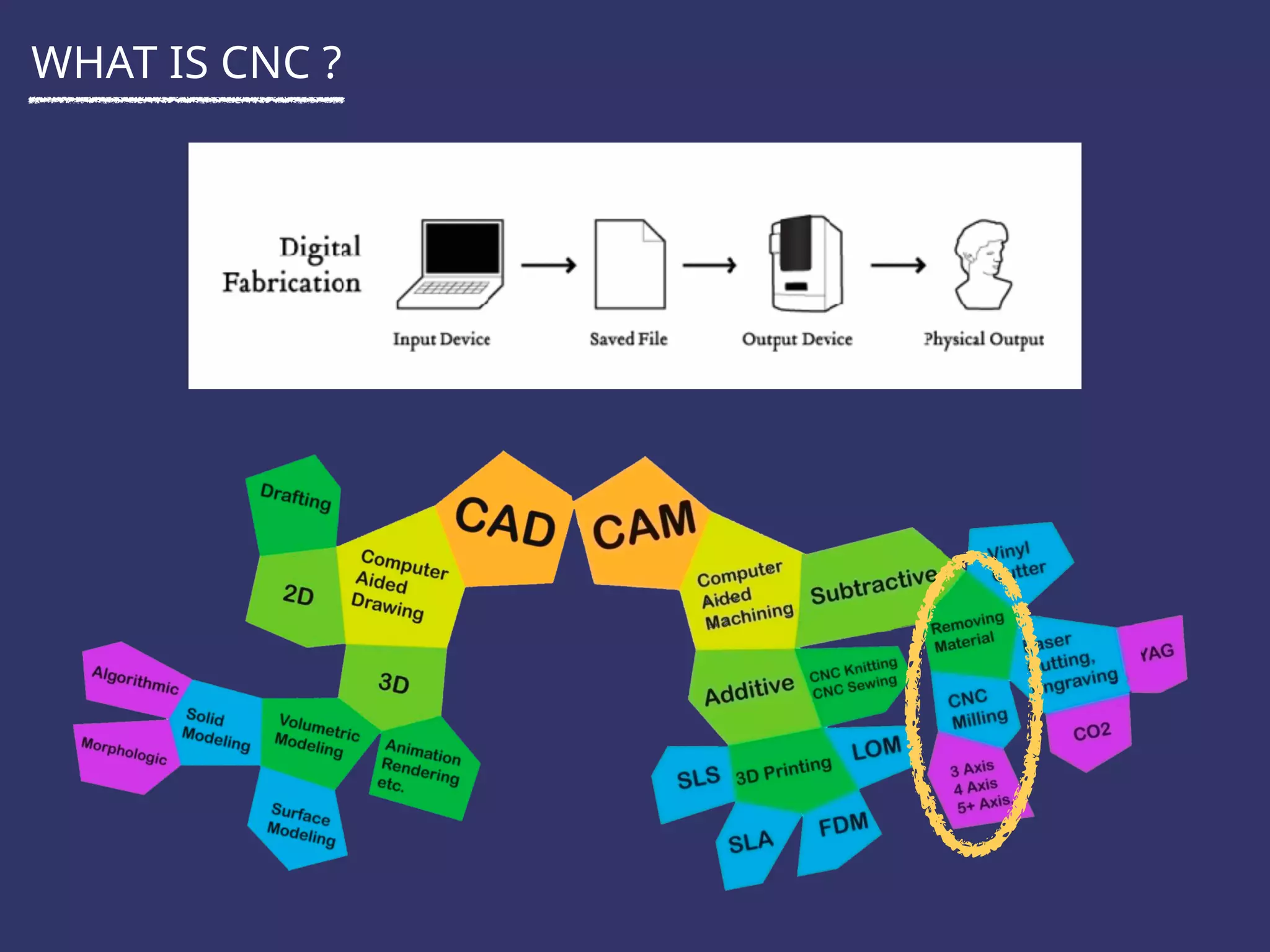

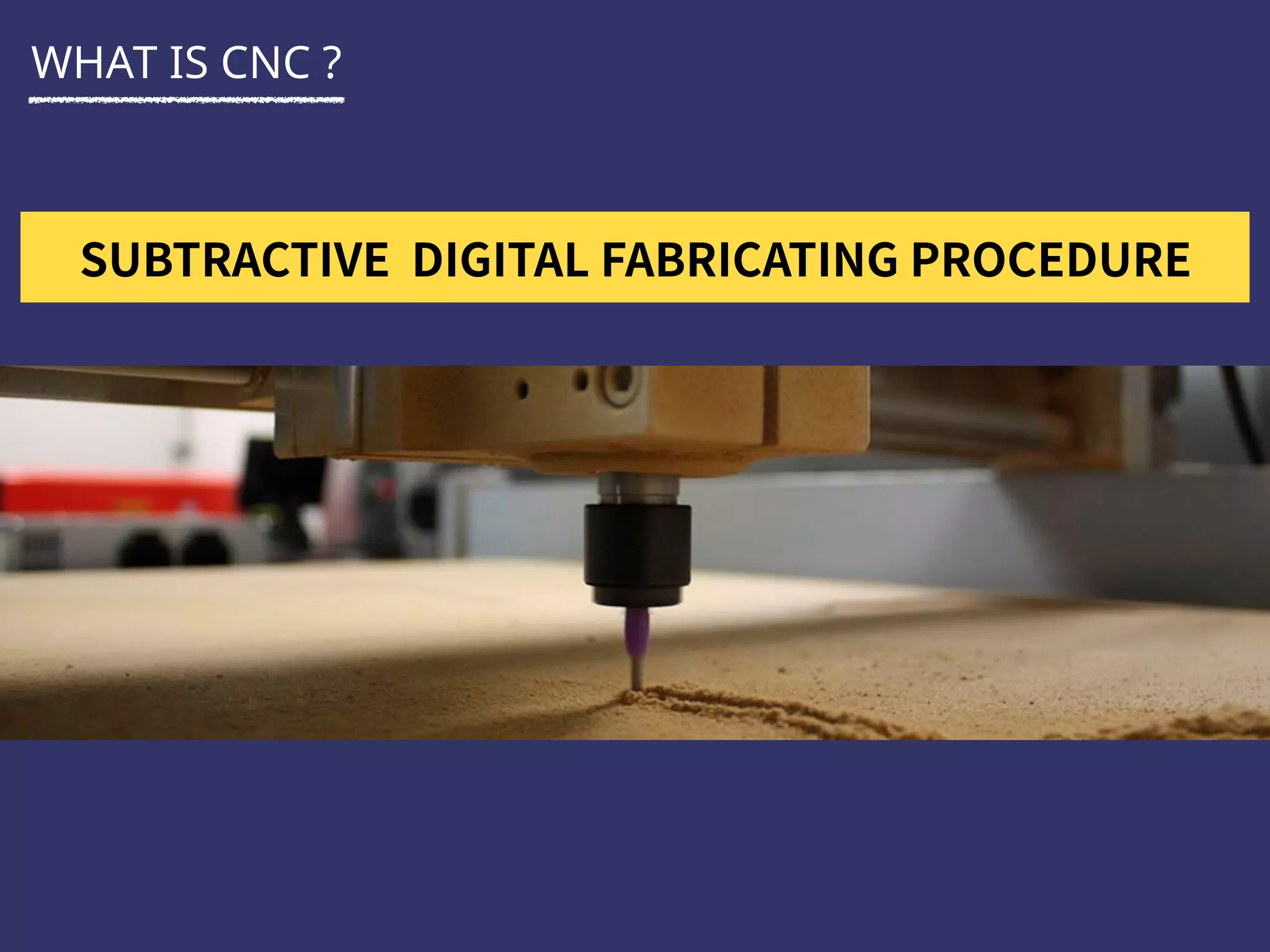

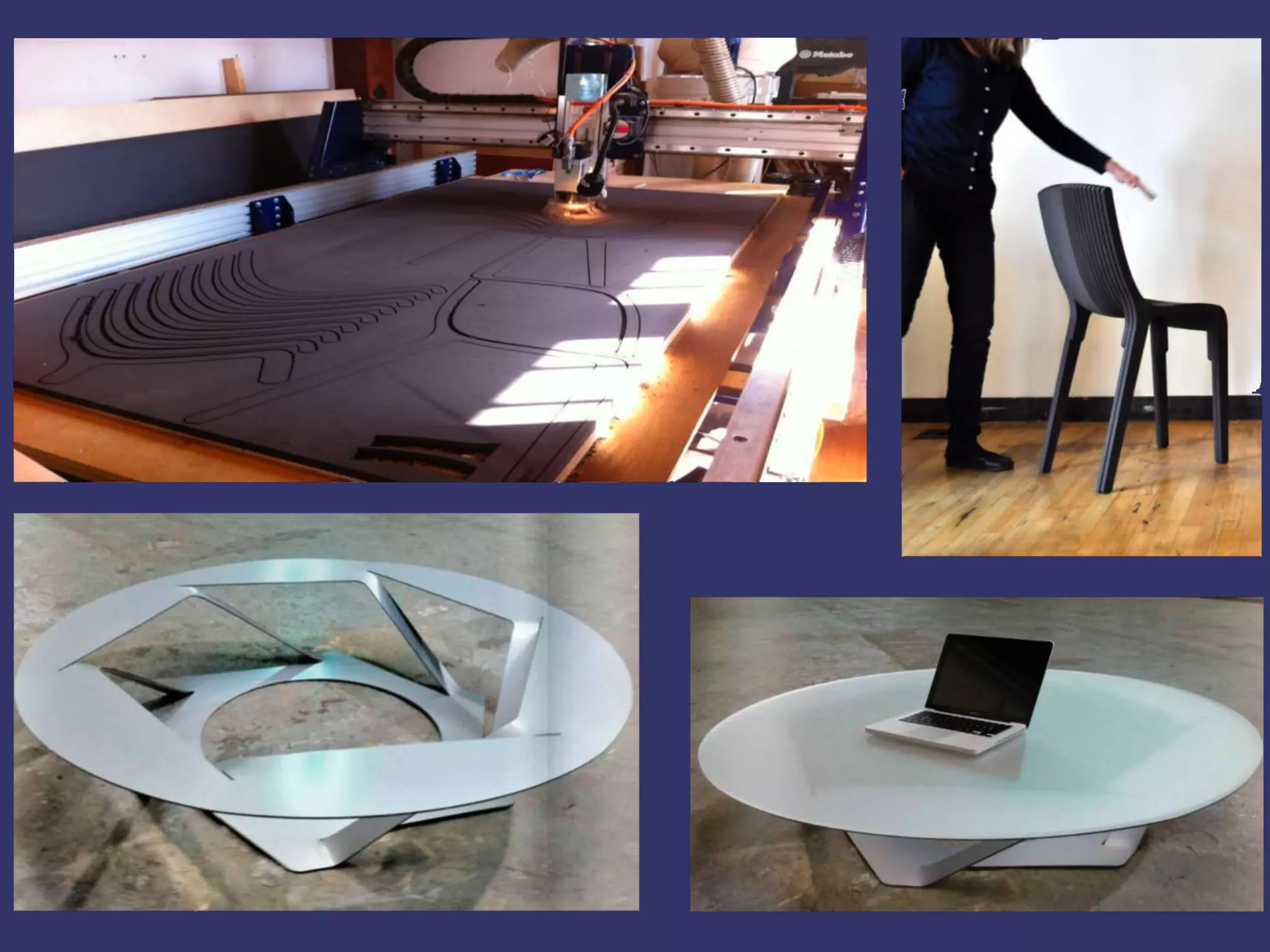

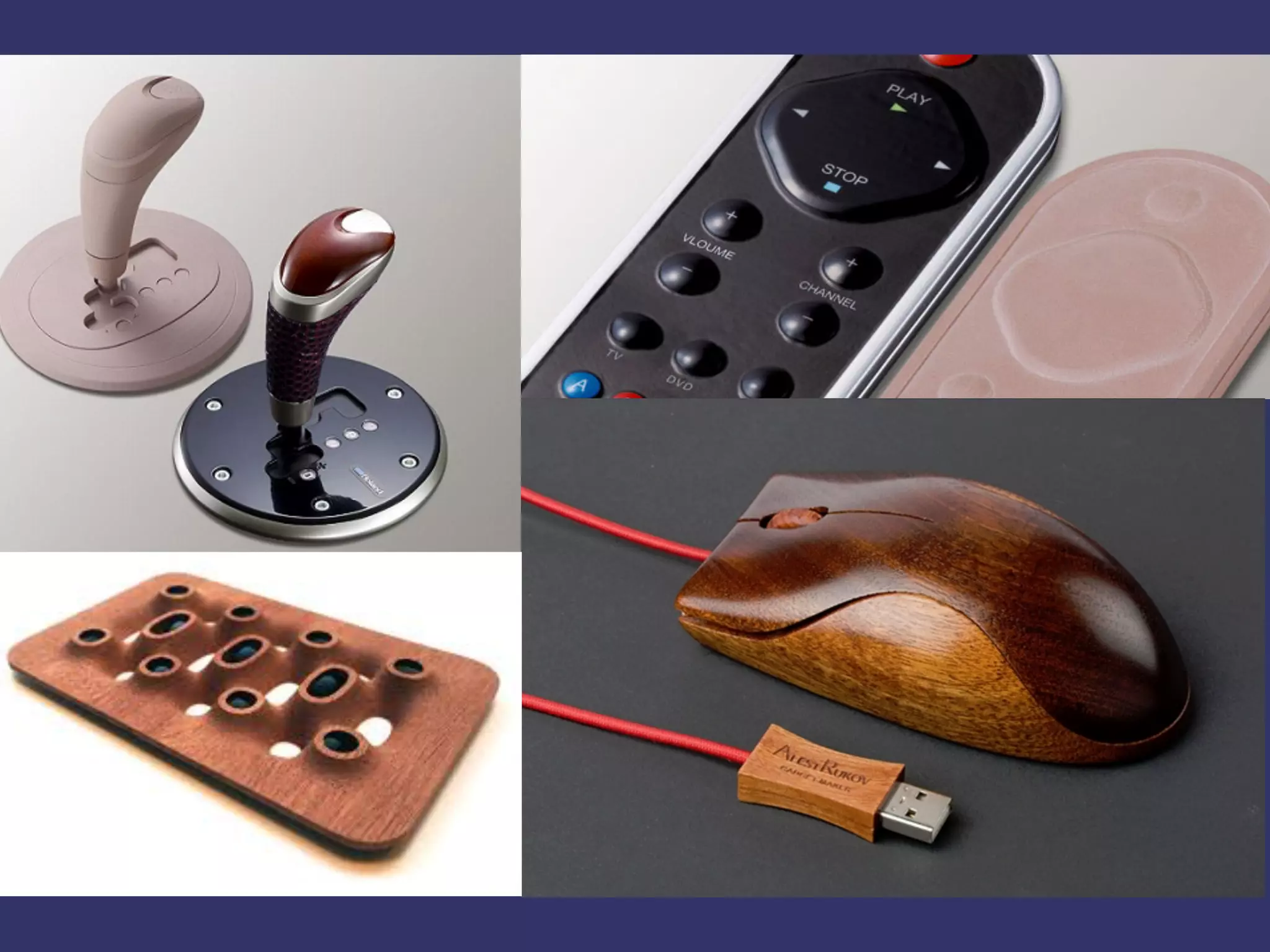

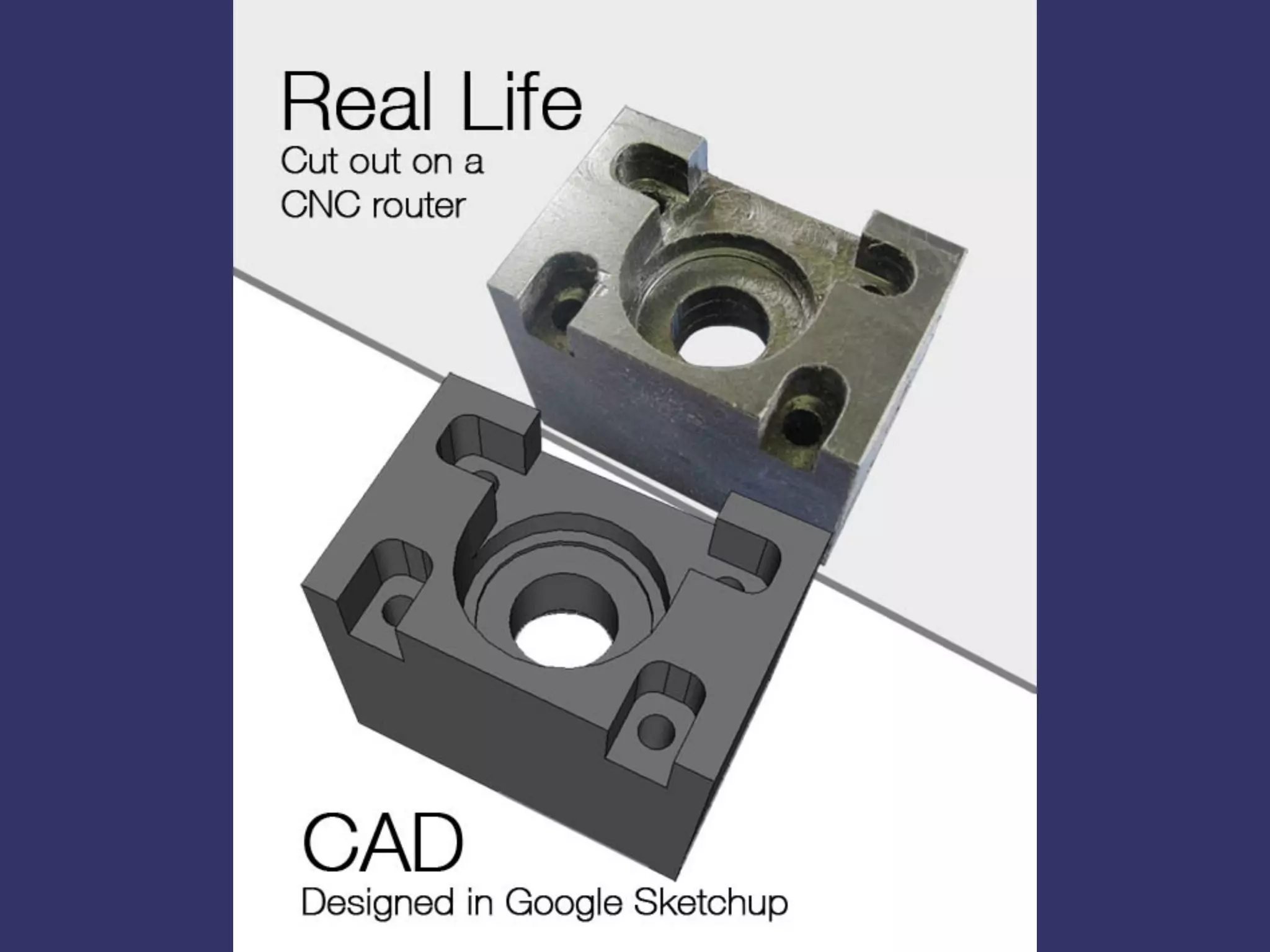

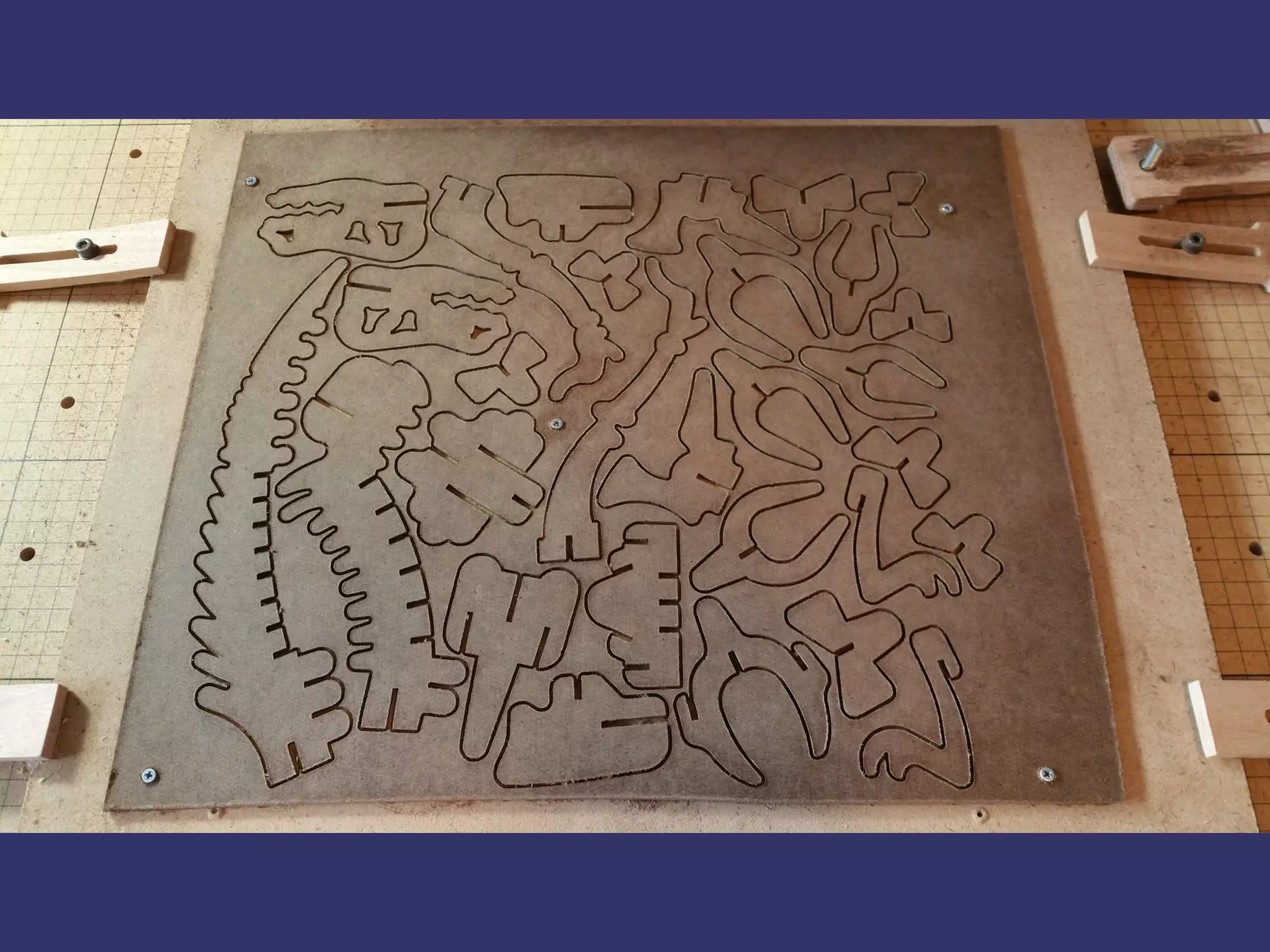

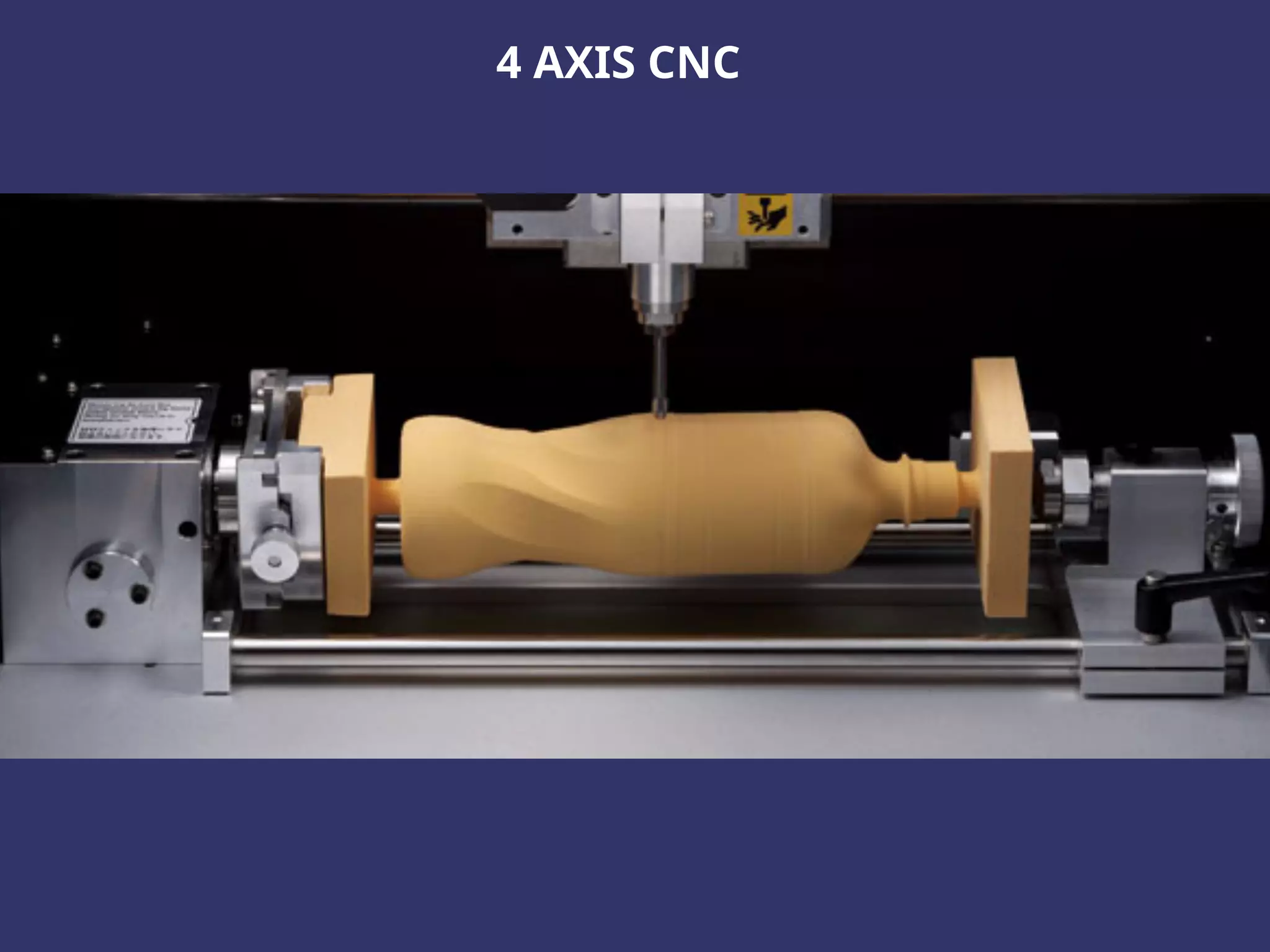

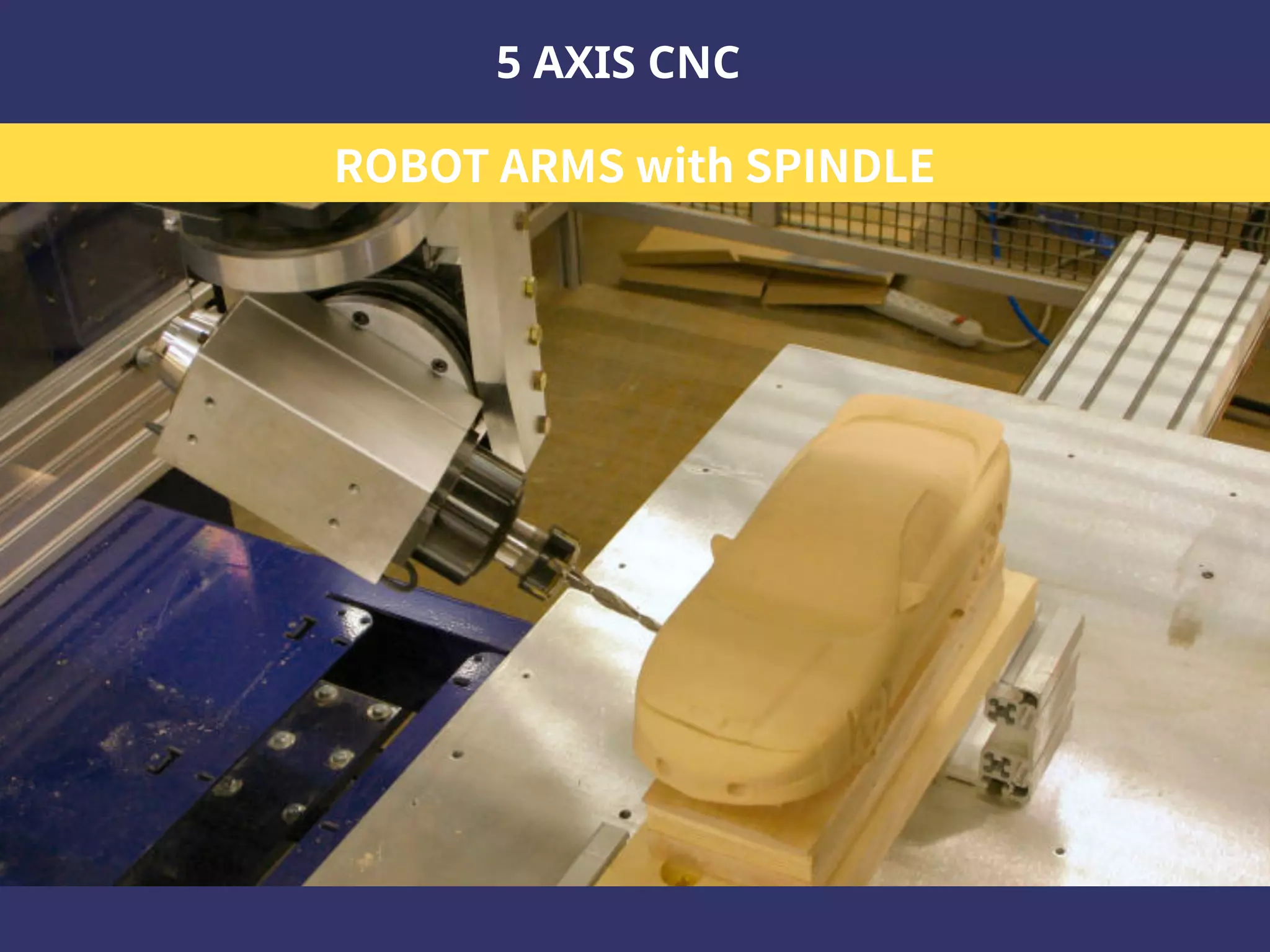

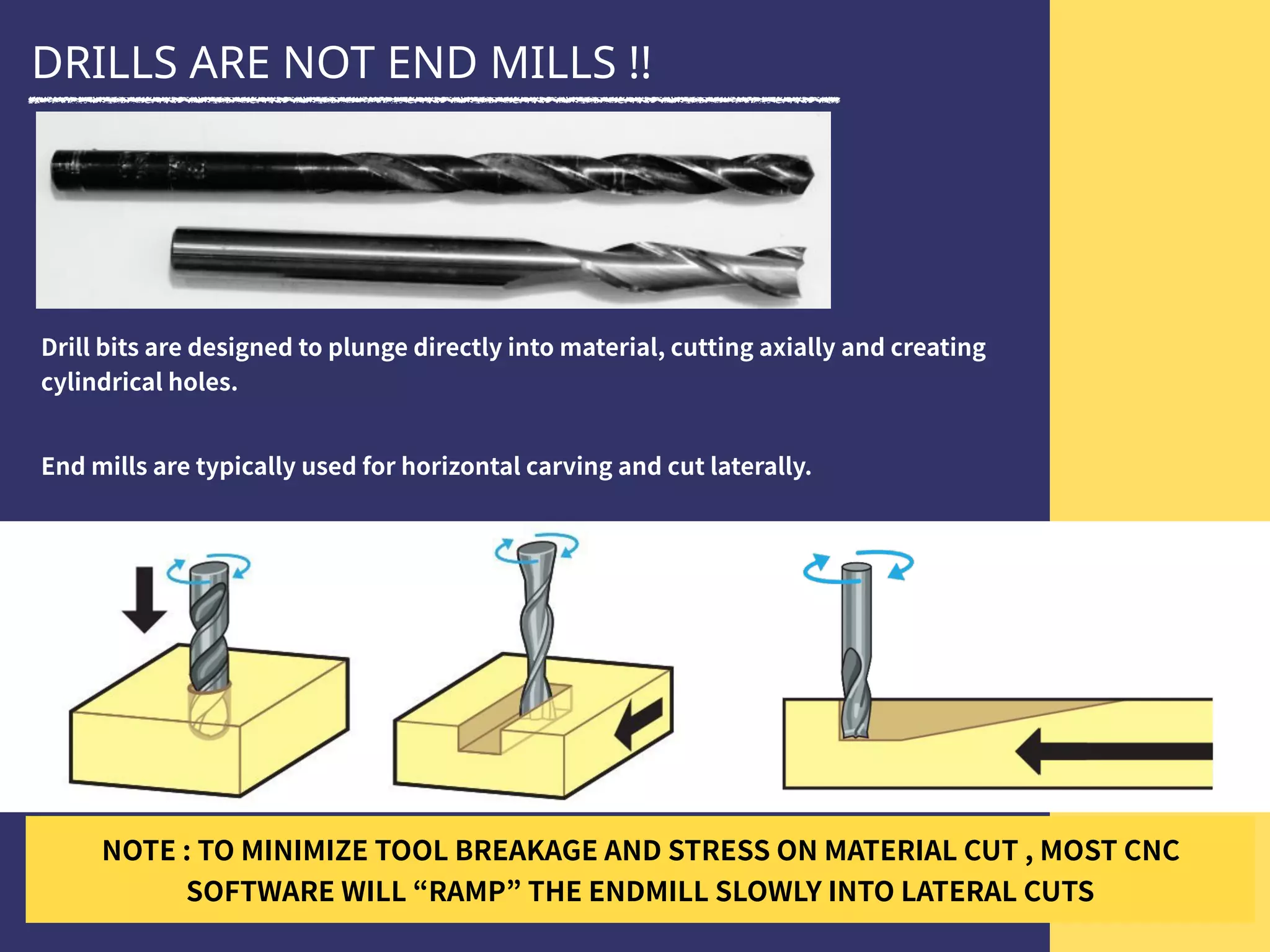

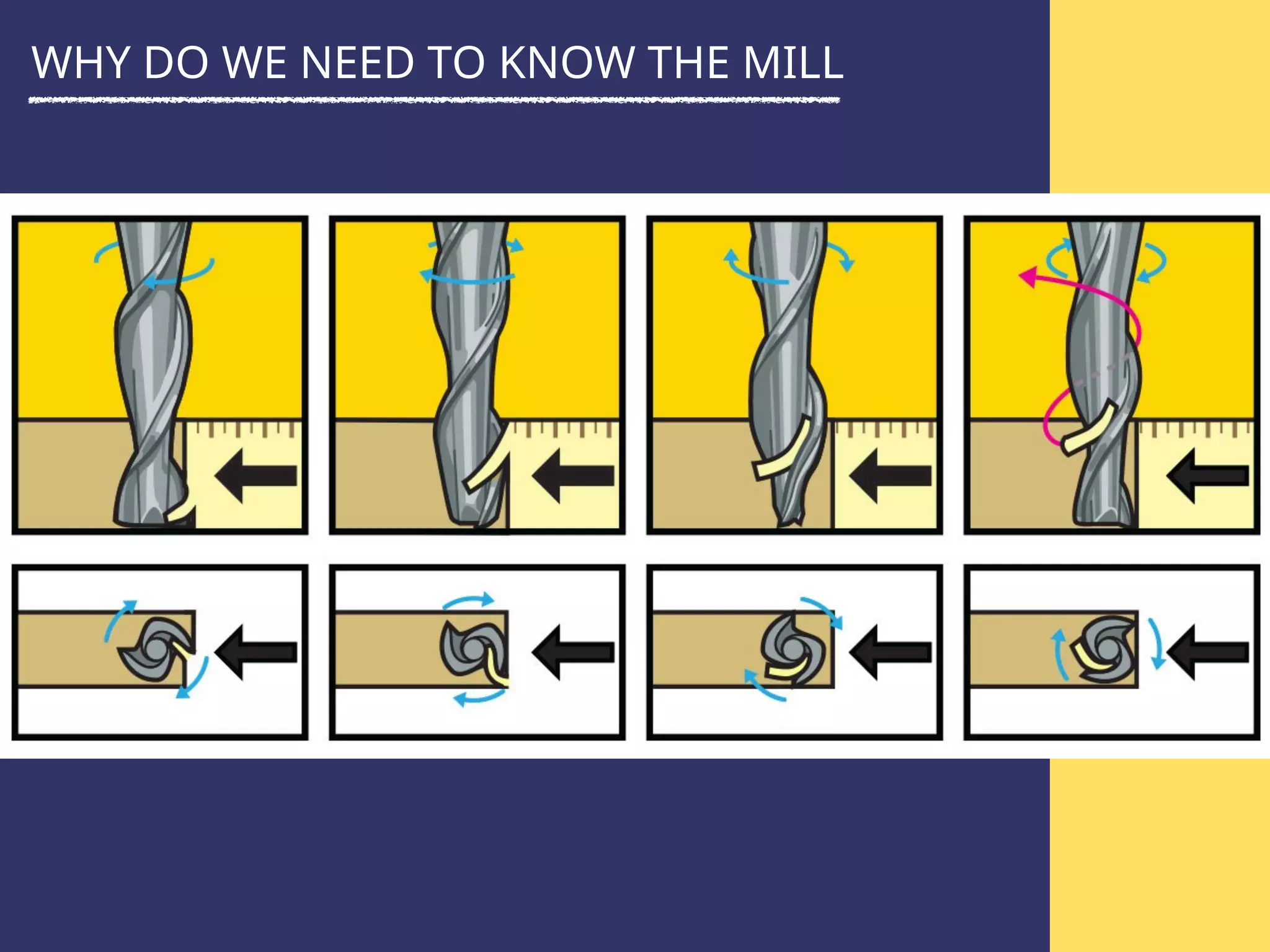

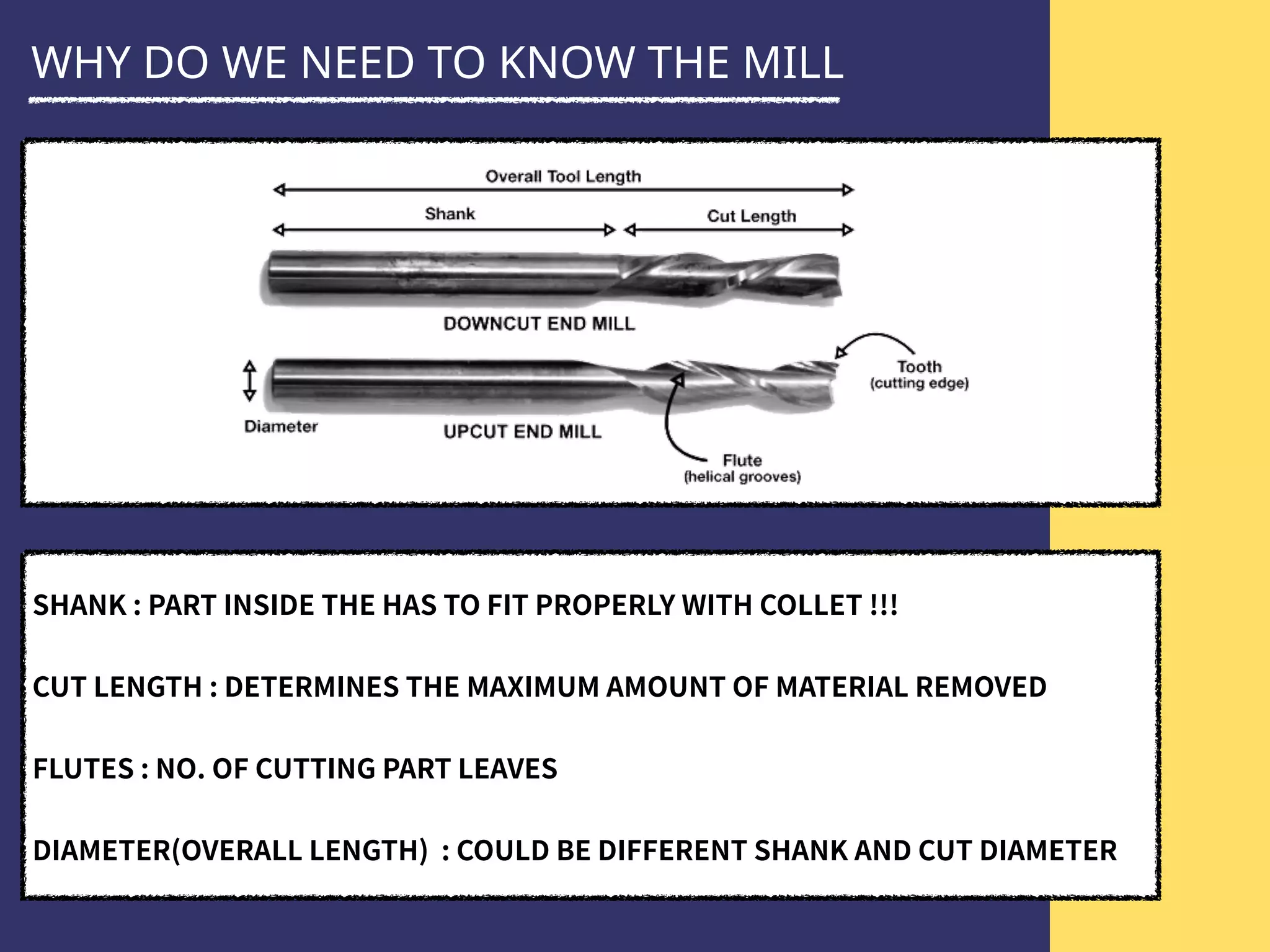

