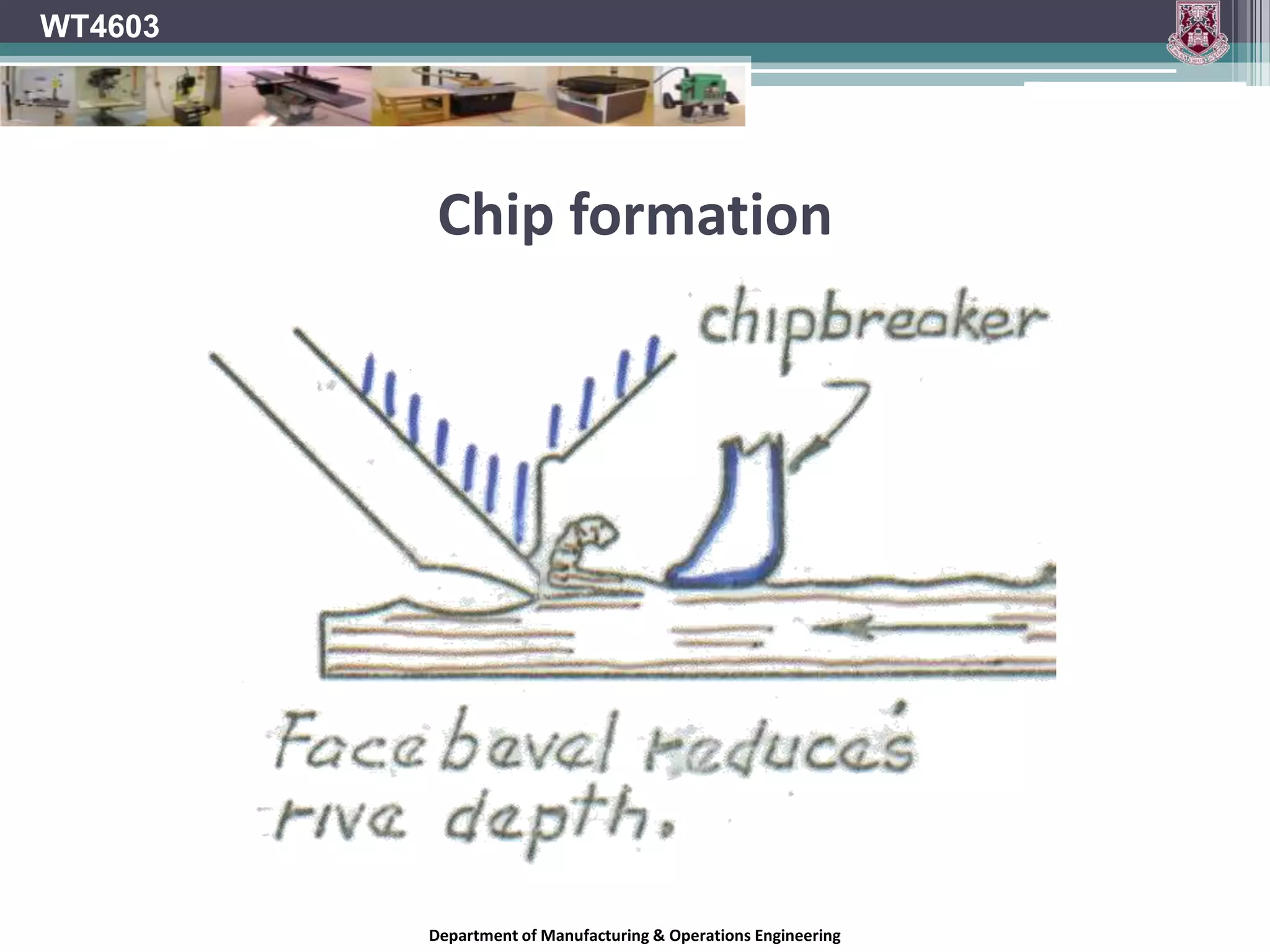

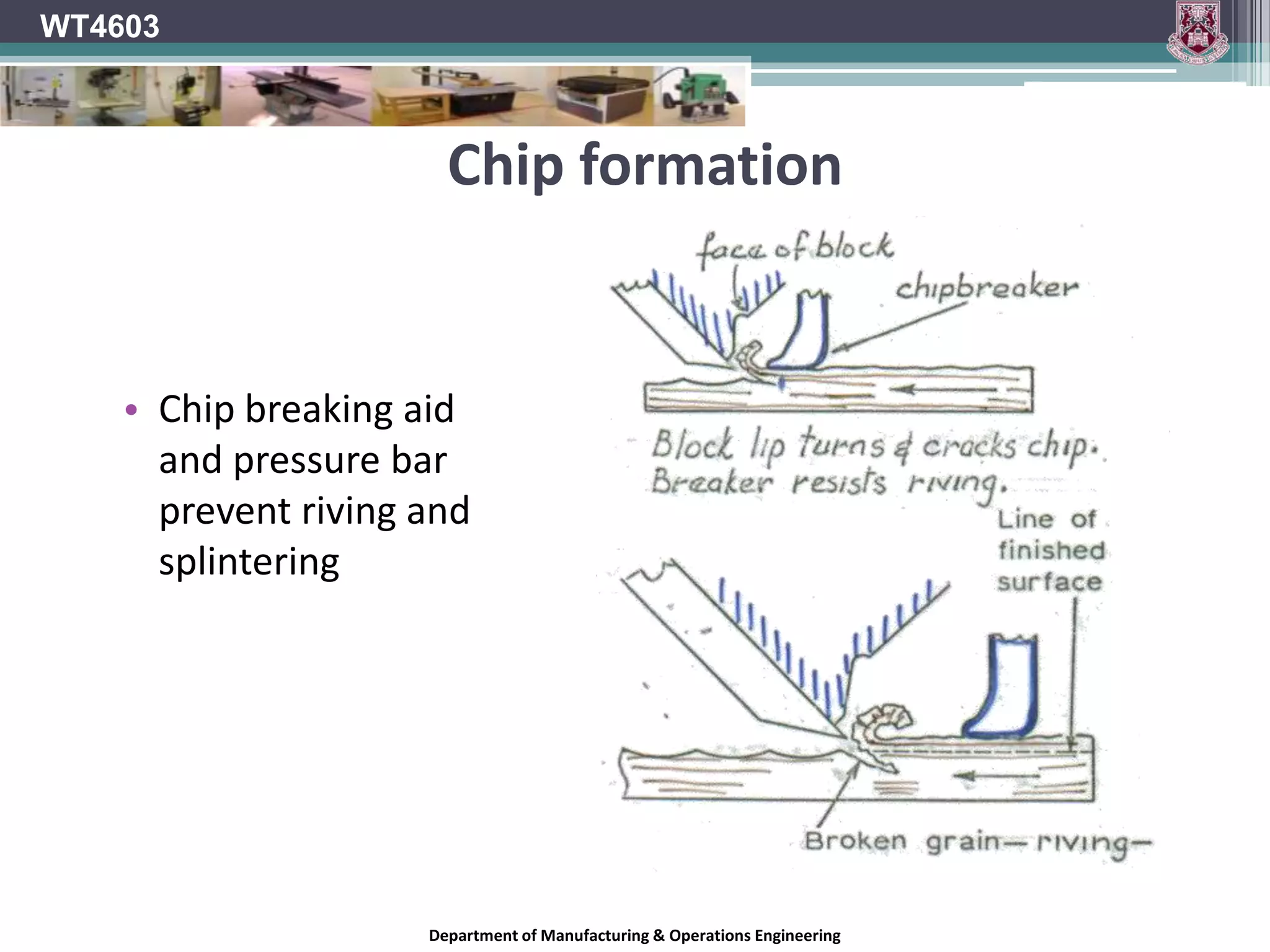

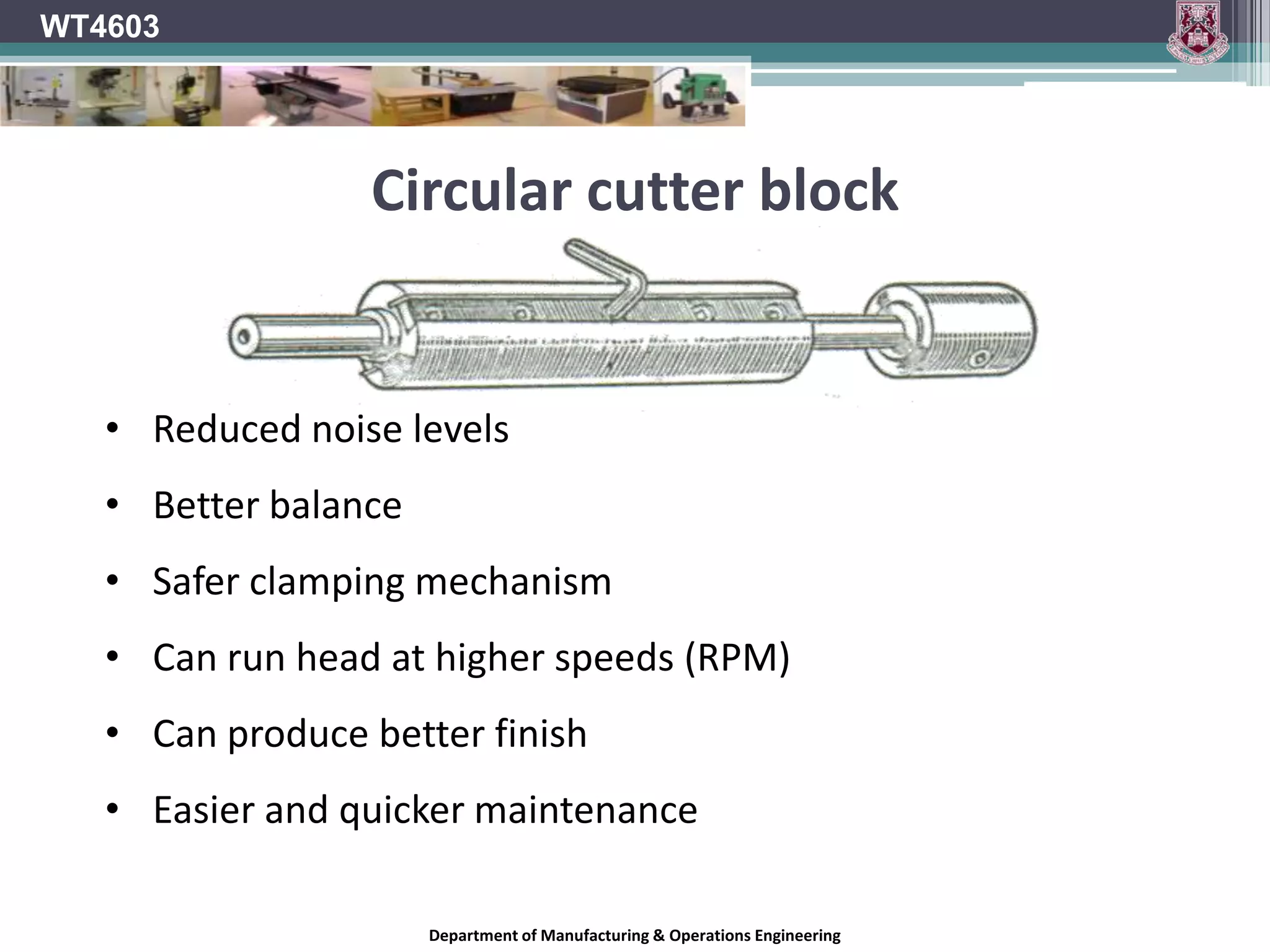

