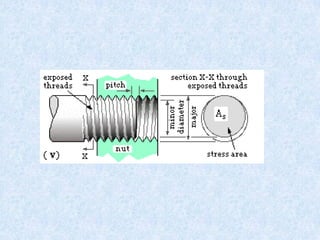

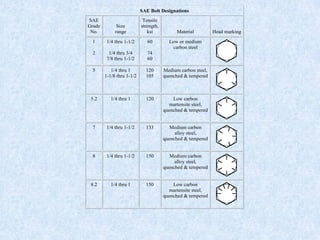

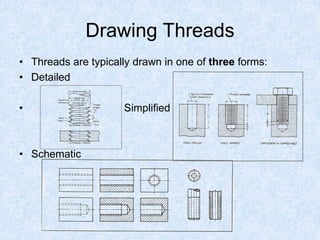

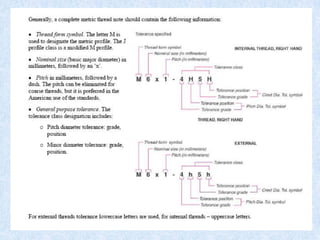

Threaded fasteners such as bolts and screws join components together through the transformation of rotational motion into linear motion. There are various thread standards that specify attributes like diameter, pitch, class of fit, and thread type. Early threaded fasteners lacked standardization but efforts in the 18th-19th centuries established conventions for sizes. Modern standards include metric and unified external and internal thread systems.