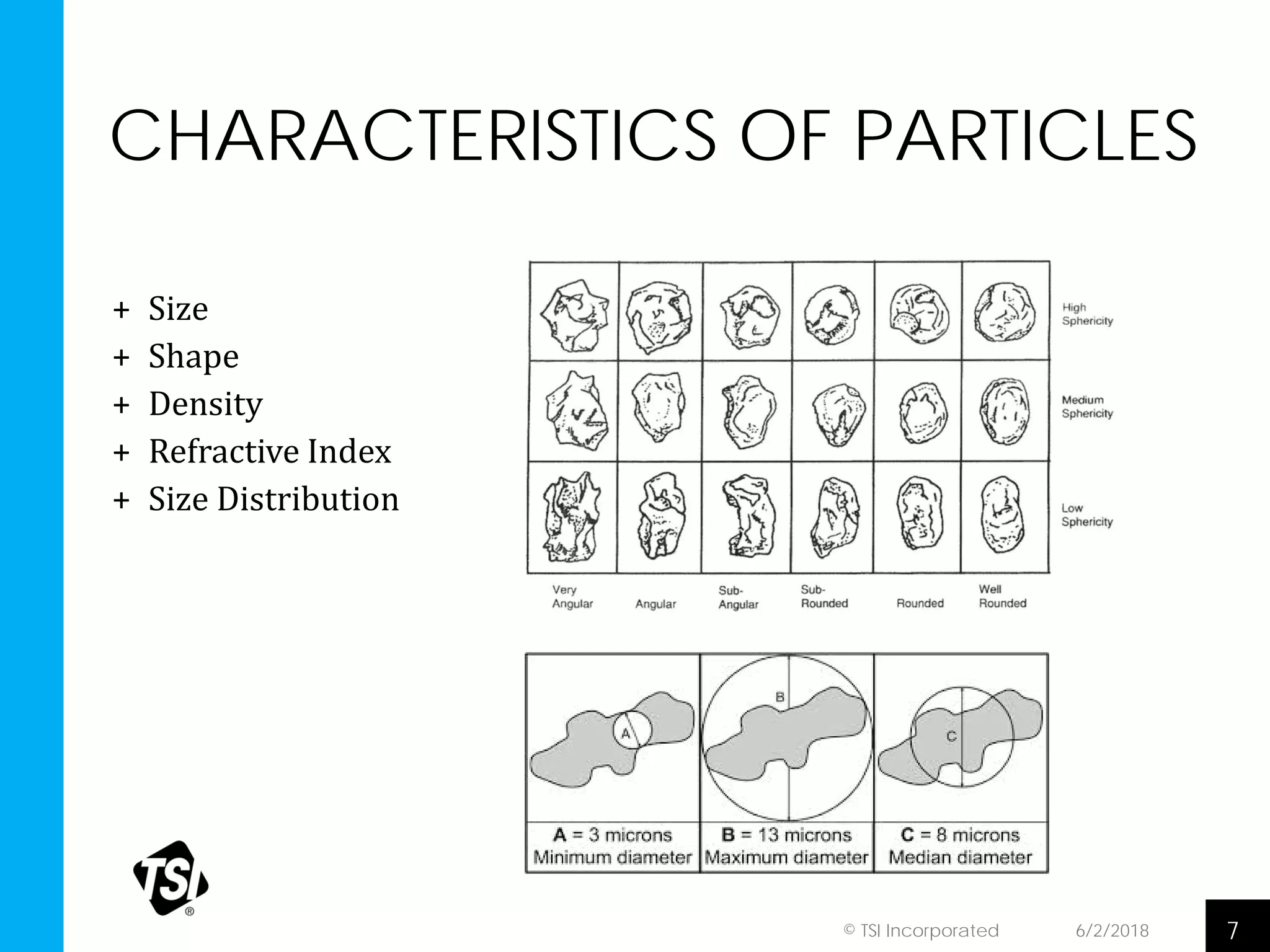

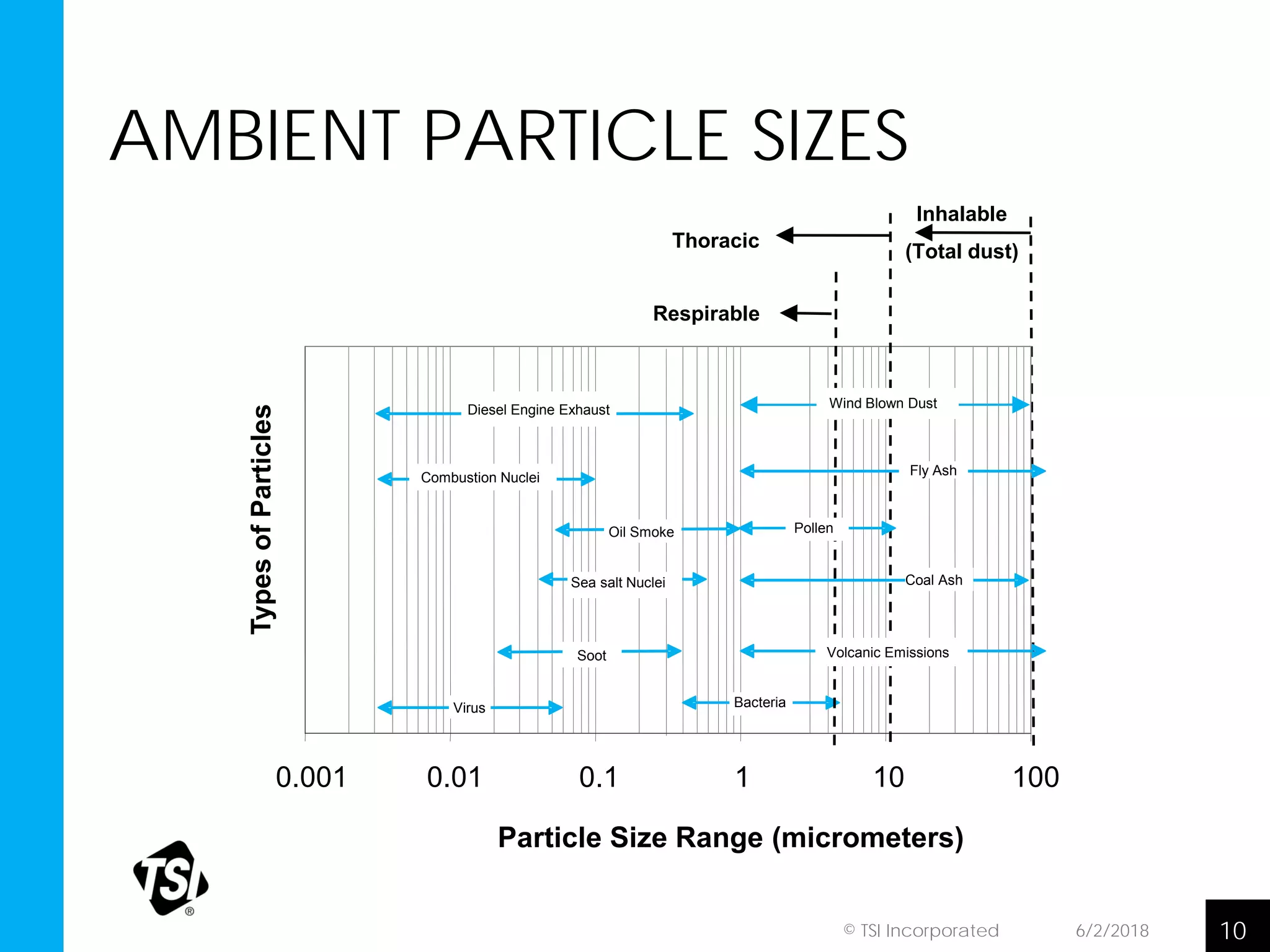

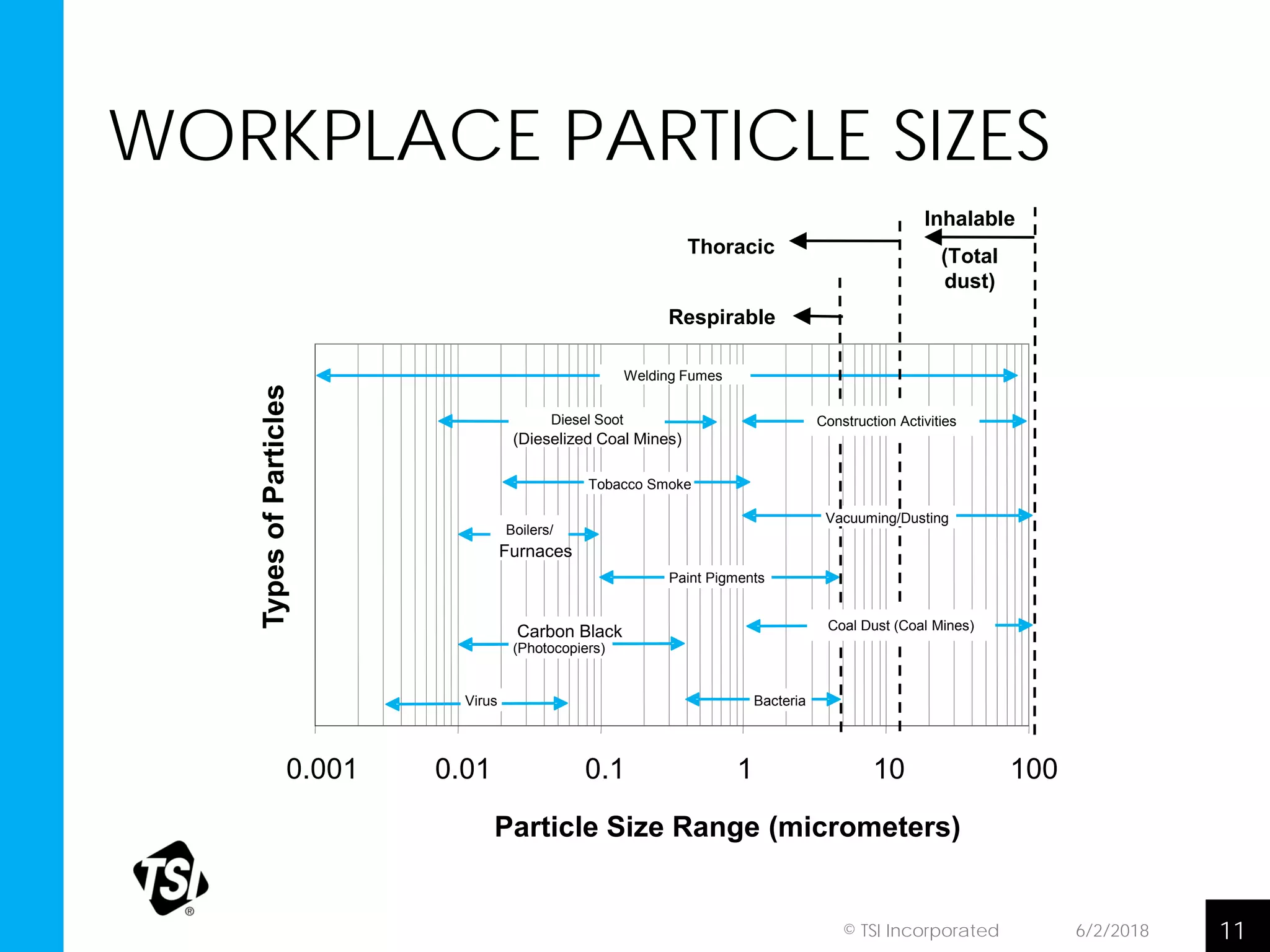

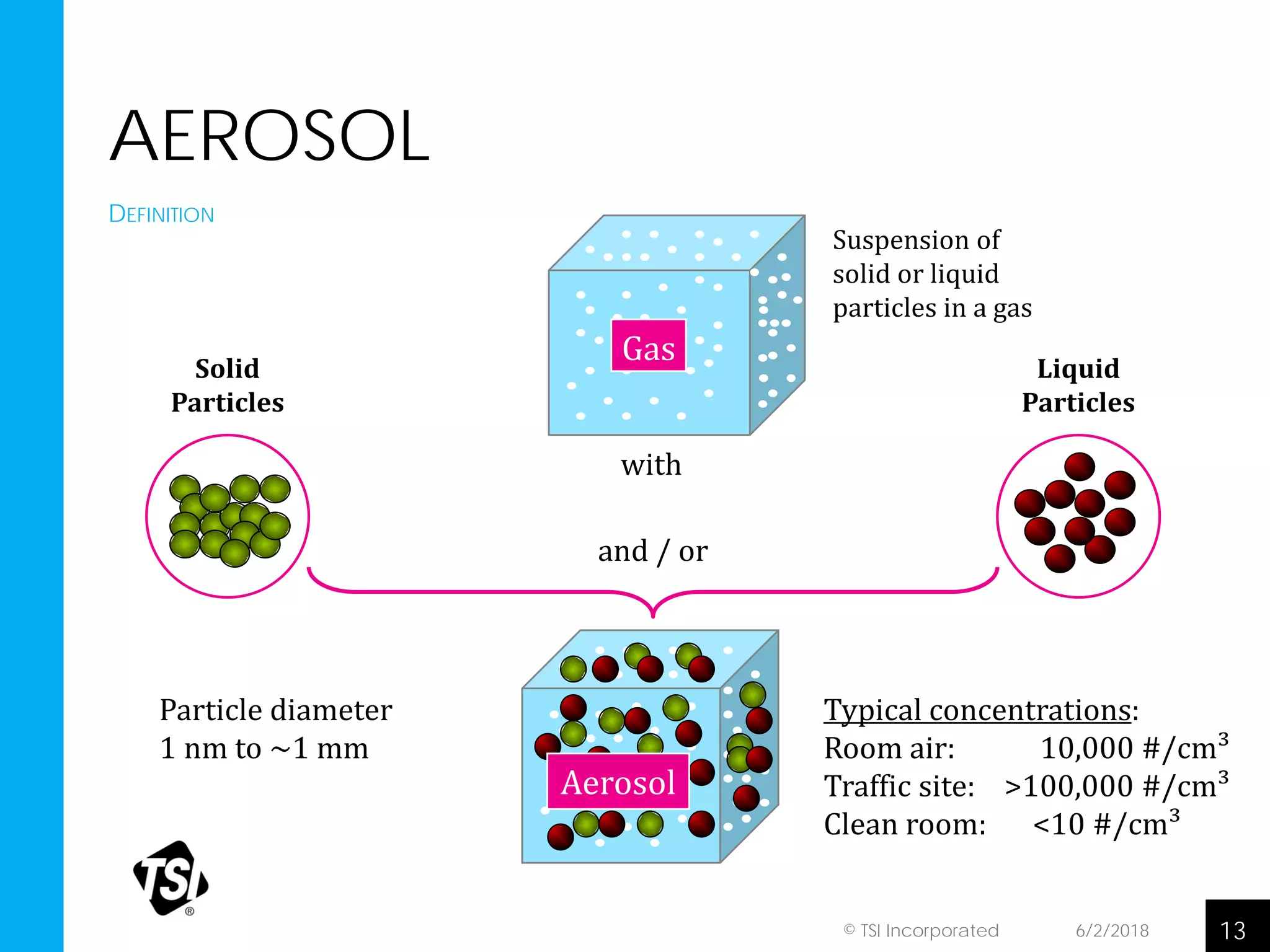

