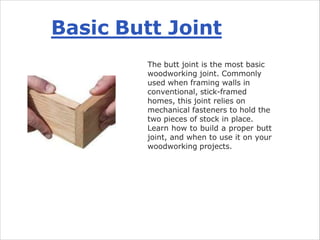

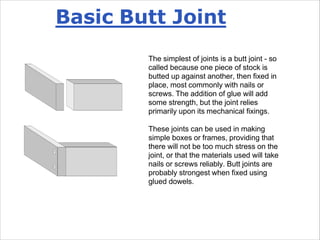

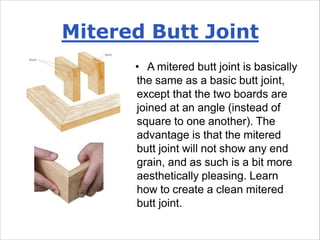

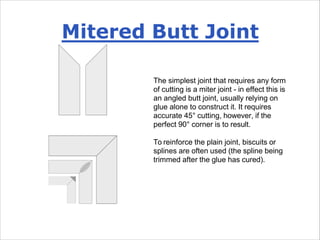

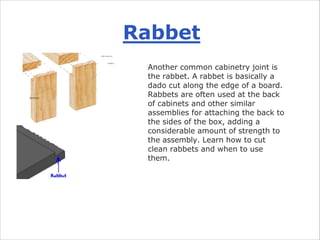

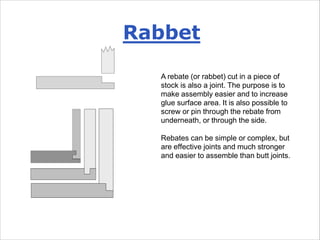

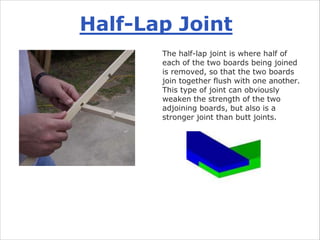

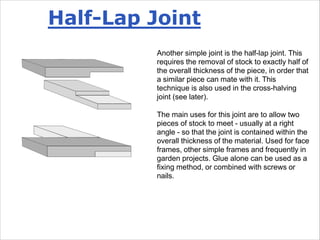

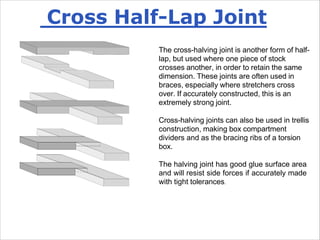

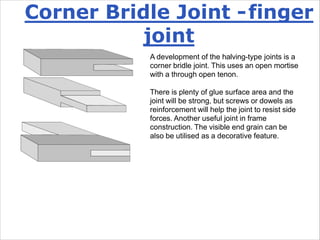

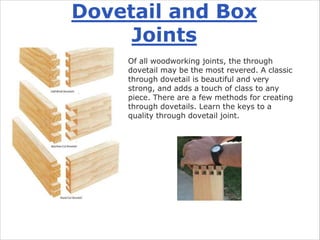

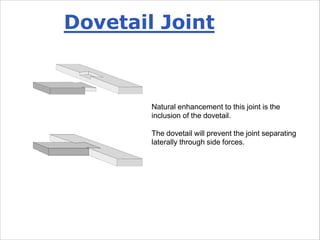

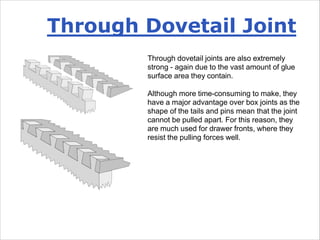

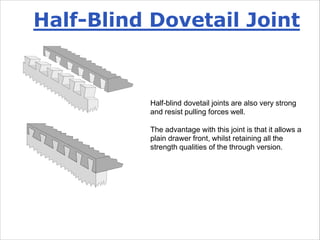

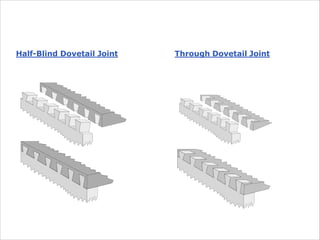

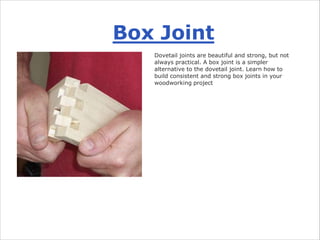

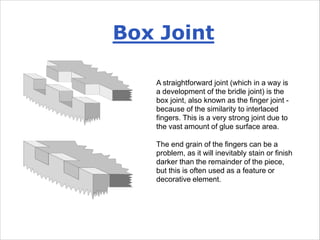

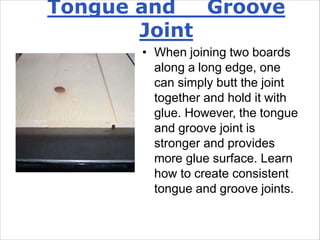

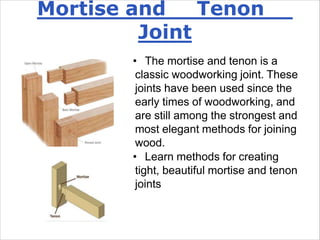

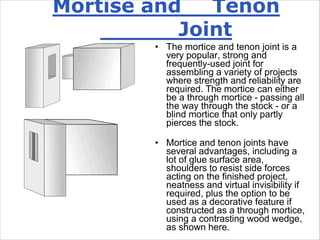

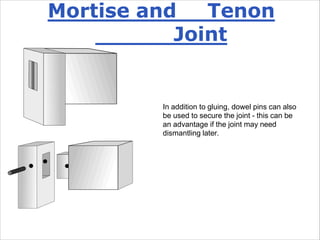

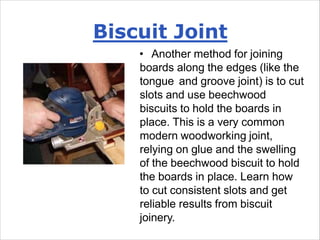

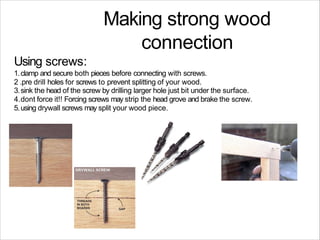

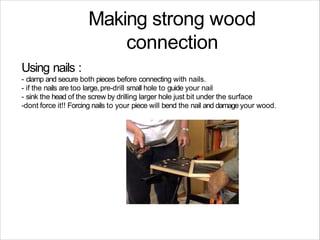

The document provides an overview of various woodworking joints, including the butt joint, mitered butt joint, rabbet, half-lap joint, dovetail joint, and more. Each joint's construction method, advantages, and applications are discussed, emphasizing their strengths and how they enhance the stability of wooden structures. Additionally, it offers tips on making strong wood connections using screws, nails, wood glue, and biscuits.