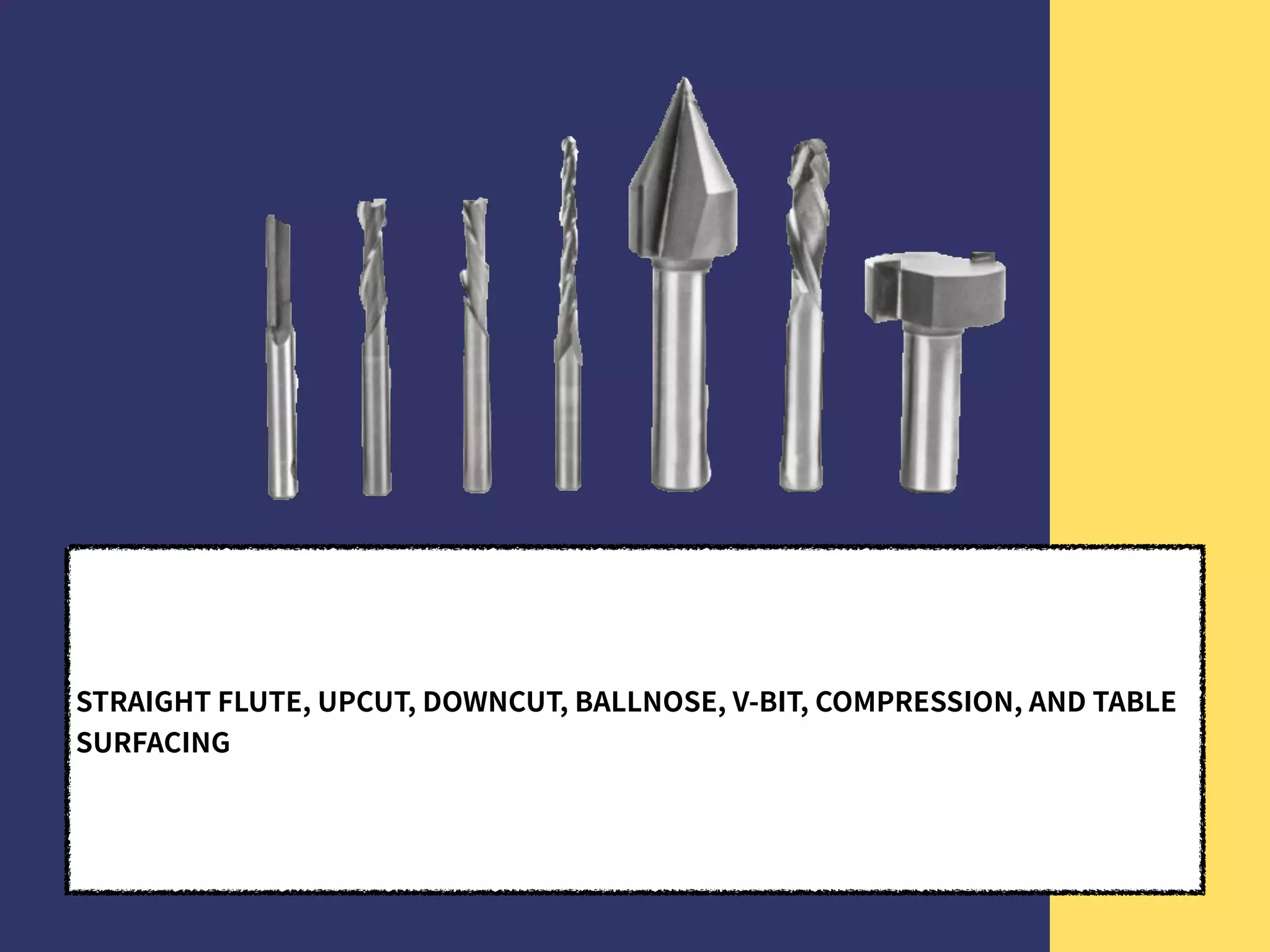

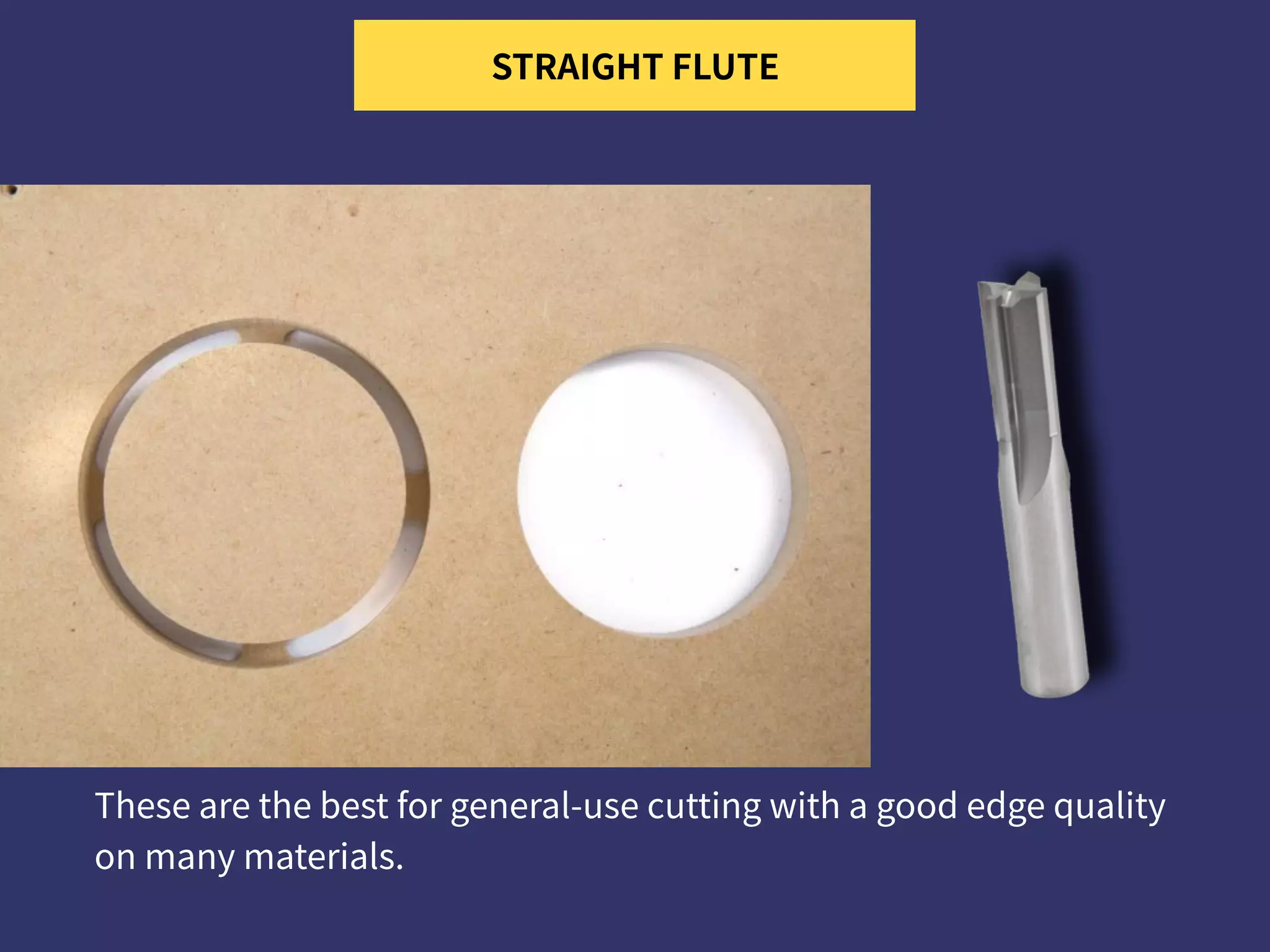

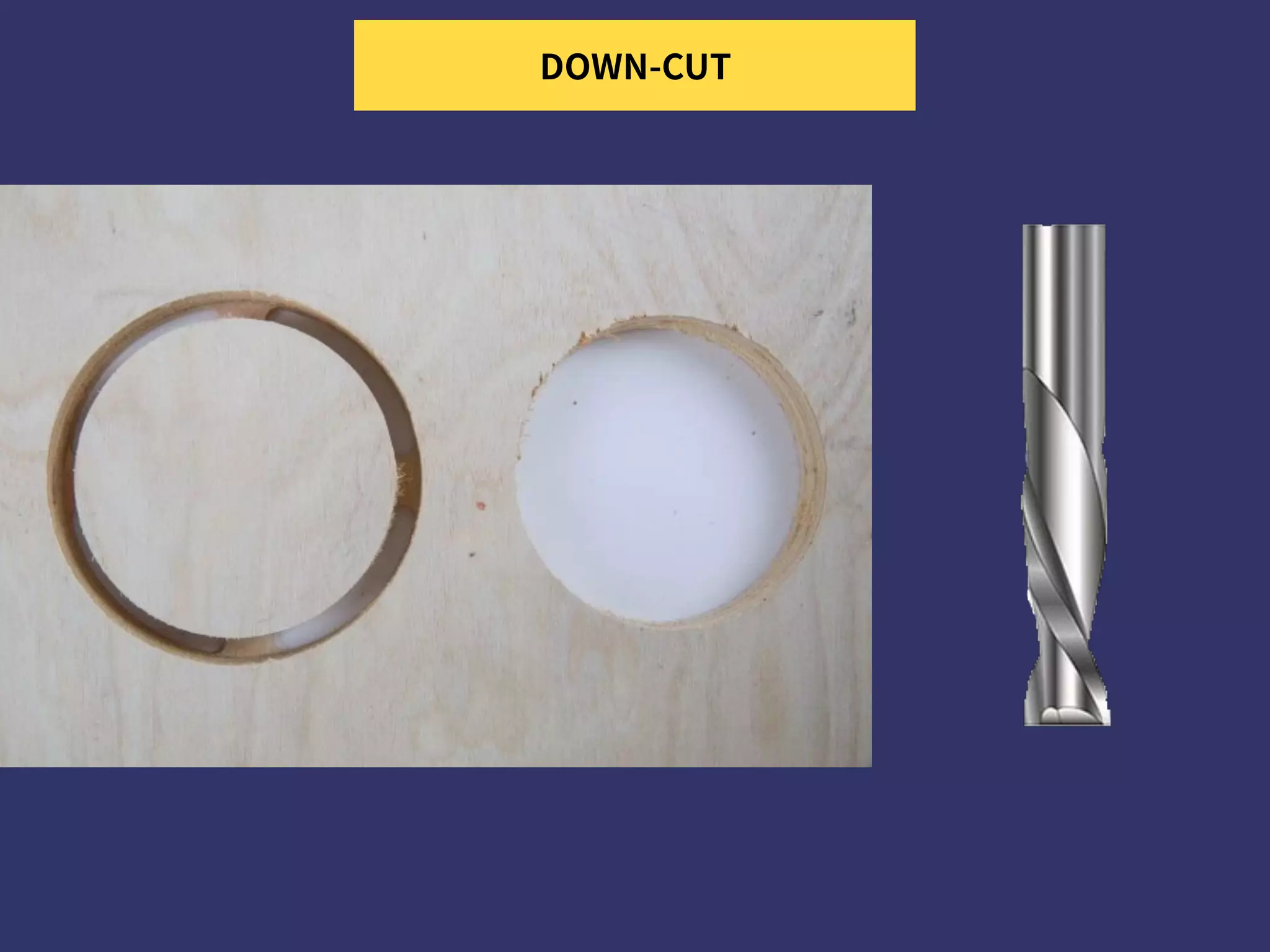

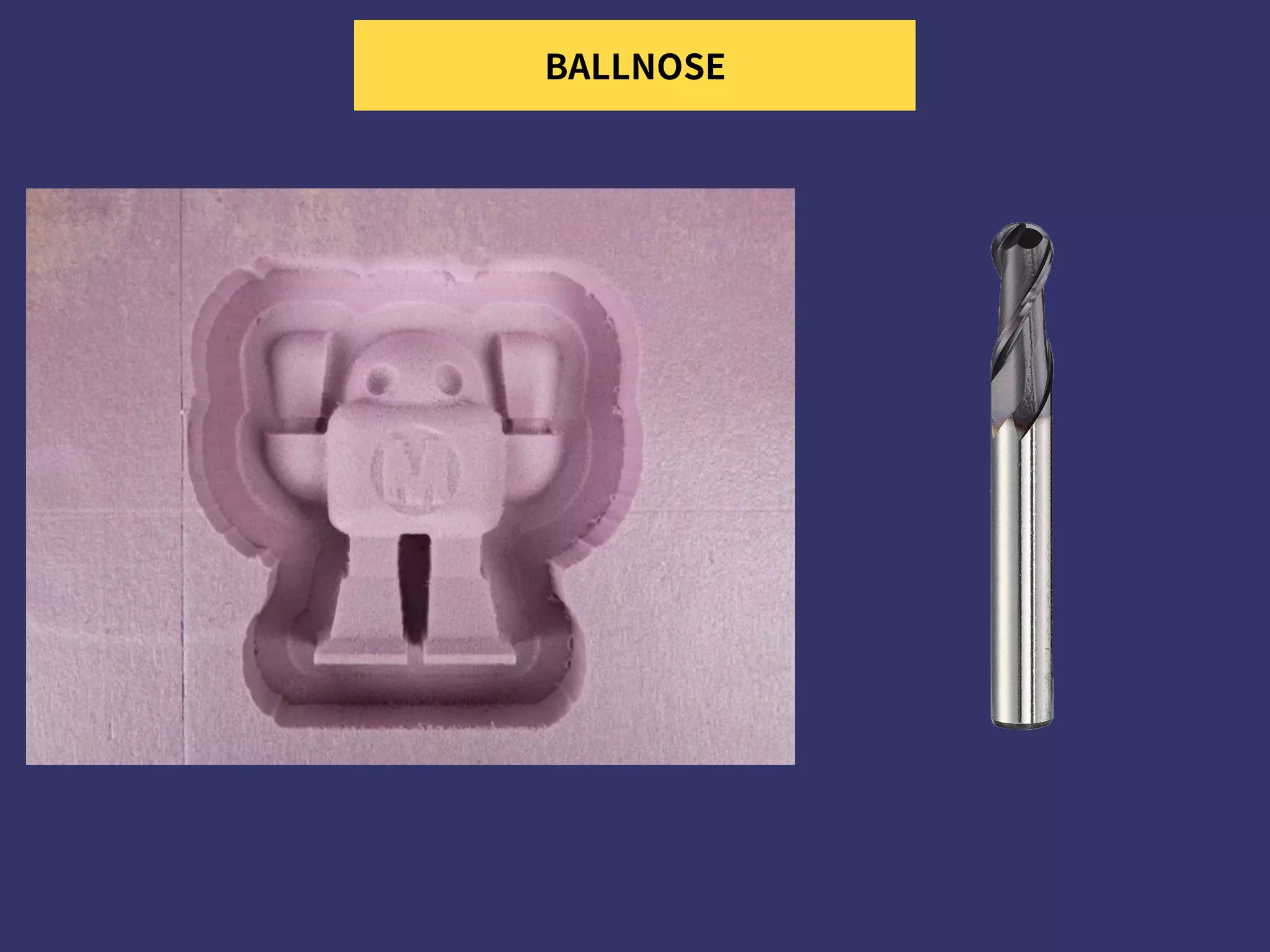

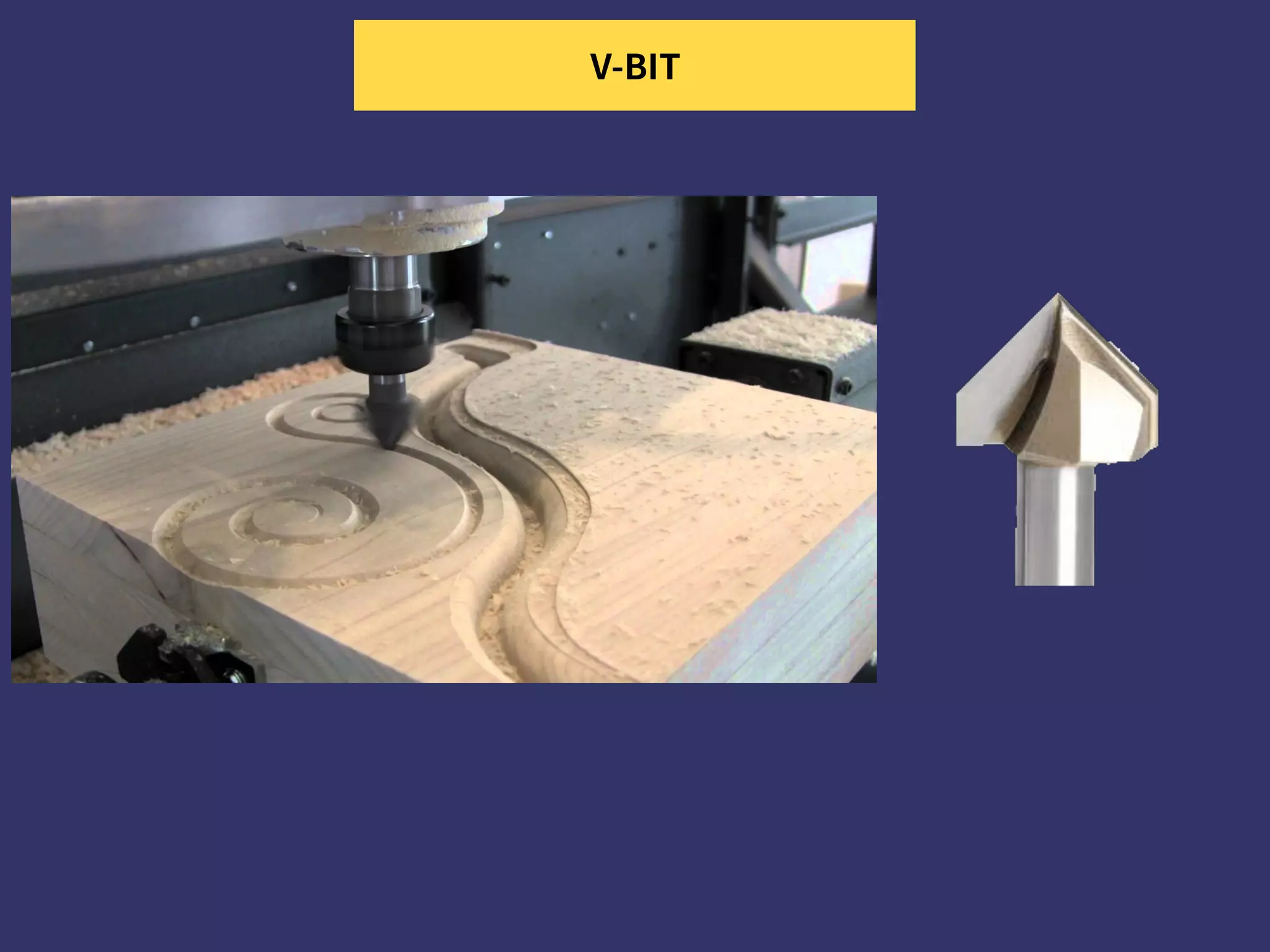

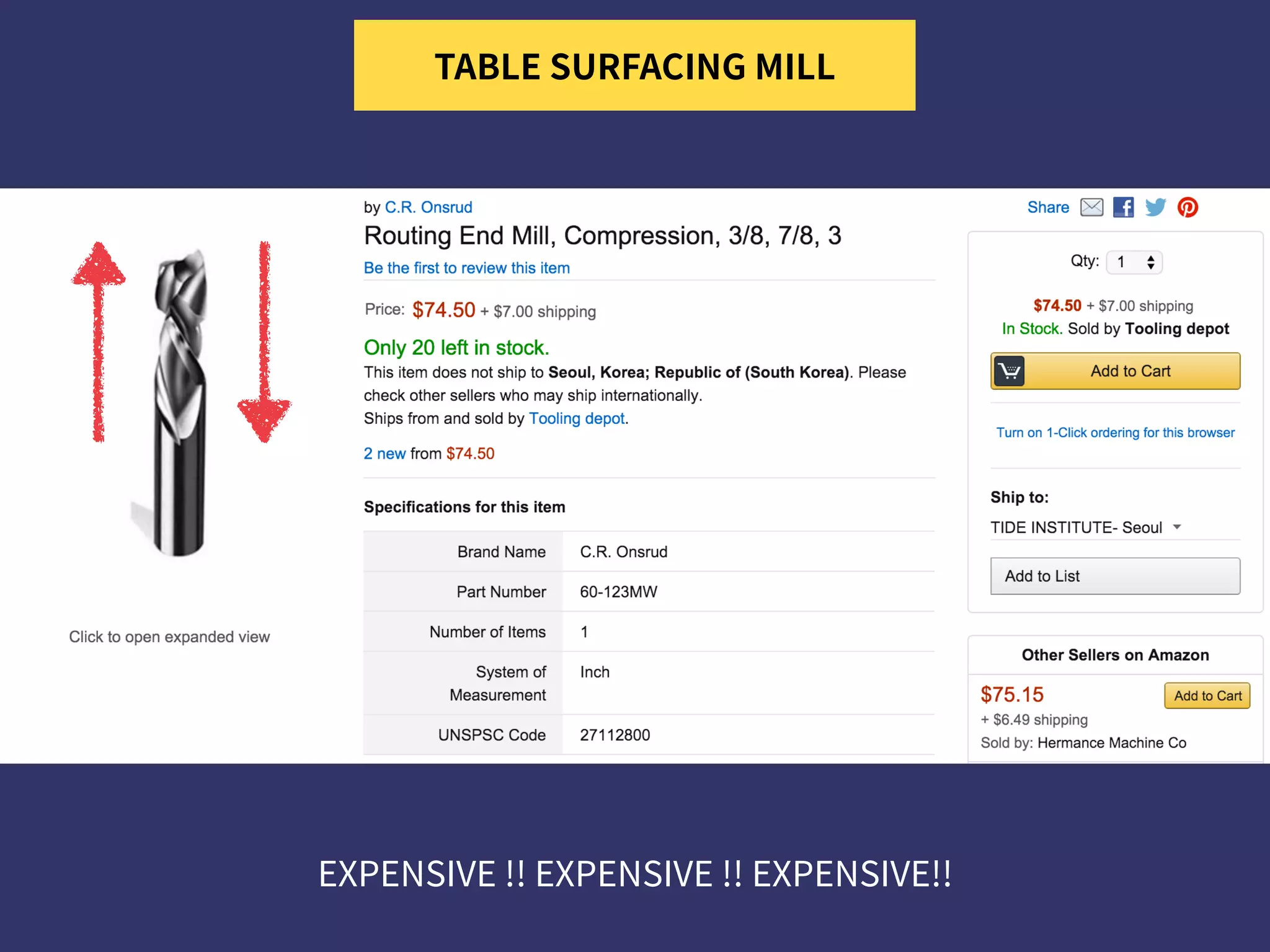

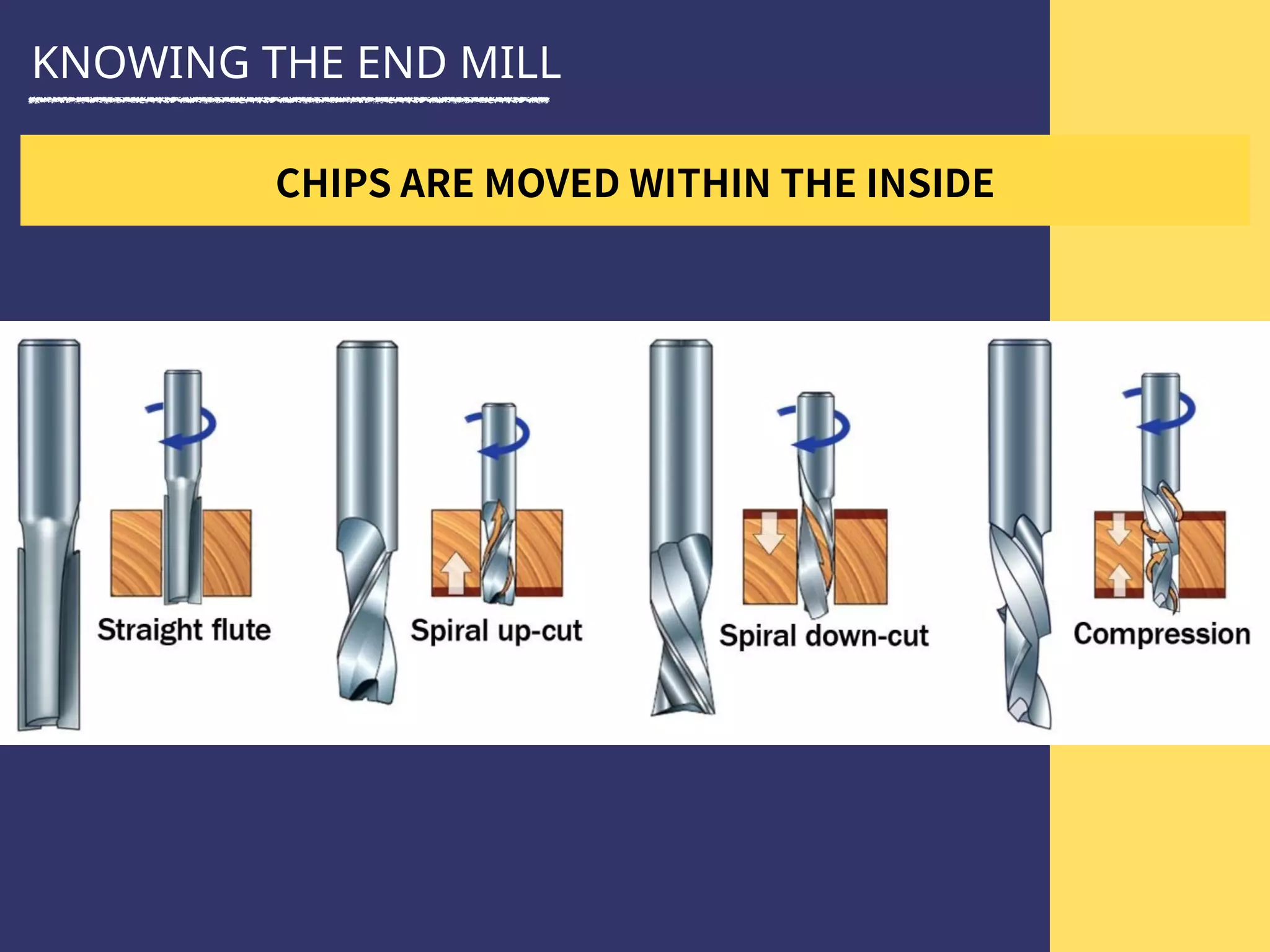

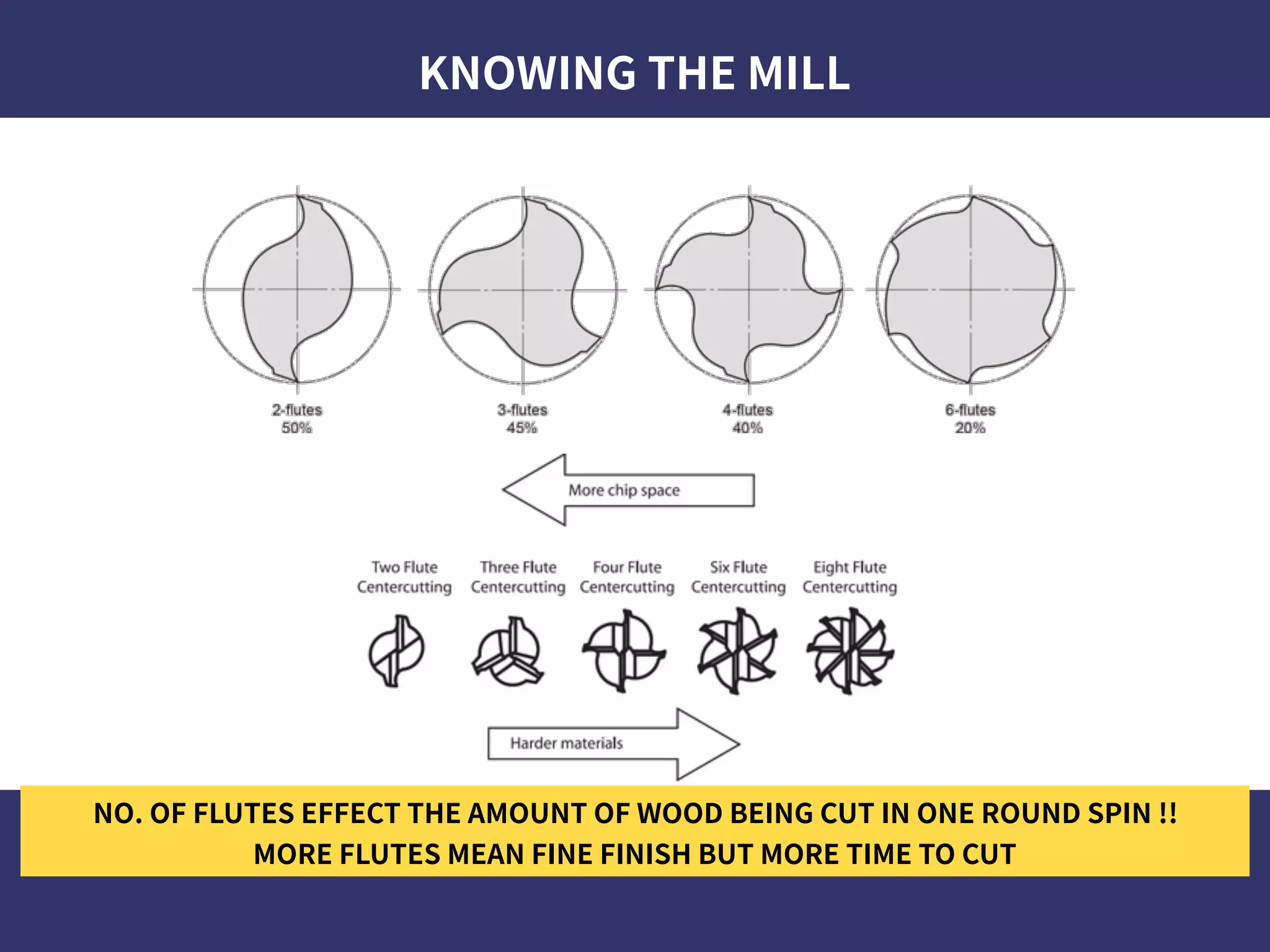

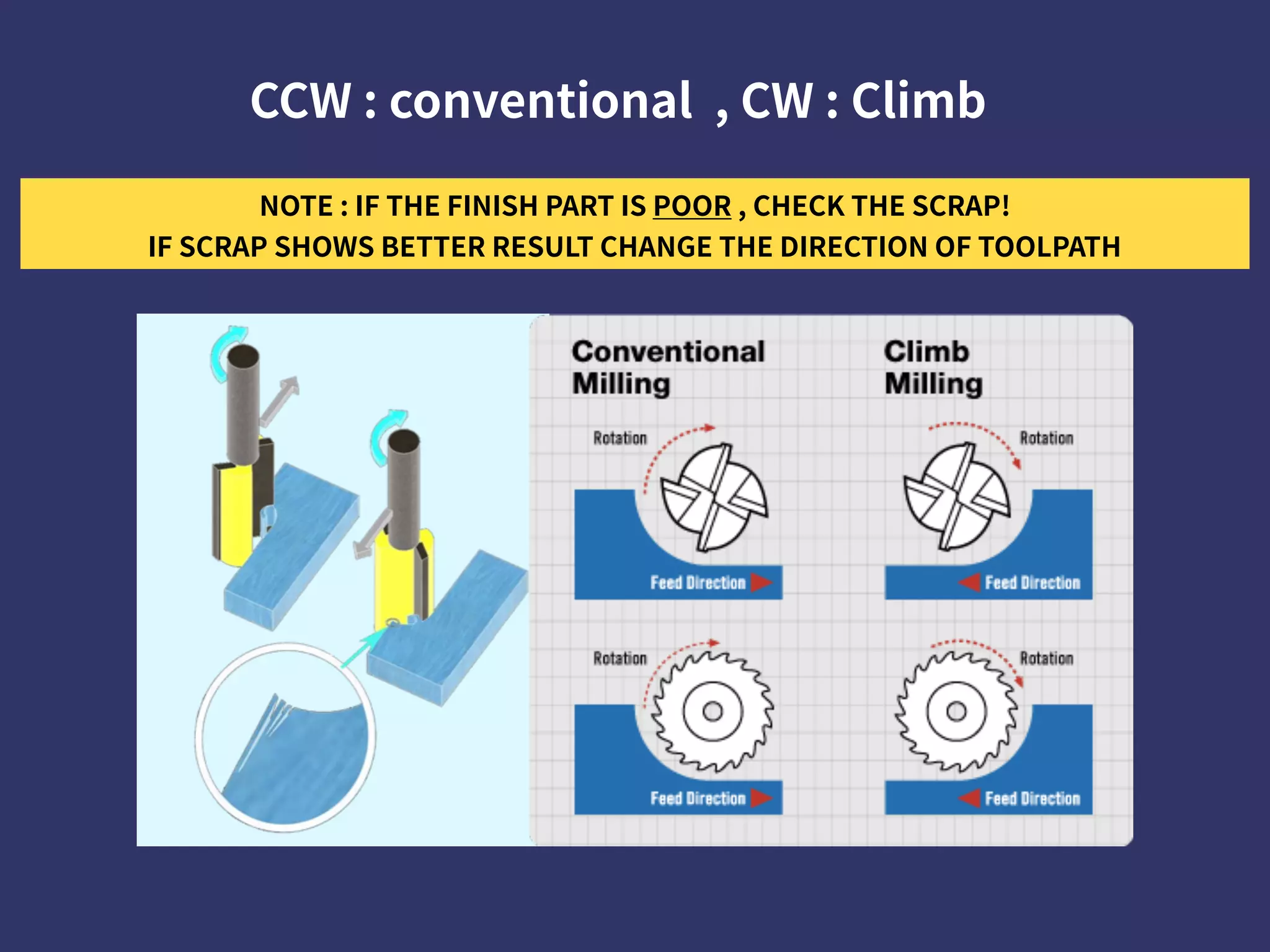

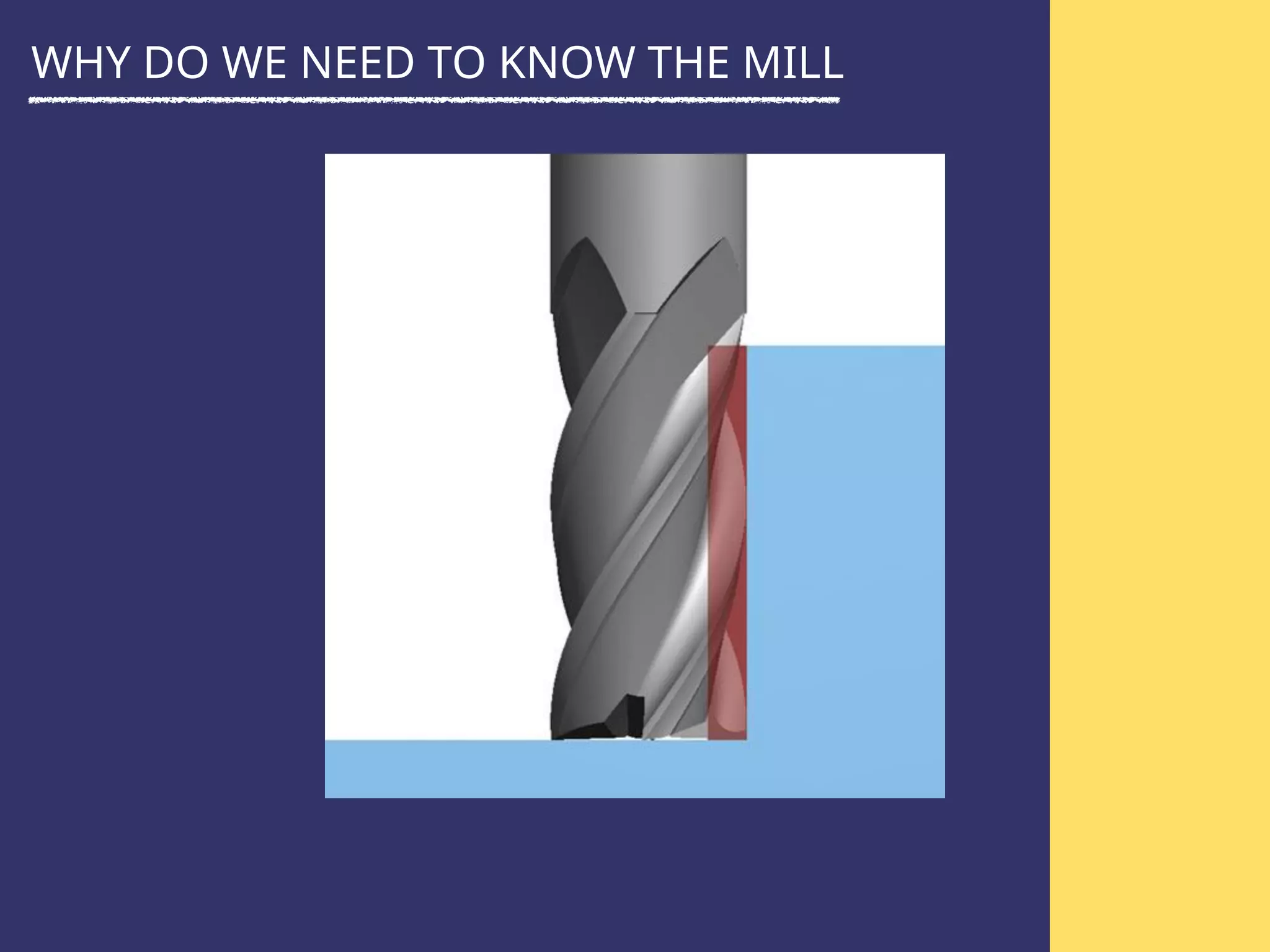