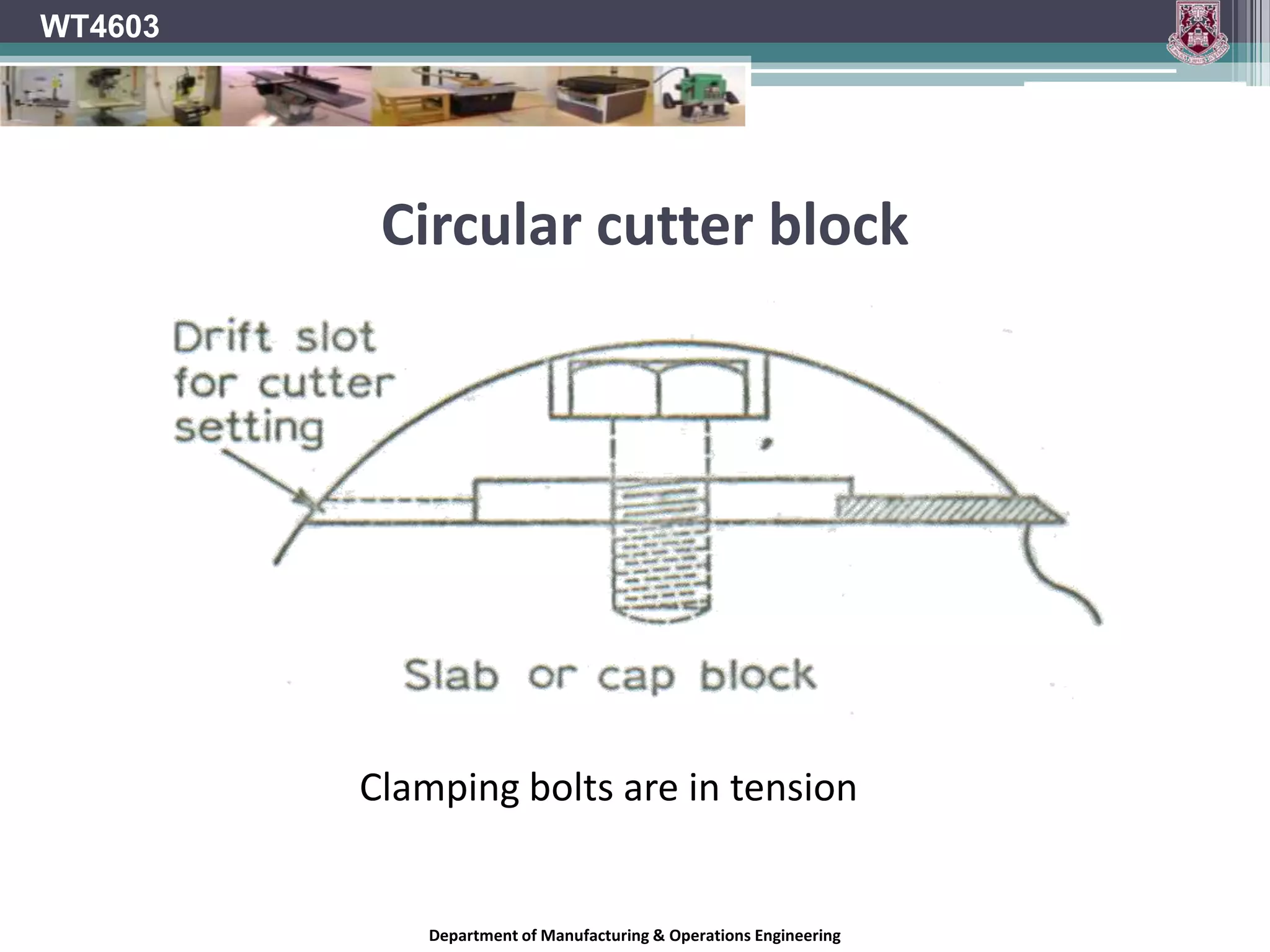

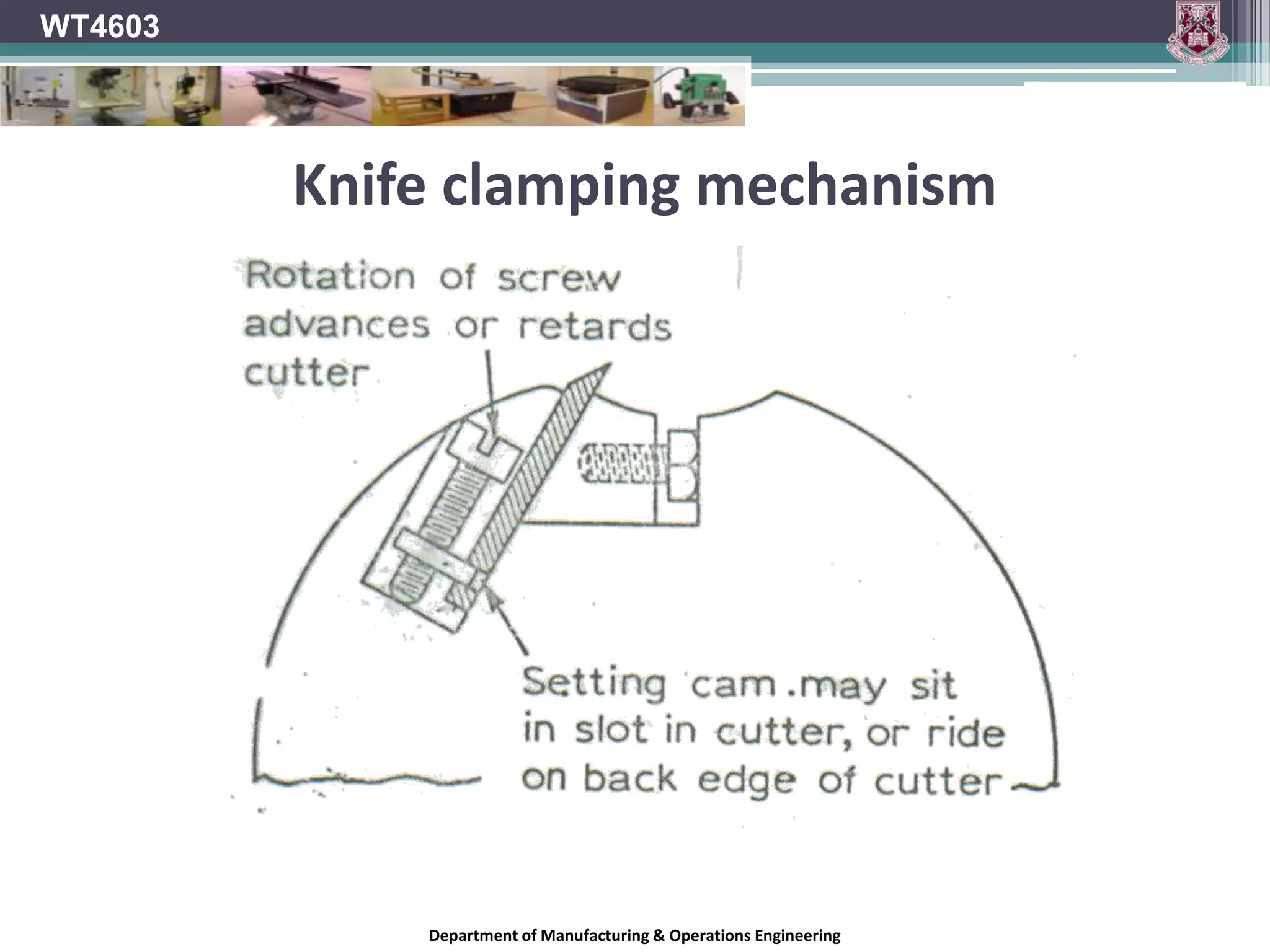

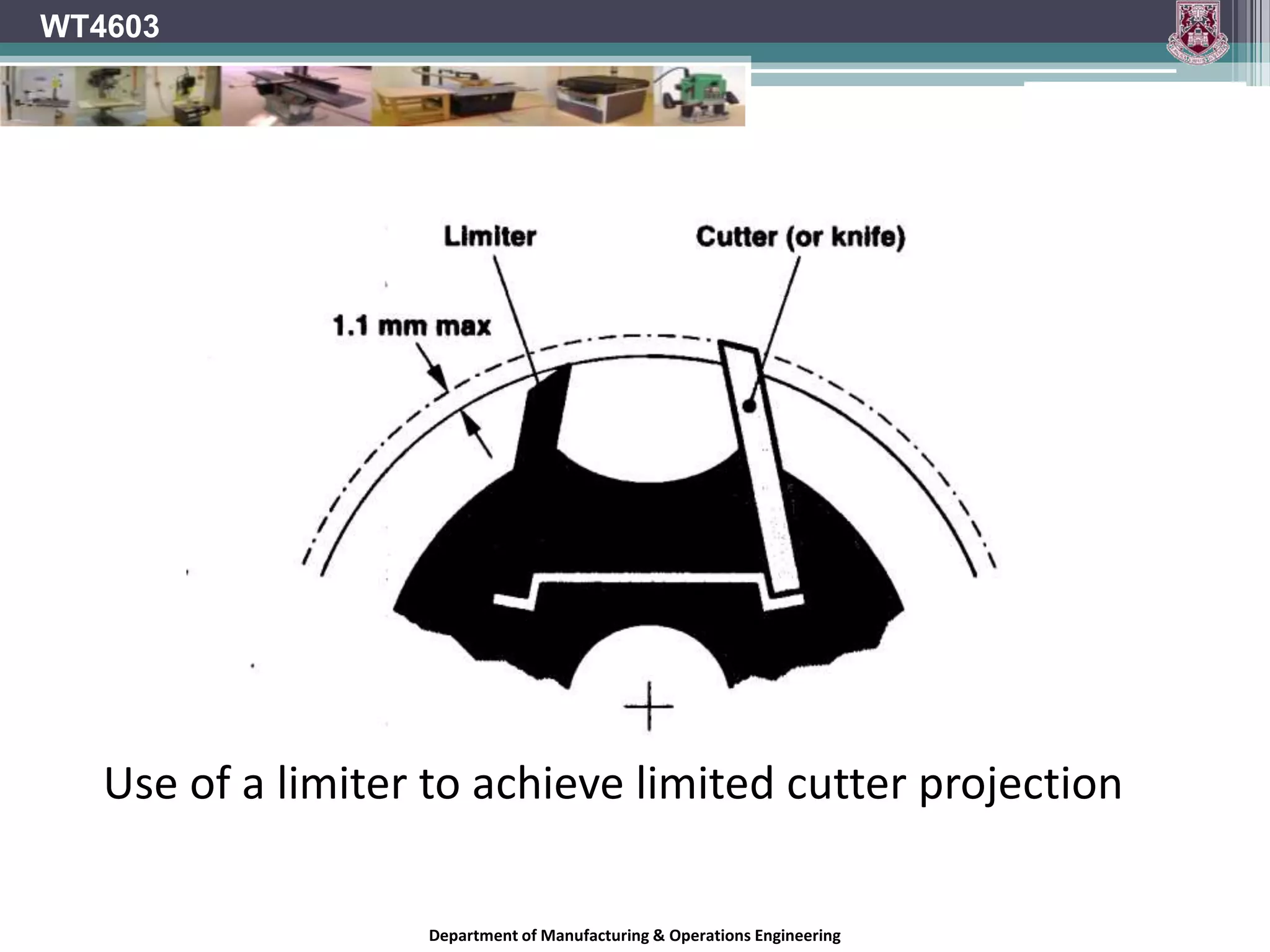

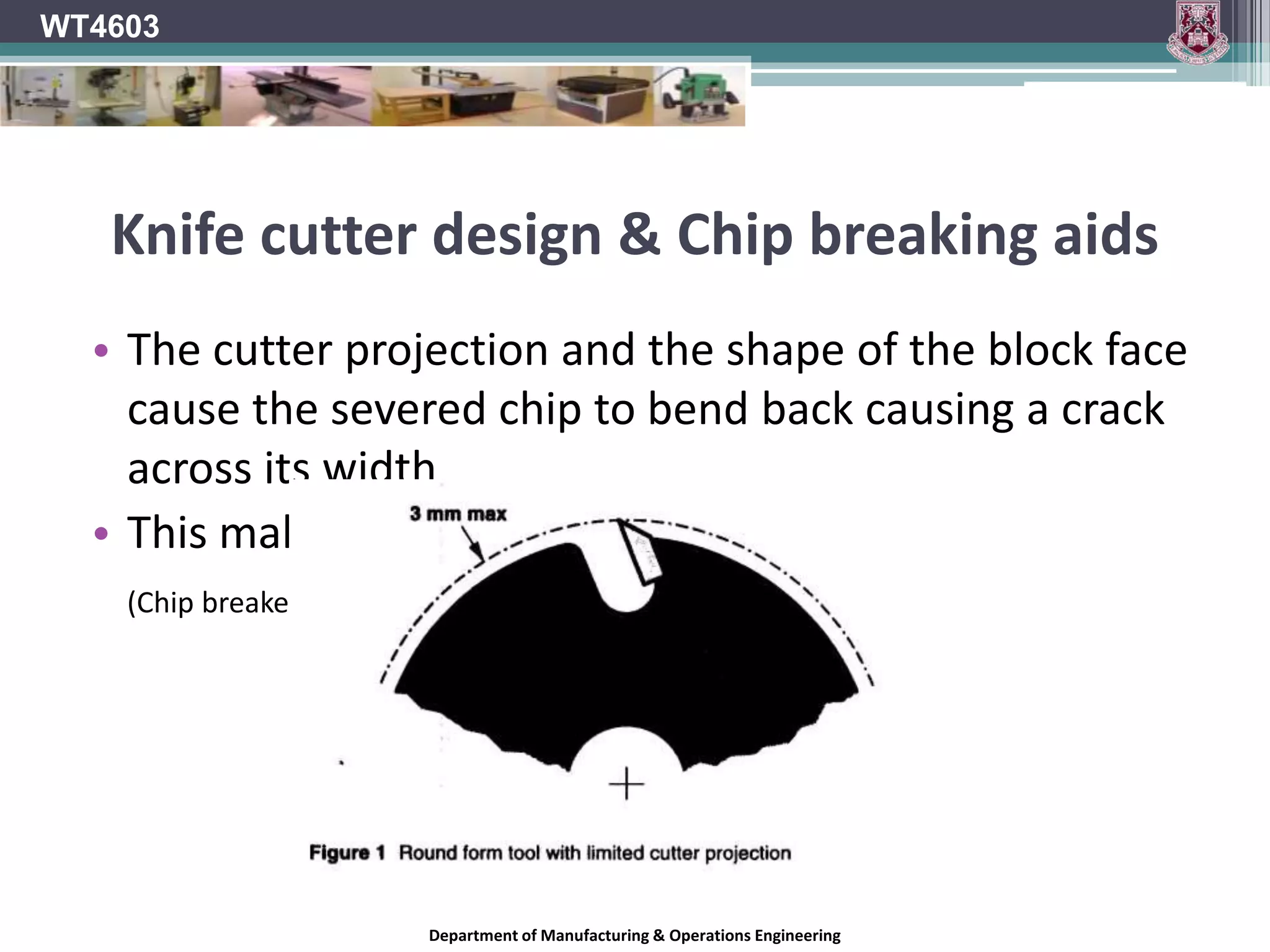

