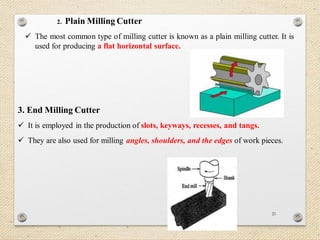

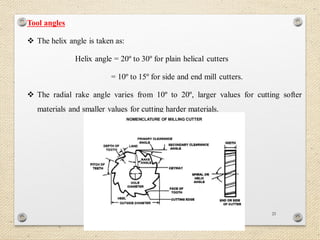

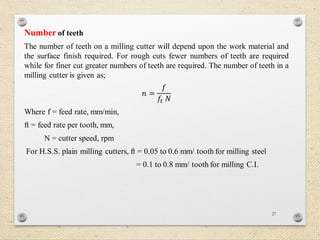

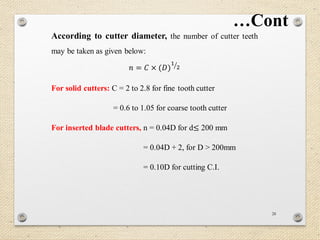

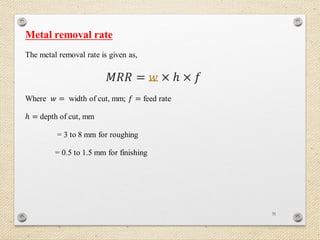

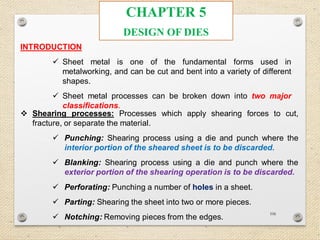

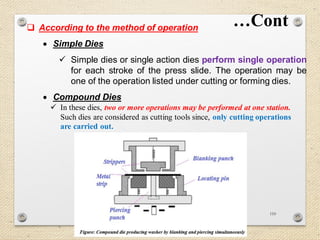

This document provides an overview of tool design for mechanical engineering. It discusses the objectives and responsibilities of tool designers, which include reducing costs, increasing production rates, and maintaining quality. The basic processes of tool design are outlined as 5 steps: defining the problem, analyzing requirements, developing initial ideas, developing alternatives, and finalizing the design. Considerations for tool design include the workpiece, operations, personnel, equipment, drawings, and factors that influence tool life such as cutting speed and metal removal rate. Common types of milling cutters are described along with design features such as size, tool angles, number of teeth, and material selection.