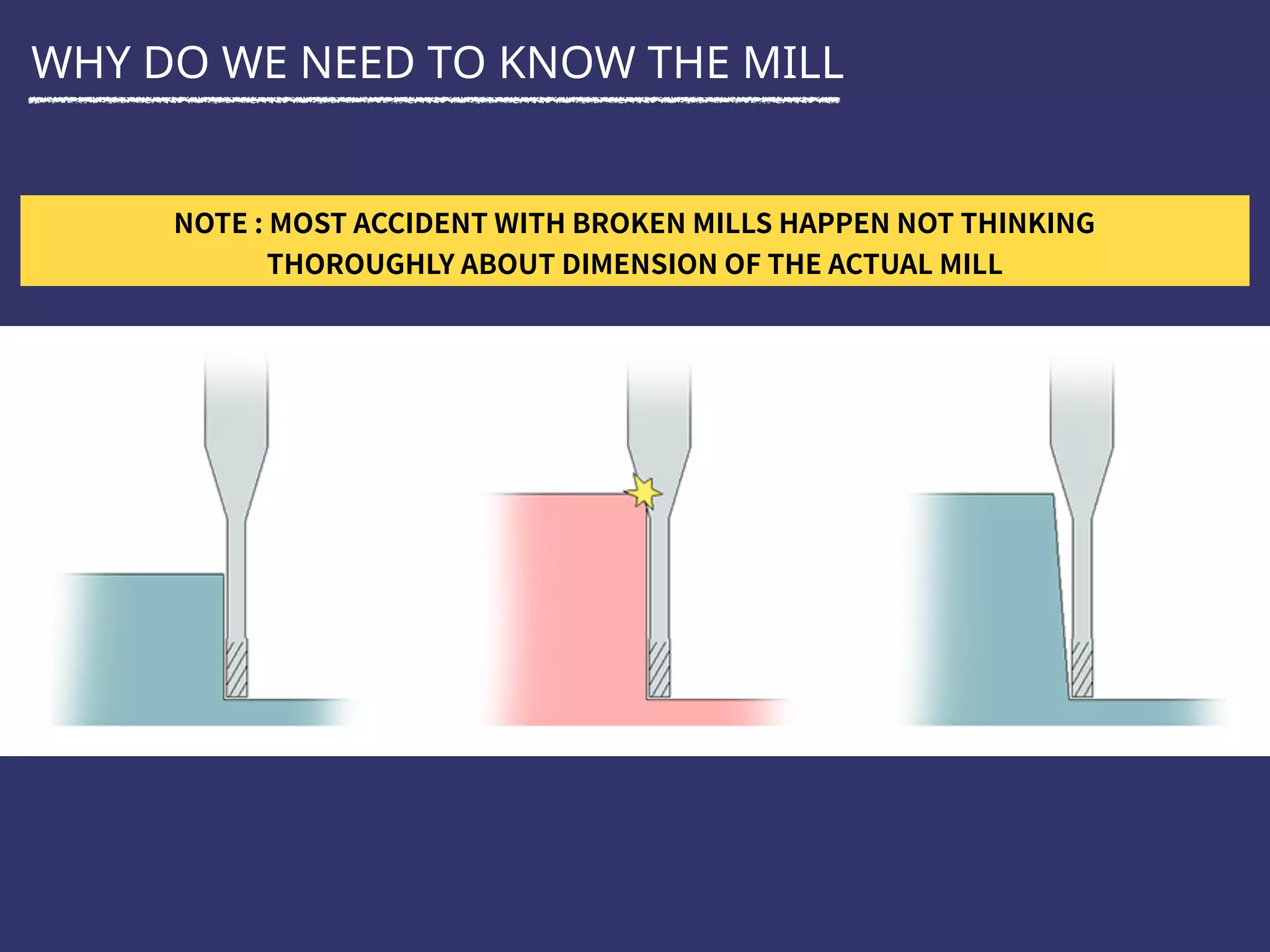

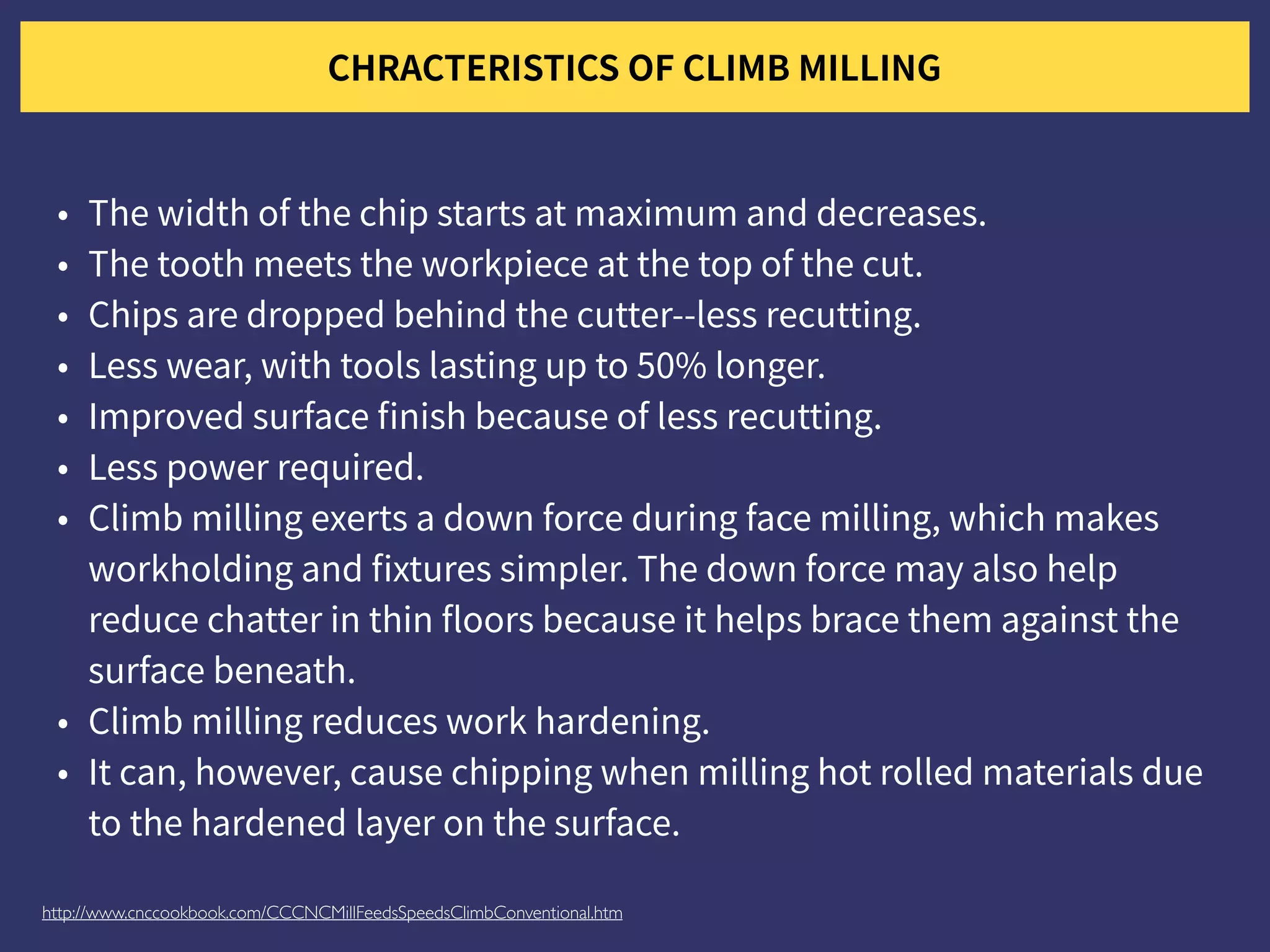

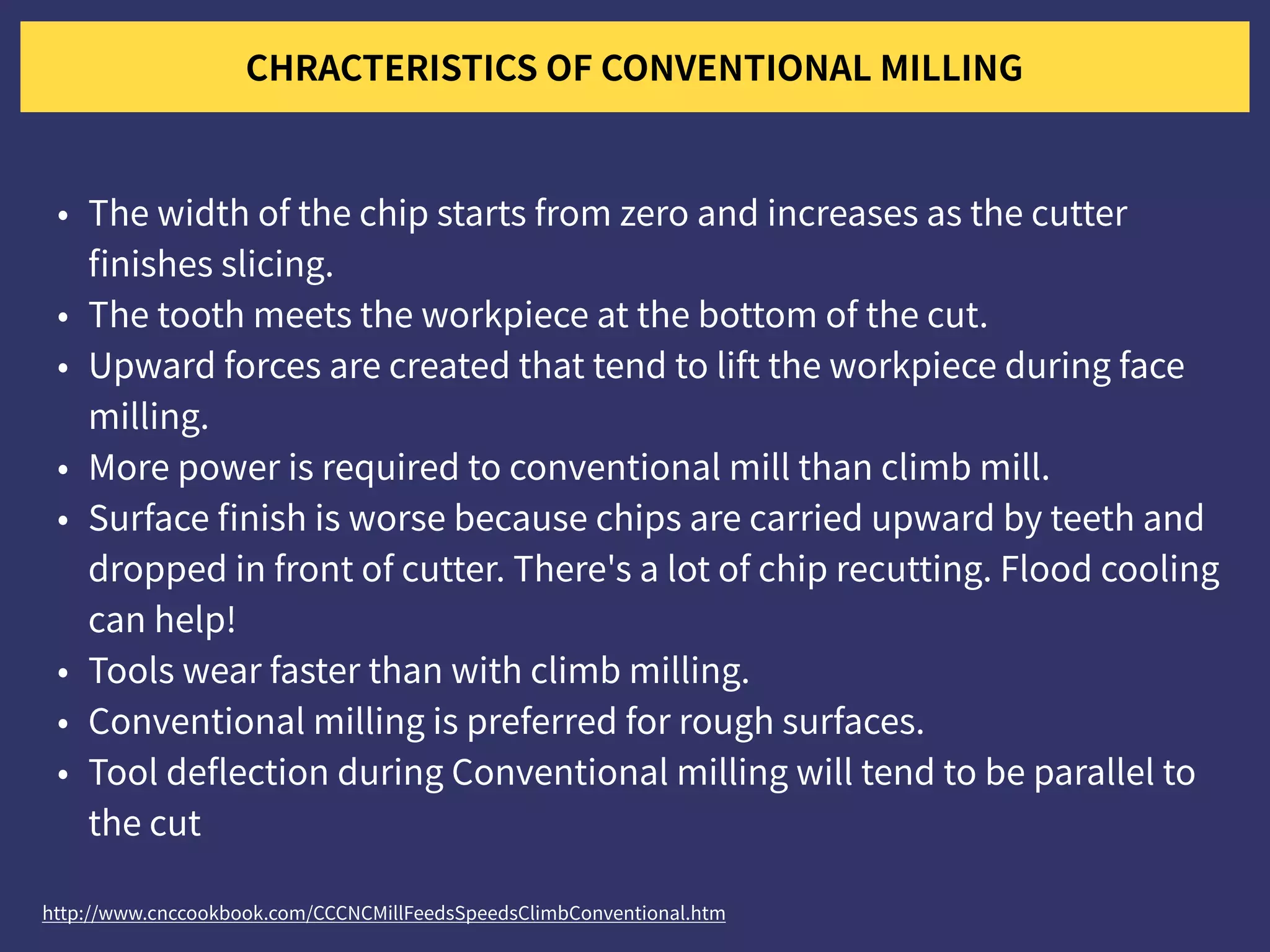

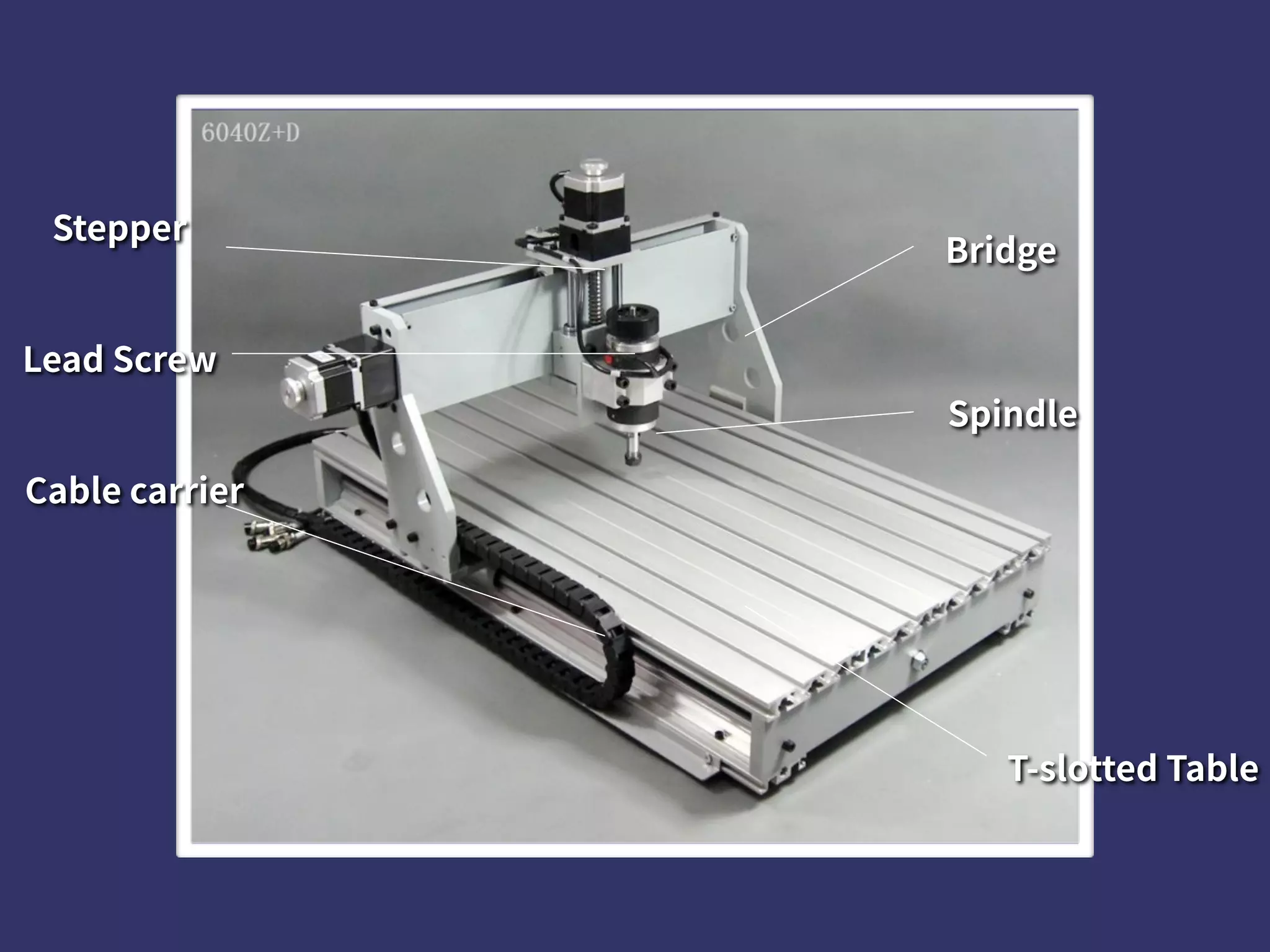

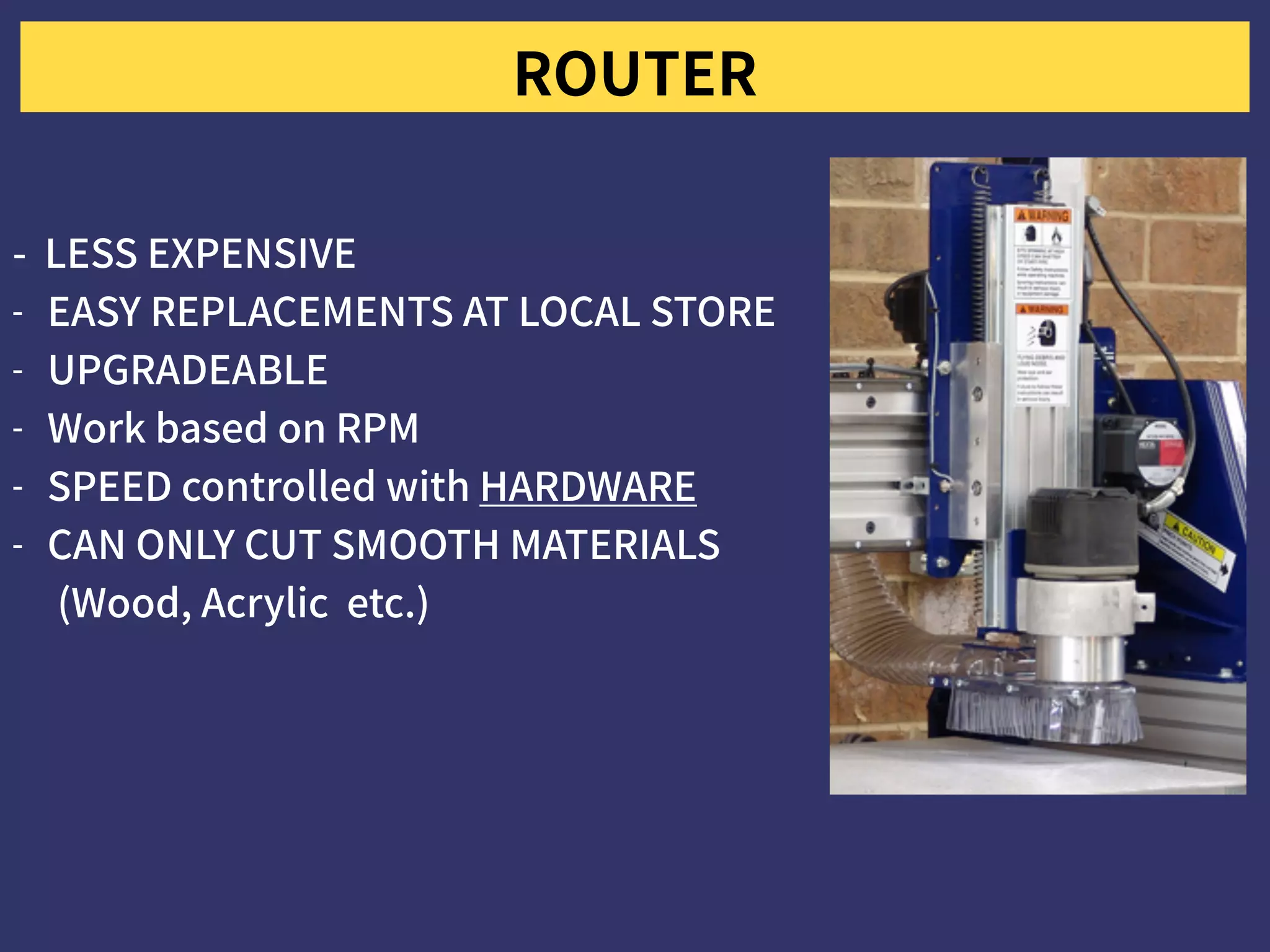

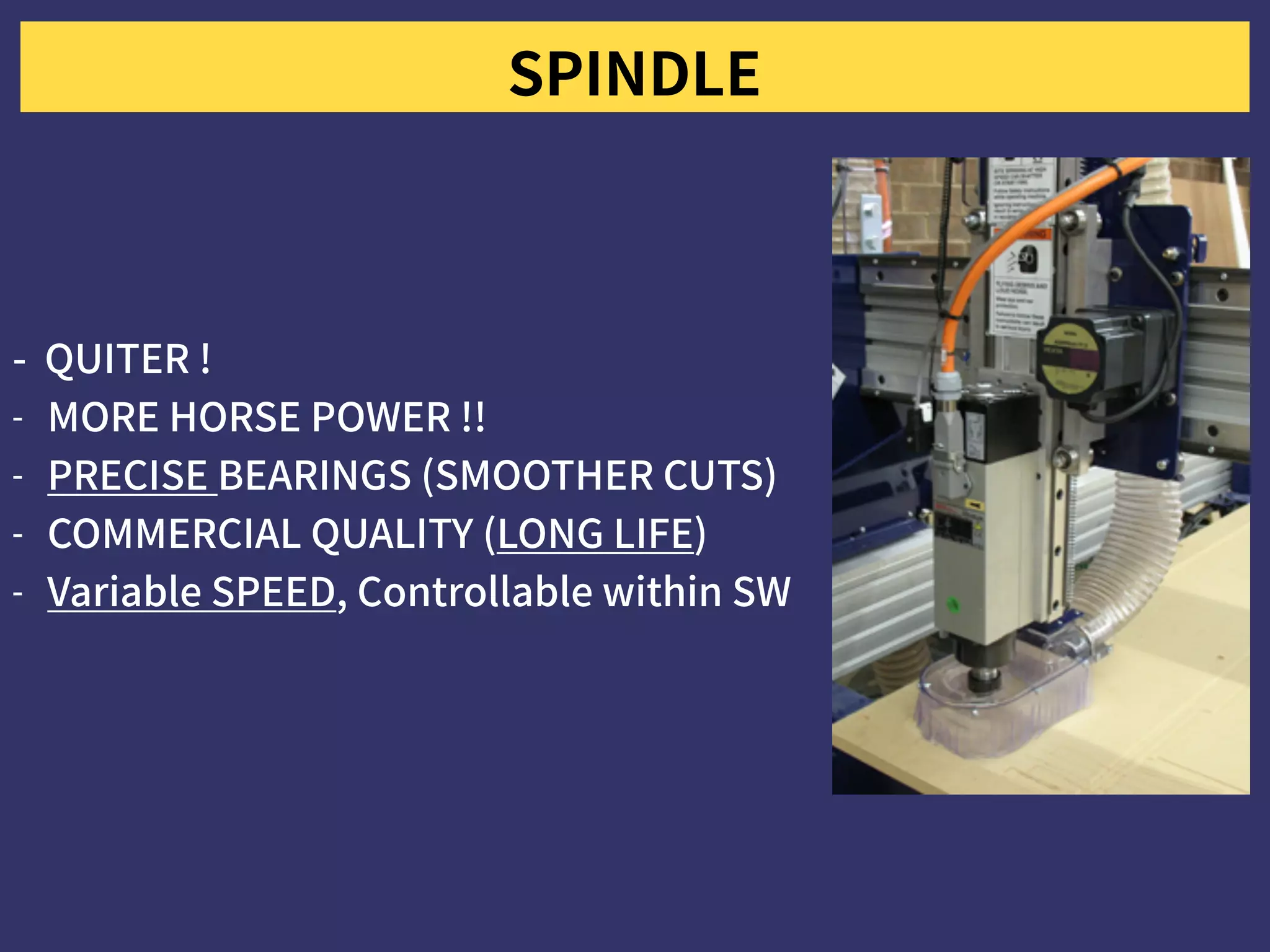

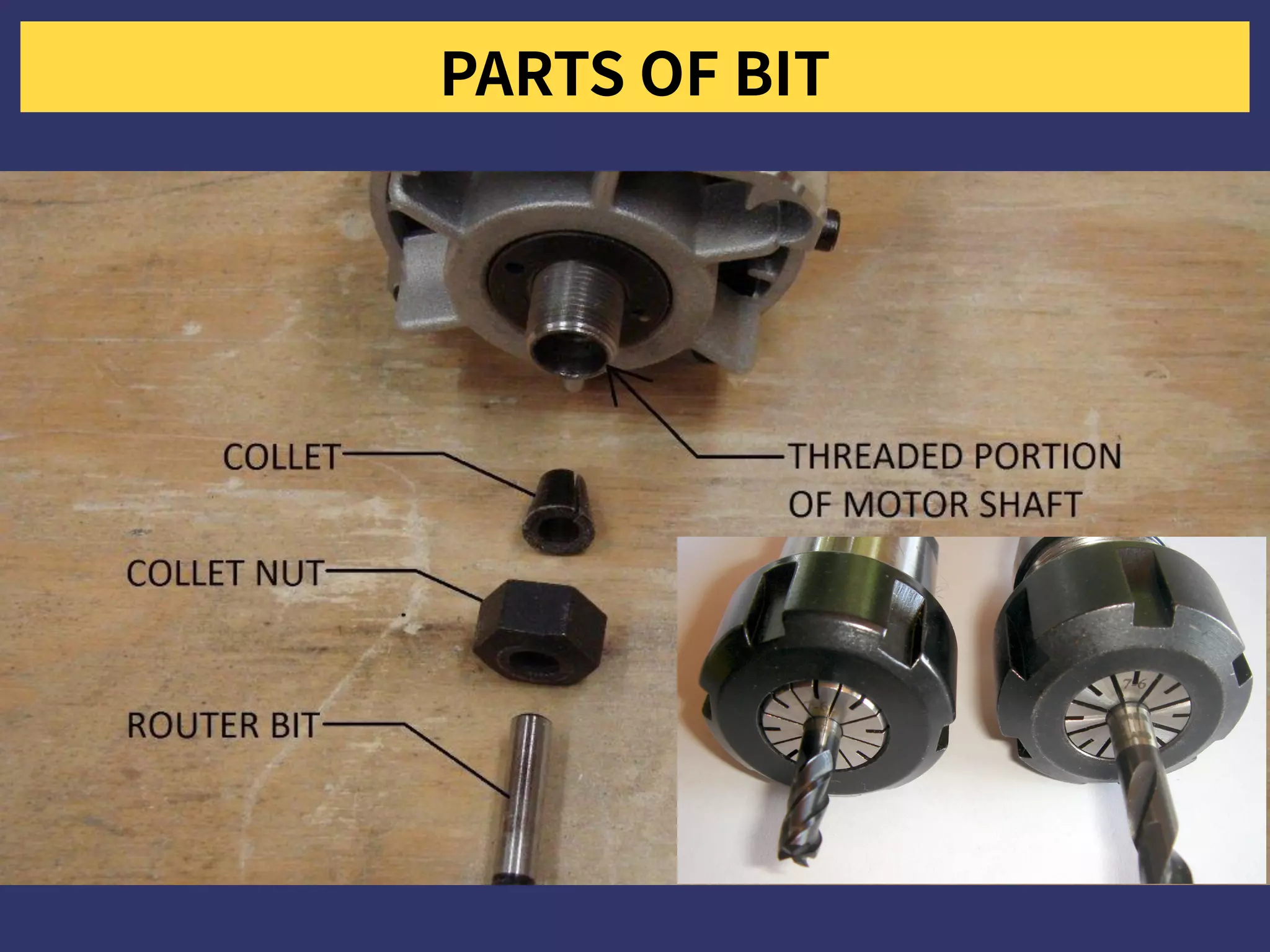

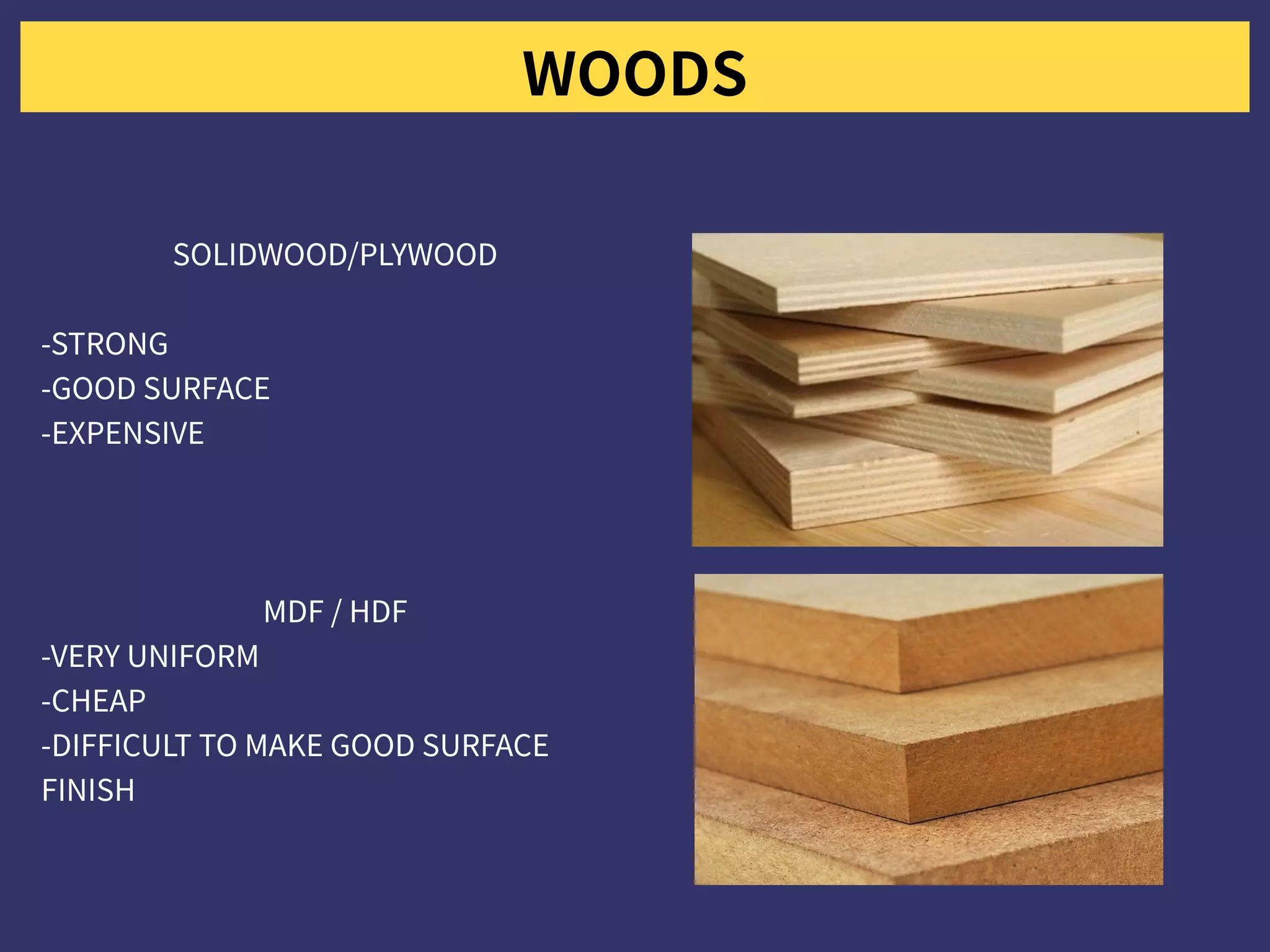

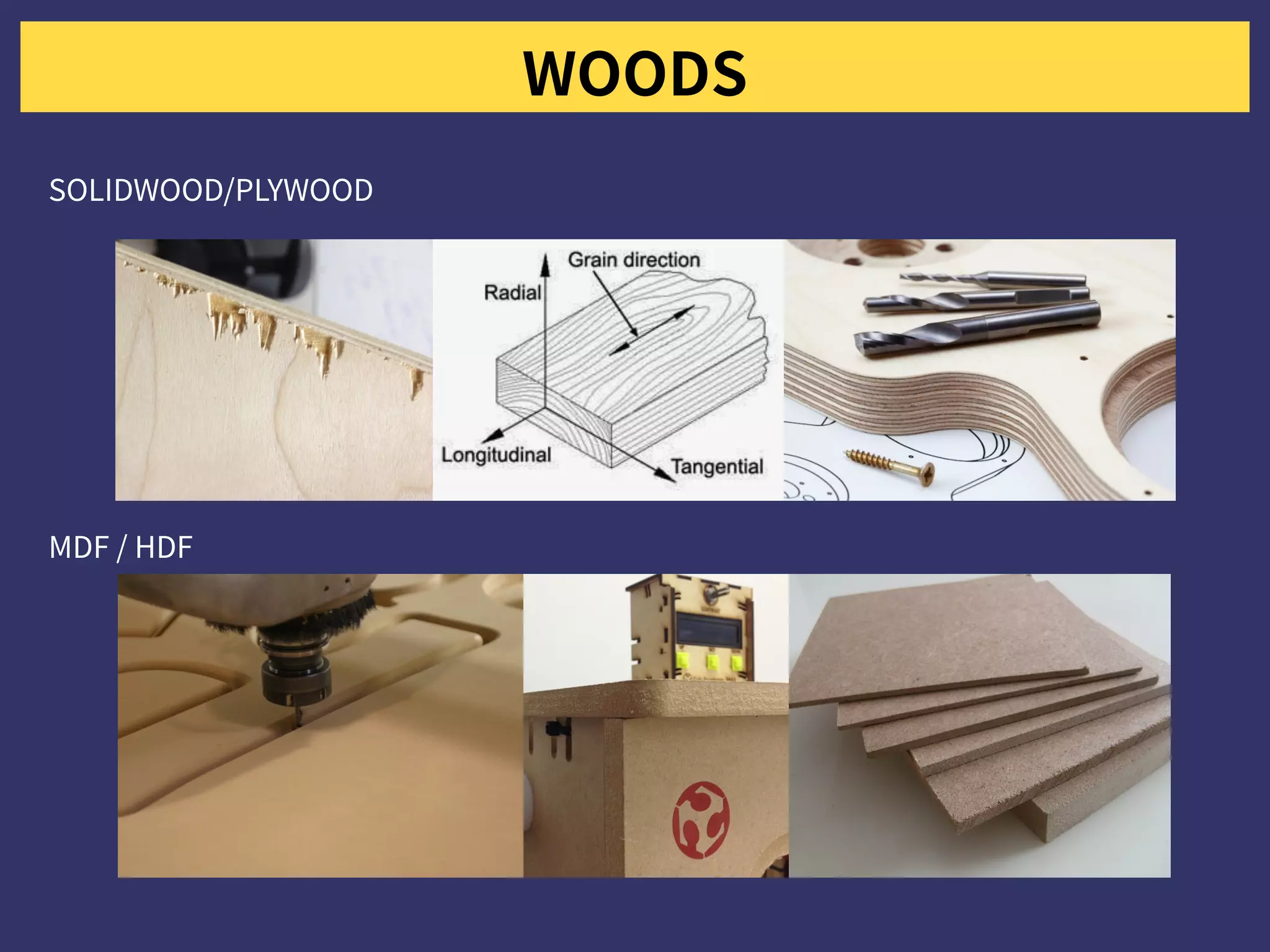

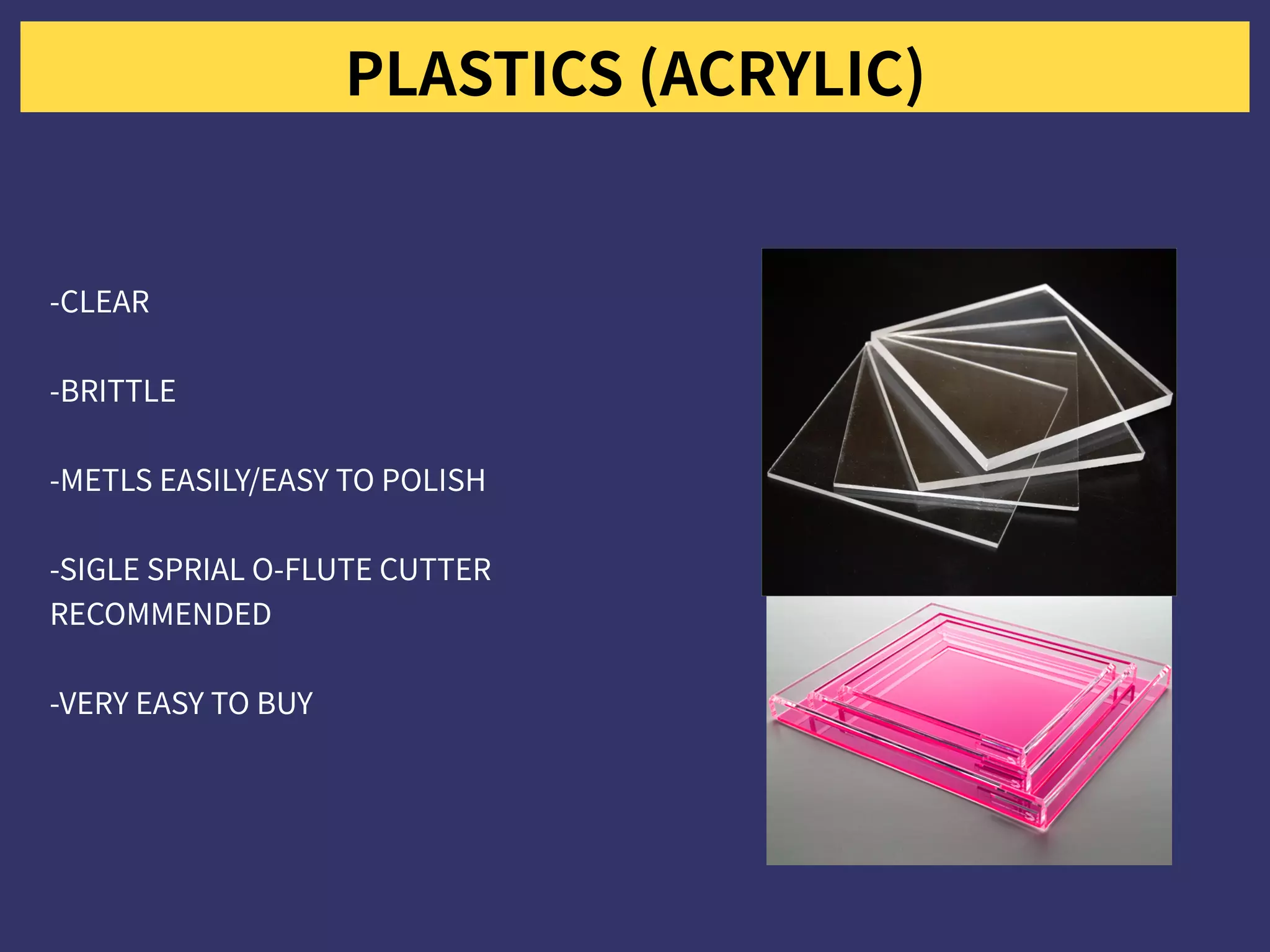

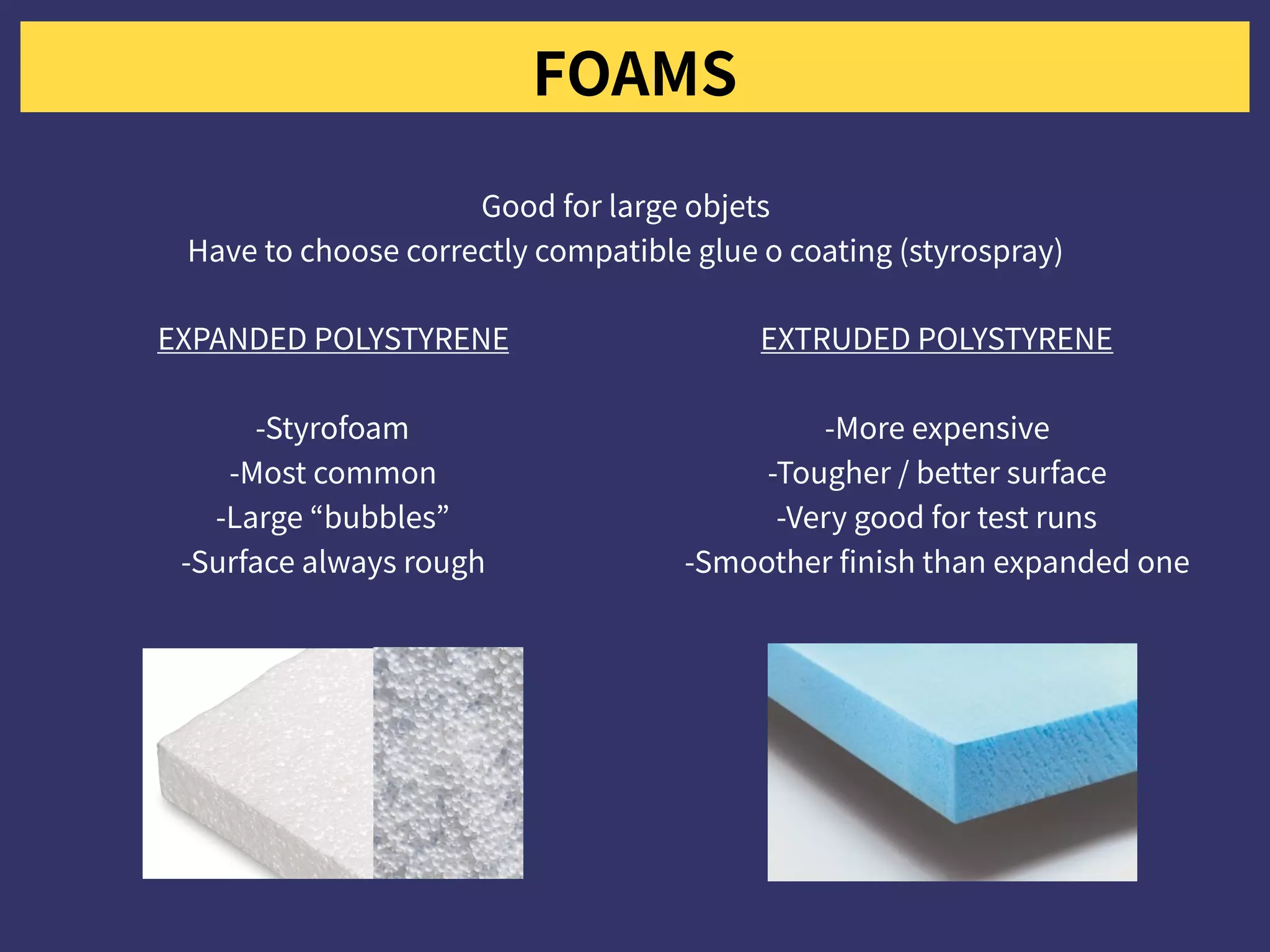