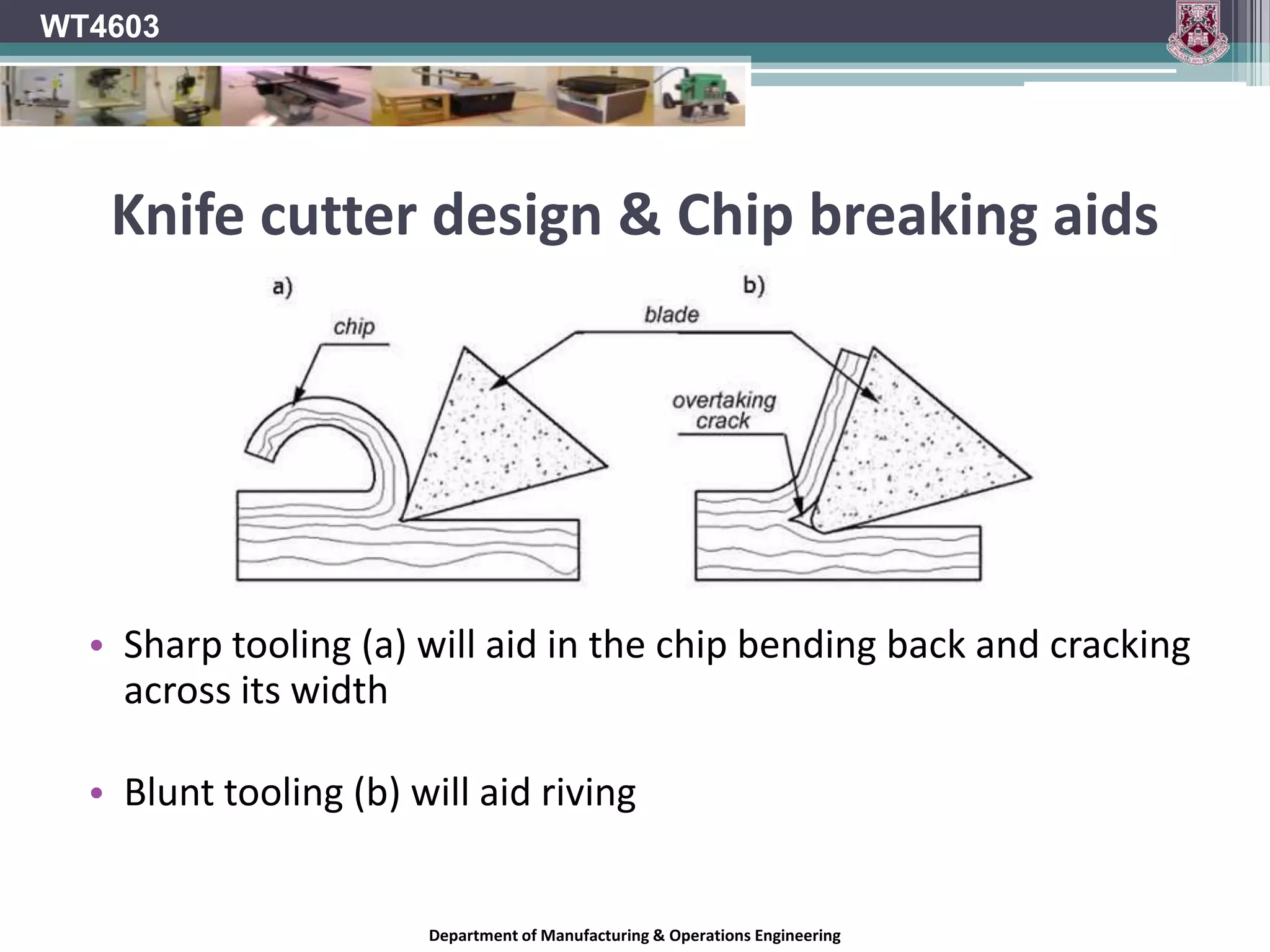

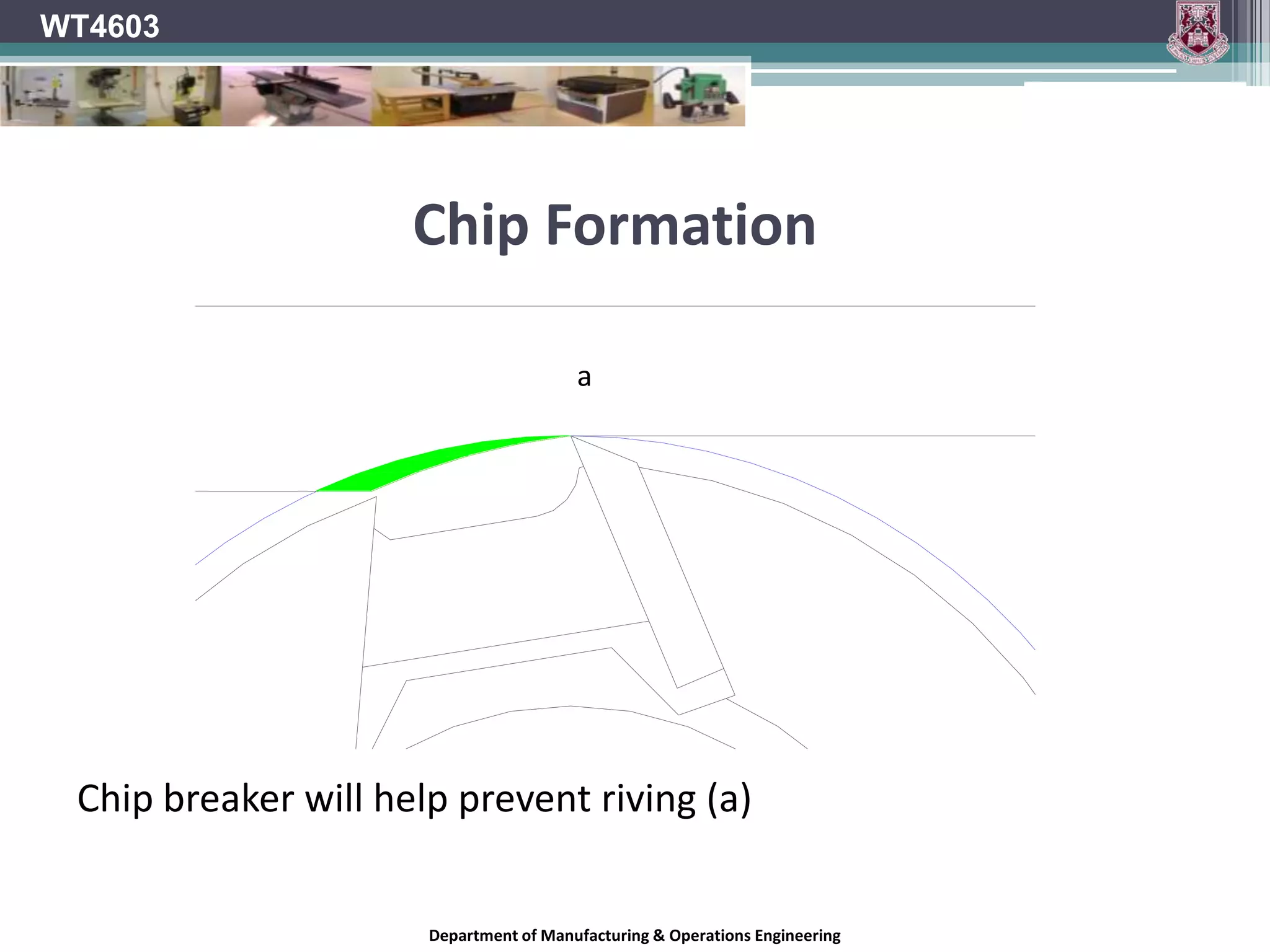

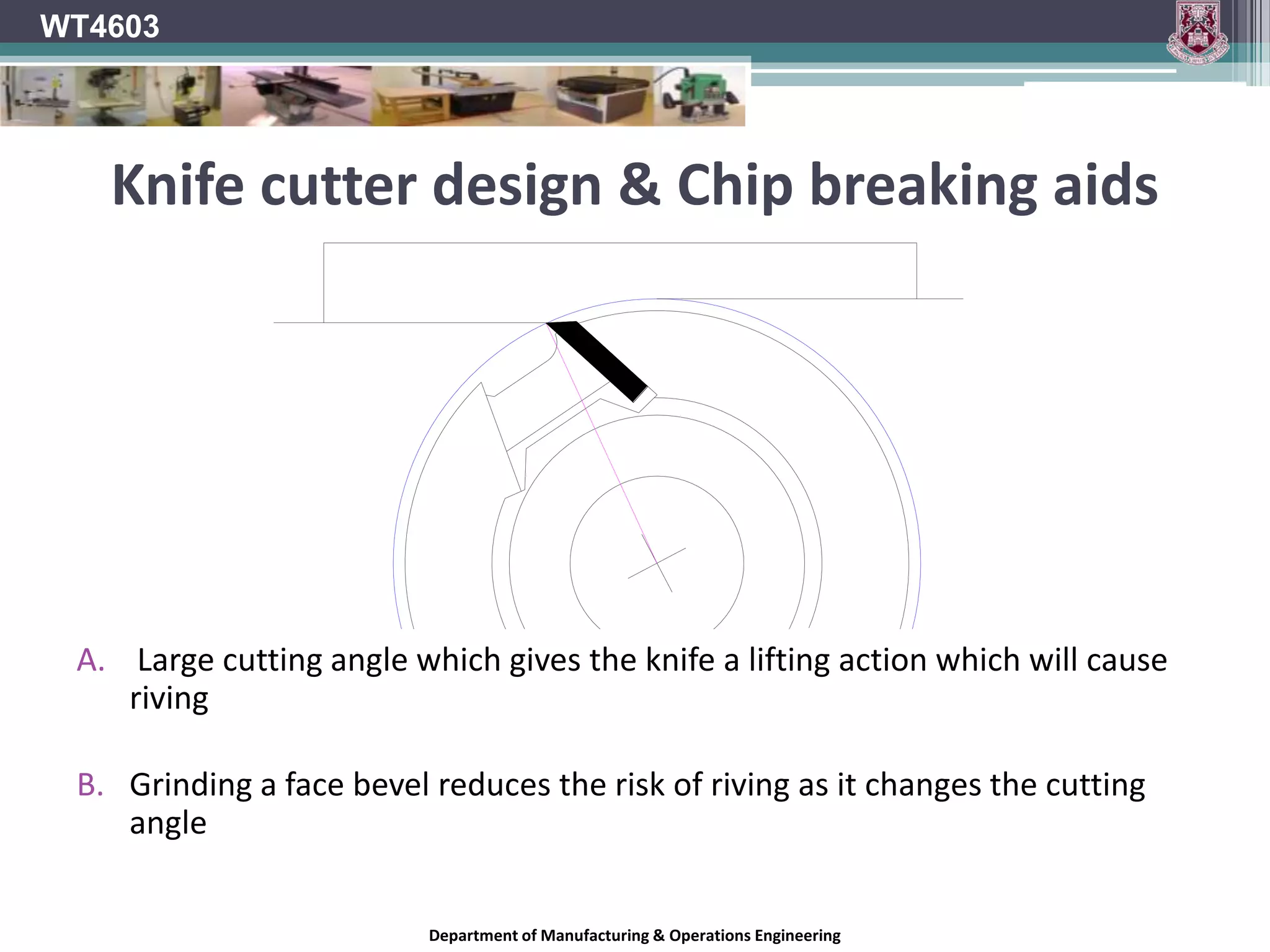