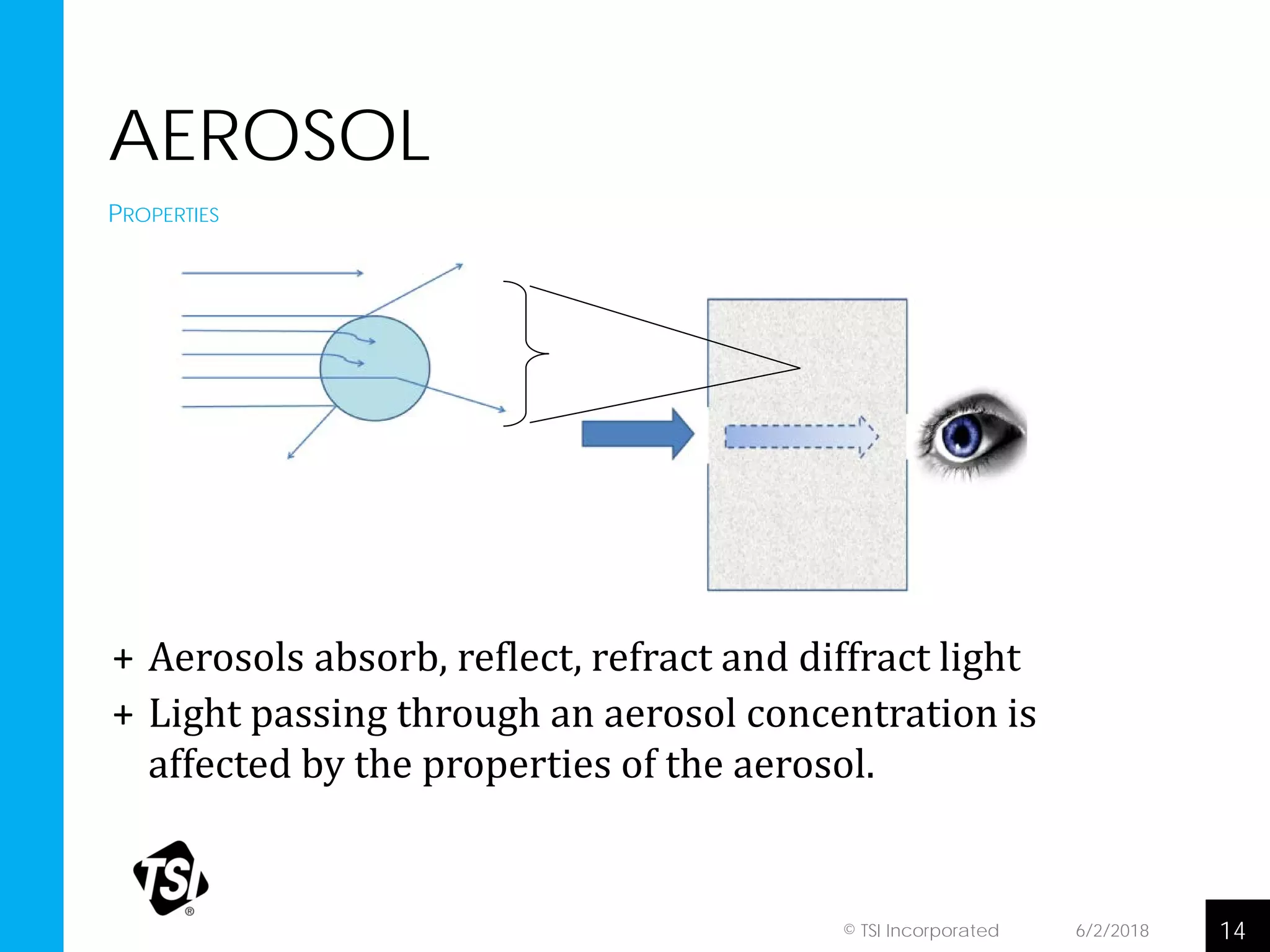

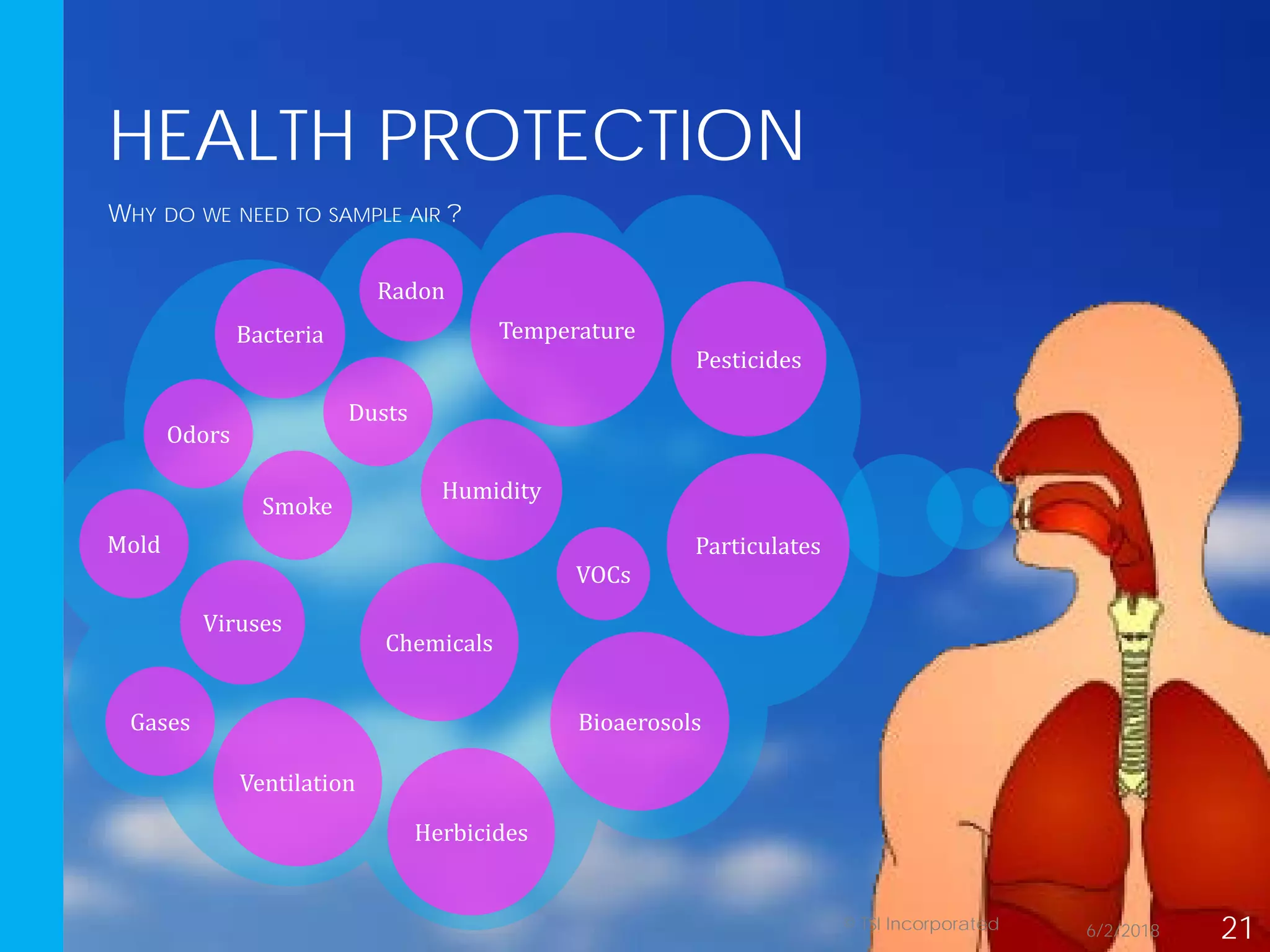

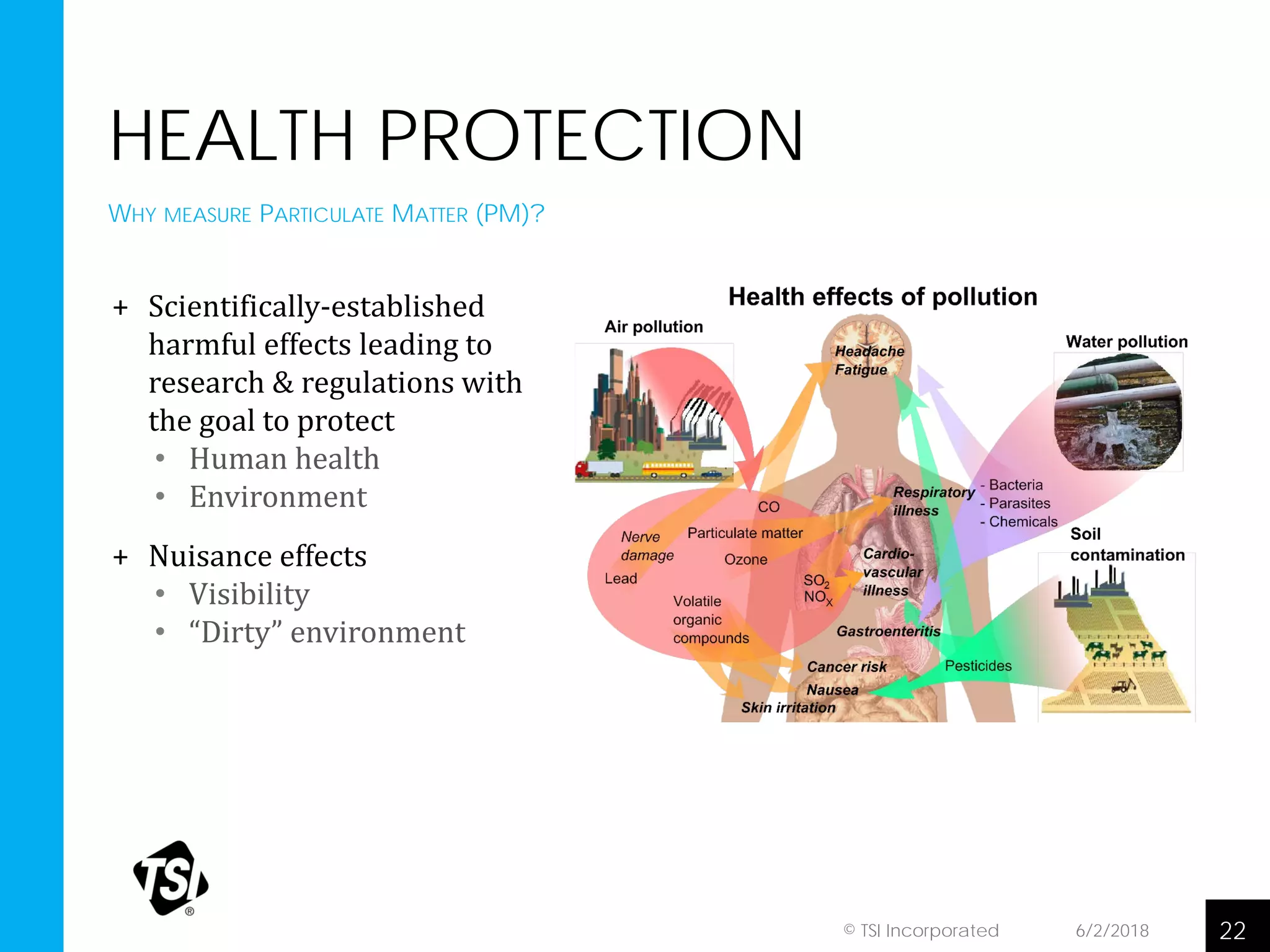

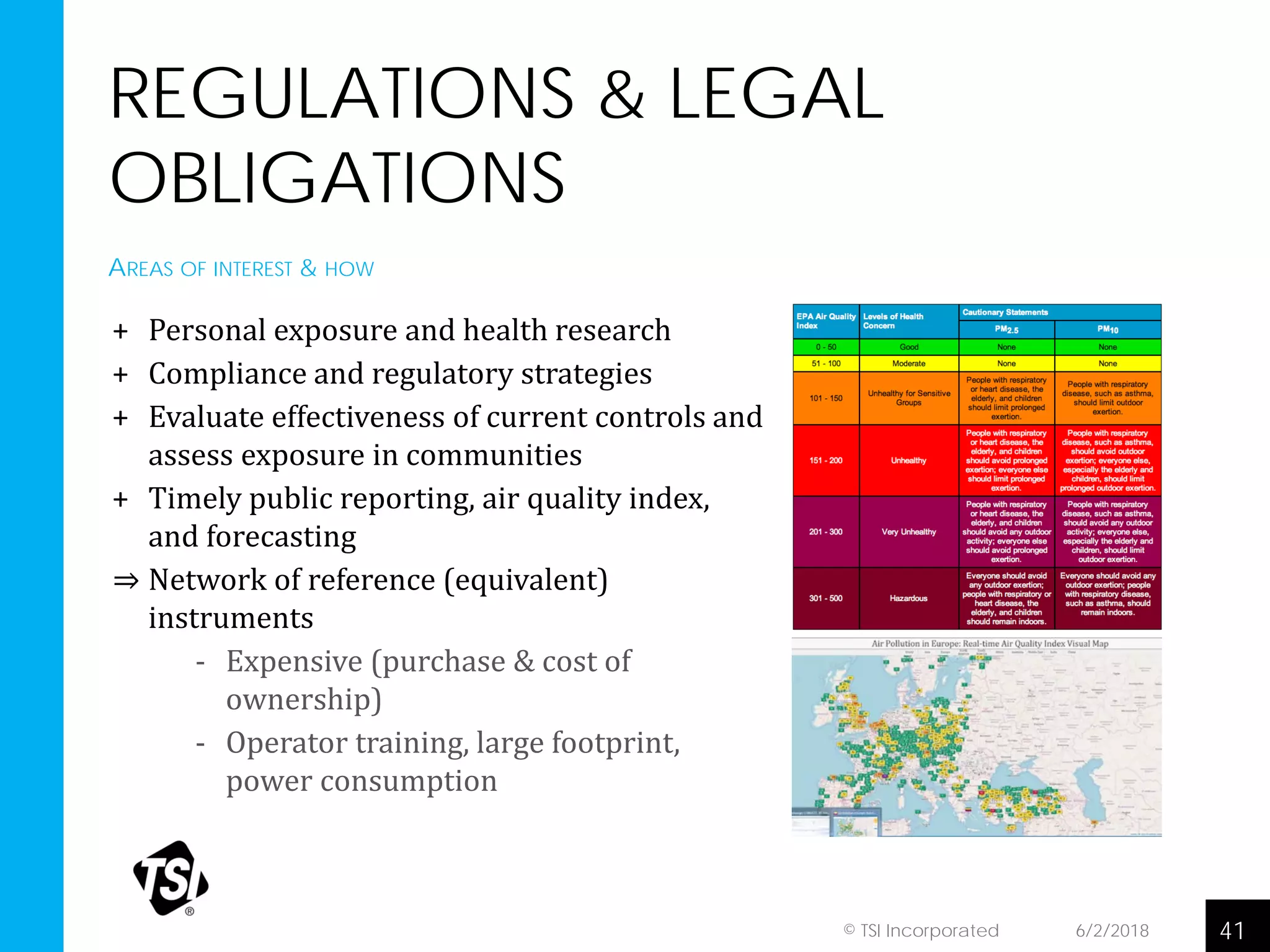