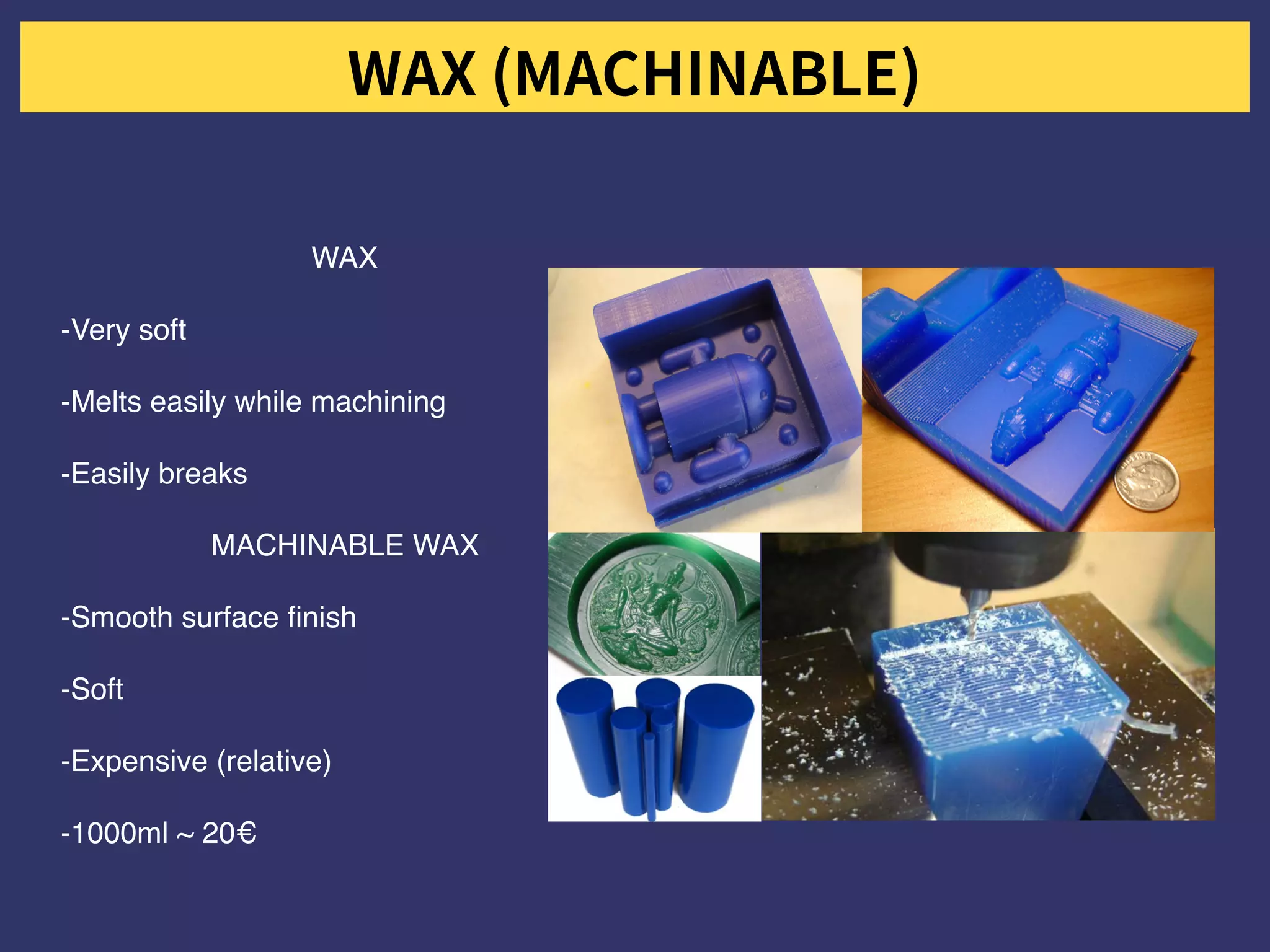

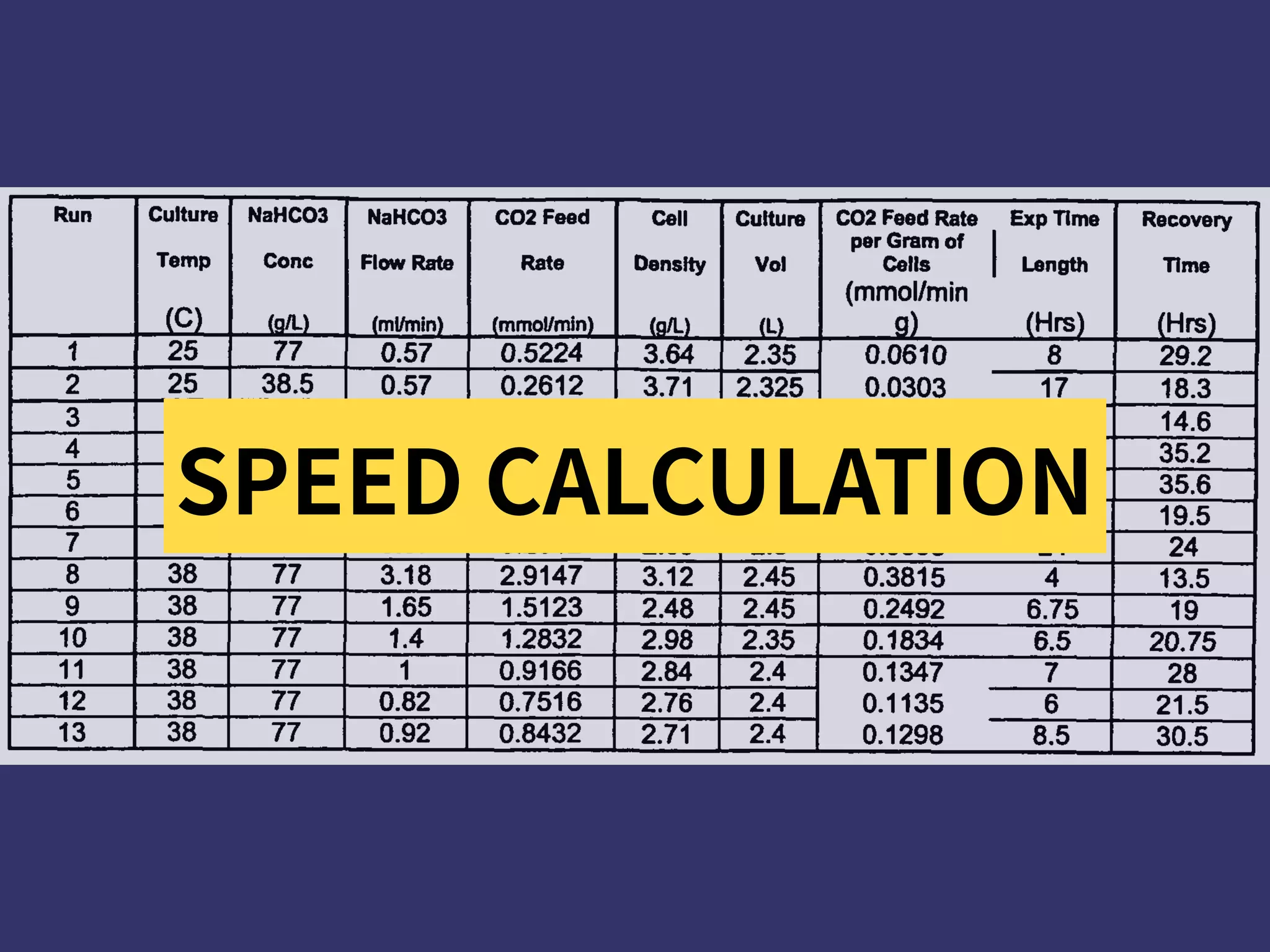

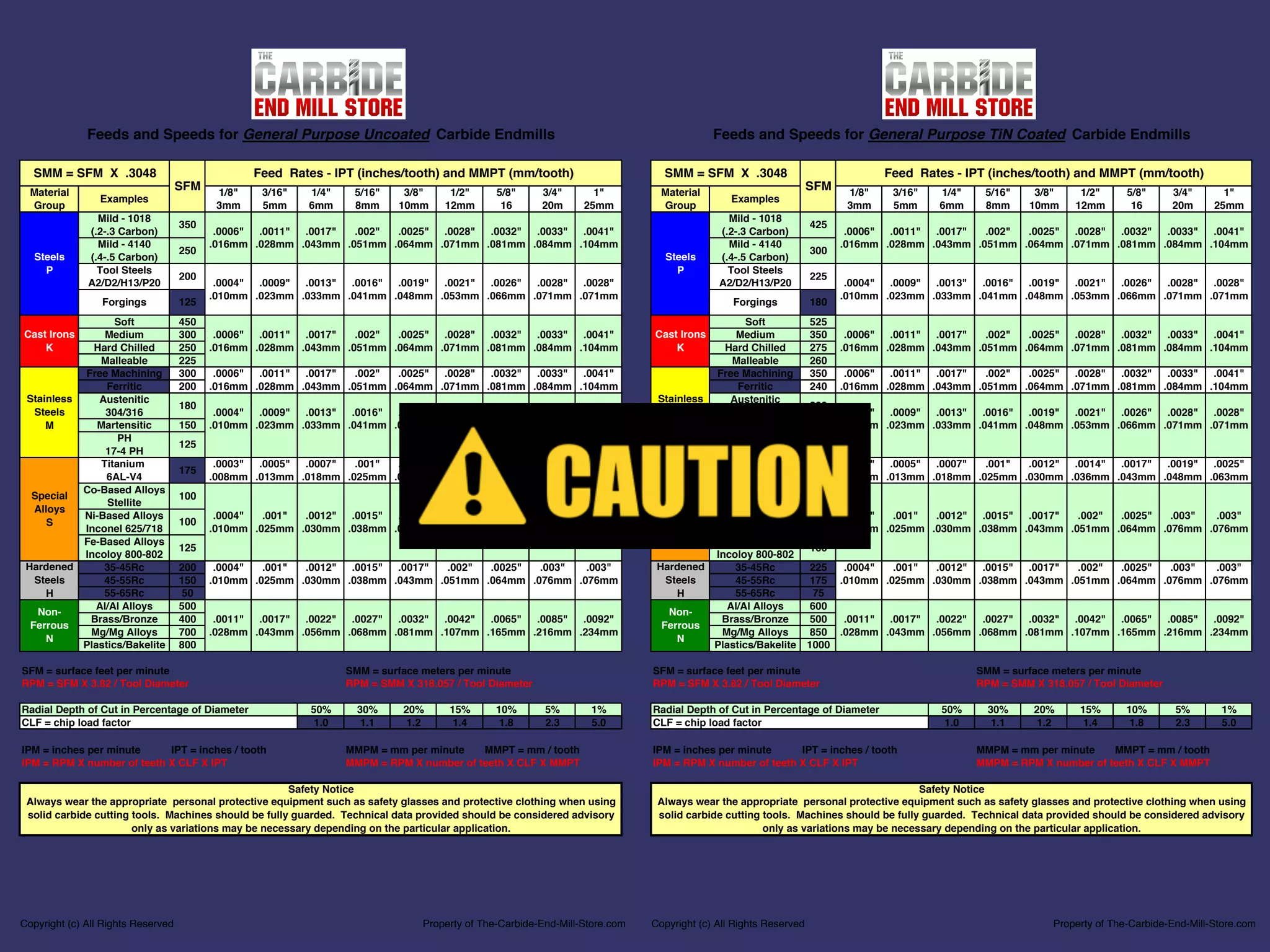

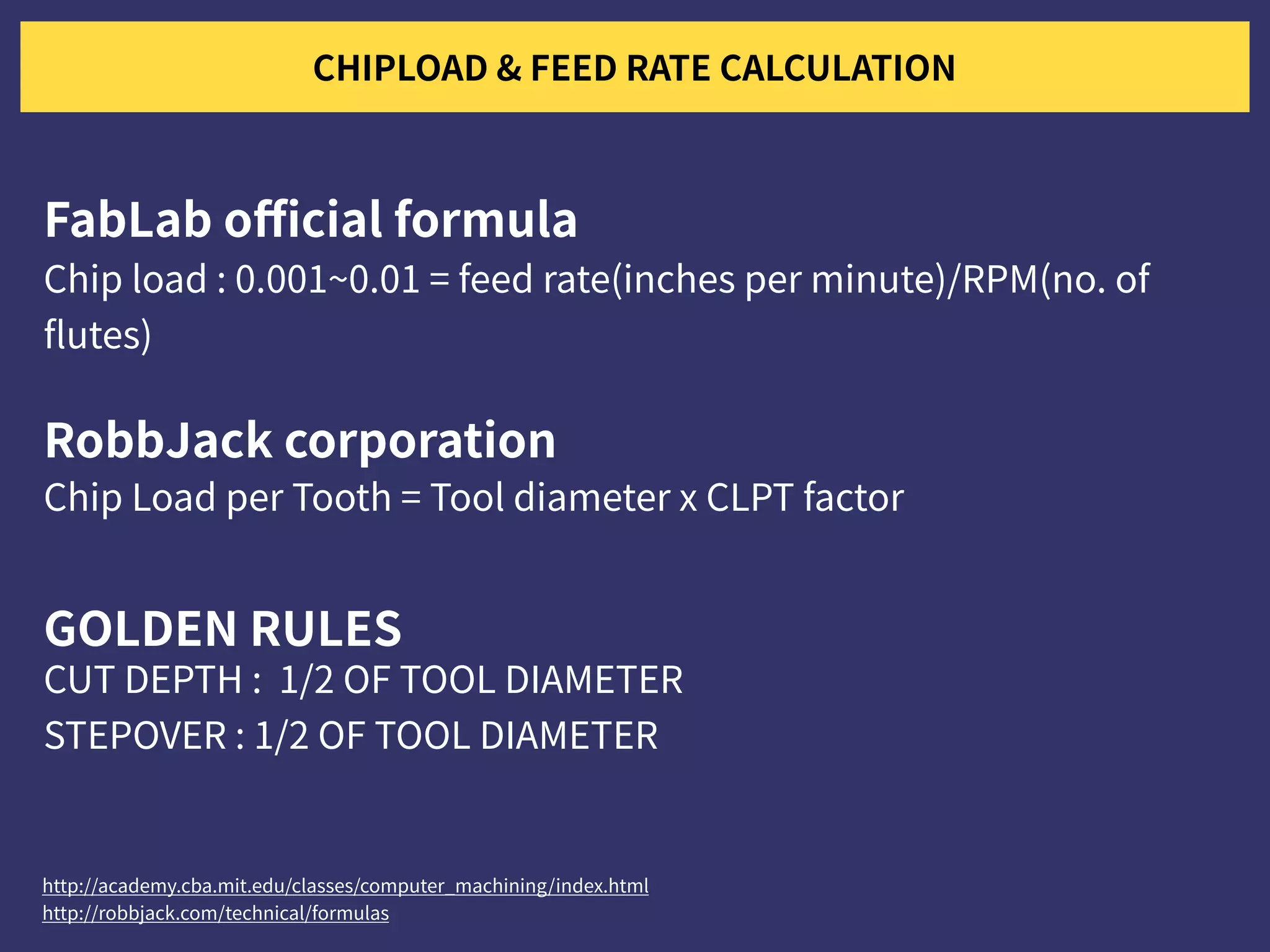

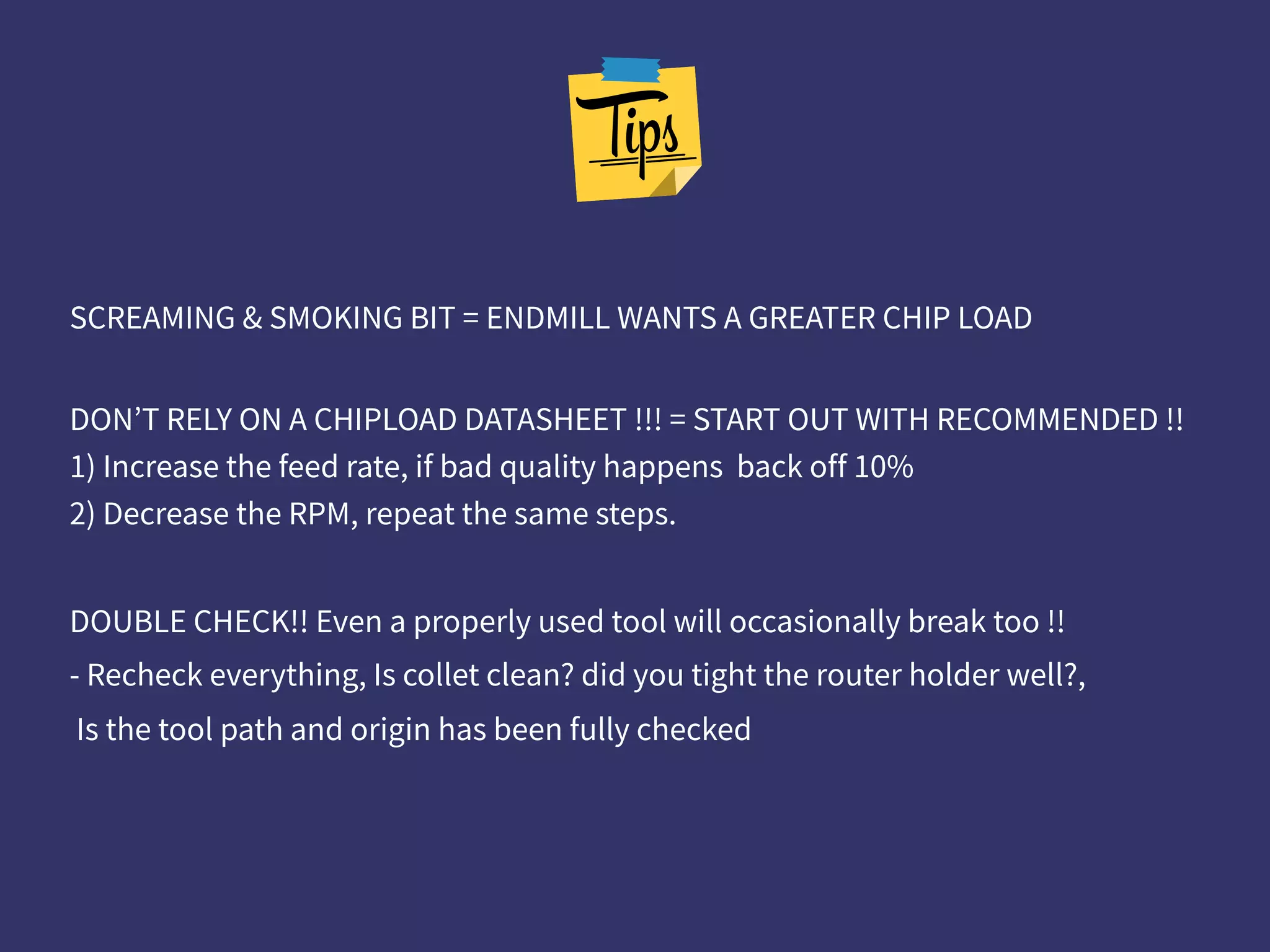

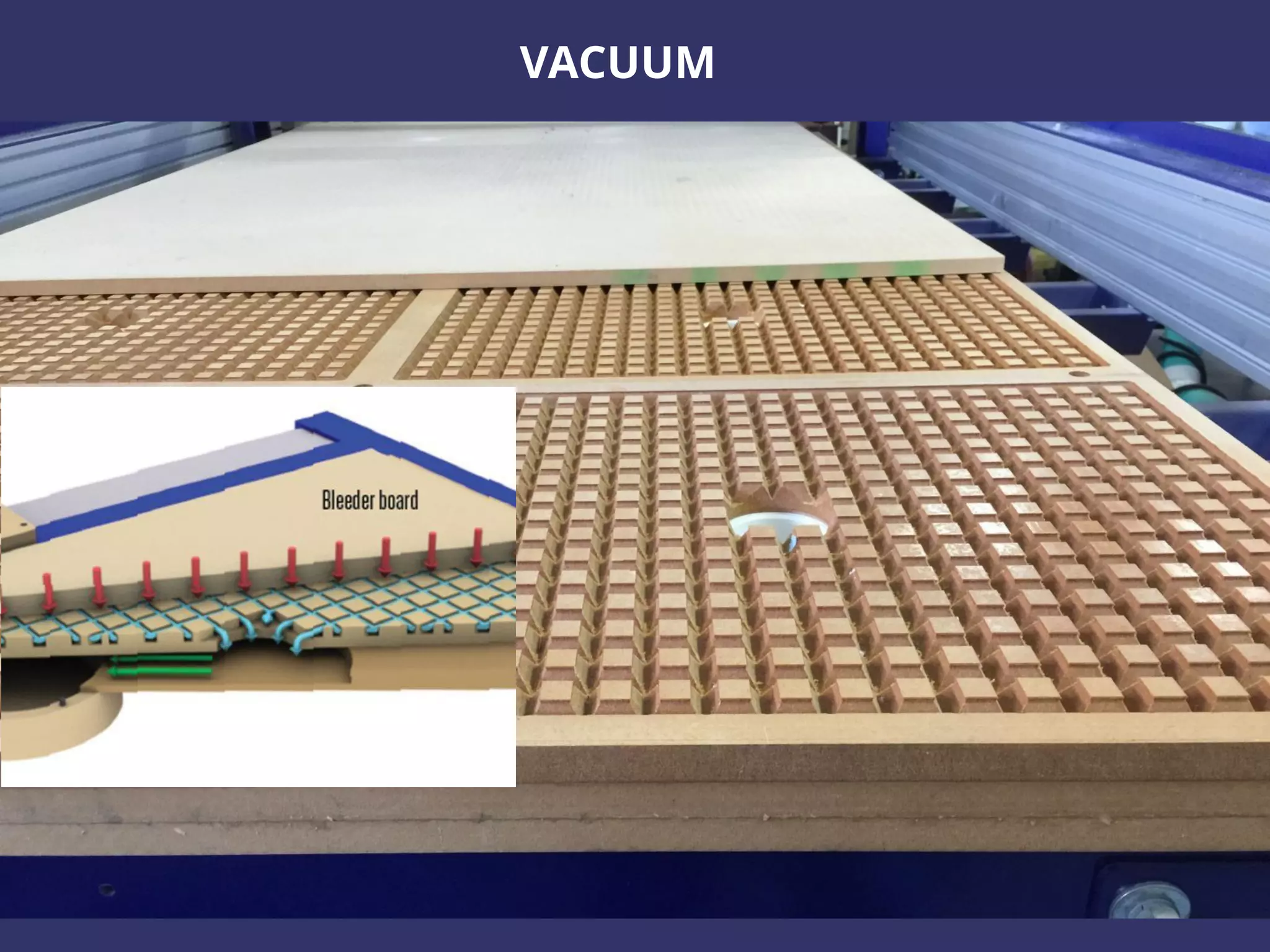

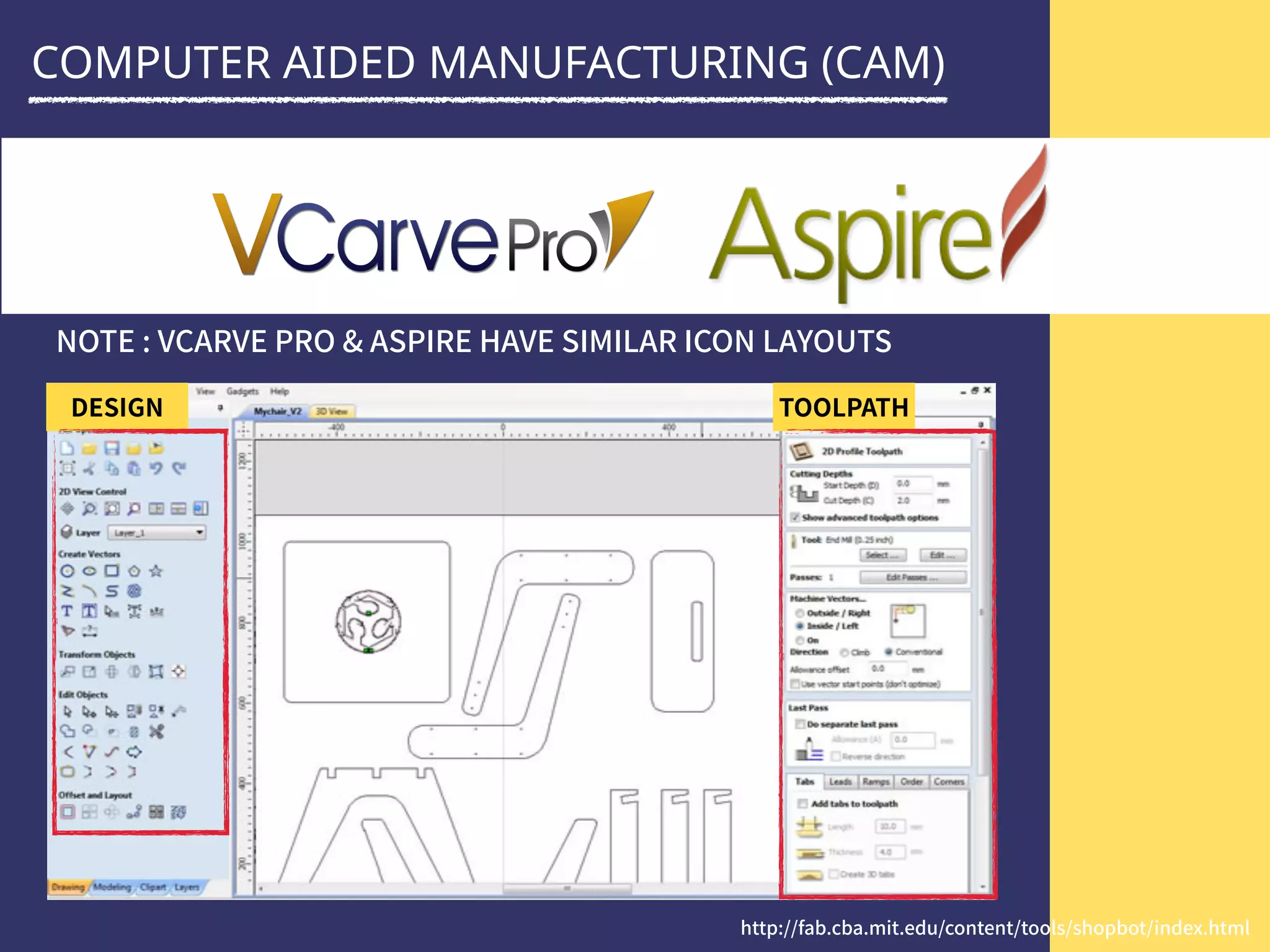

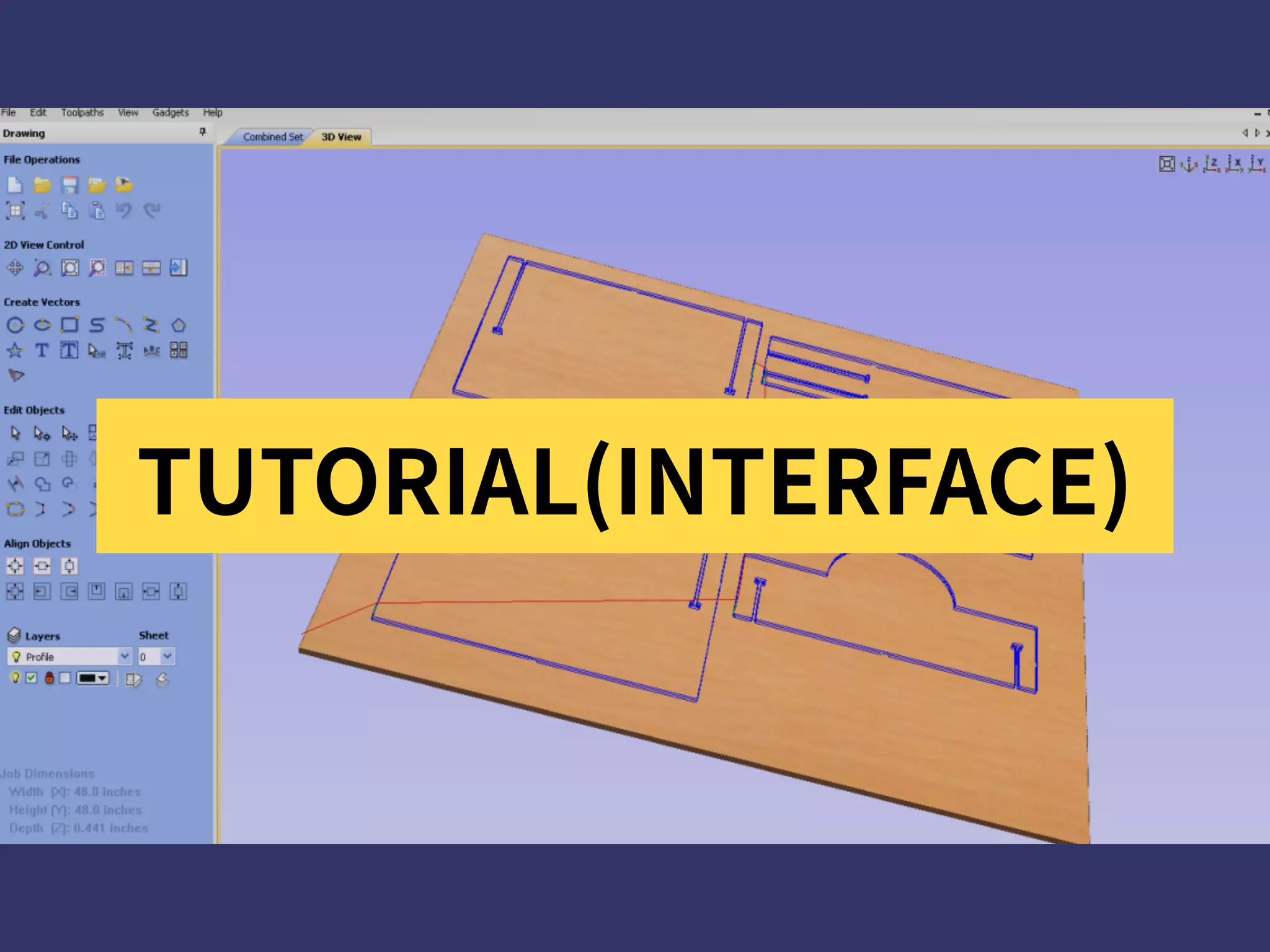

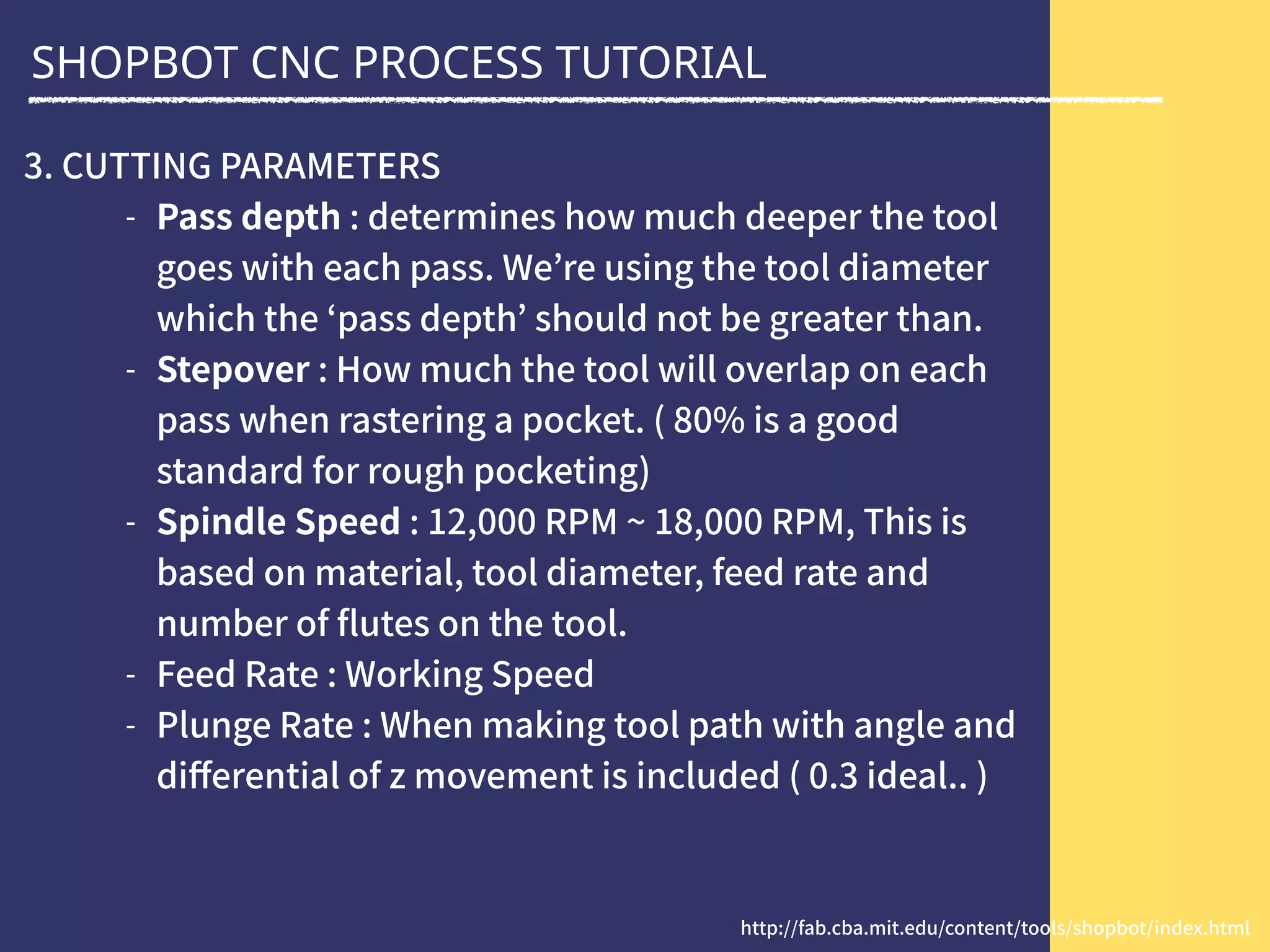

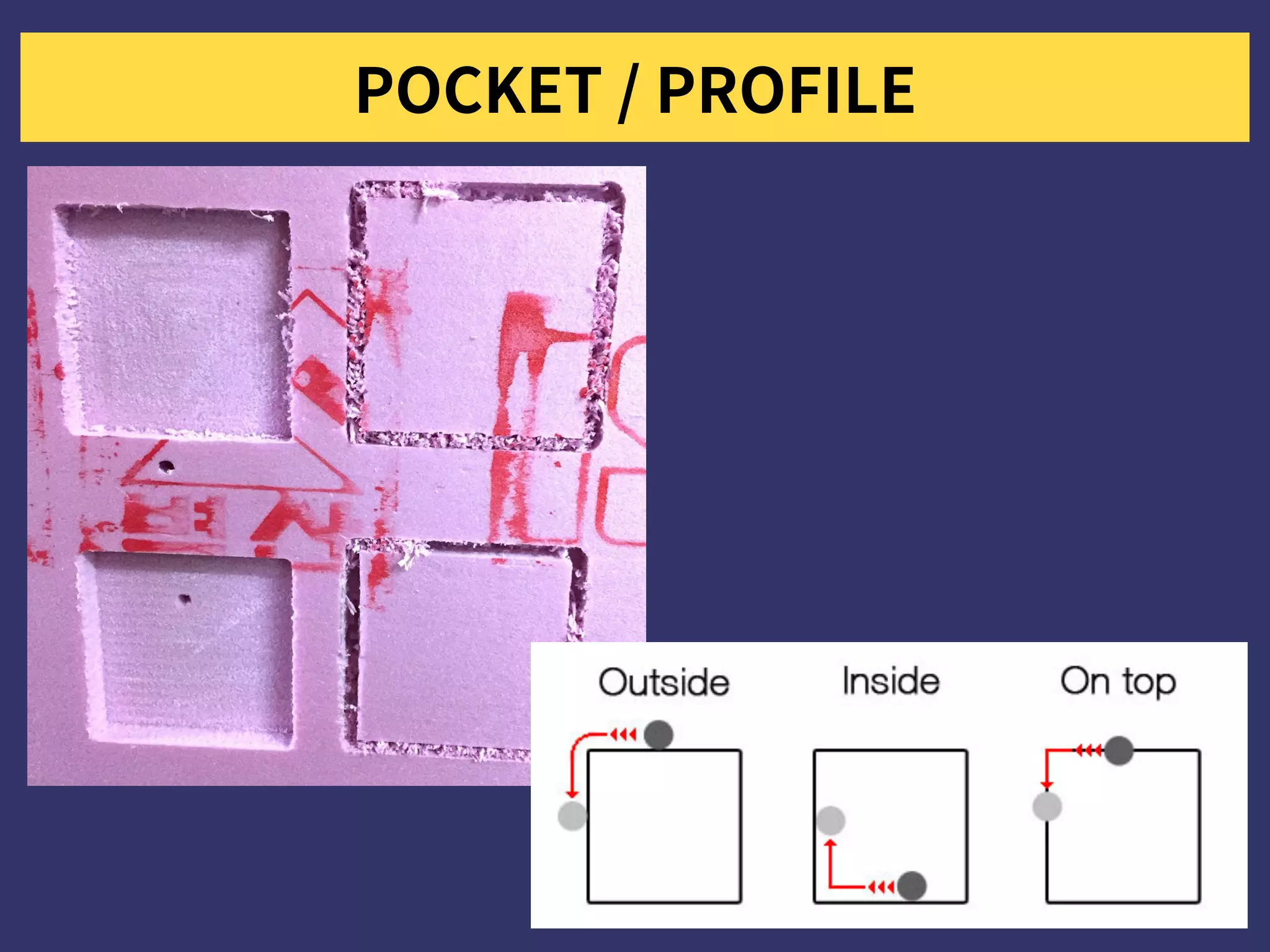

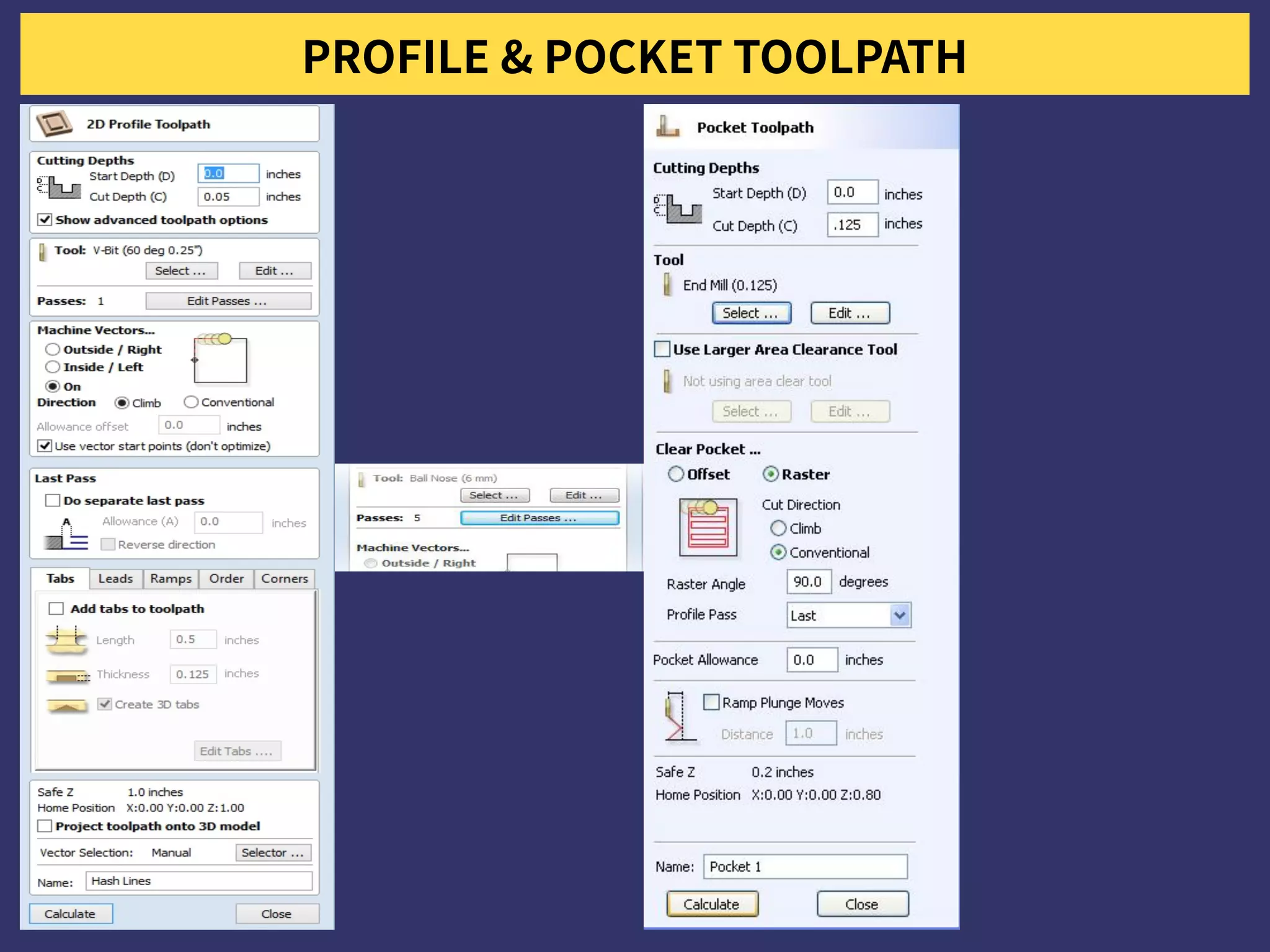

