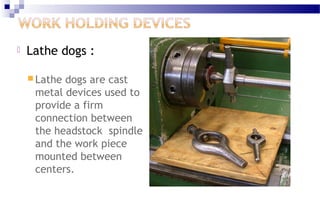

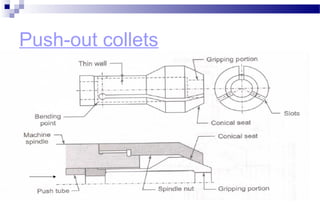

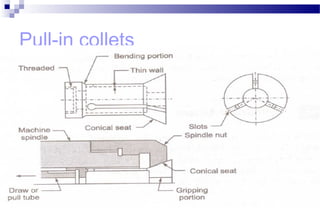

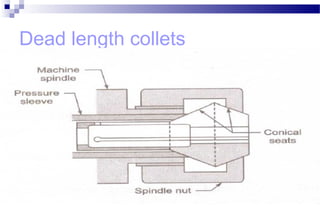

This document discusses various types of turning fixtures used in lathe machines, including chucks, centers, mandrels, collets, and fixtures. Four jaw independent chucks hold irregular shapes but take more time for initial setup. Three jaw universal chucks allow for speedy centering of workpieces but cannot hold large sizes. Combination chucks have advantages of both. Magnetic chucks hold thin workpieces. Collet chucks provide accurate centering for bar stock. Drill chucks hold tools for drilling operations. Lathe centers and steady rests provide workpiece support. Mandrels are used to hold hollow or drilled workpieces for external turning. Fixtures mounted to lathe faceplates allow for machining of irregular