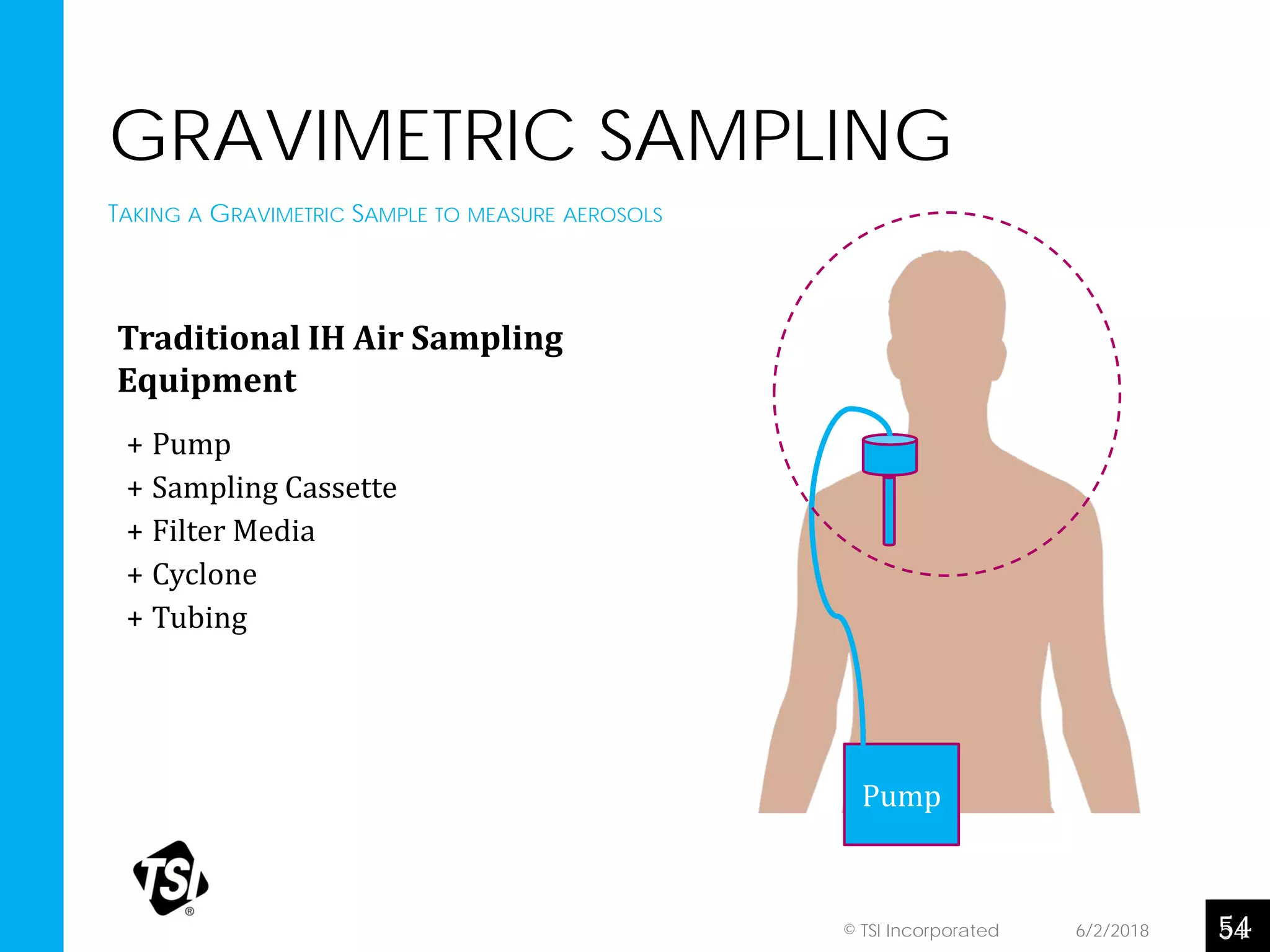

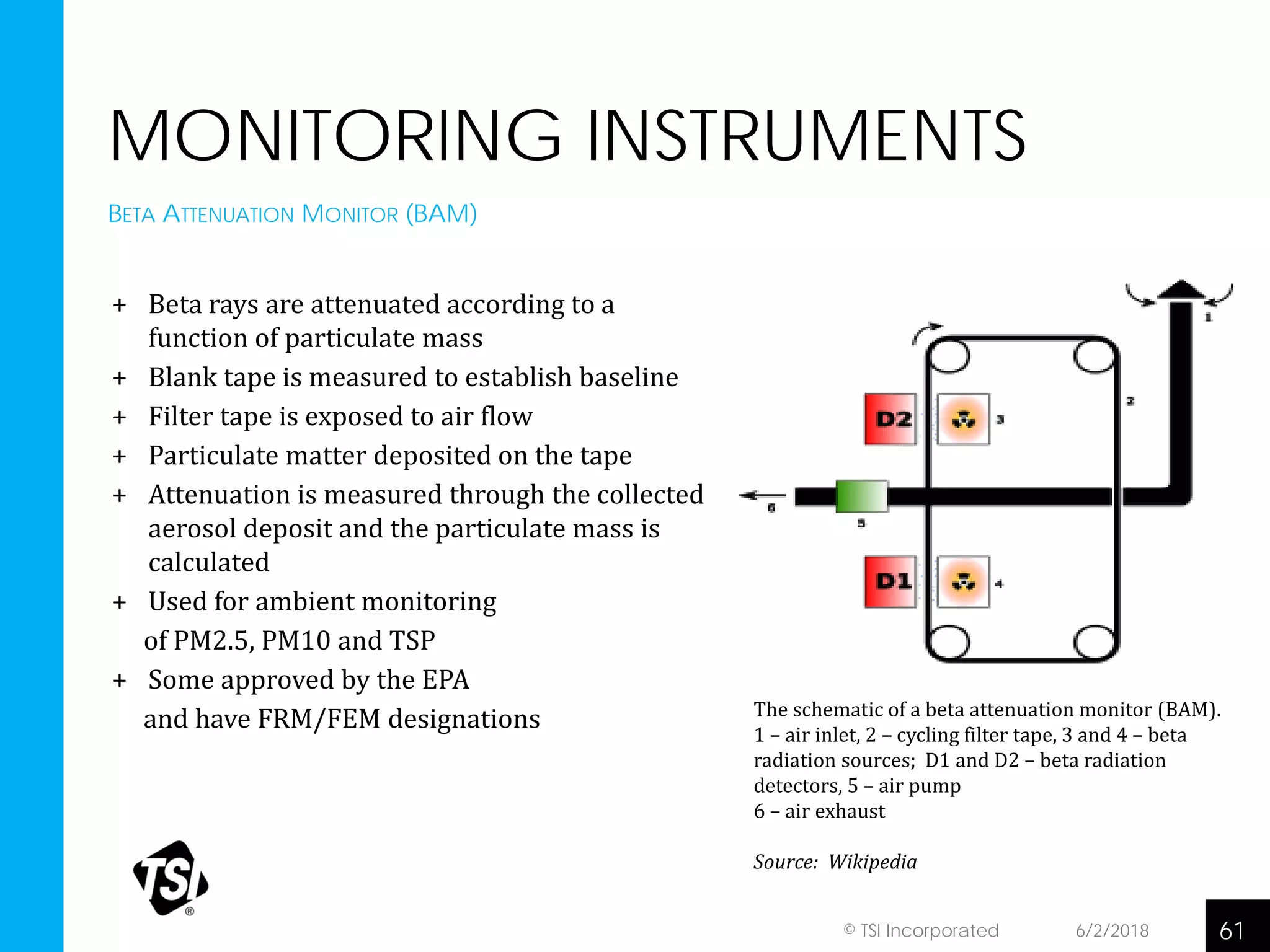

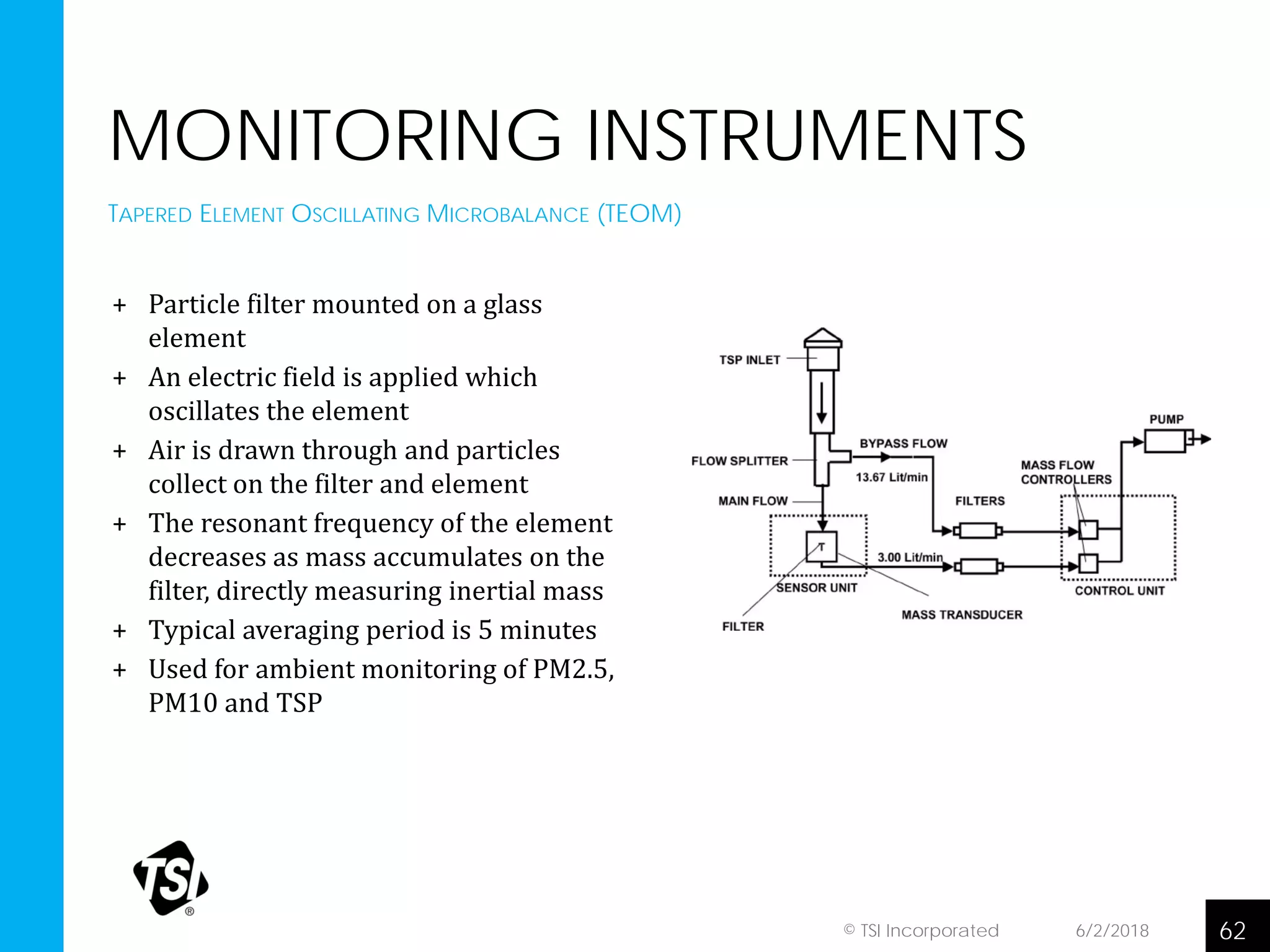

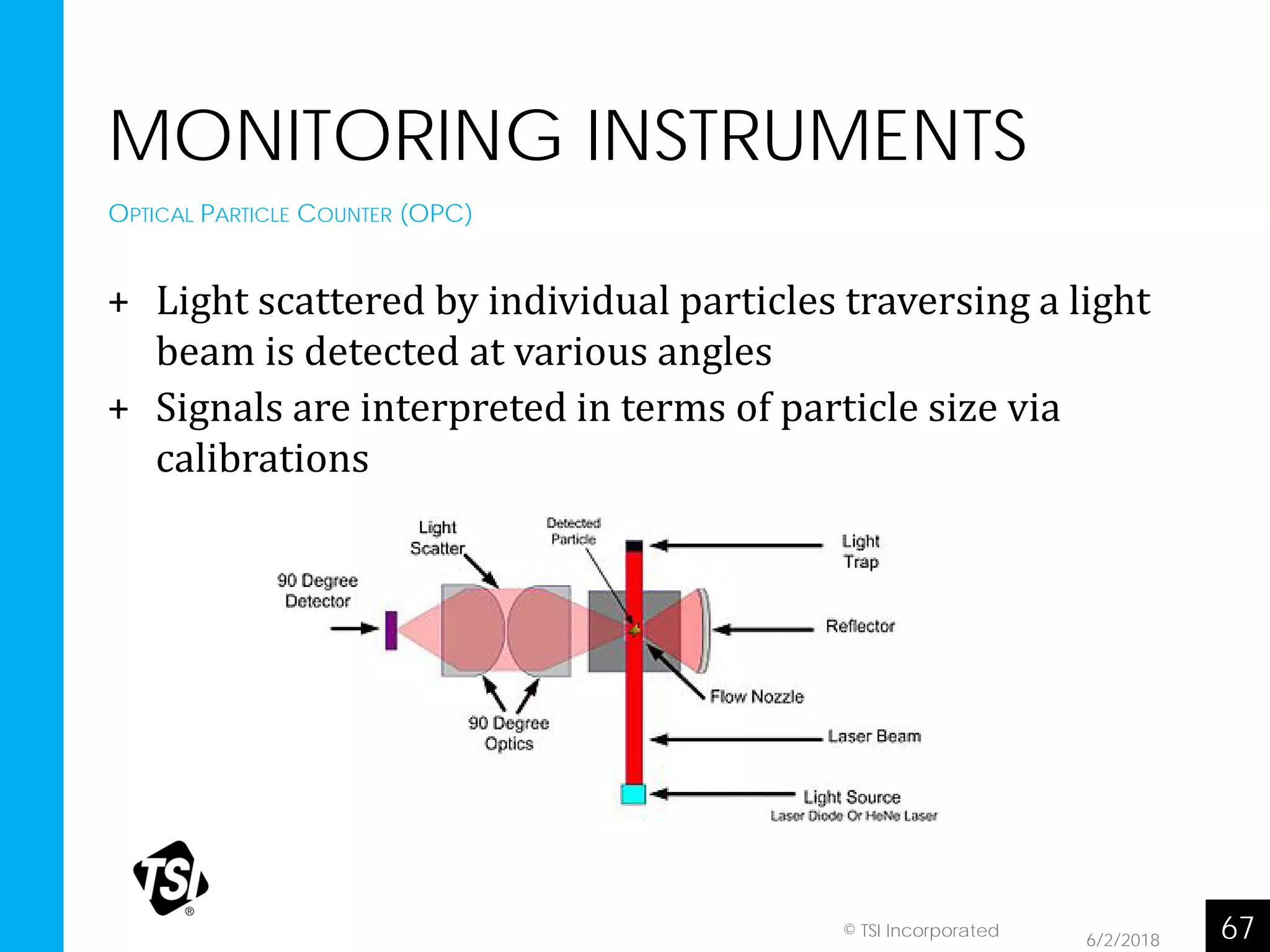