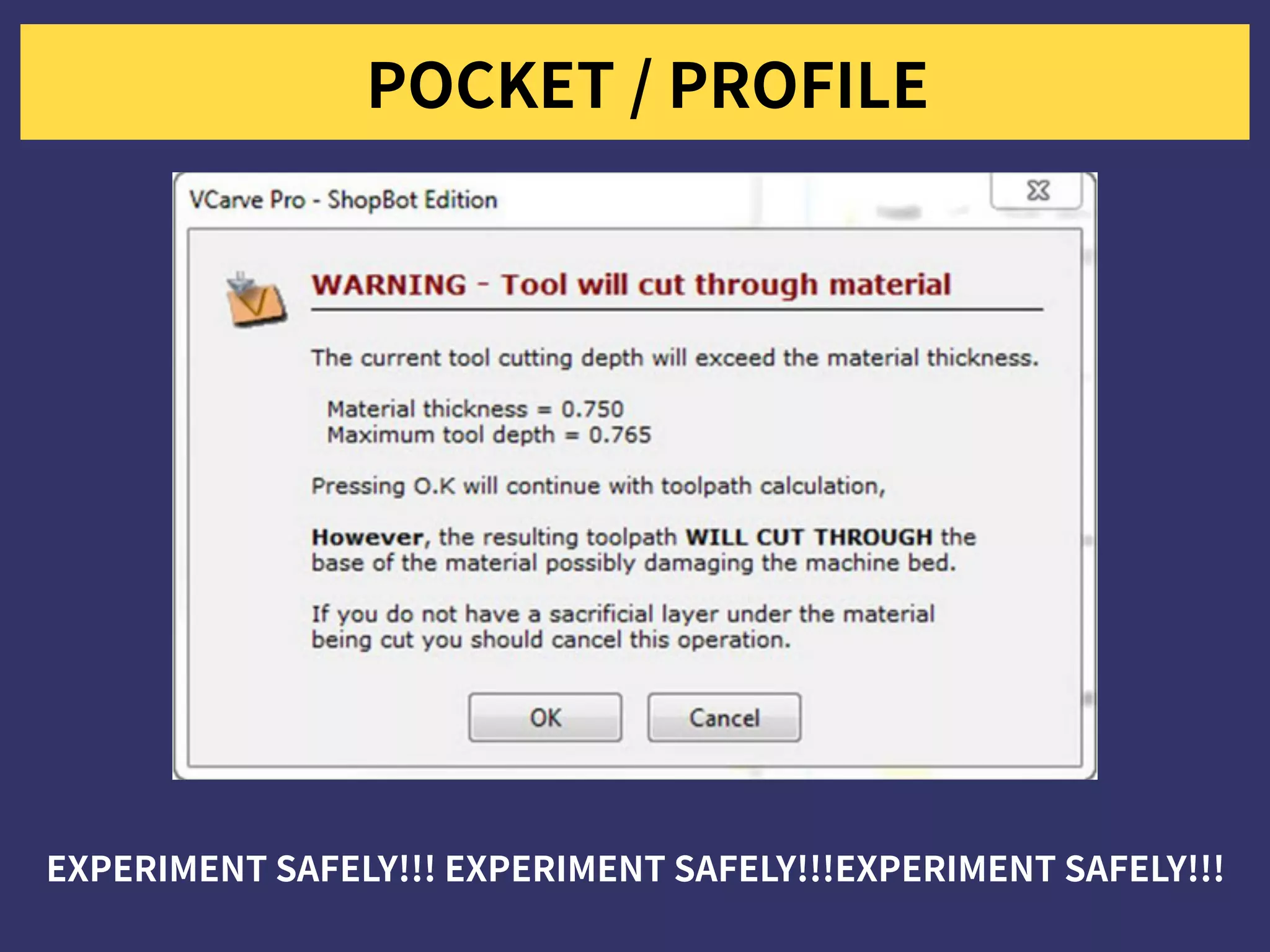

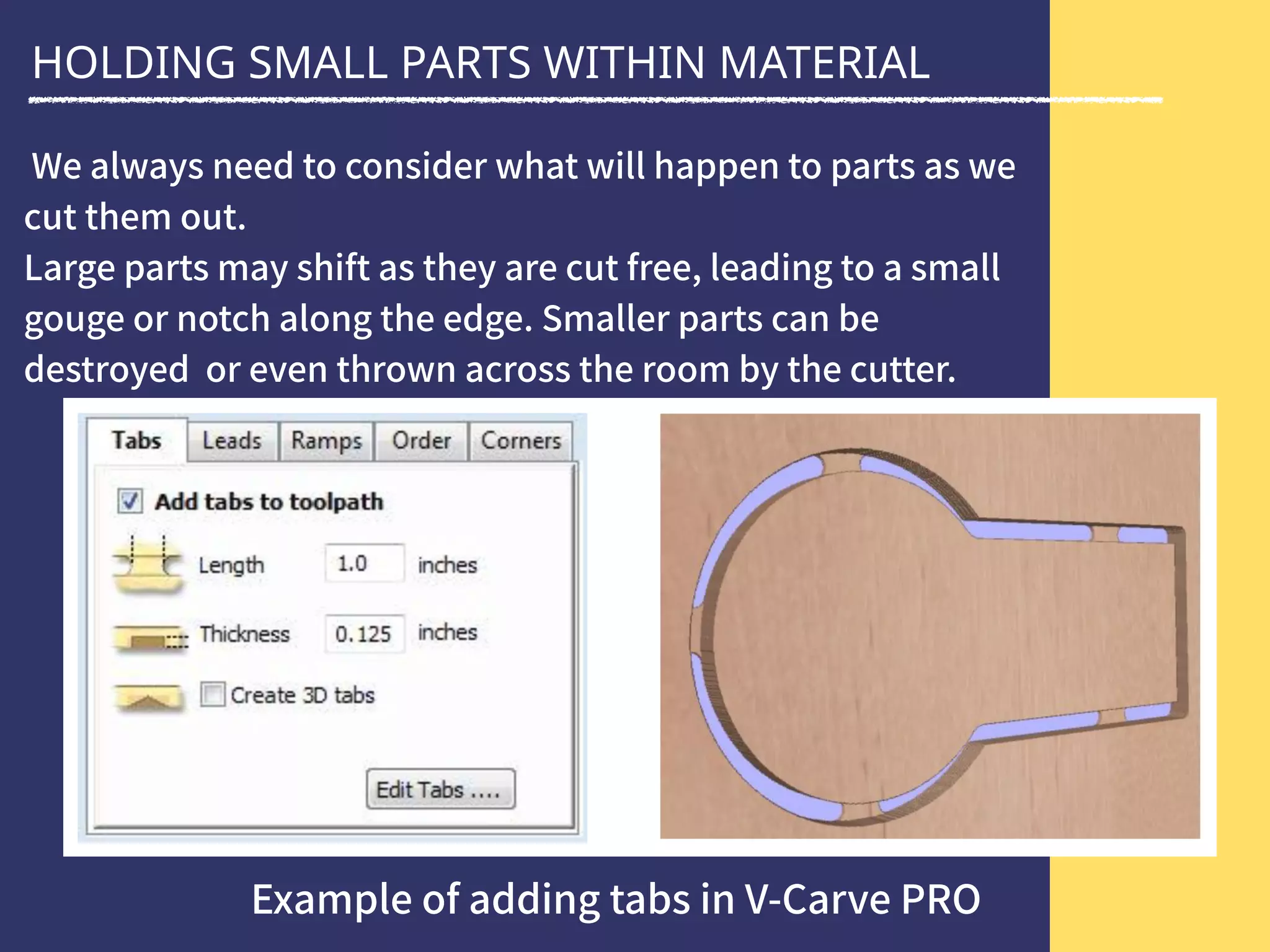

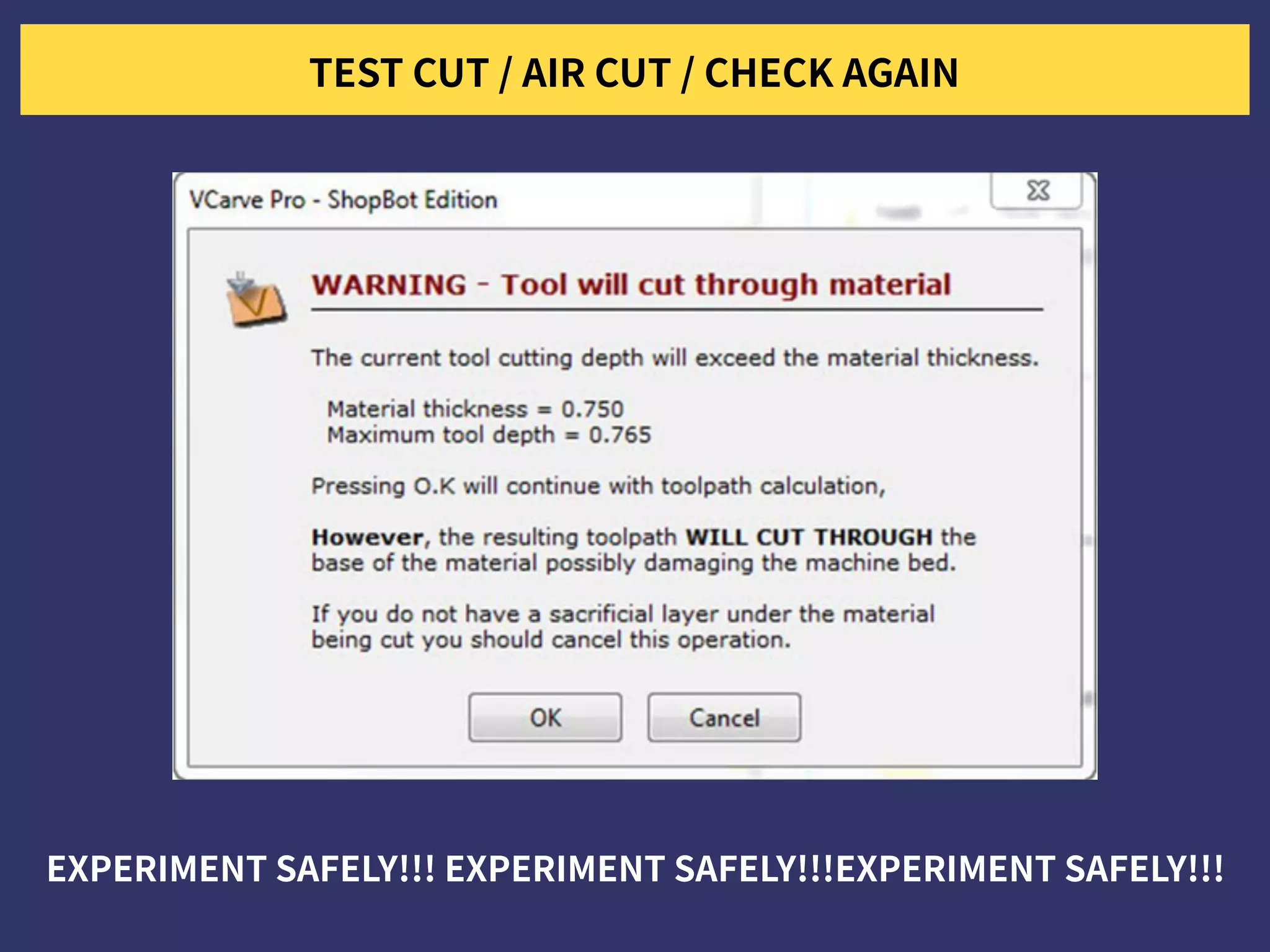

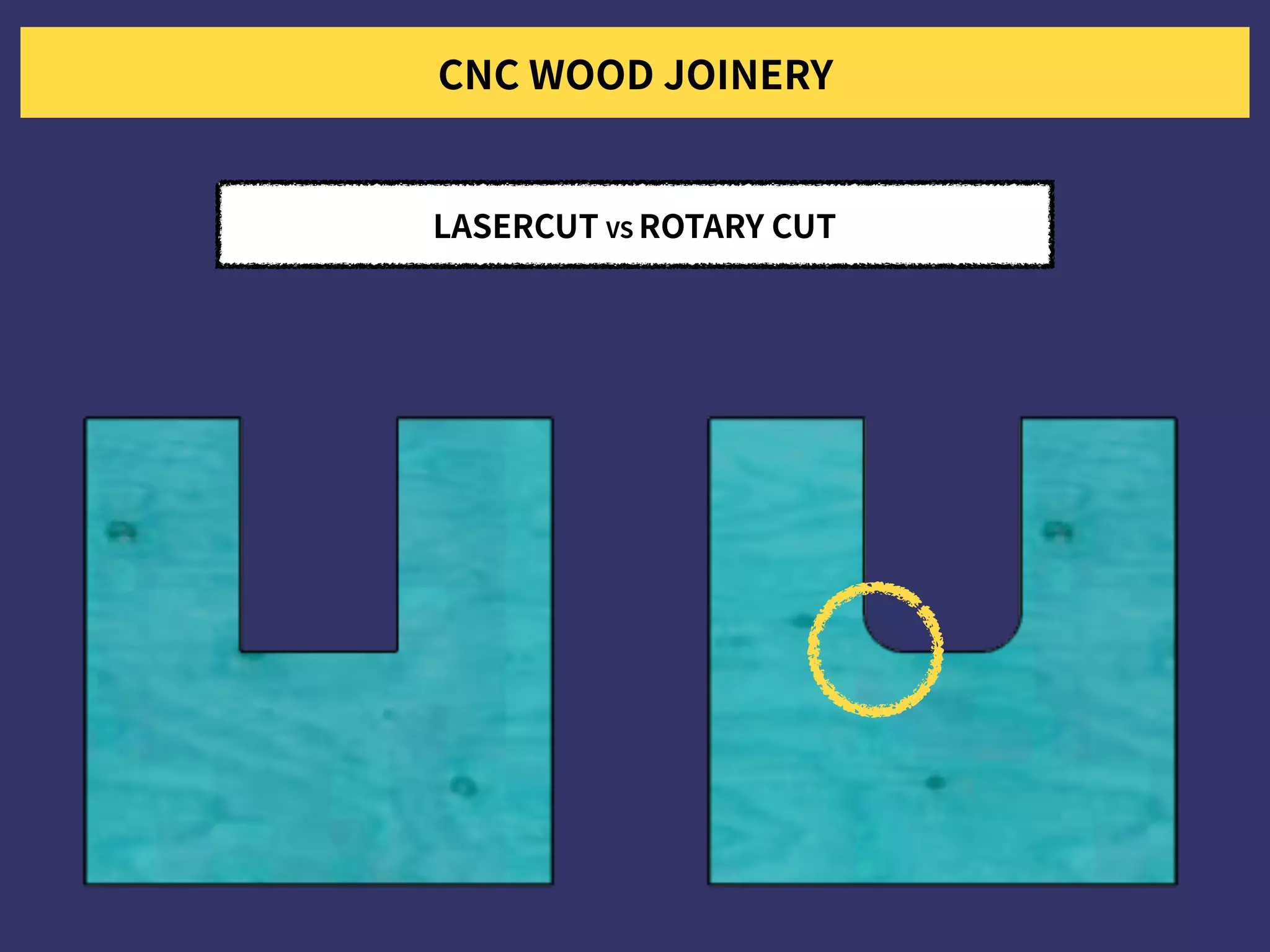

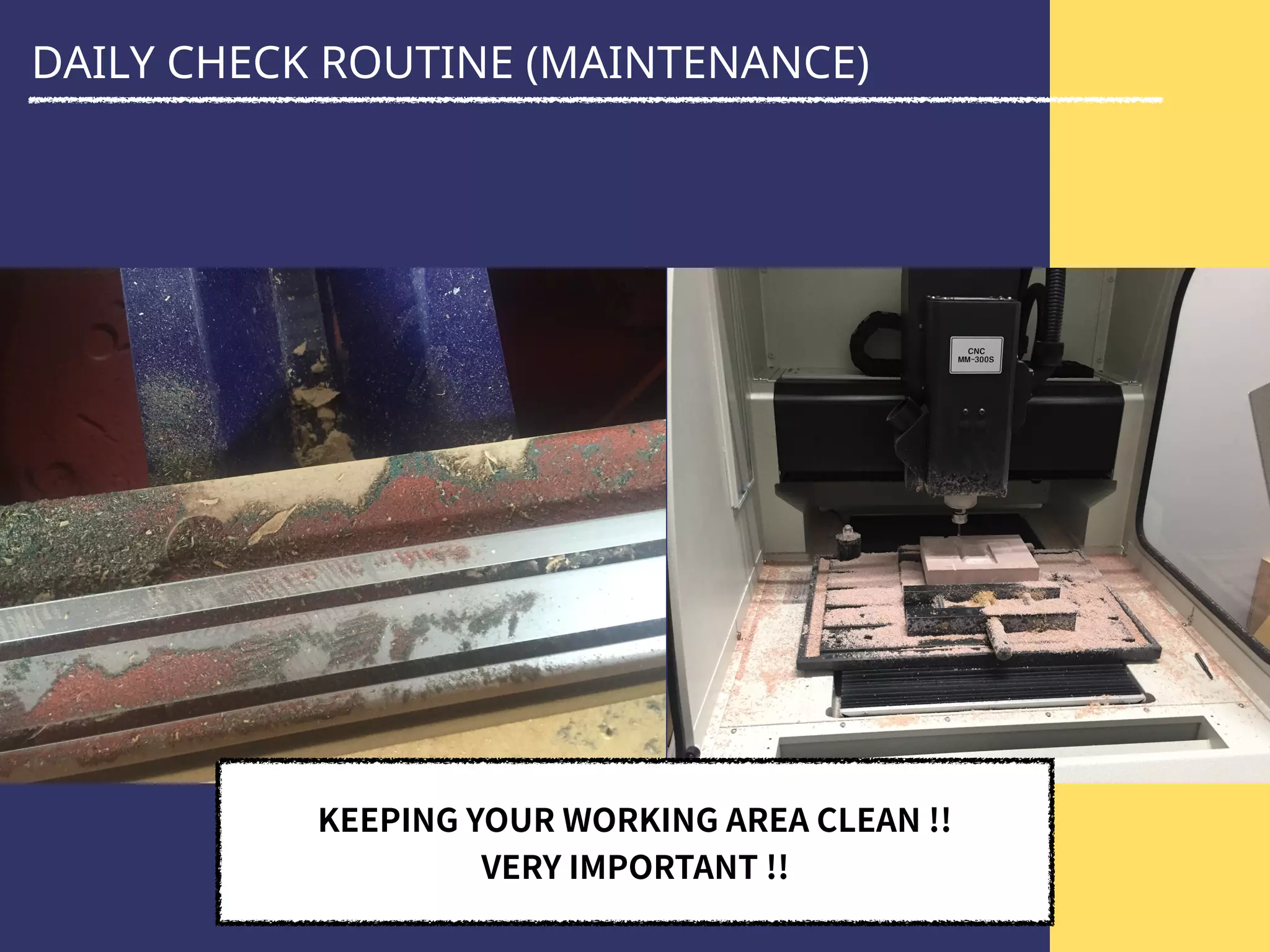

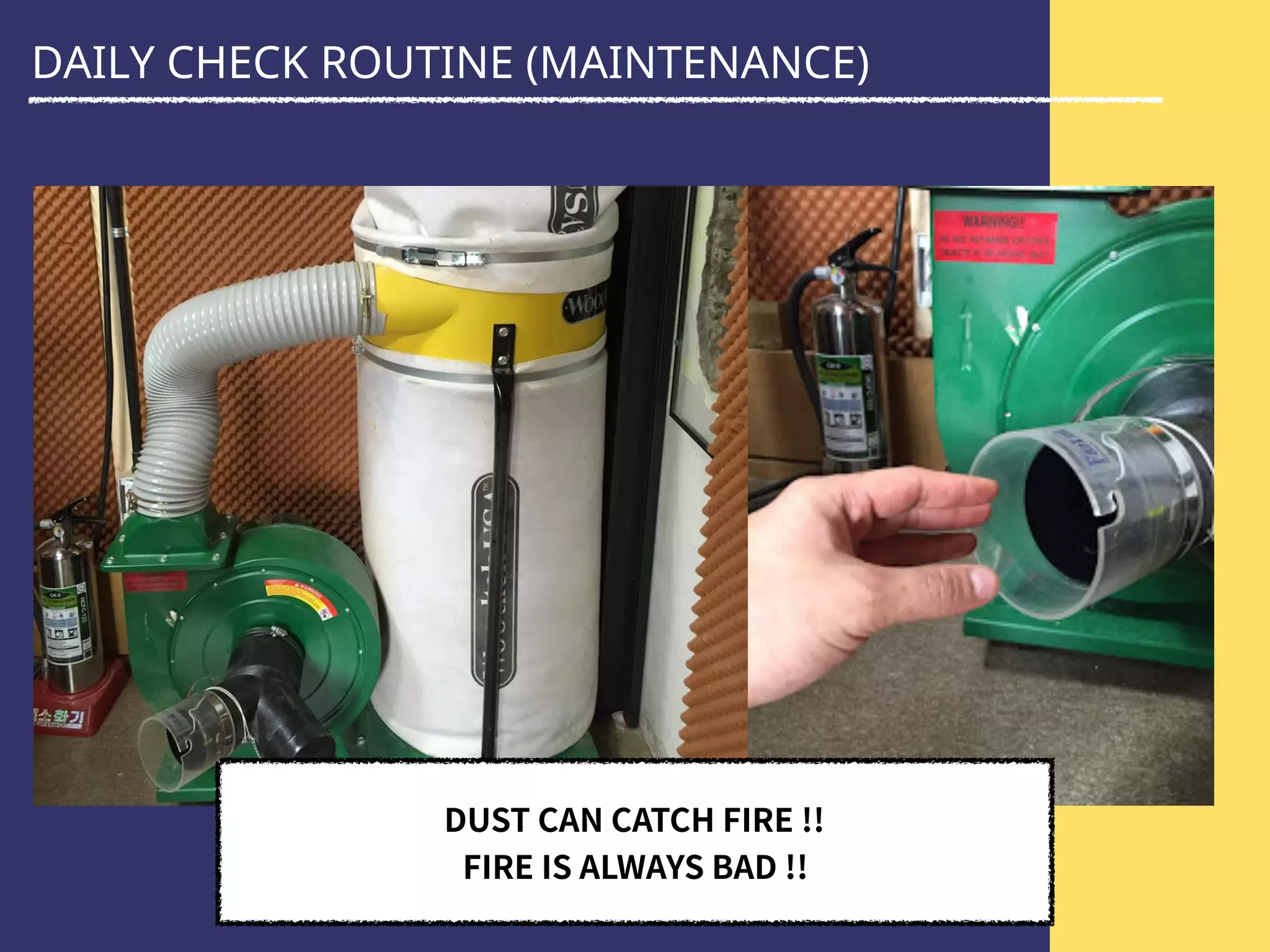

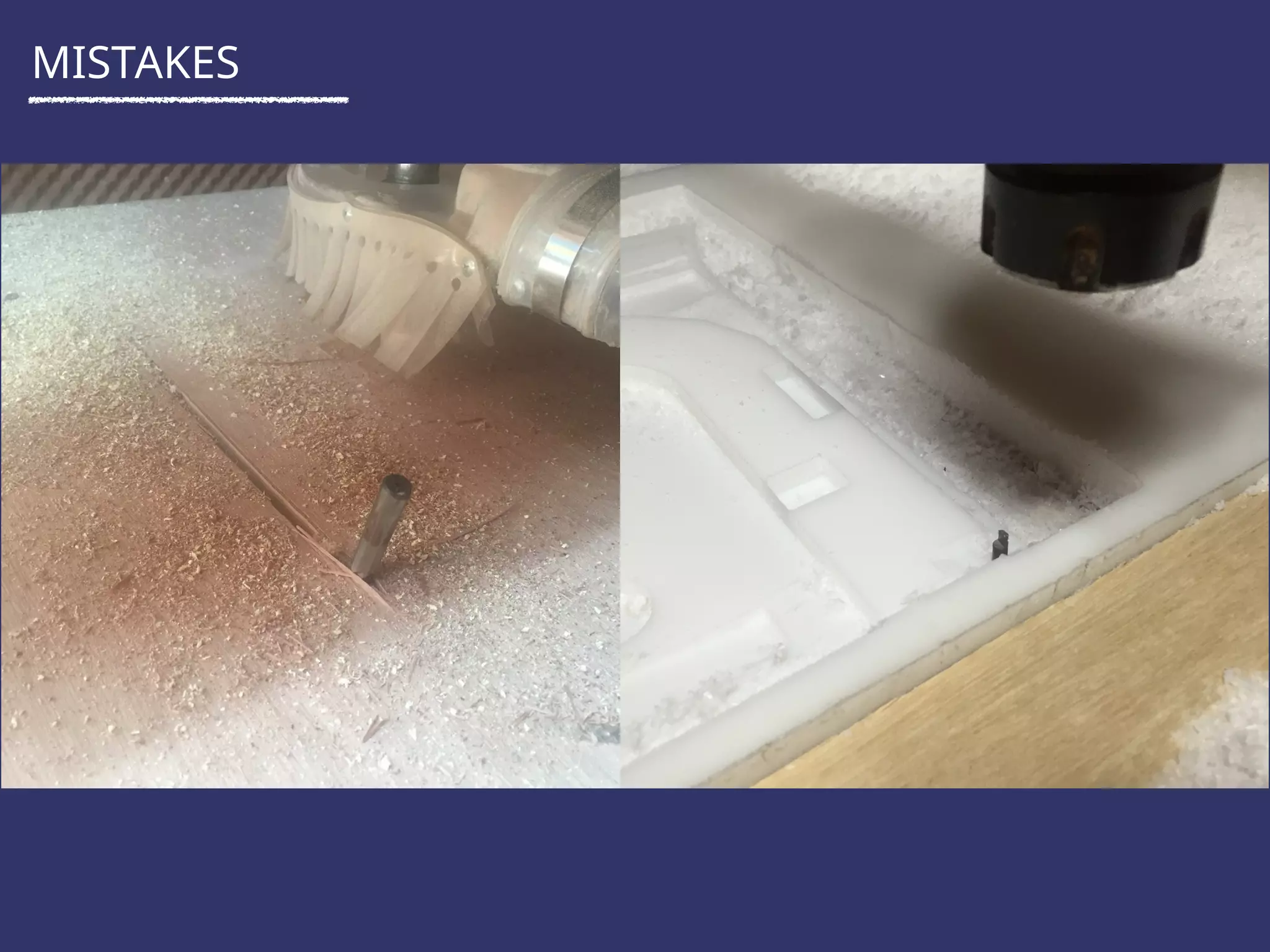

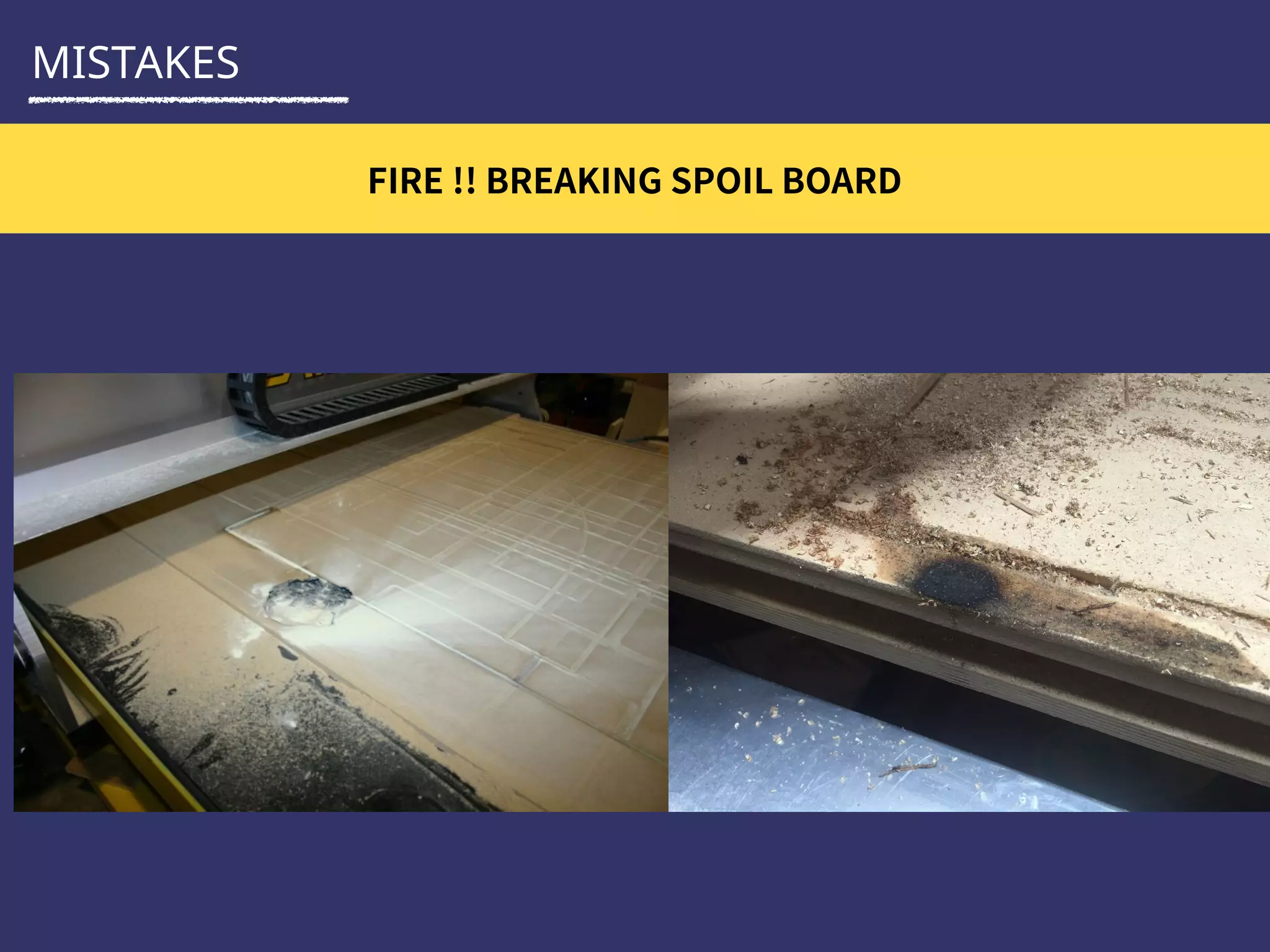

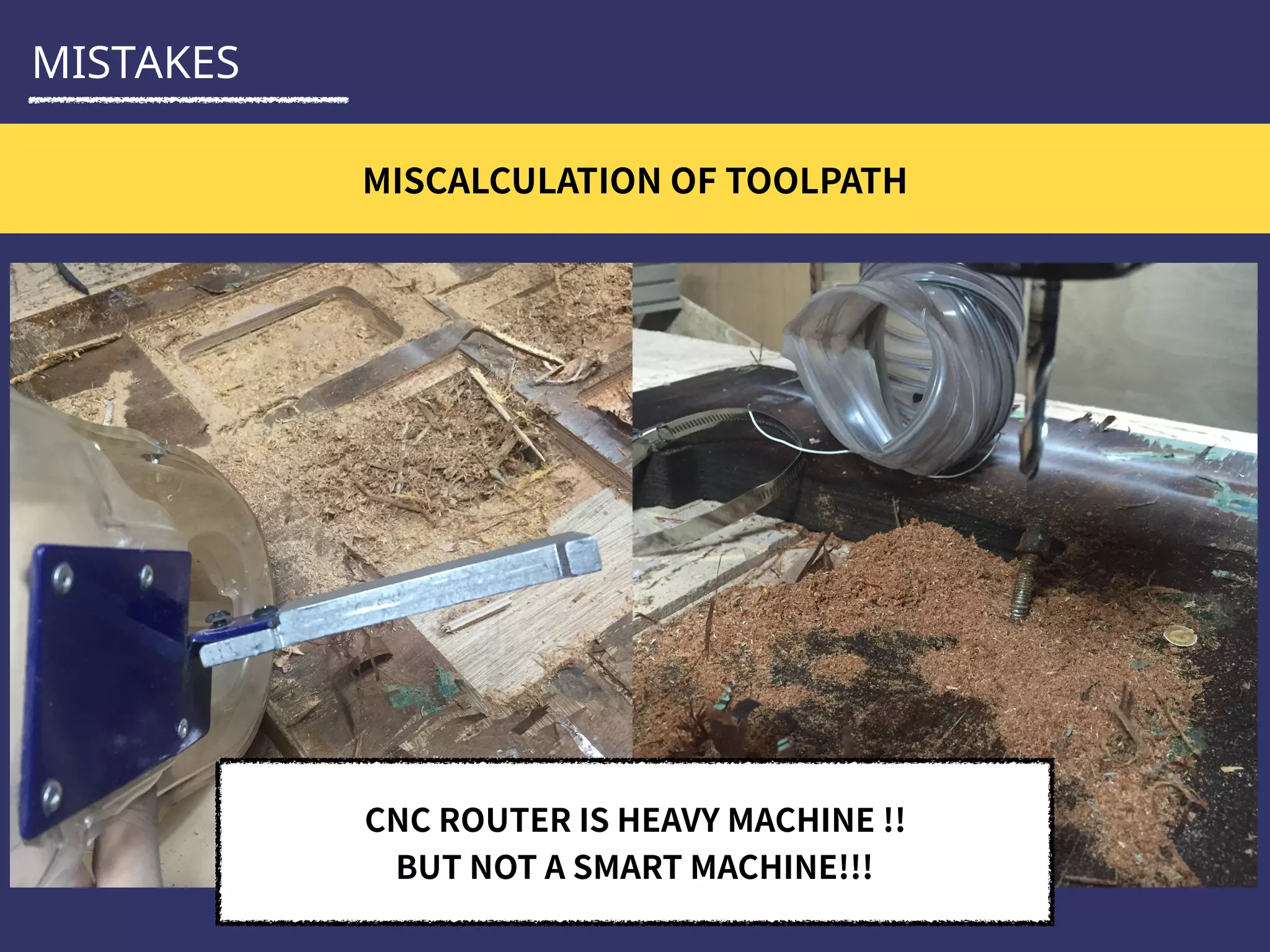

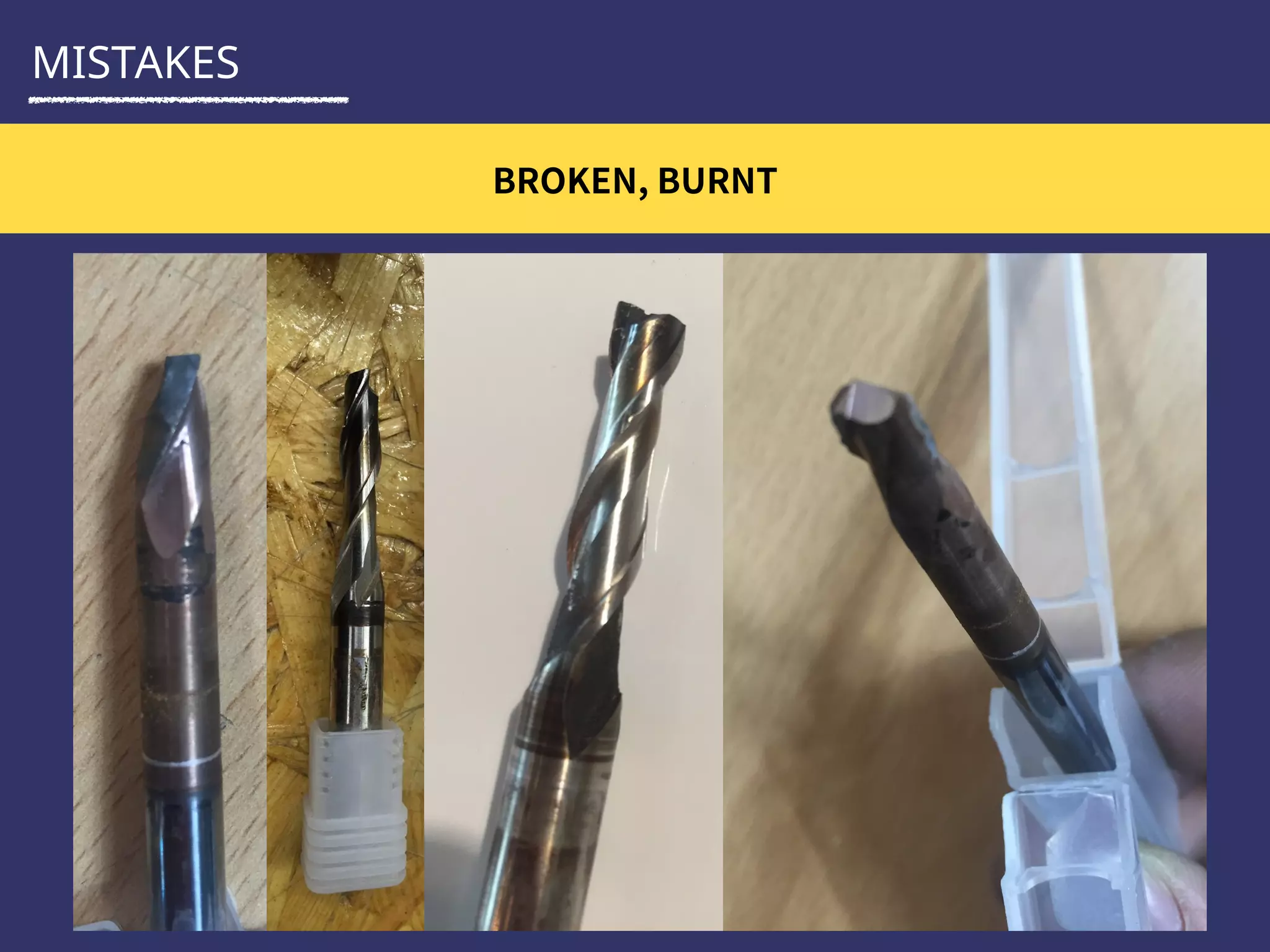

