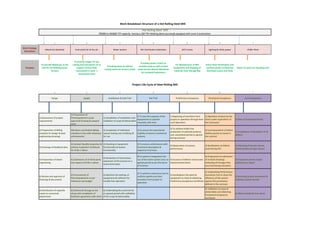

This document outlines the work packages, purpose, design, and project life cycle of a hot rolling steel mill project. The work packages include a mixed gas manifold, instrument air and dry air system, water system, distribution substation, EOT cranes, lighting, chiller plant. The project life cycle involves 7 stages: design, supply, installation, cold trial, hot trial, preliminary acceptance, and provisional acceptance. It describes the key activities and objectives of each stage such as procurement, testing, optimization, and handover of the plant to the client.