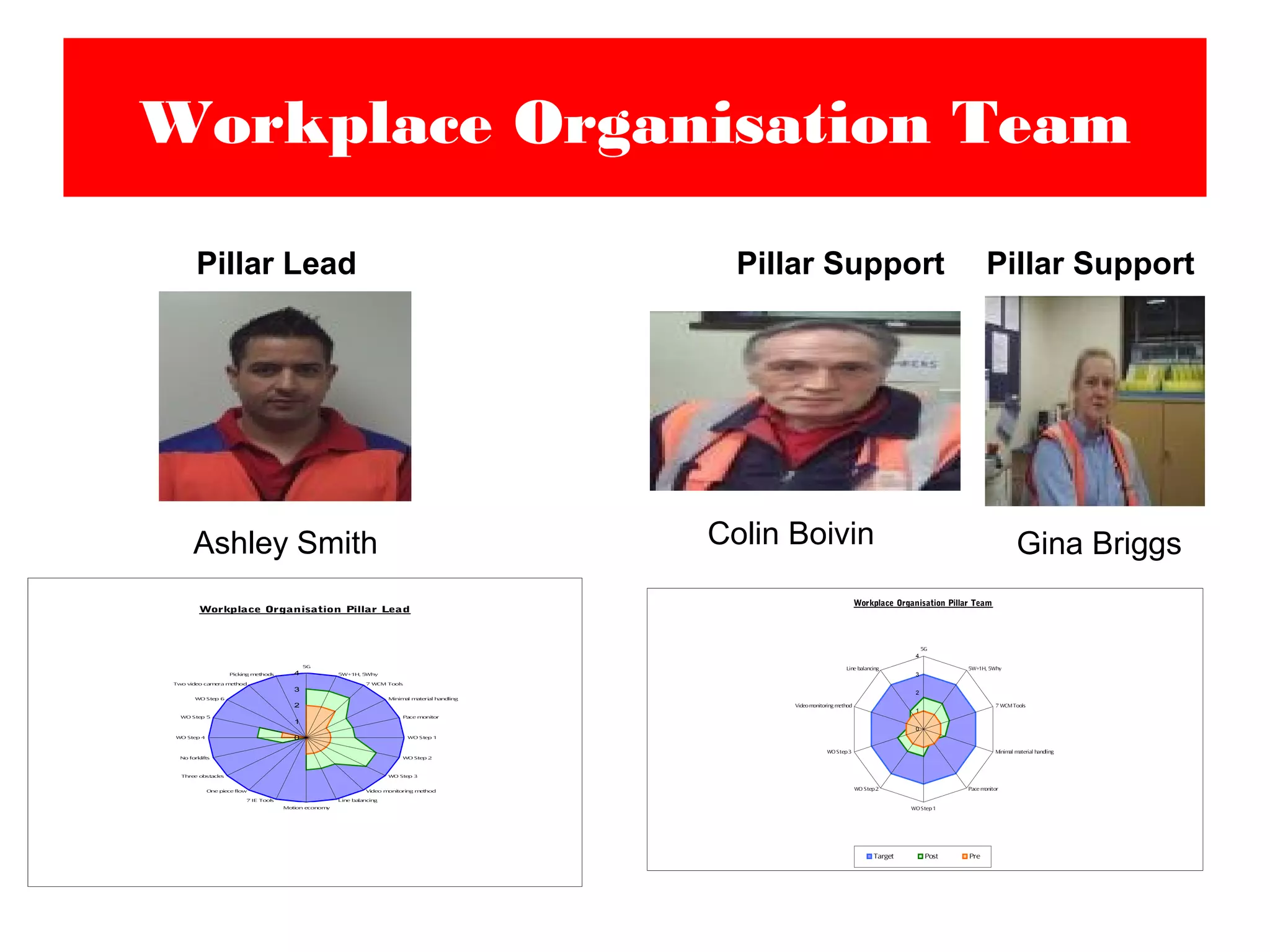