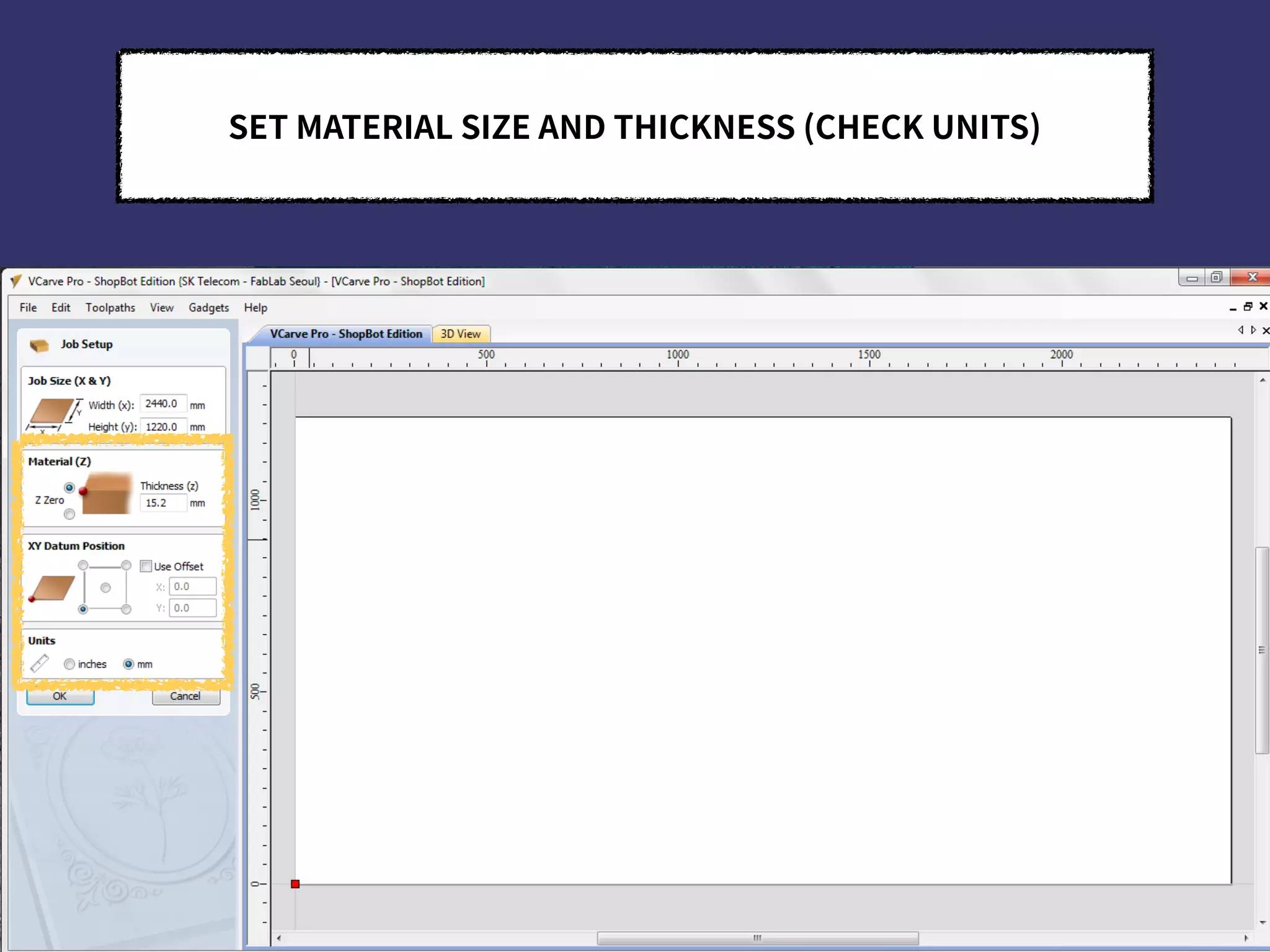

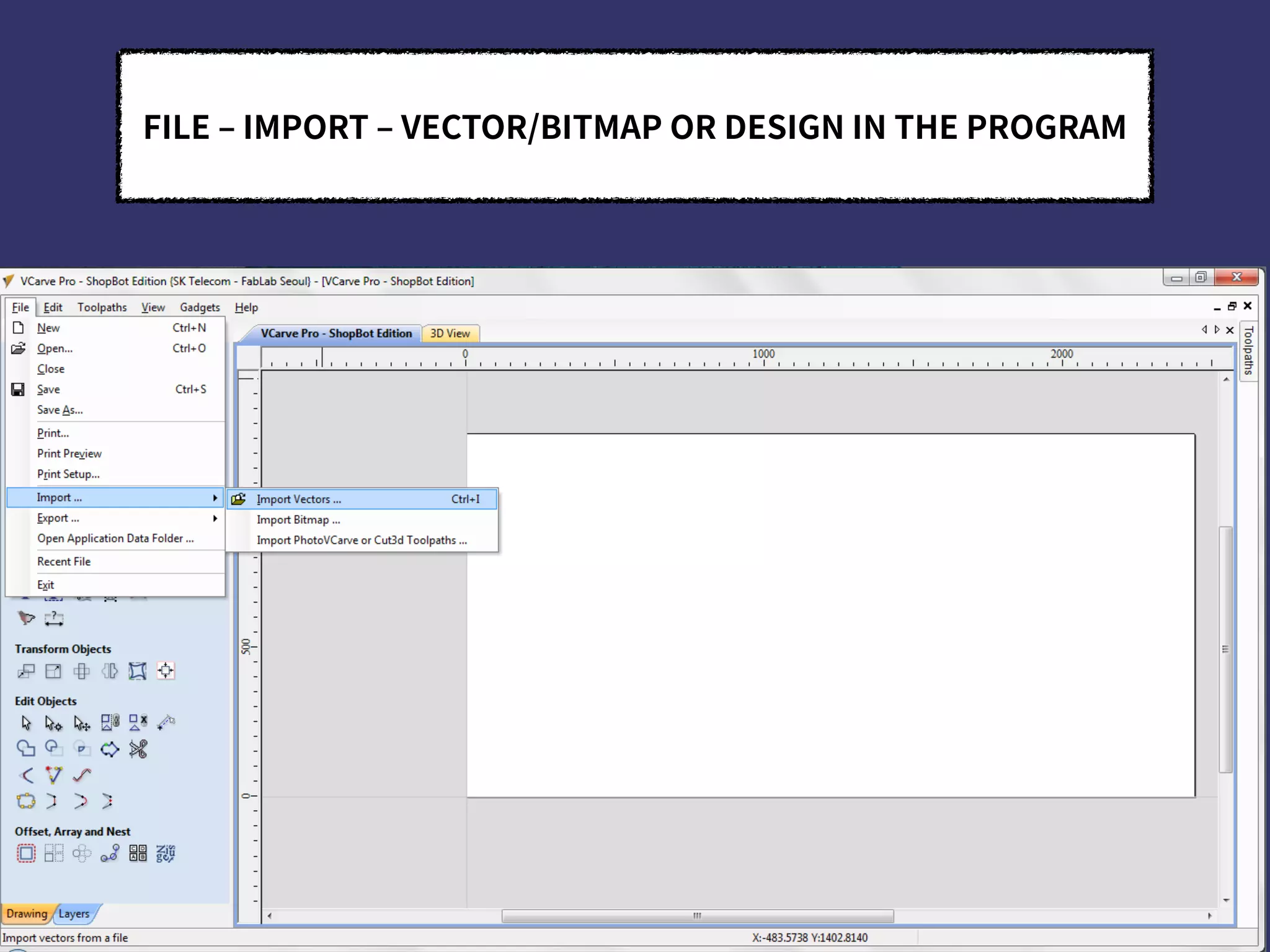

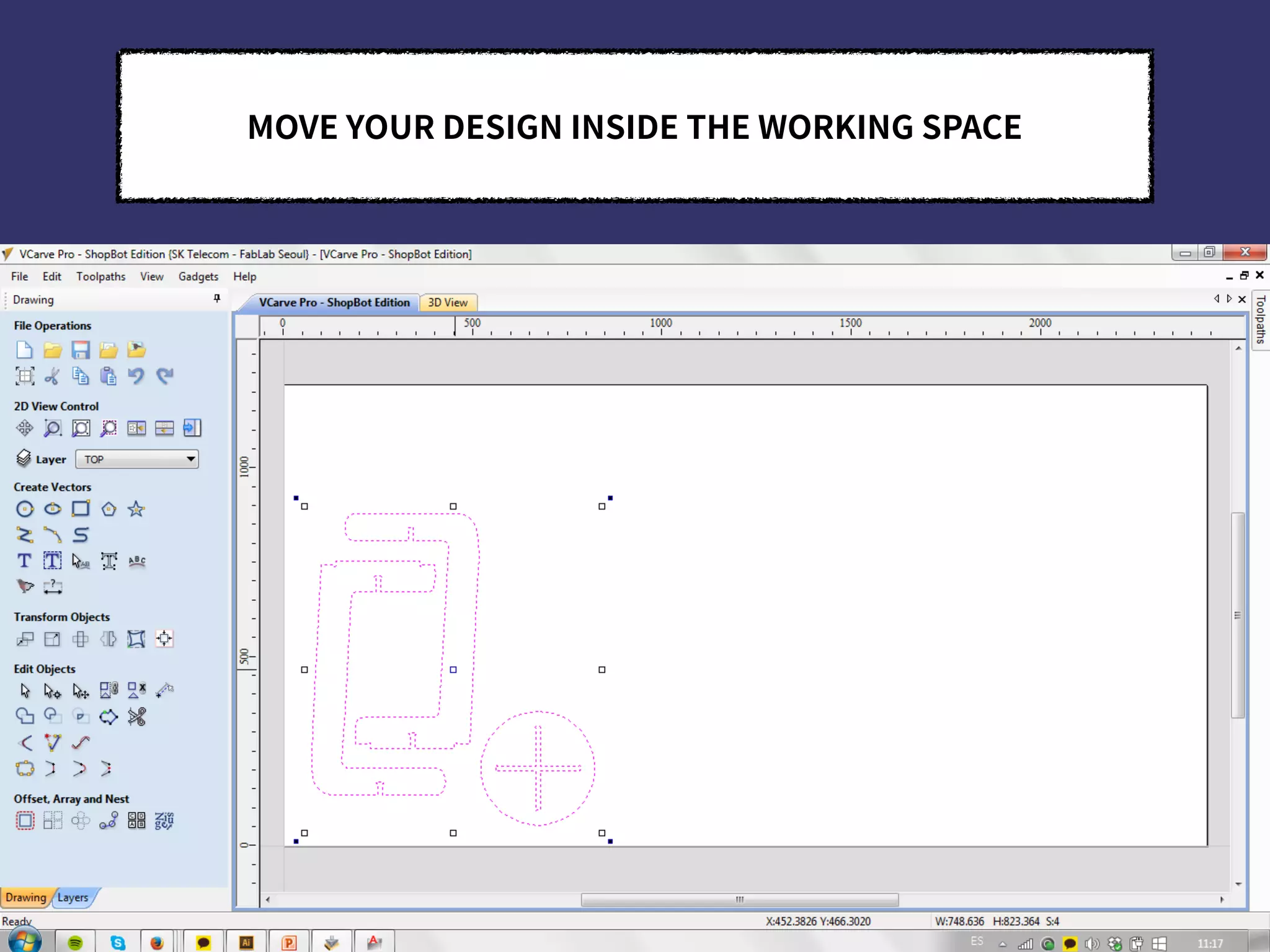

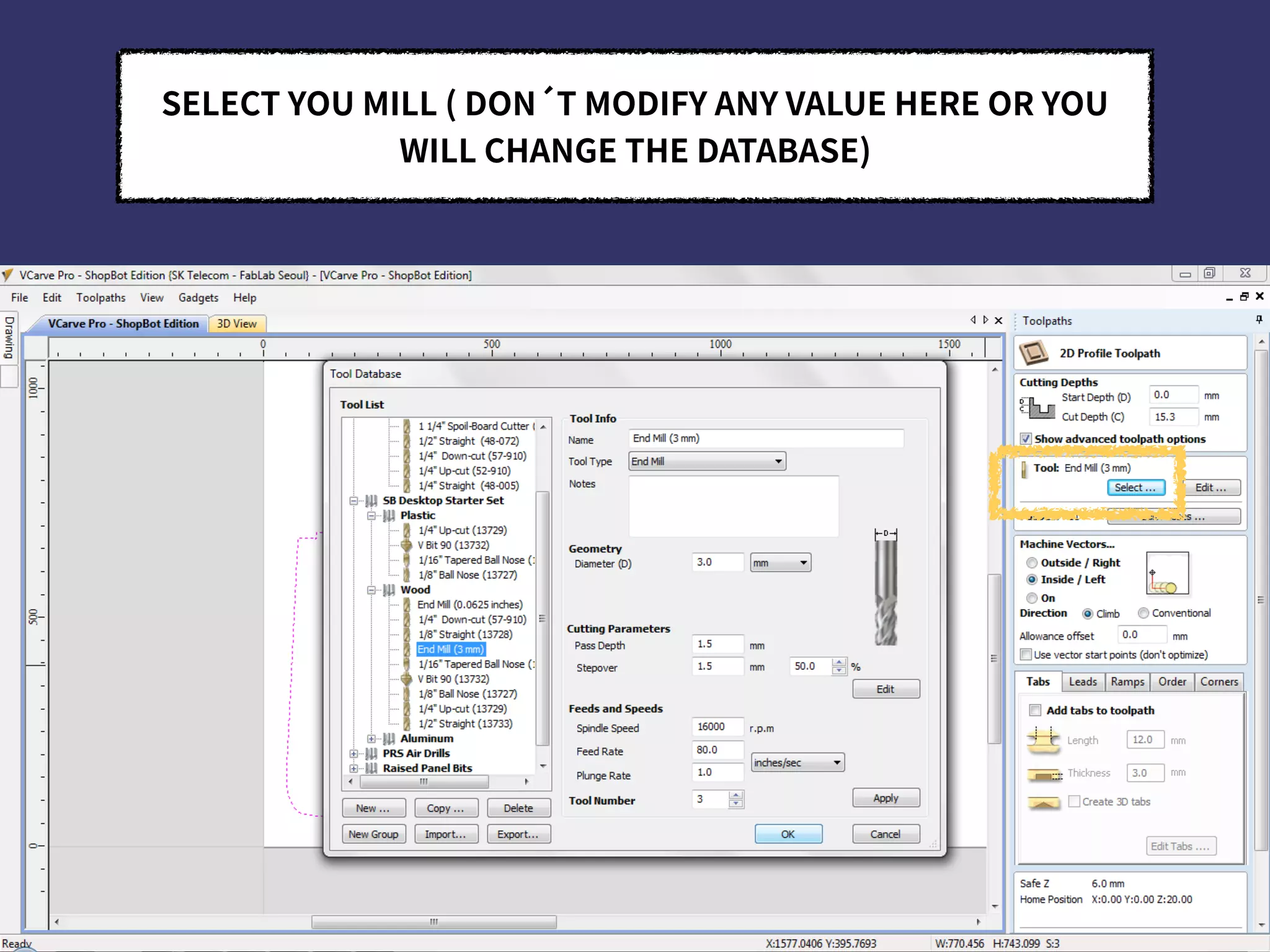

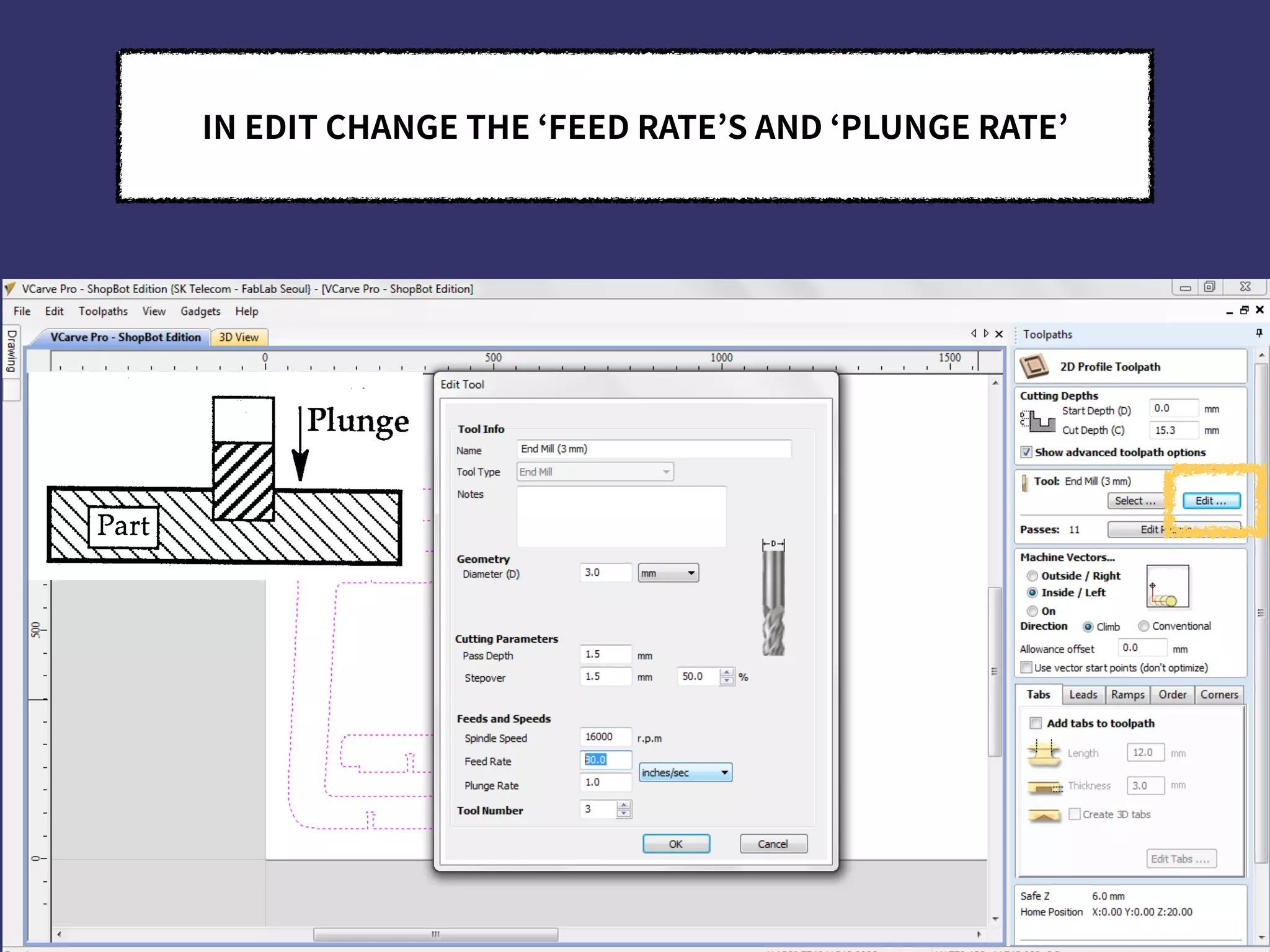

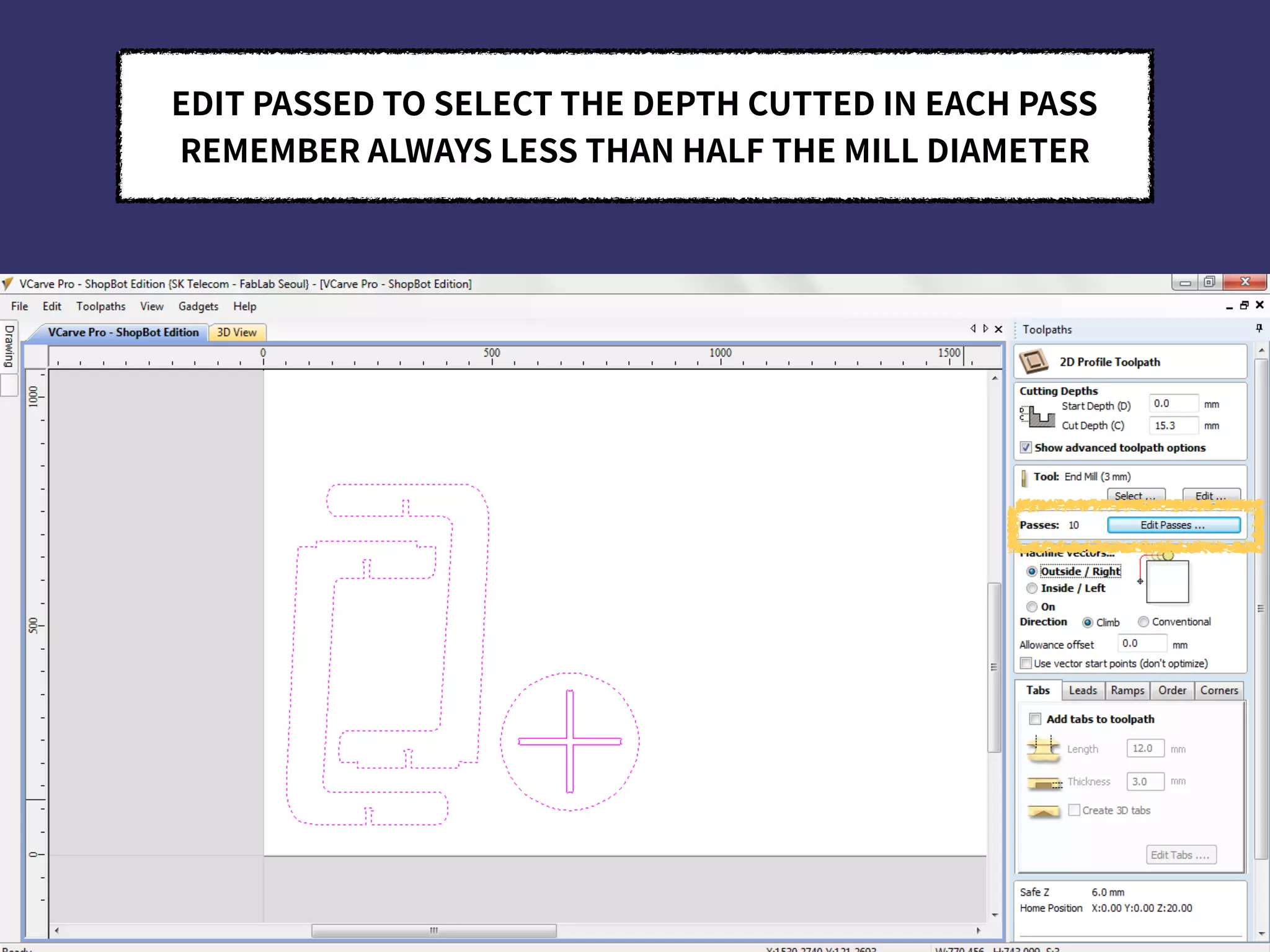

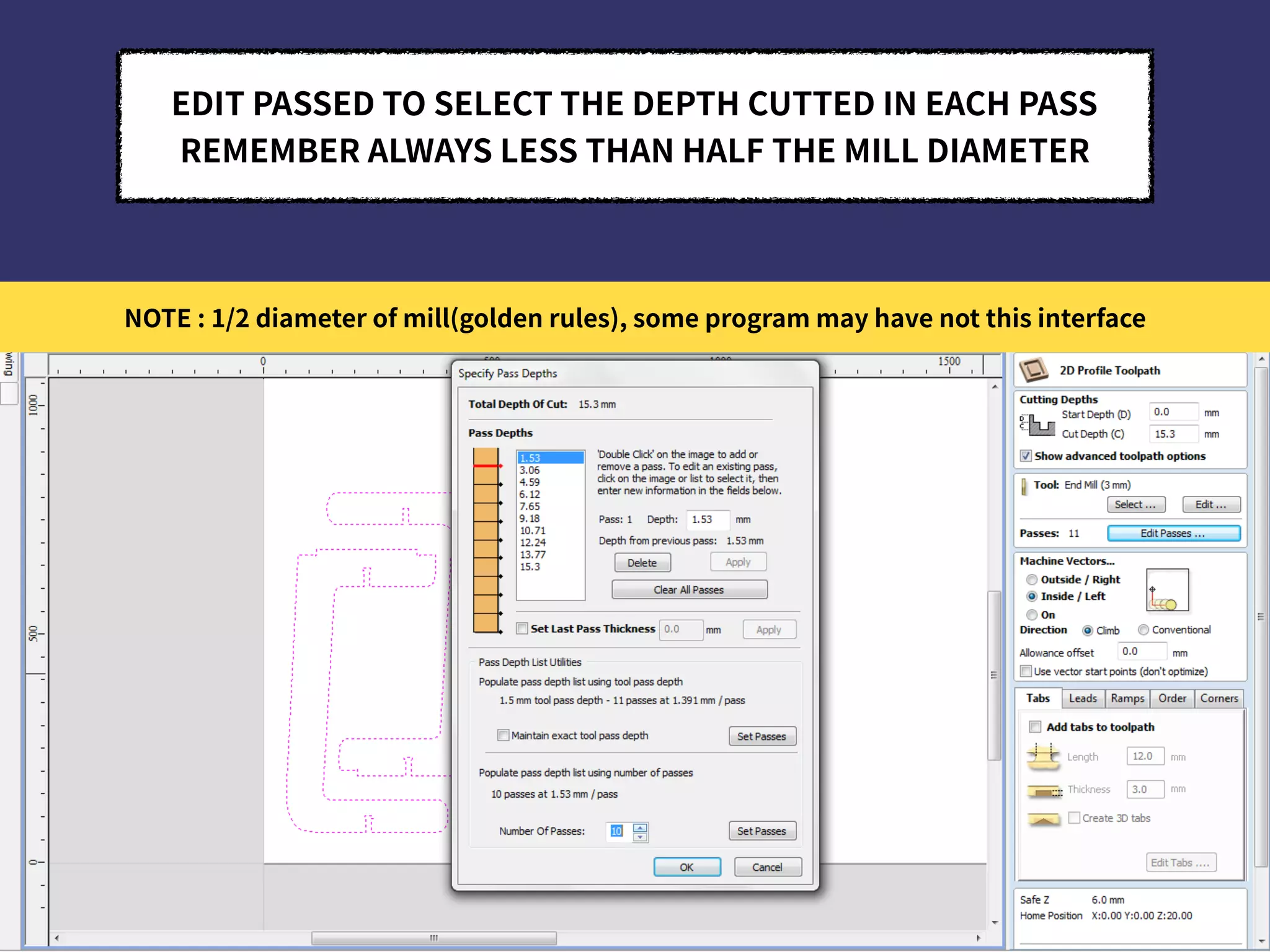

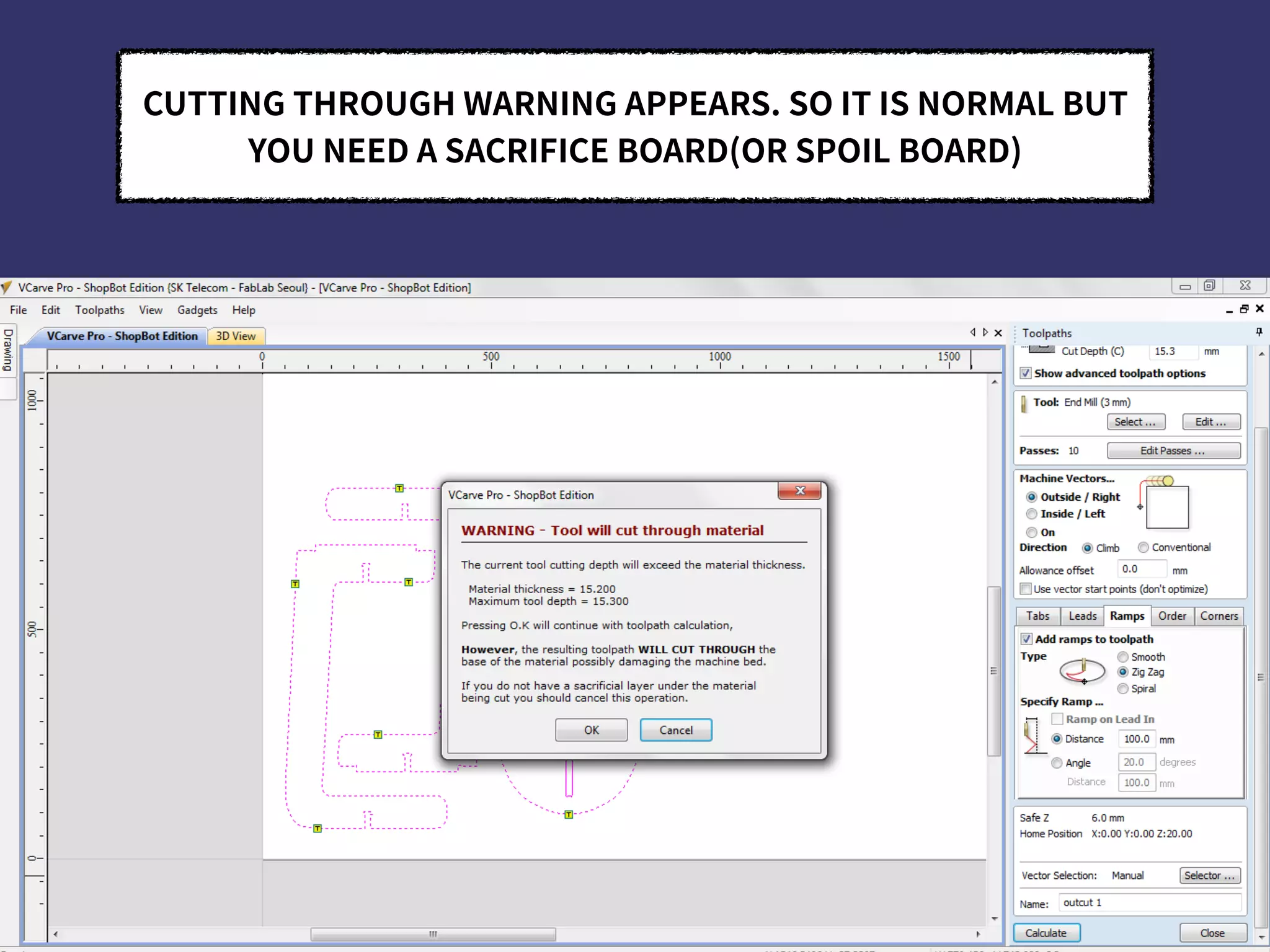

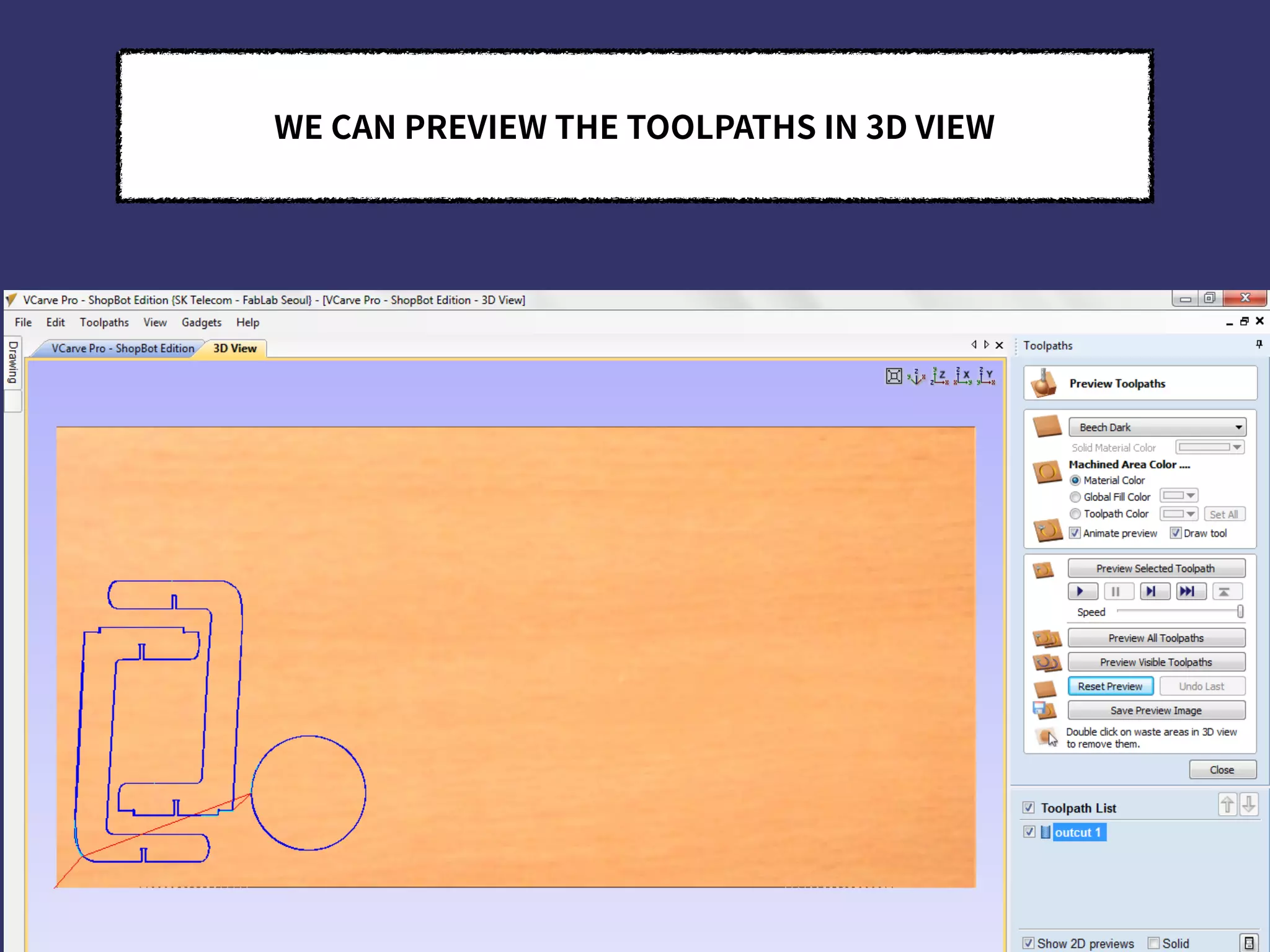

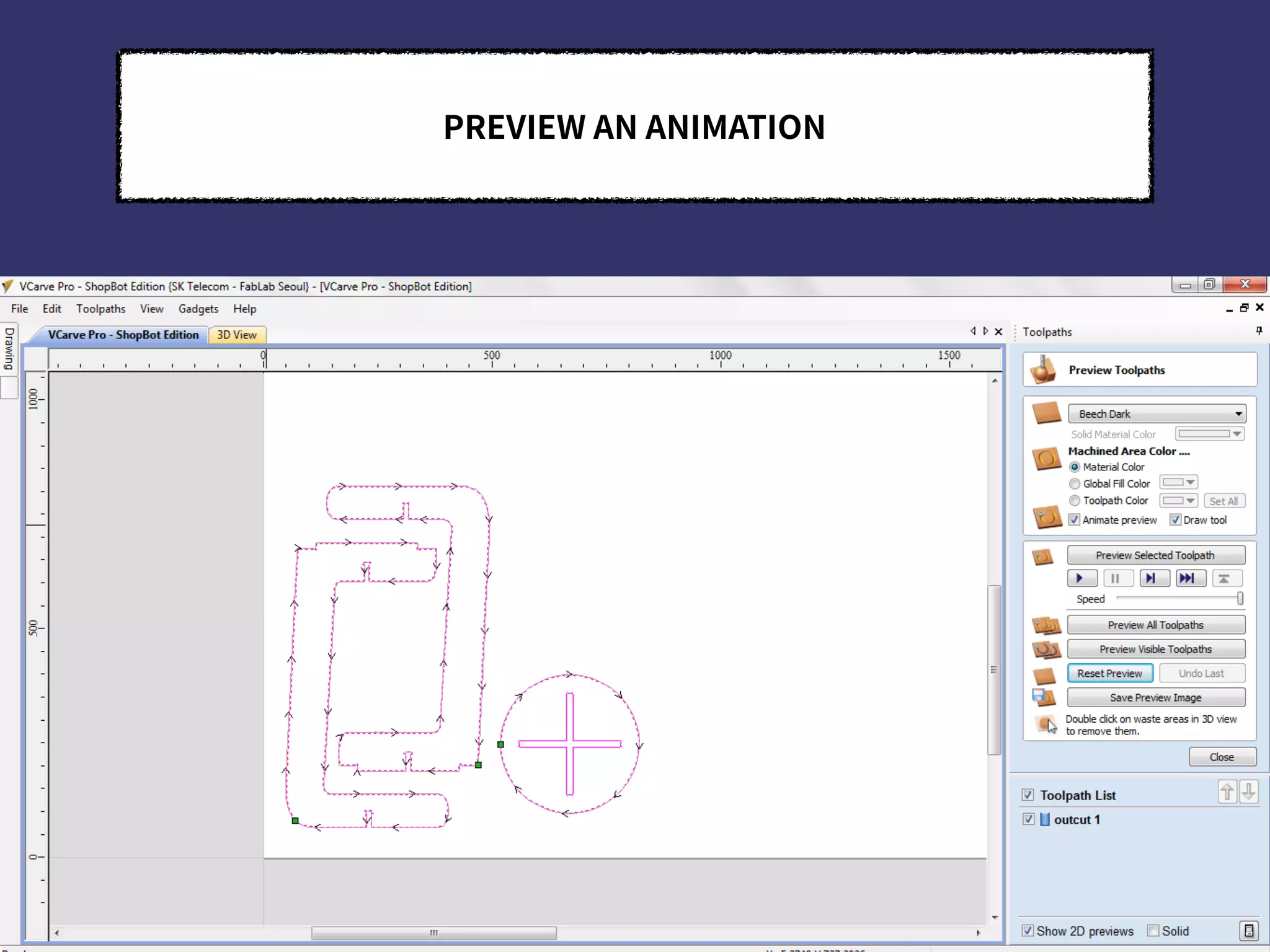

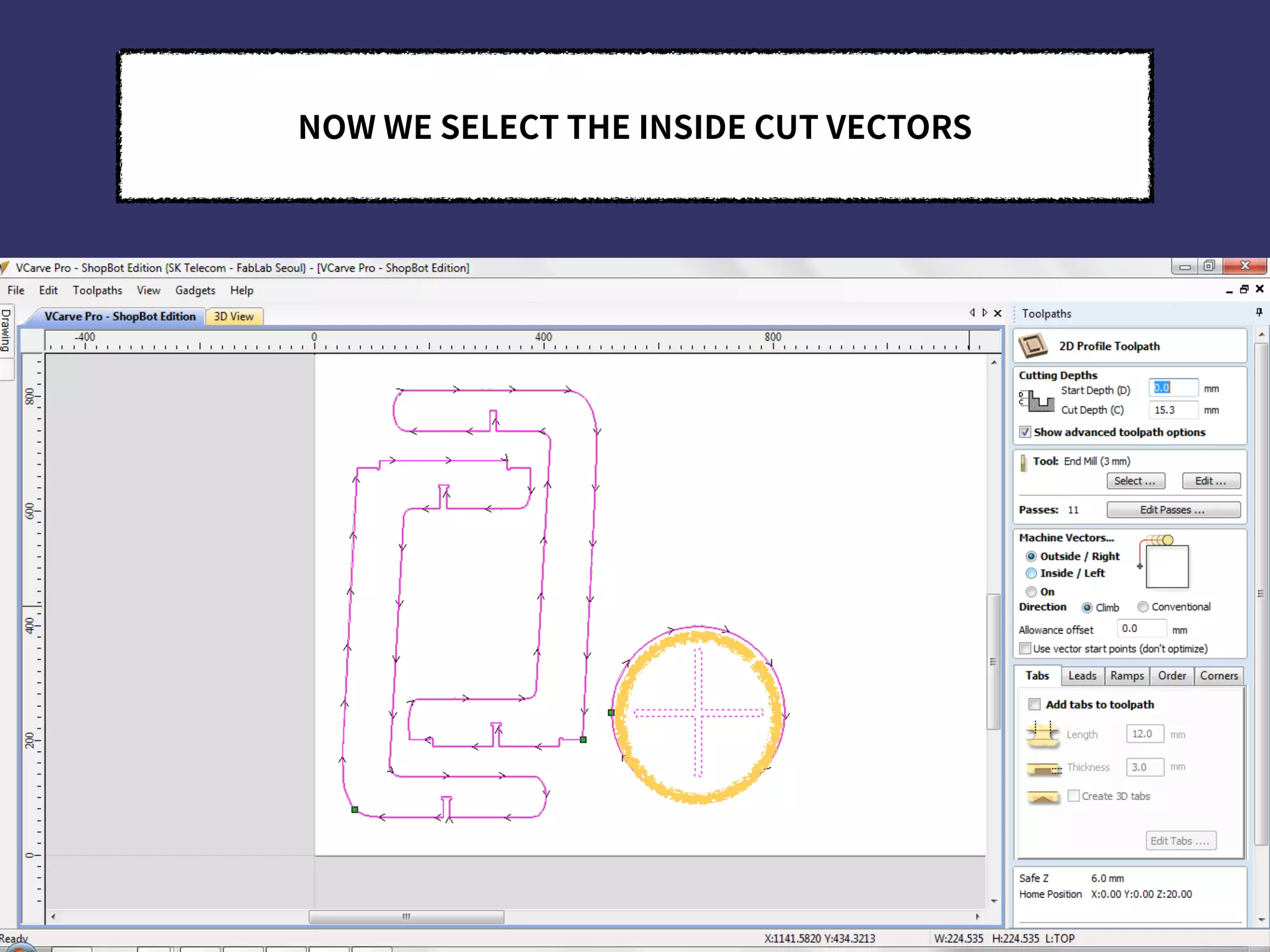