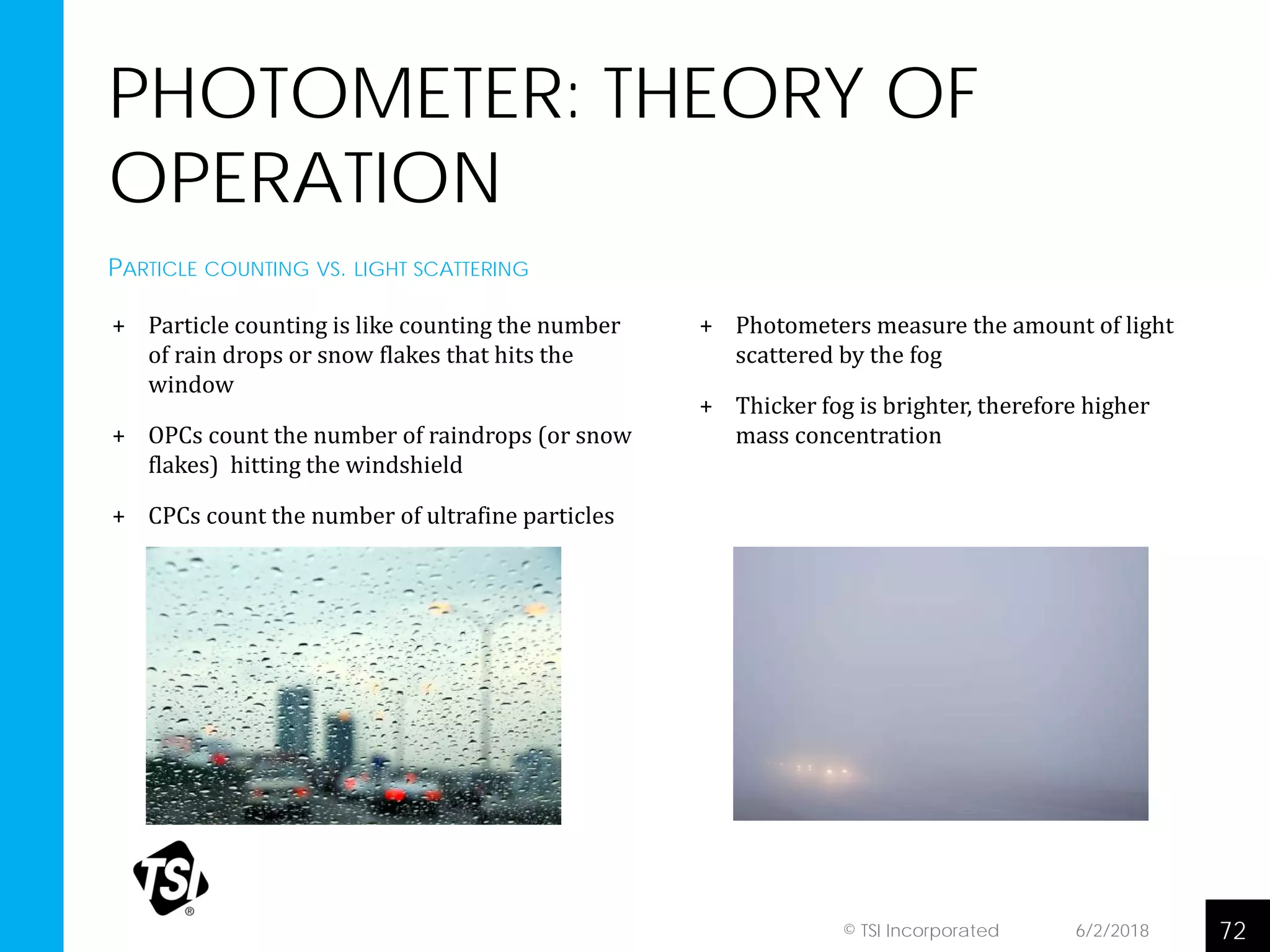

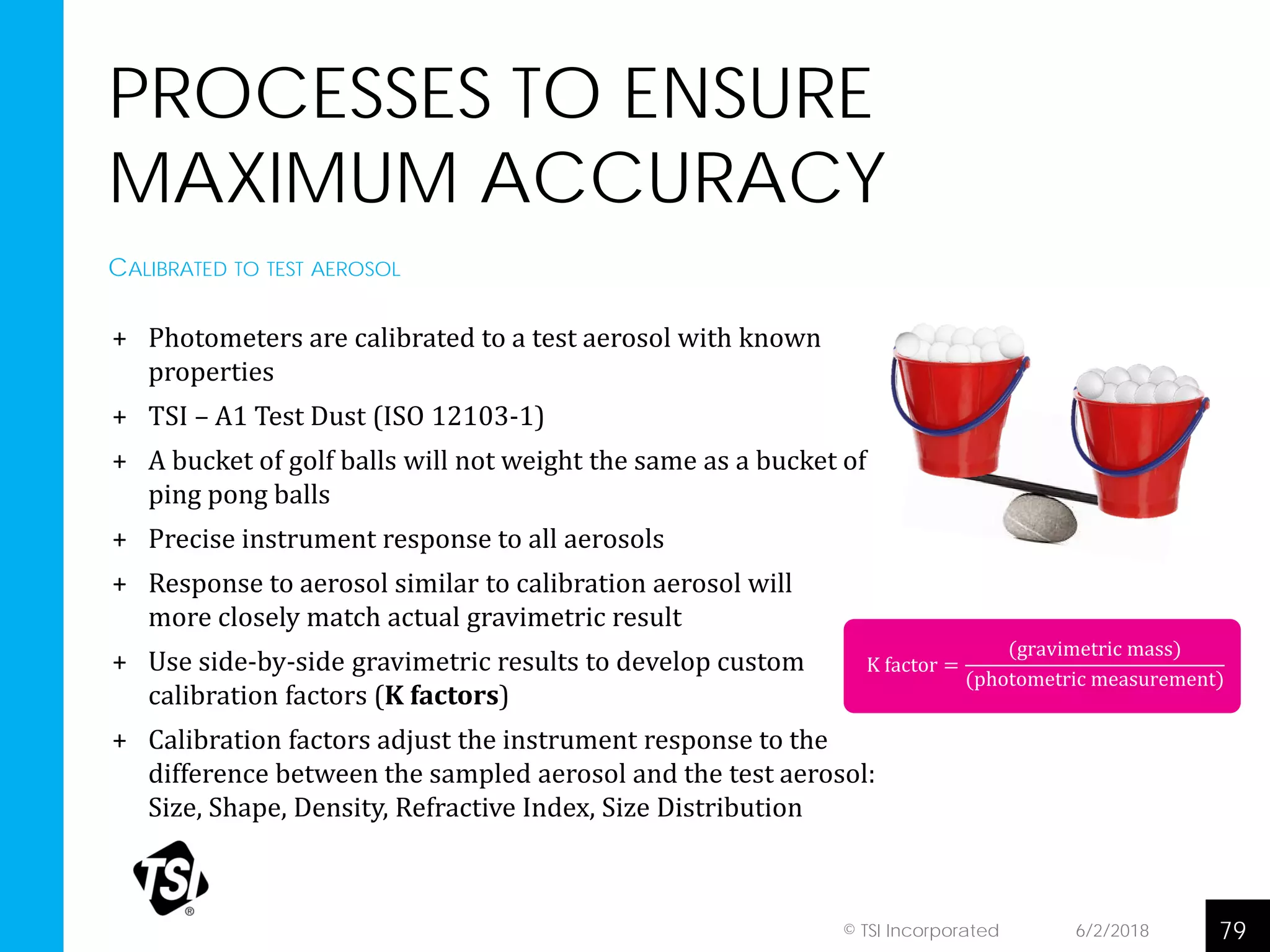

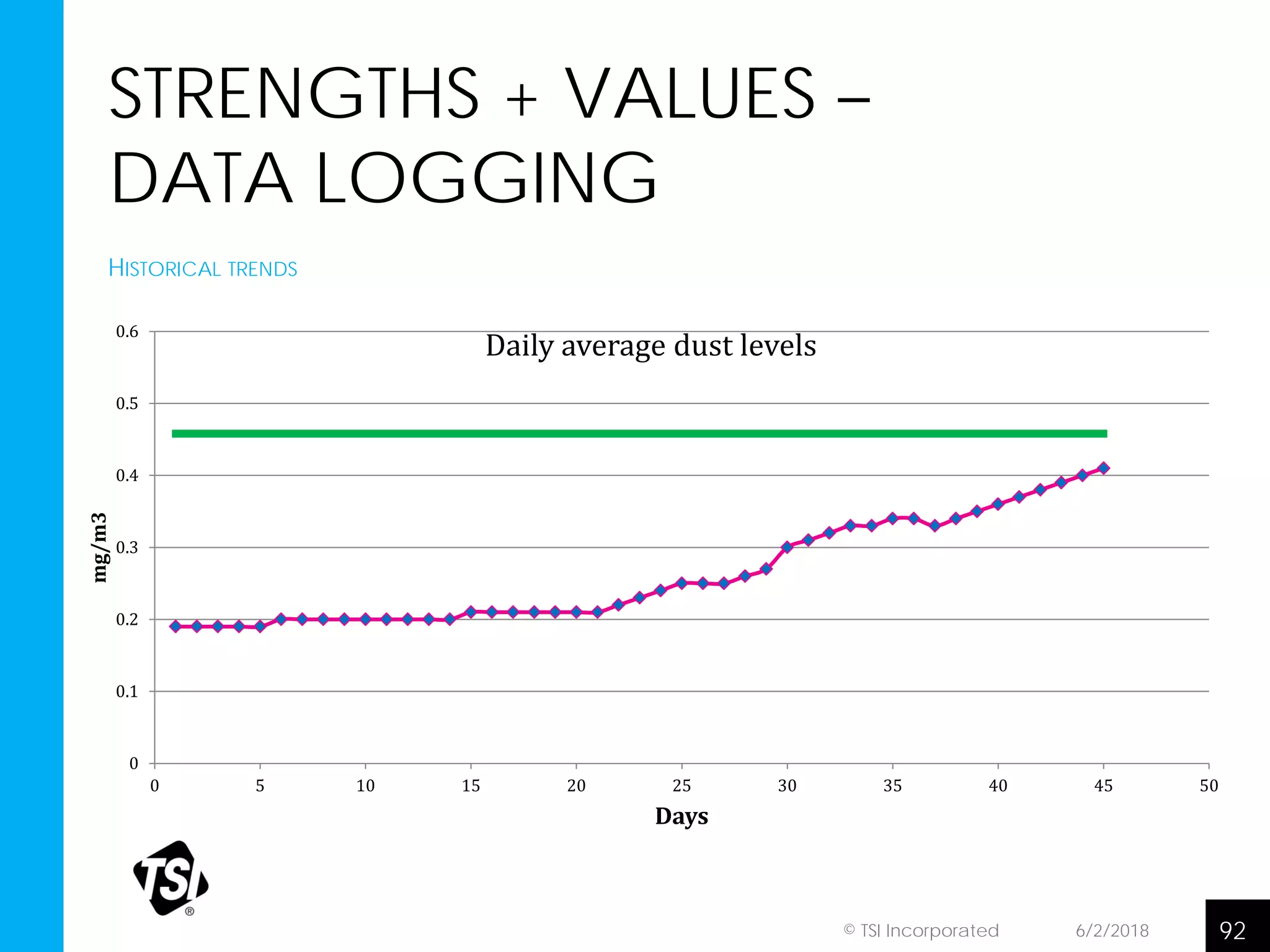

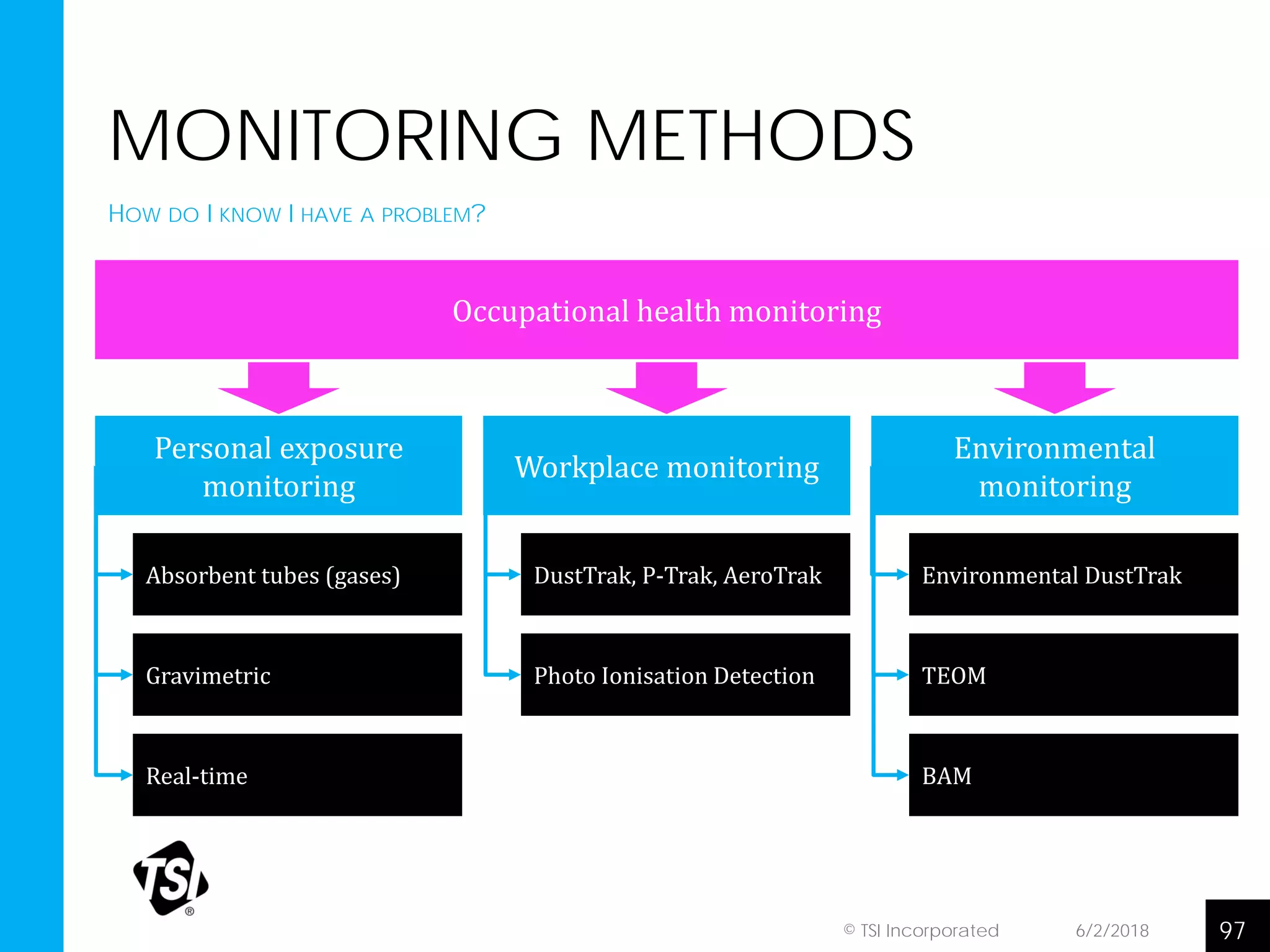

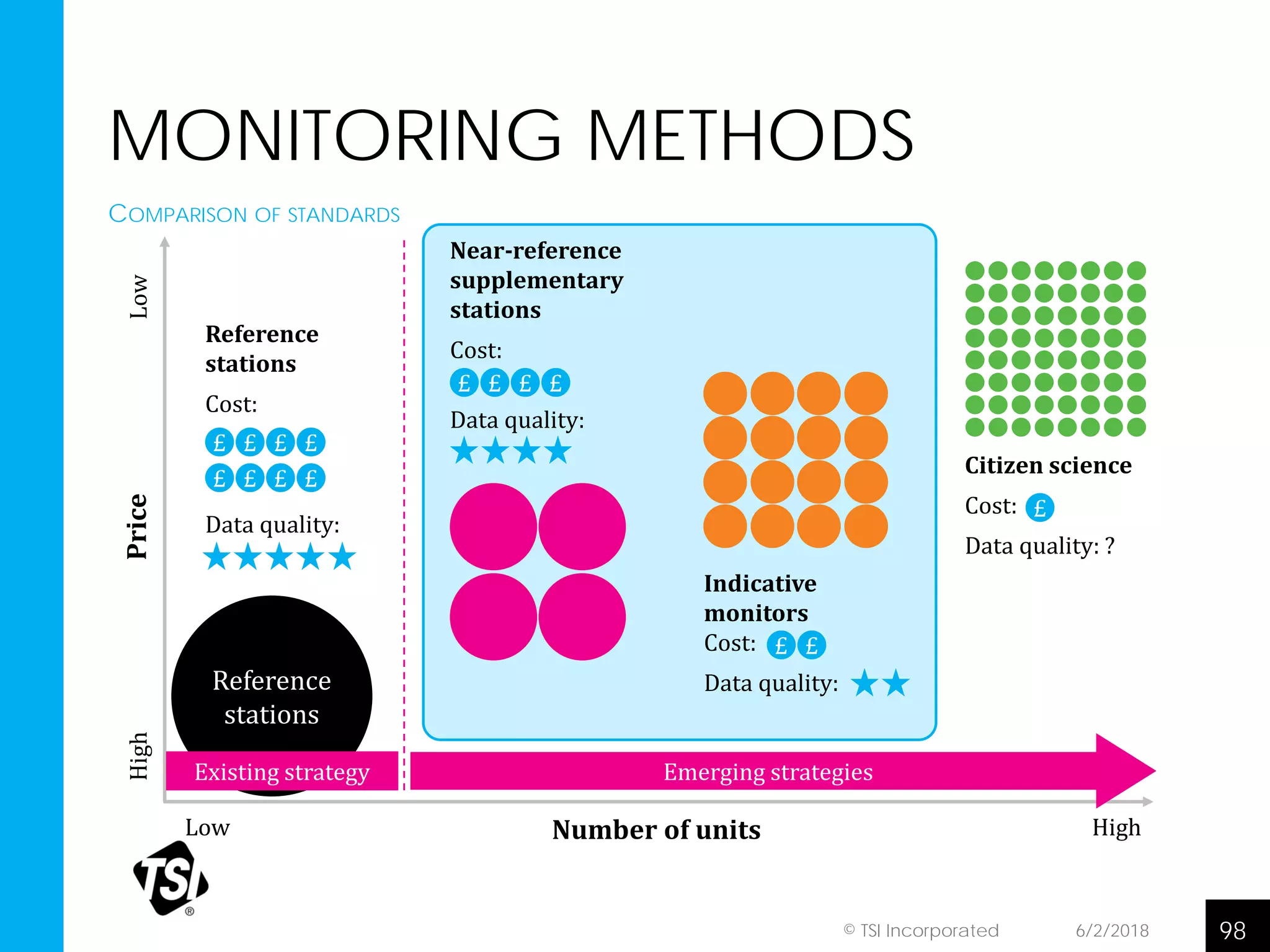