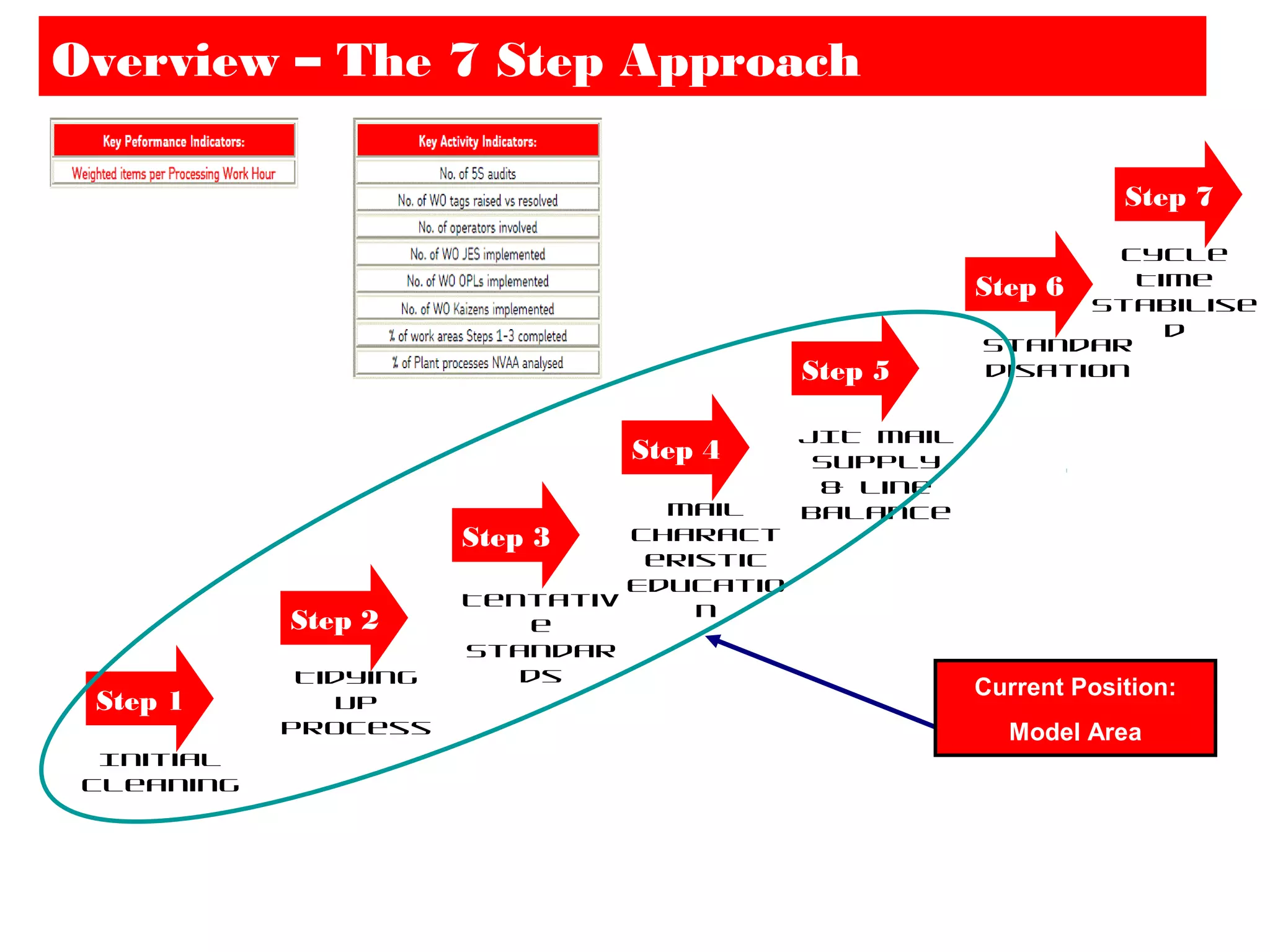