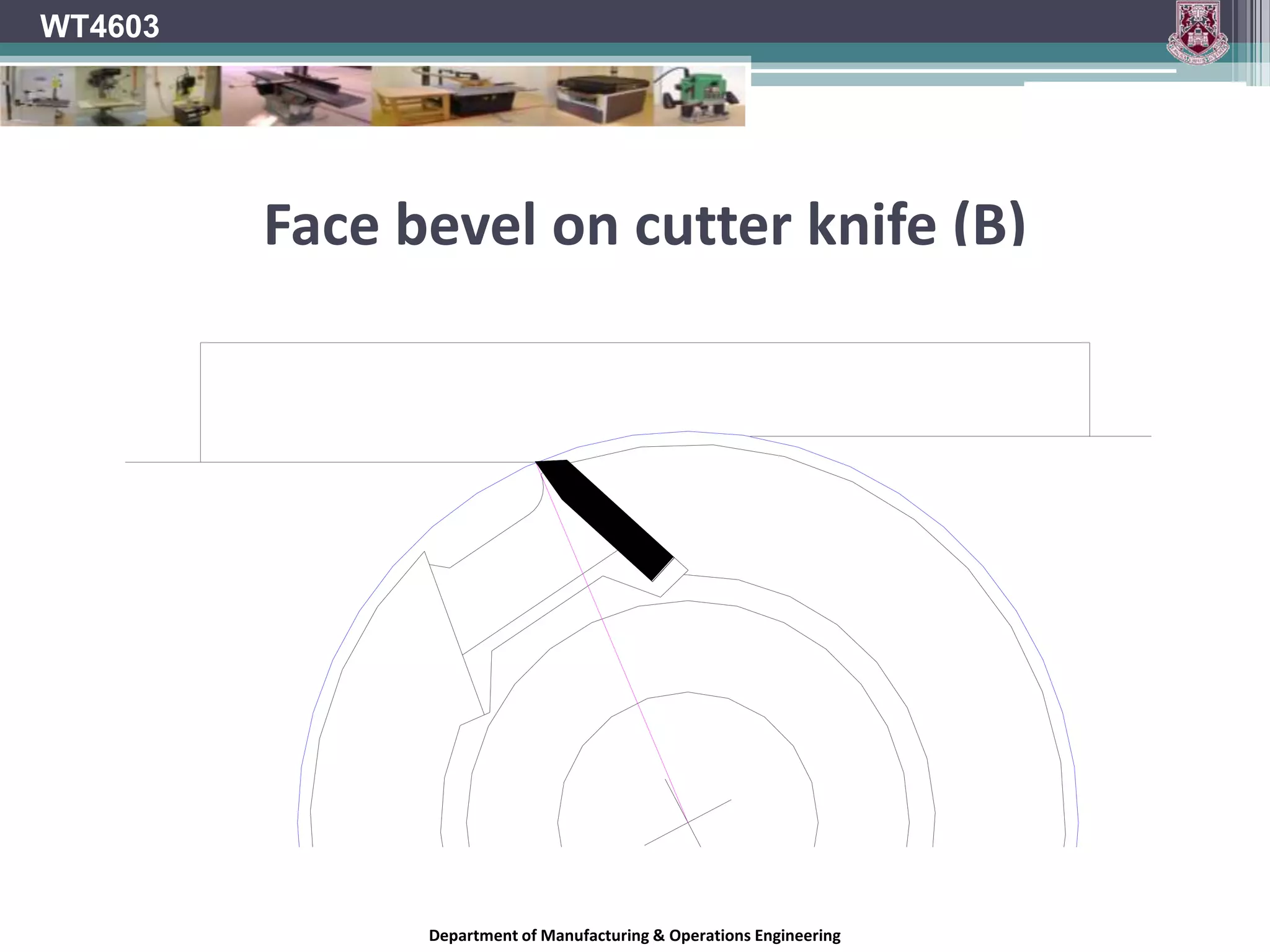

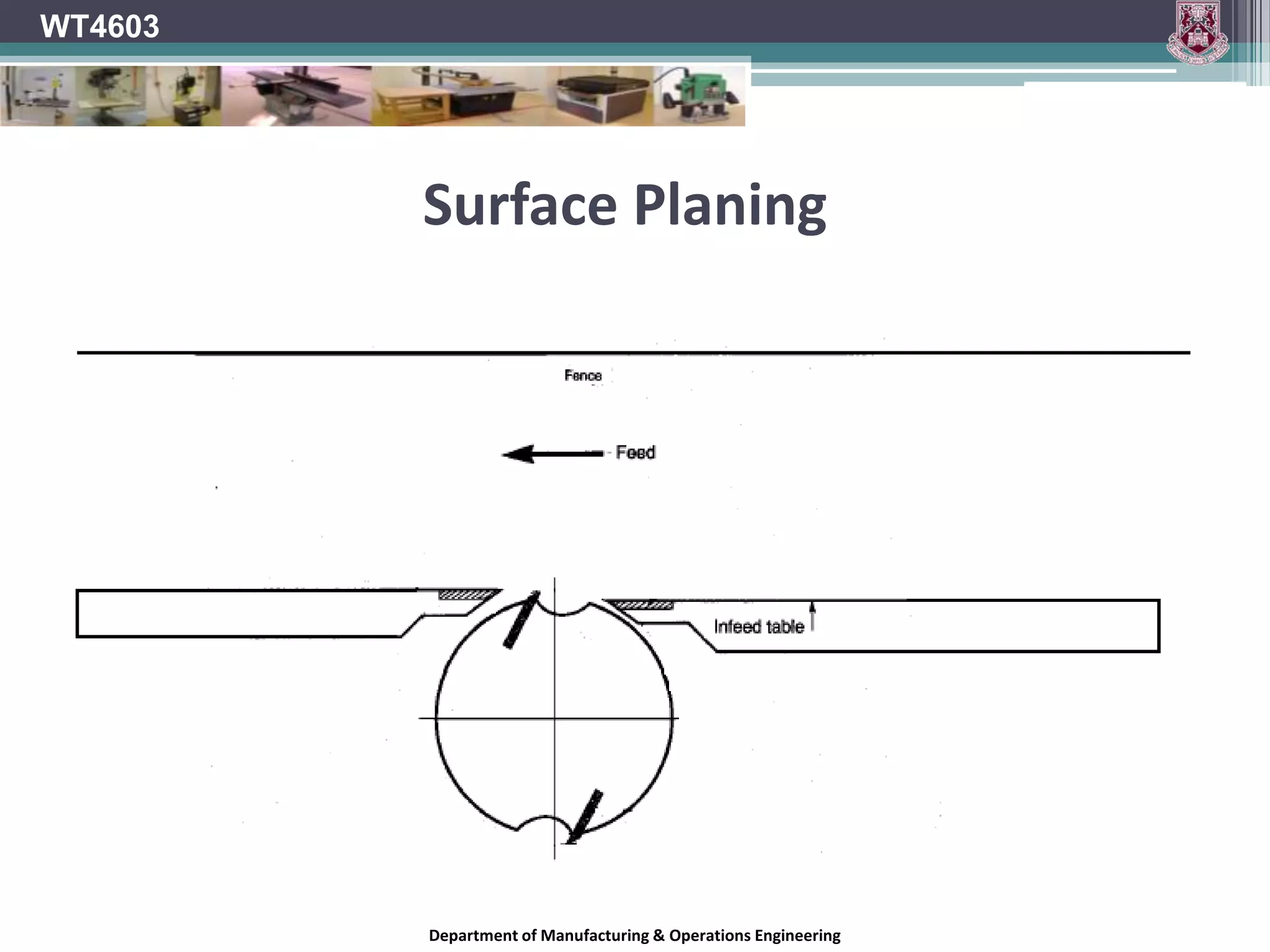

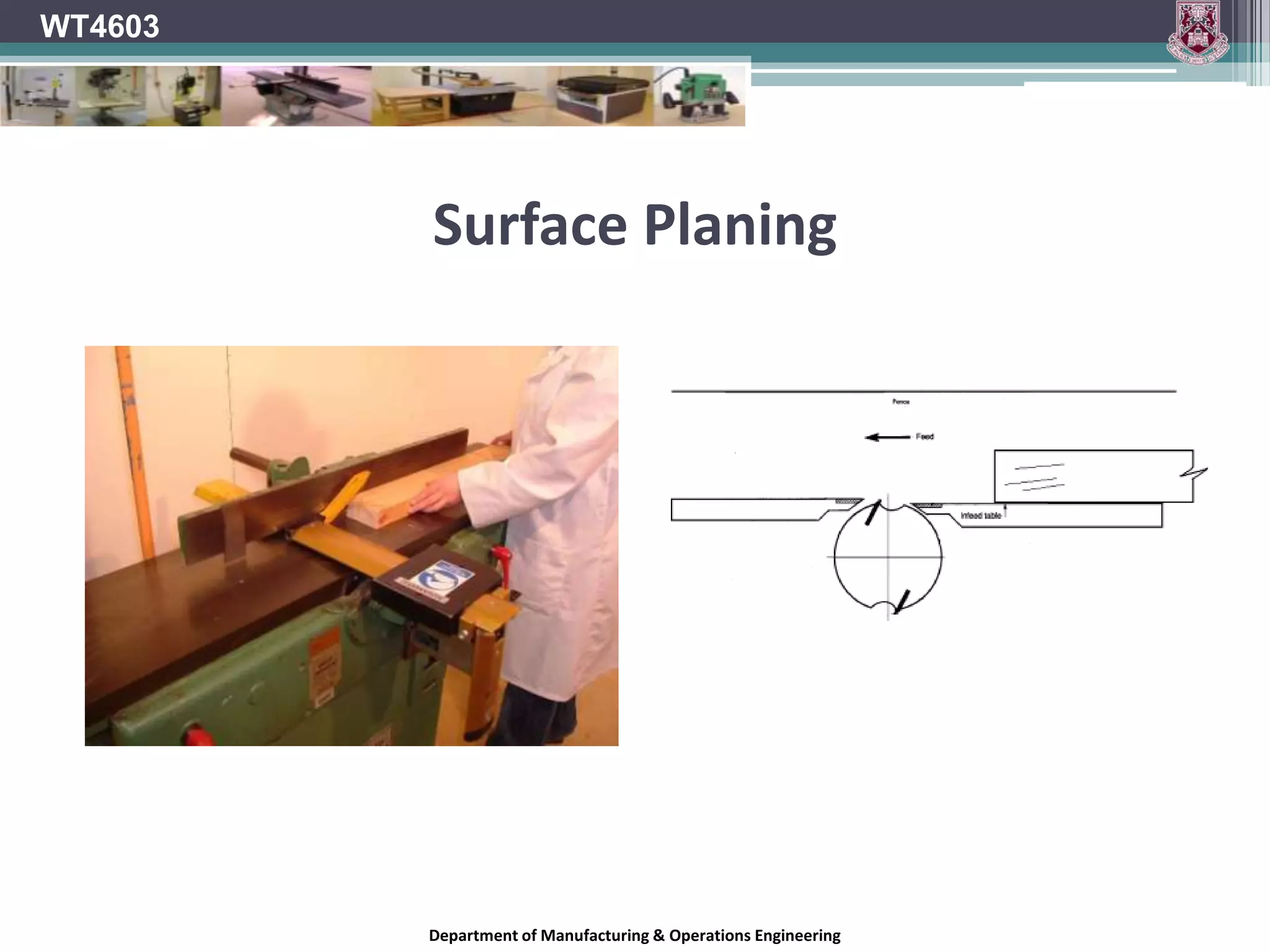

This document provides information on planing machines and their components. It discusses different types of planer knives and the factors to consider when selecting knives, such as the material being processed. It describes various knife materials like chrome vanadium steel, high speed steel, and tungsten carbide. The document outlines knife geometry specifications, including rake angle, bevel angle, clearance angle, and peripheral cutting speed. It also addresses pitch distance, chip formation, riving, cutter projection, and maintenance of planing machines.