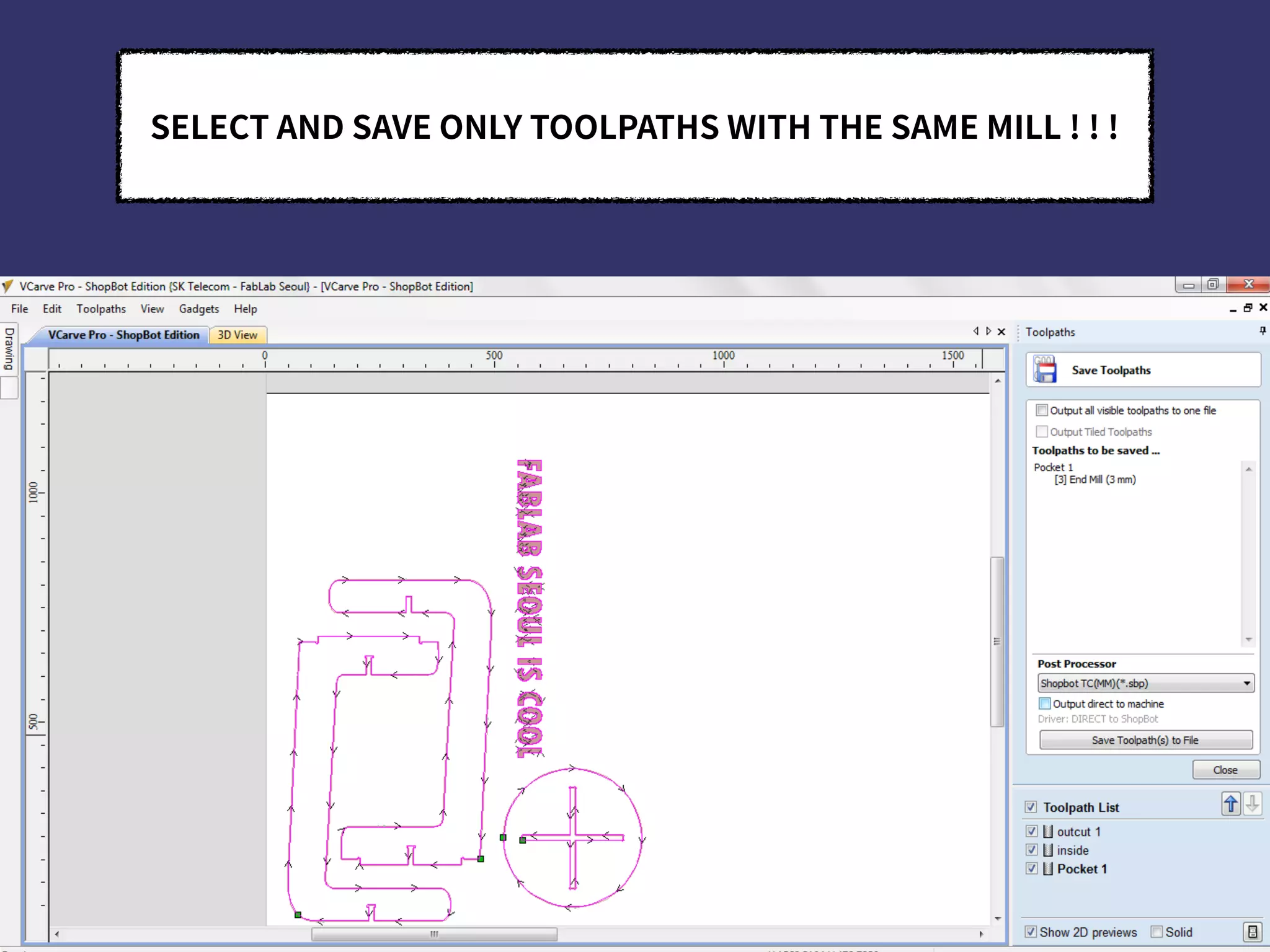

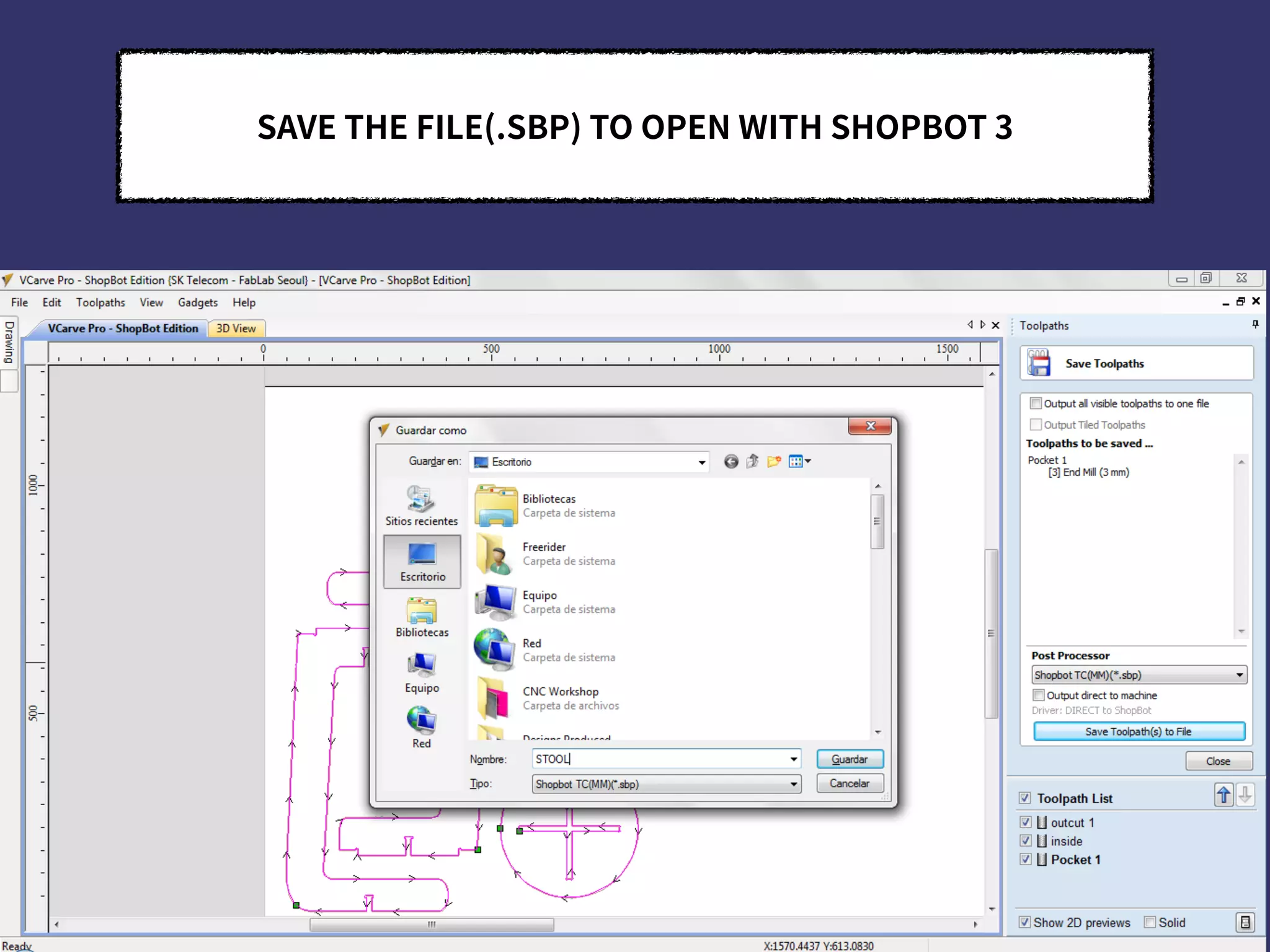

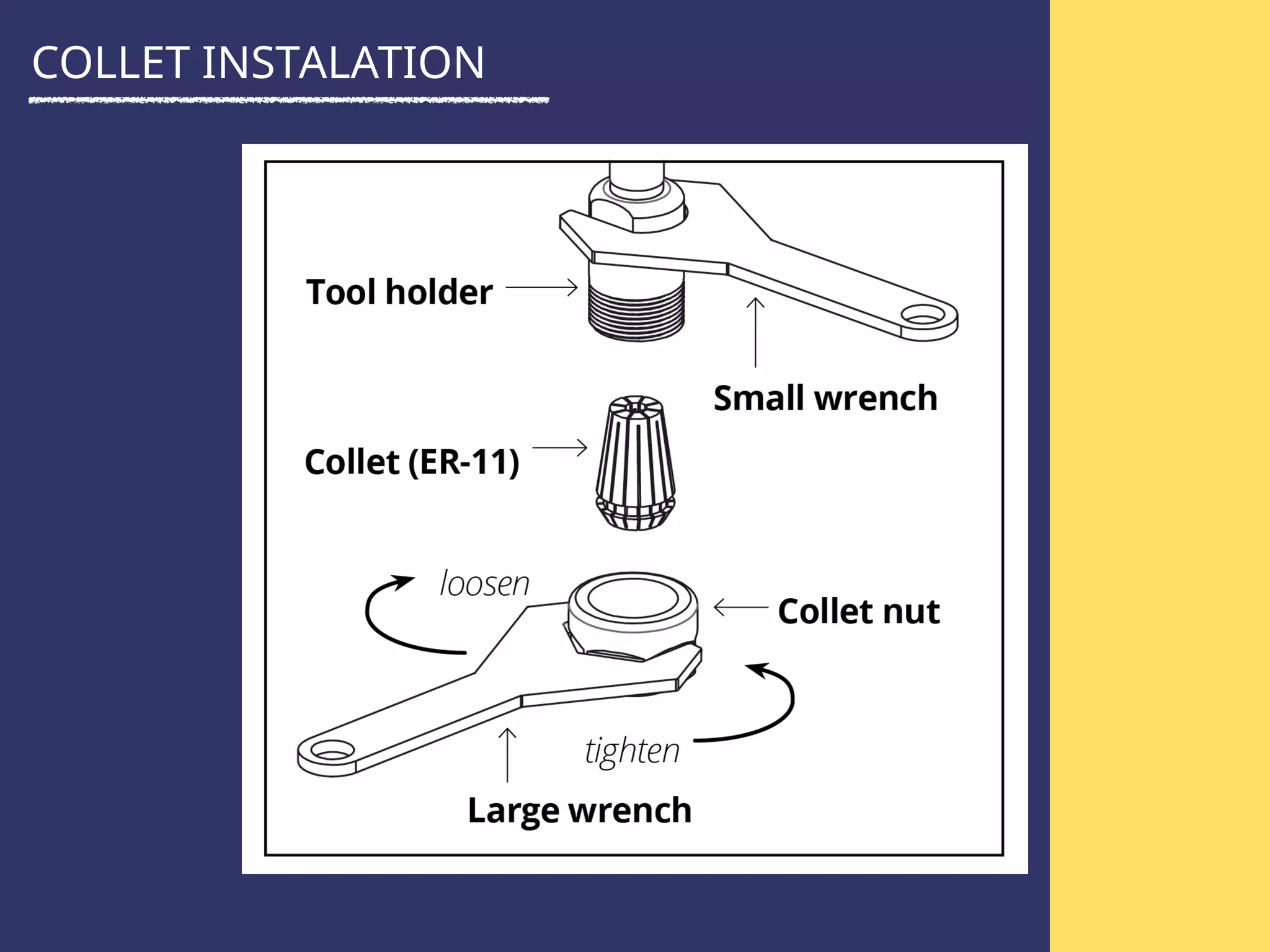

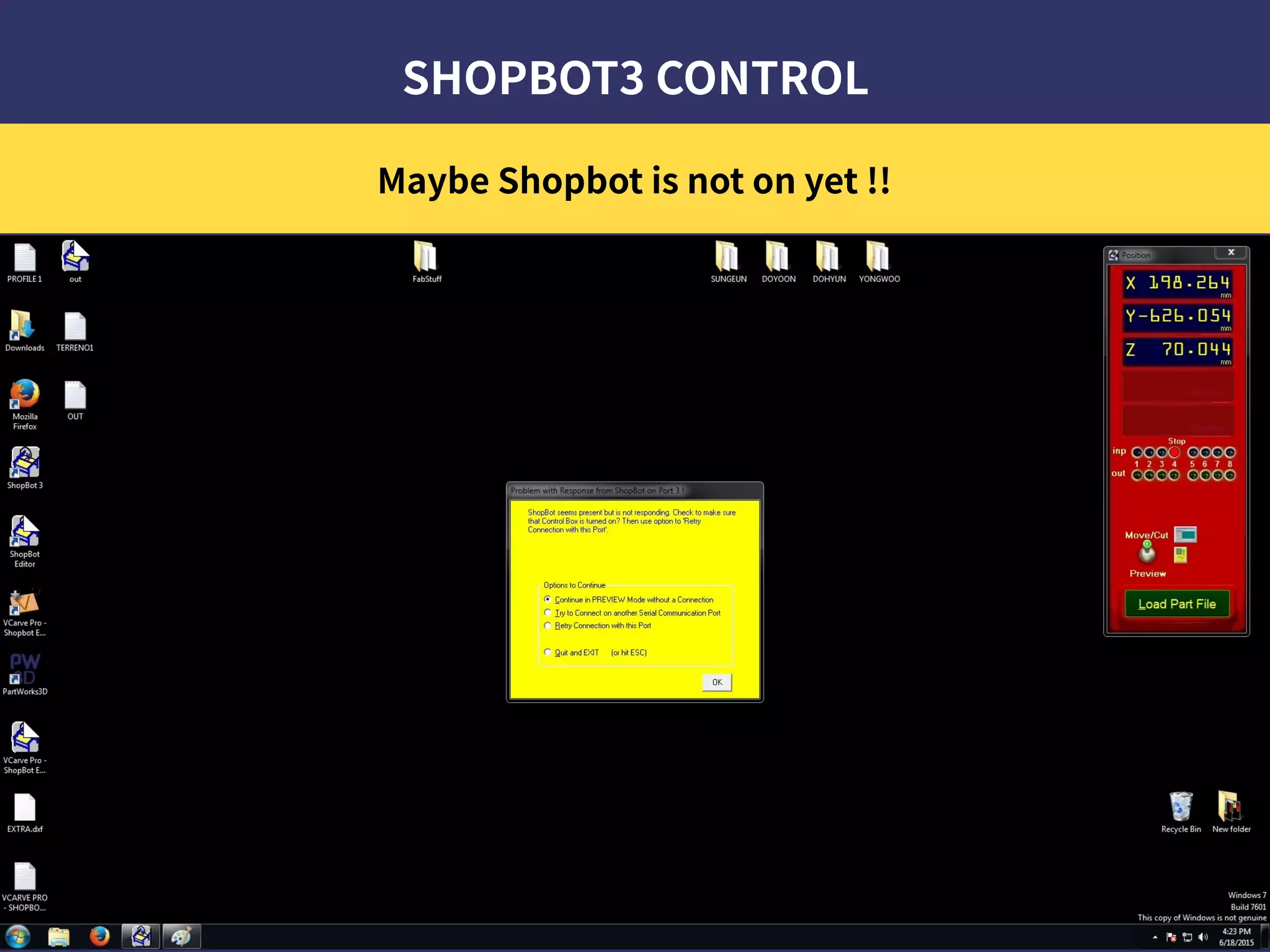

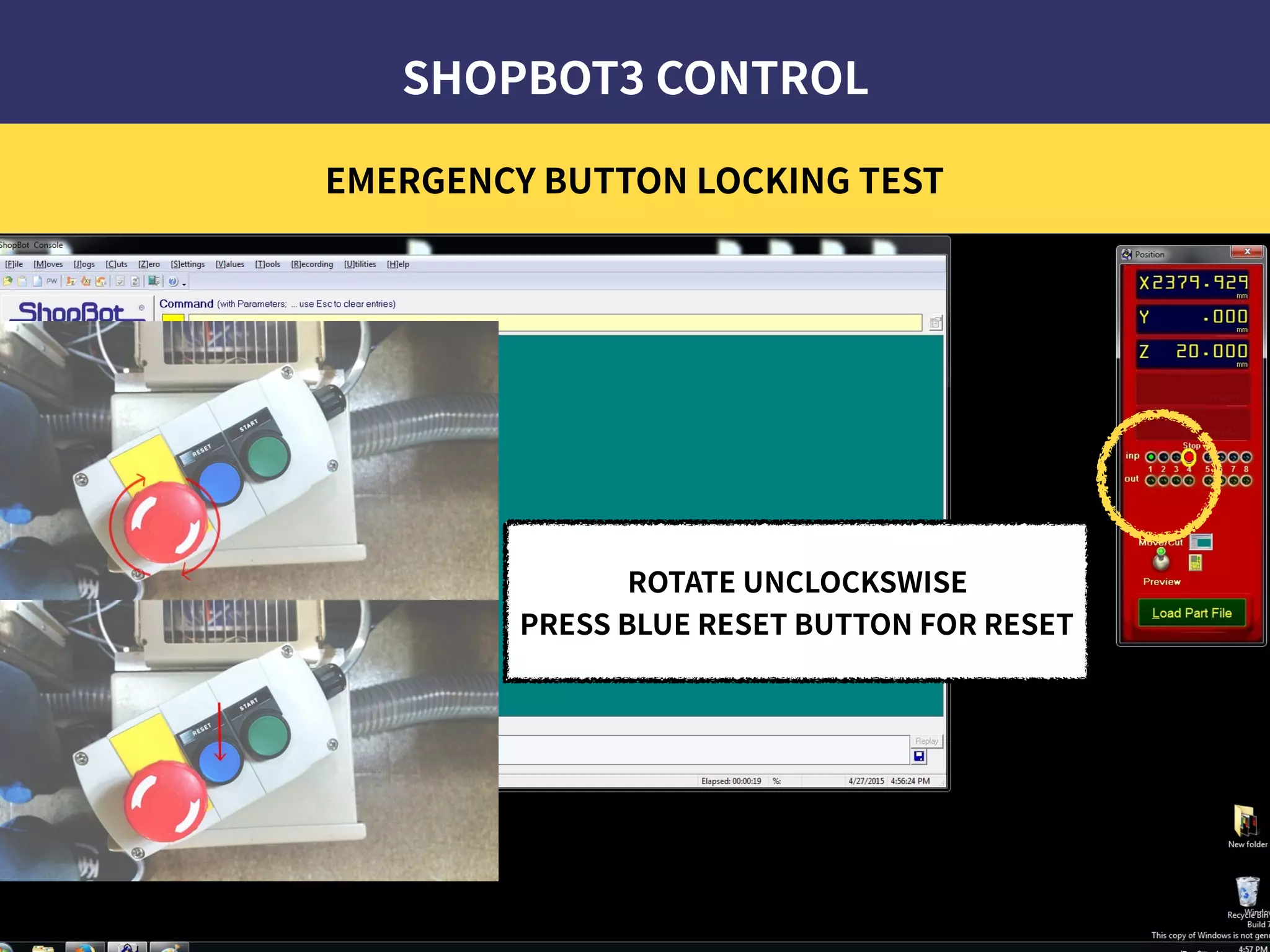

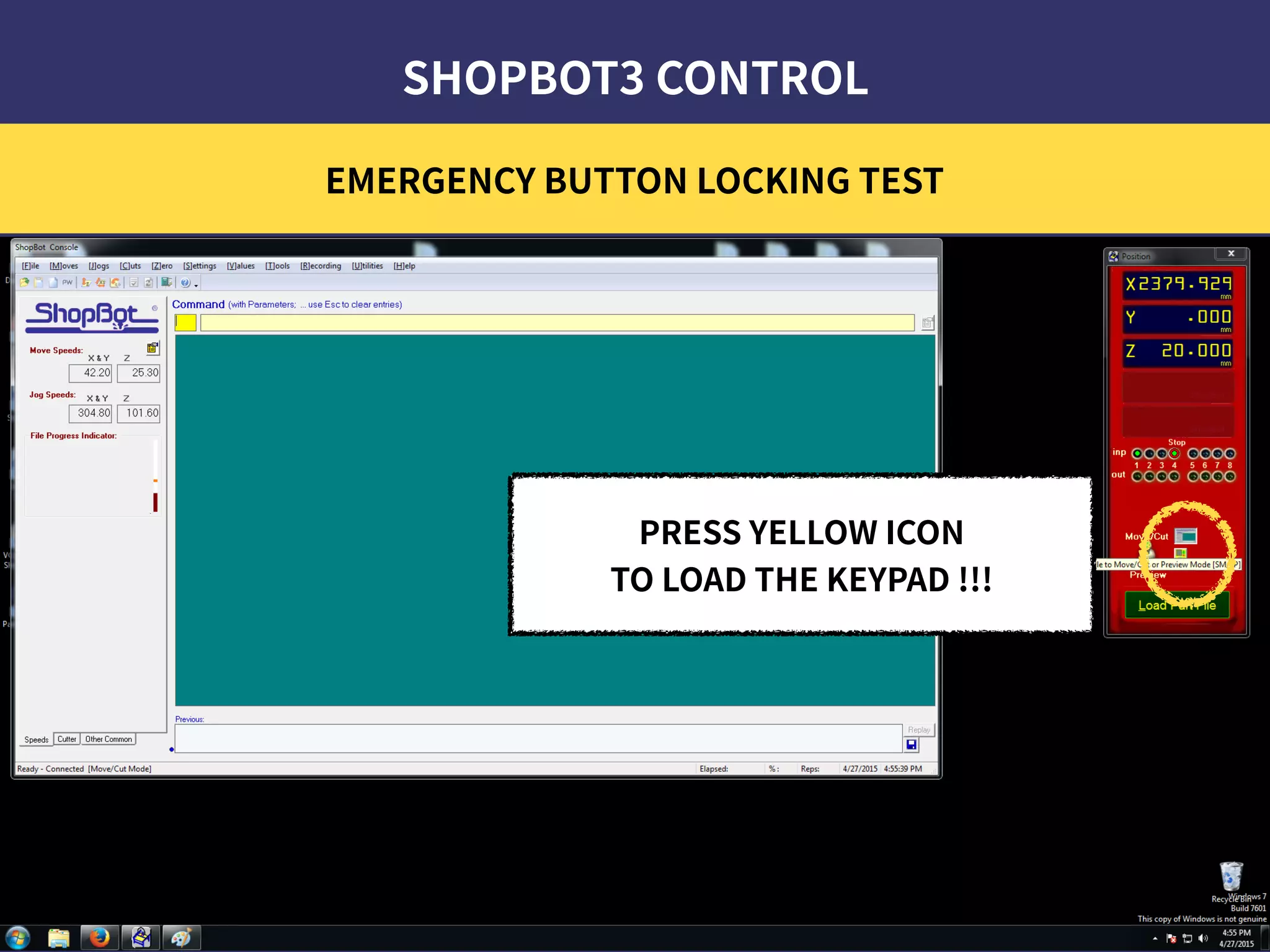

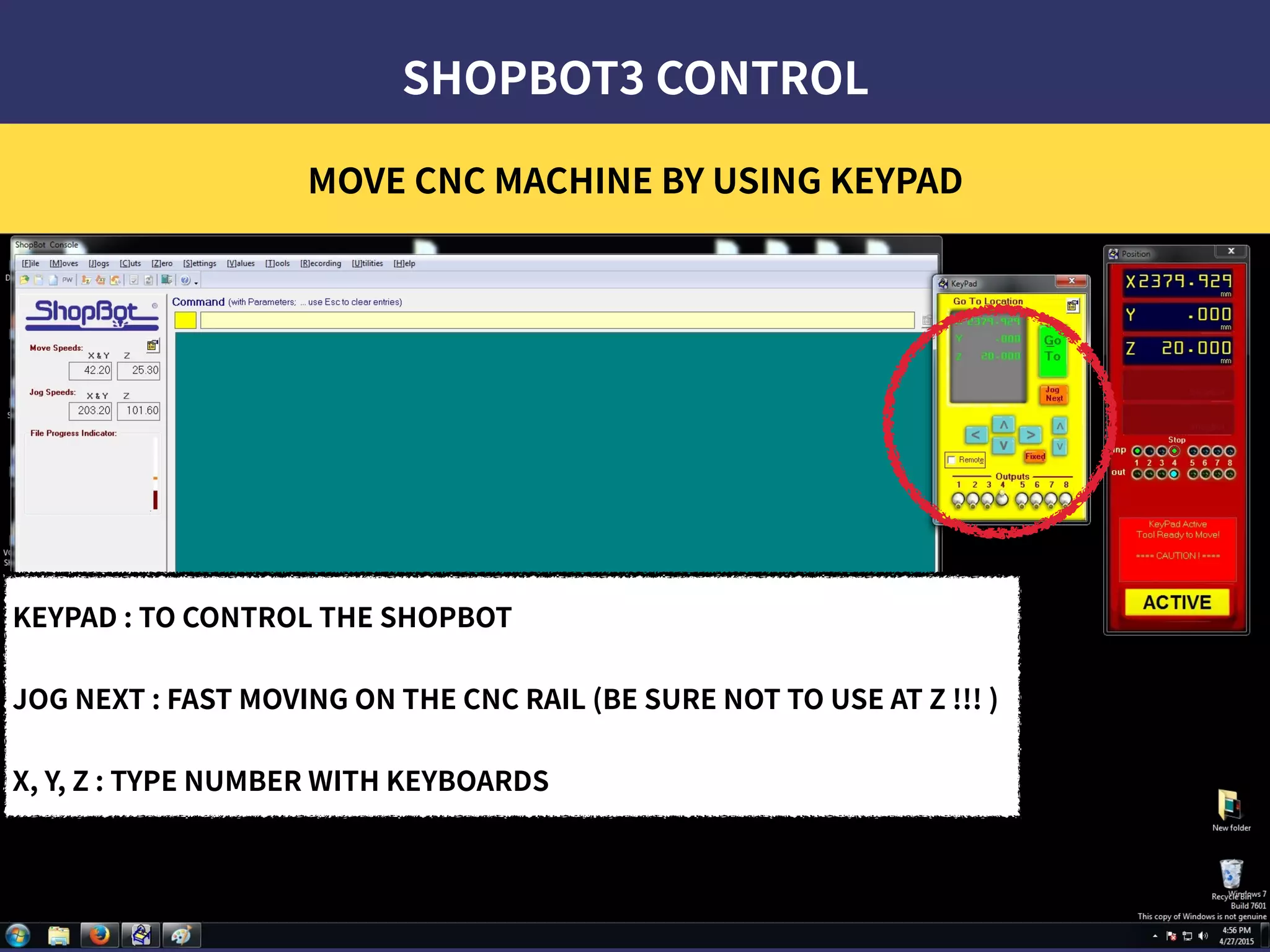

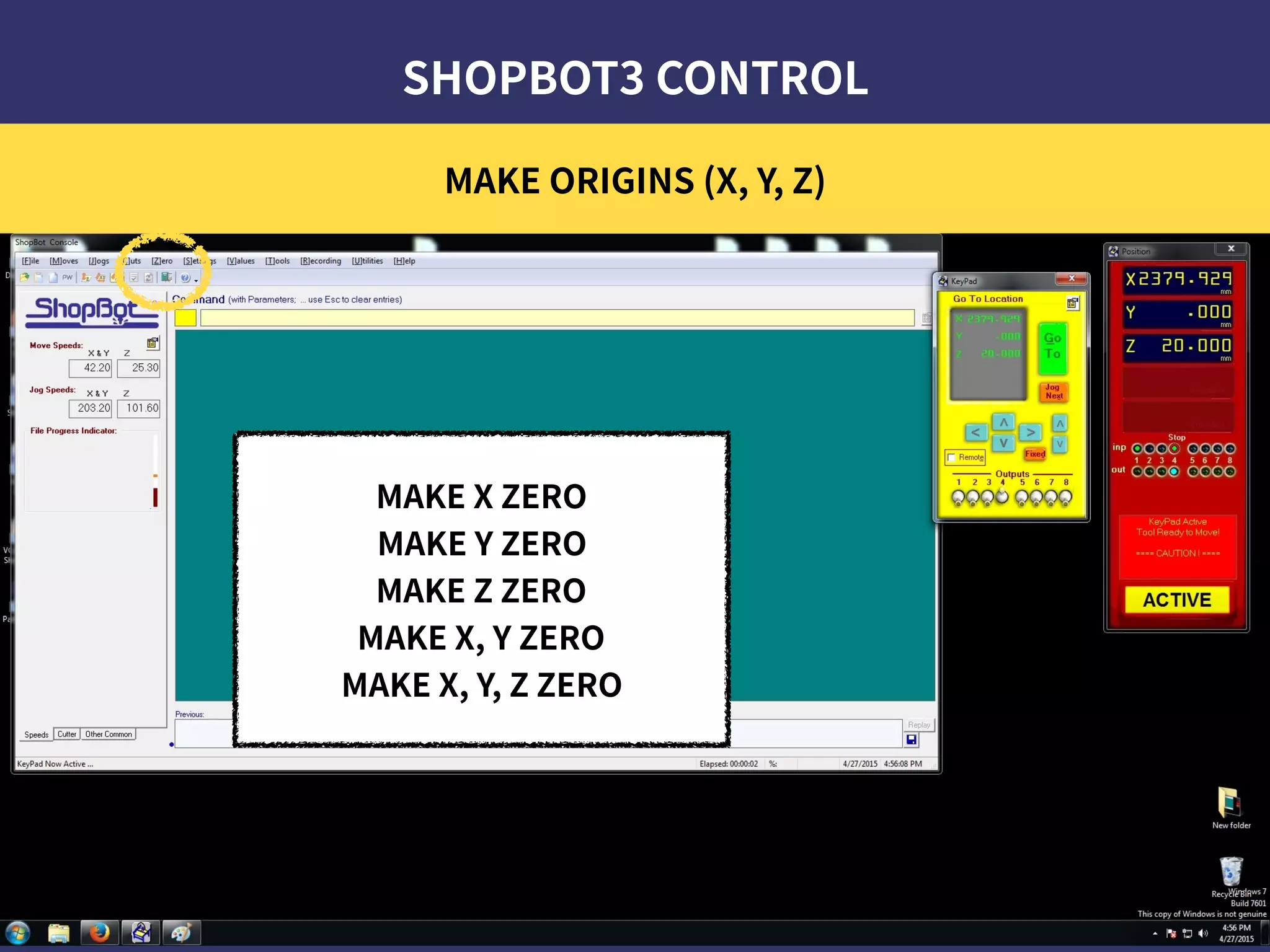

This document contains information about CNC machines, their operation, and best practices. It discusses different types of CNC machines like 3, 4, and 5 axis machines. It provides guidelines on tooling, materials, feeds and speeds for different materials. Safety procedures are outlined, including daily maintenance checks and accident prevention. Mistakes to avoid like bad tool paths or cutting are also mentioned.

![[Workshop] cnc router ver 0.4](https://image.slidesharecdn.com/workshopcncrouterver0-160830113607/75/Workshop-cnc-router-ver-0-4-225-2048.jpg)