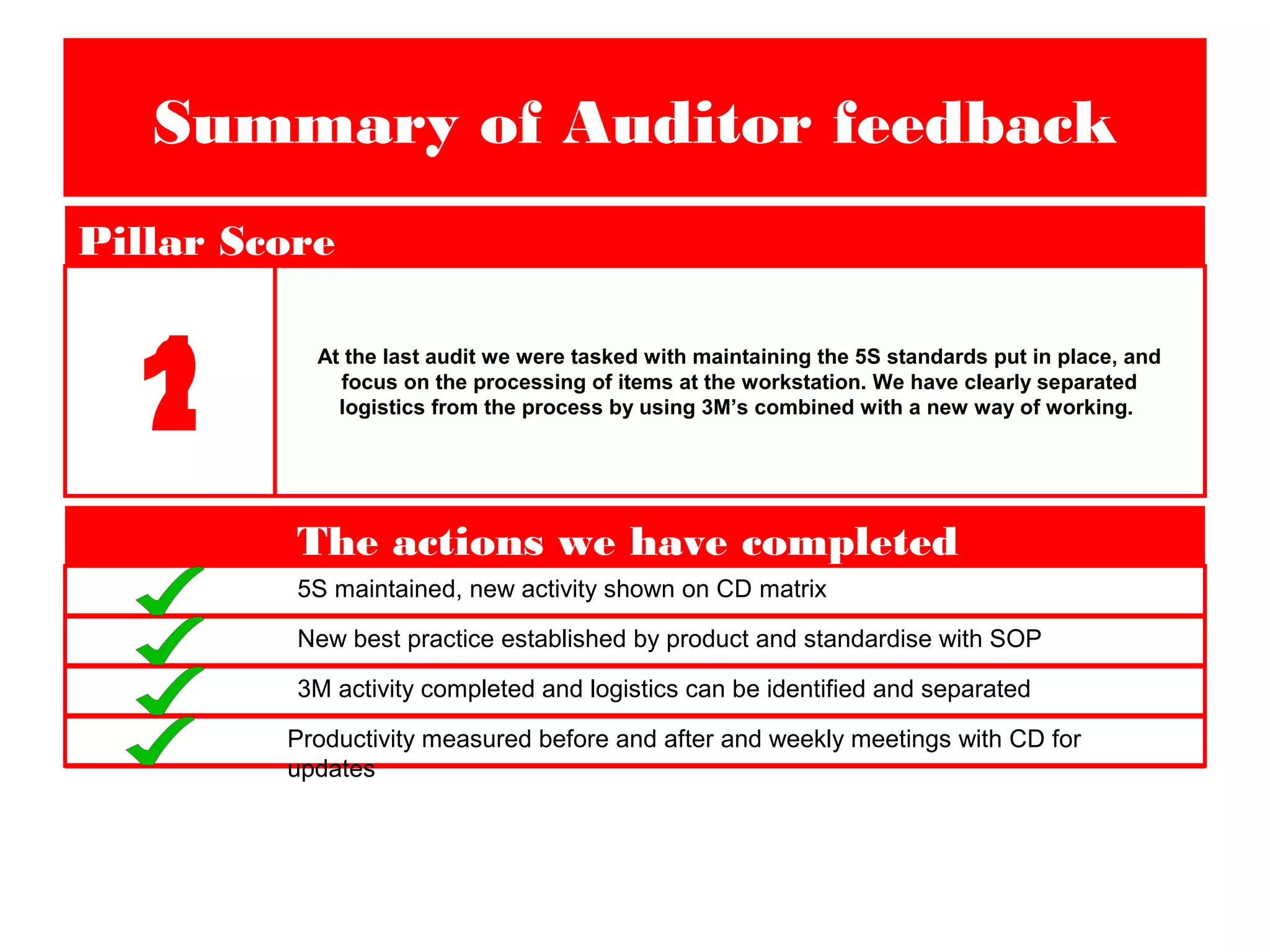