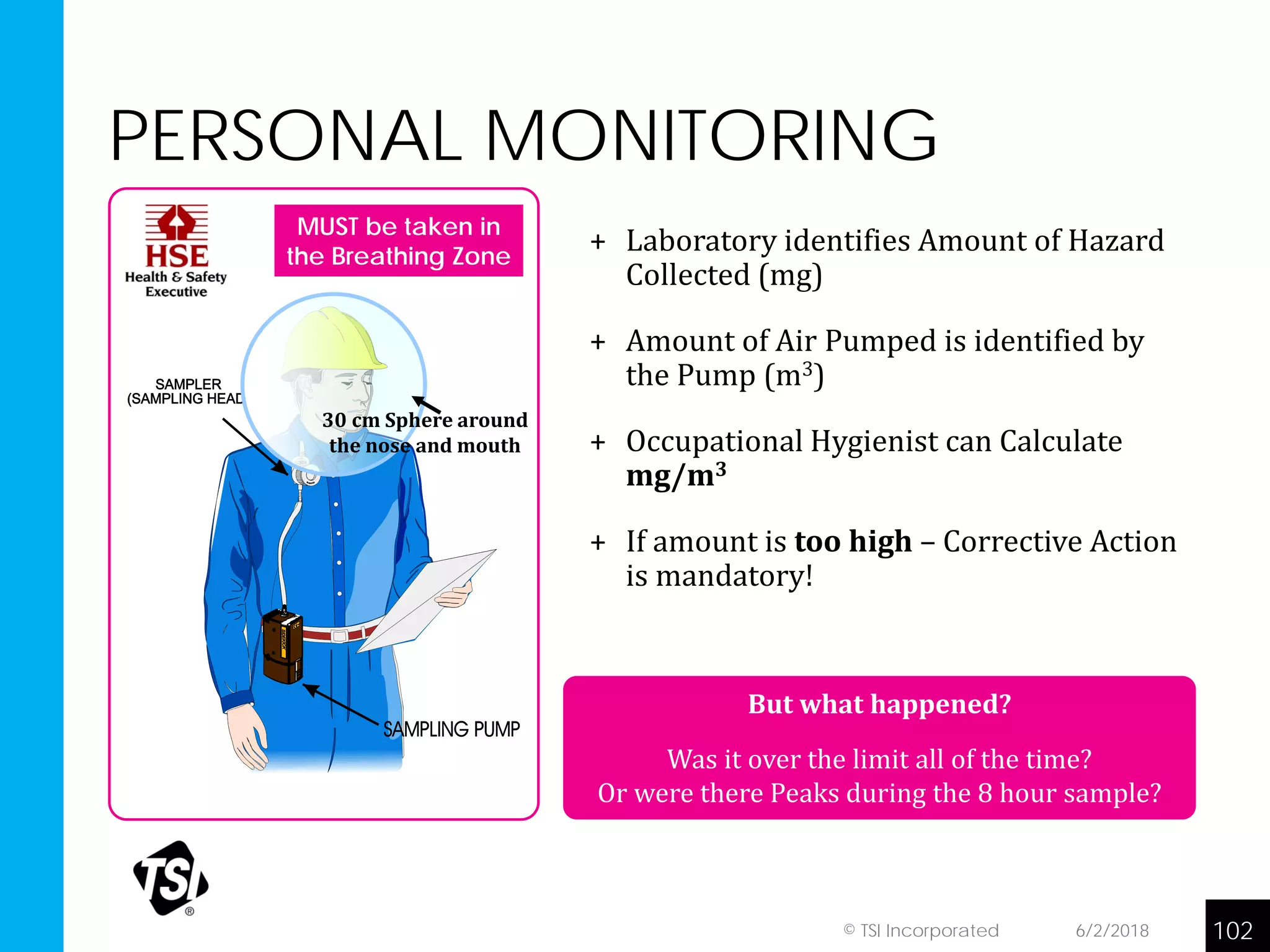

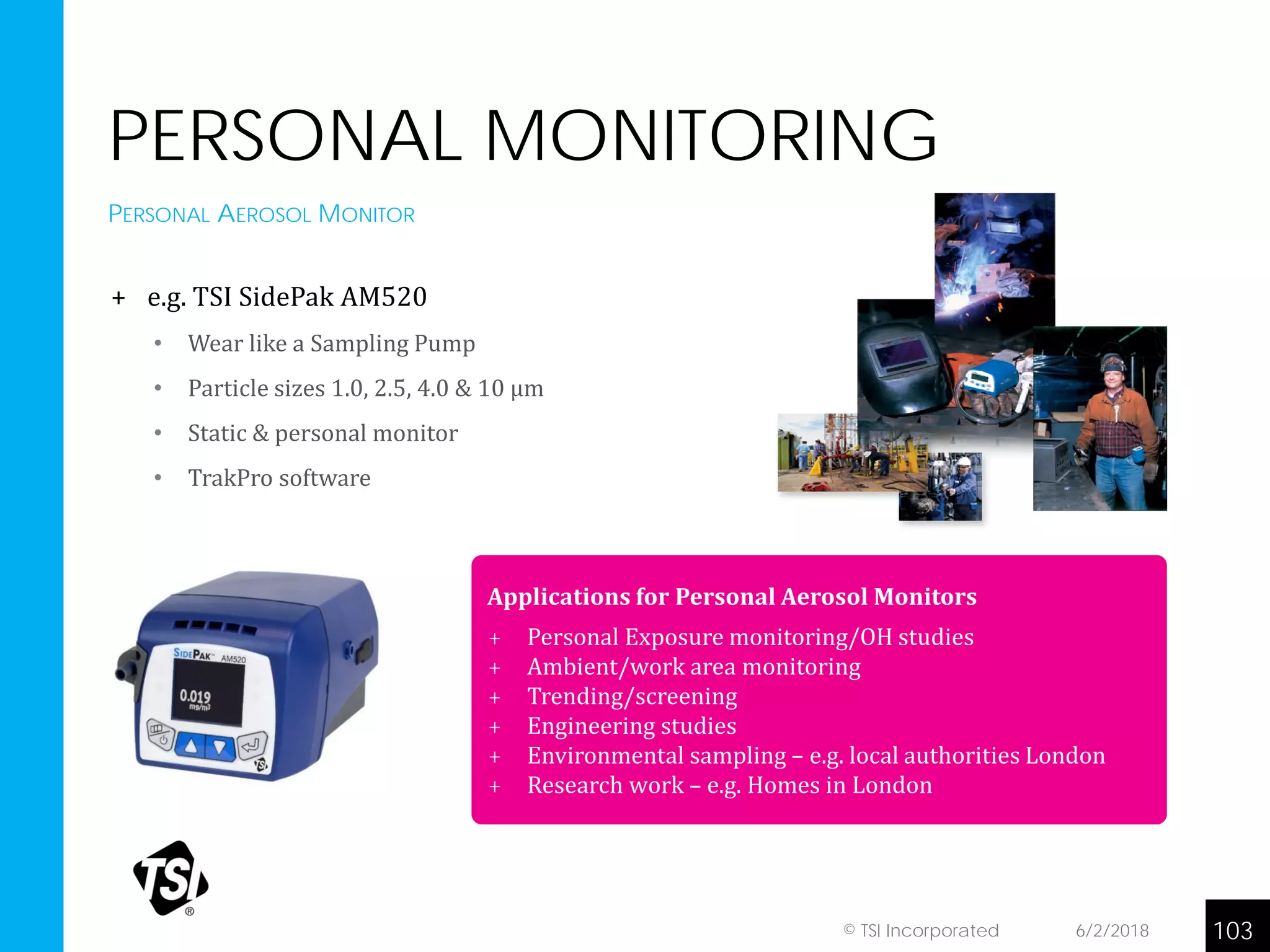

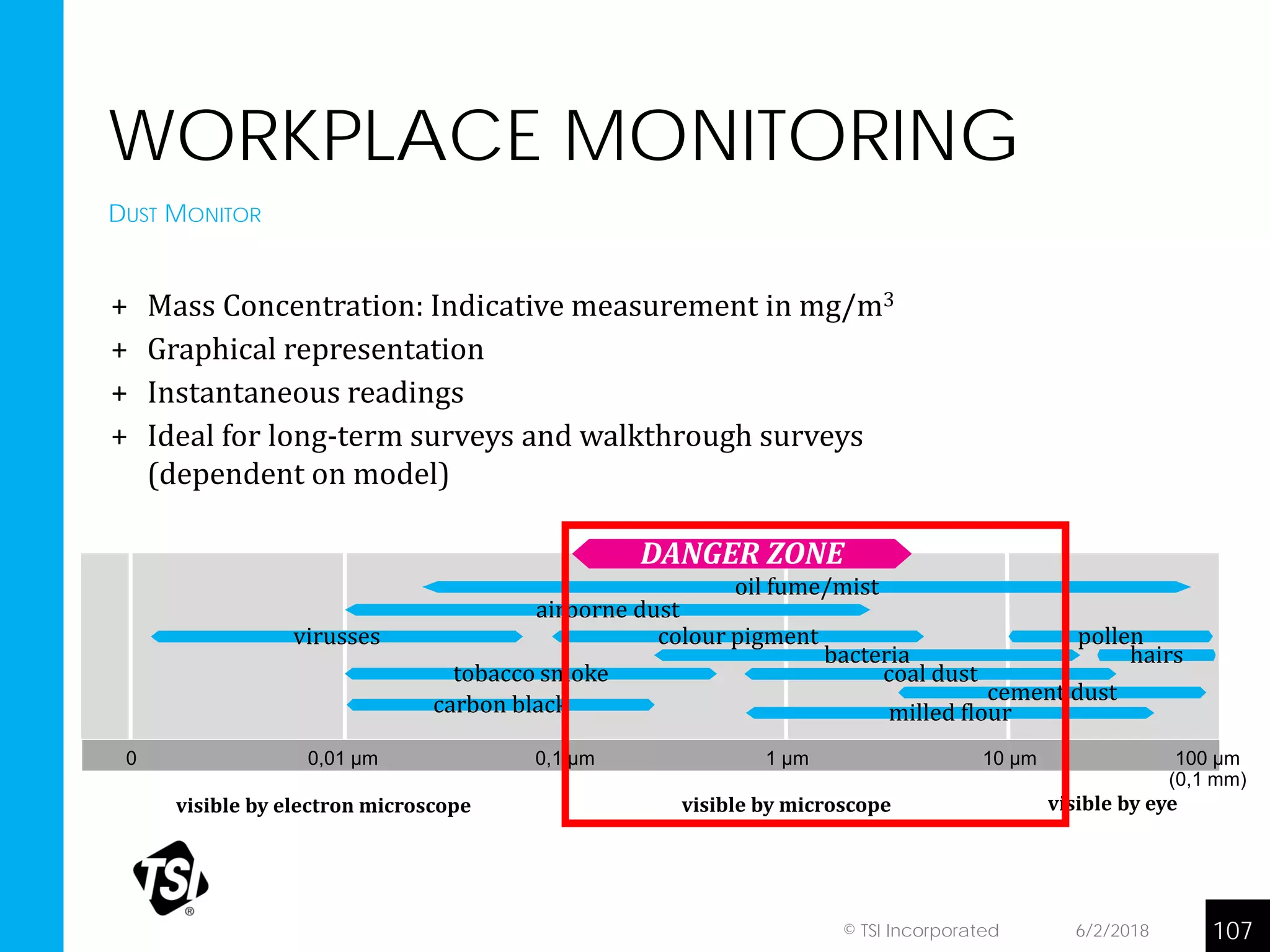

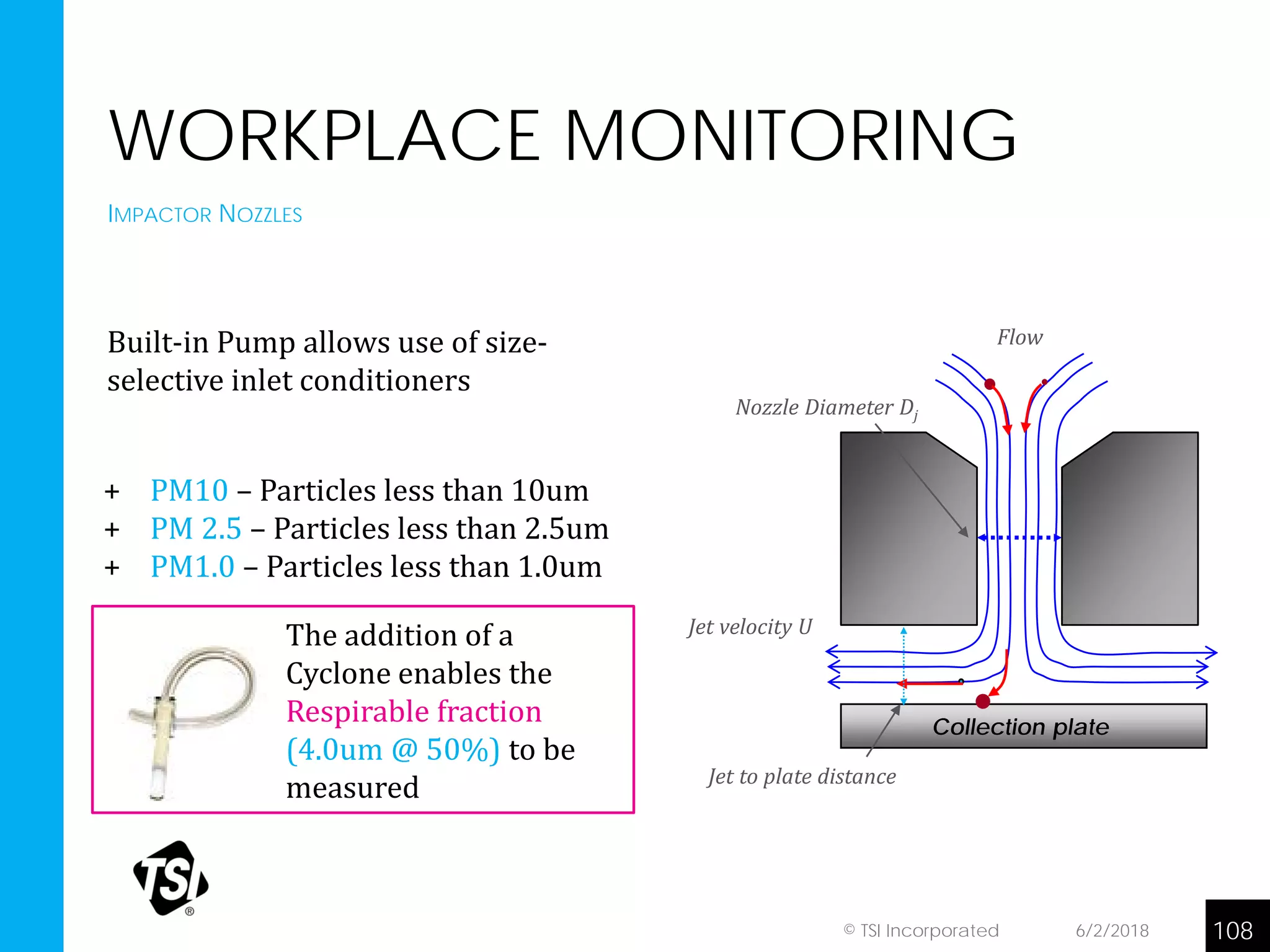

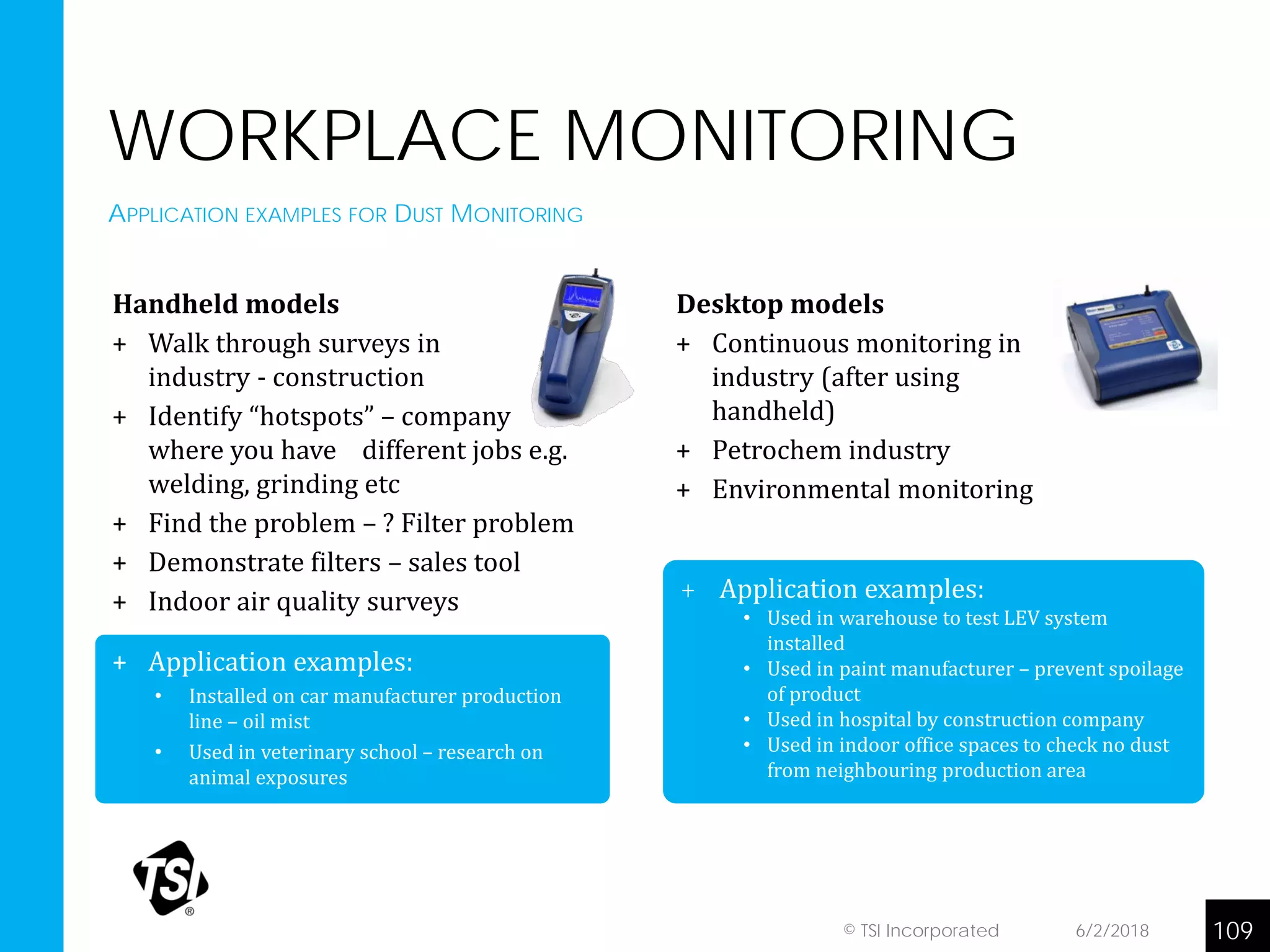

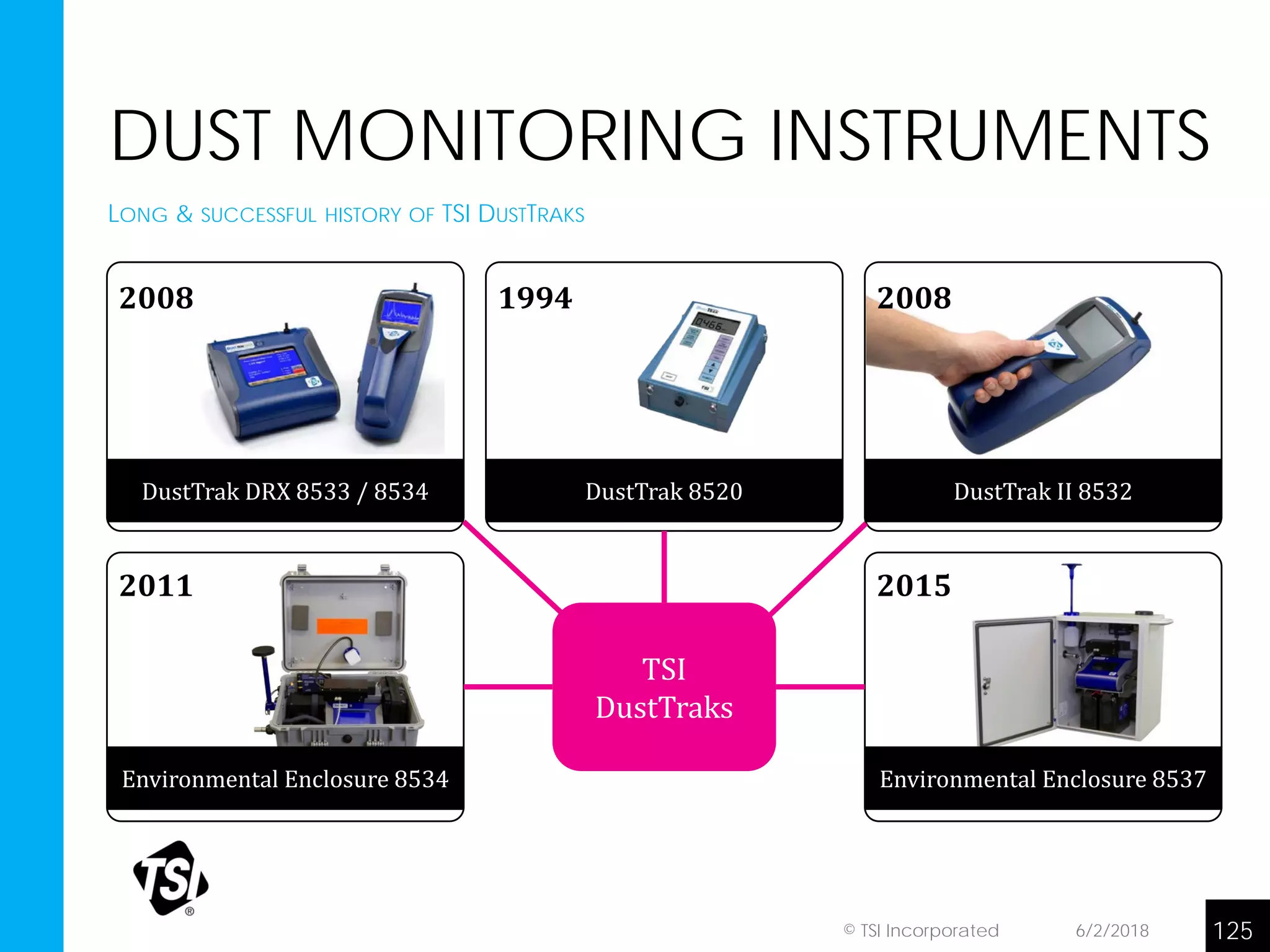

The document outlines the significance of dust monitoring for health, environmental, and regulatory protection. It discusses particle characteristics, measurement methodologies, and the importance of compliance with regulations to mitigate health risks and environmental impacts associated with particulate matter. It emphasizes the necessity of tools and methods for accurate measurement and monitoring of dust in various settings.