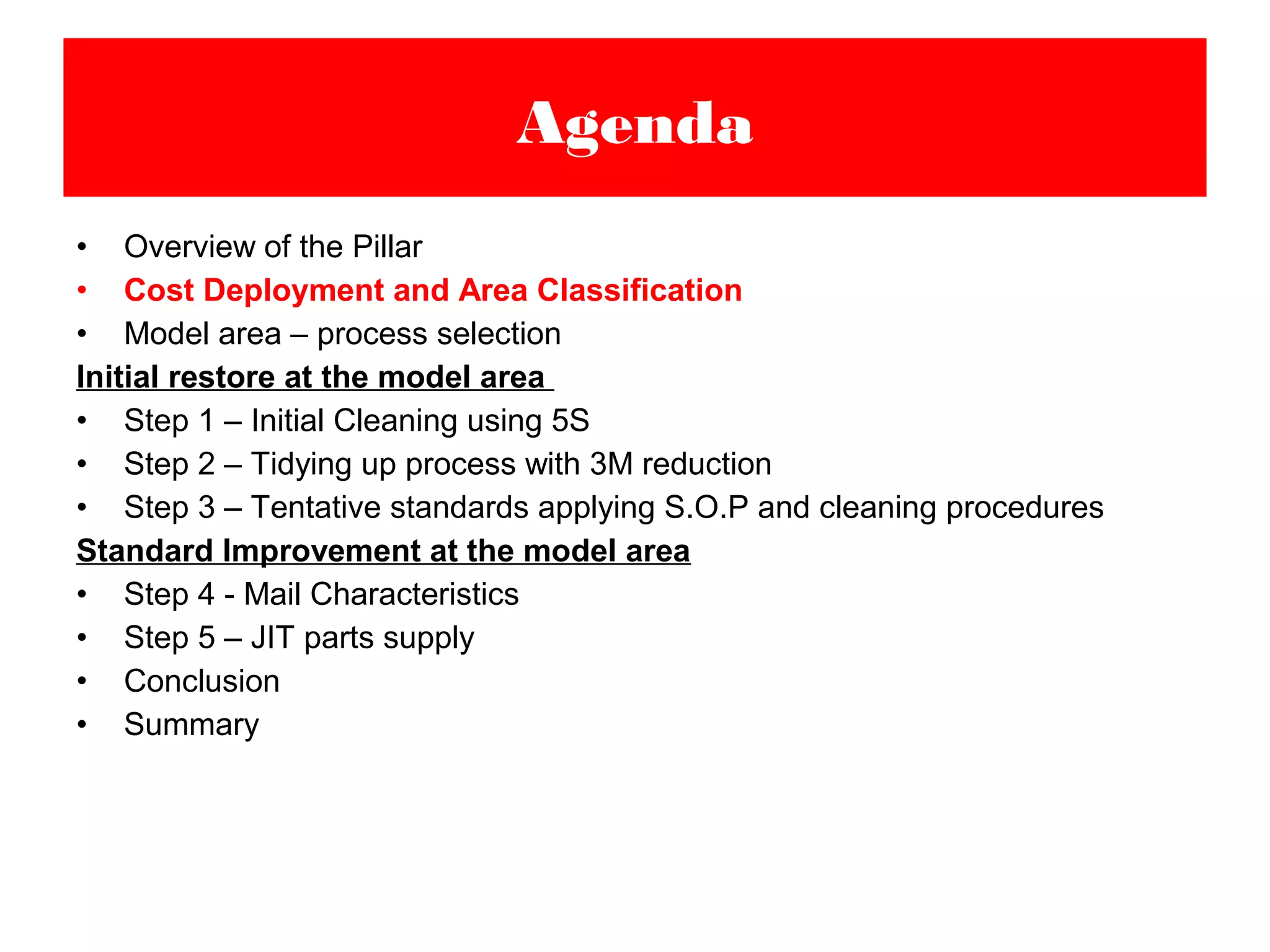

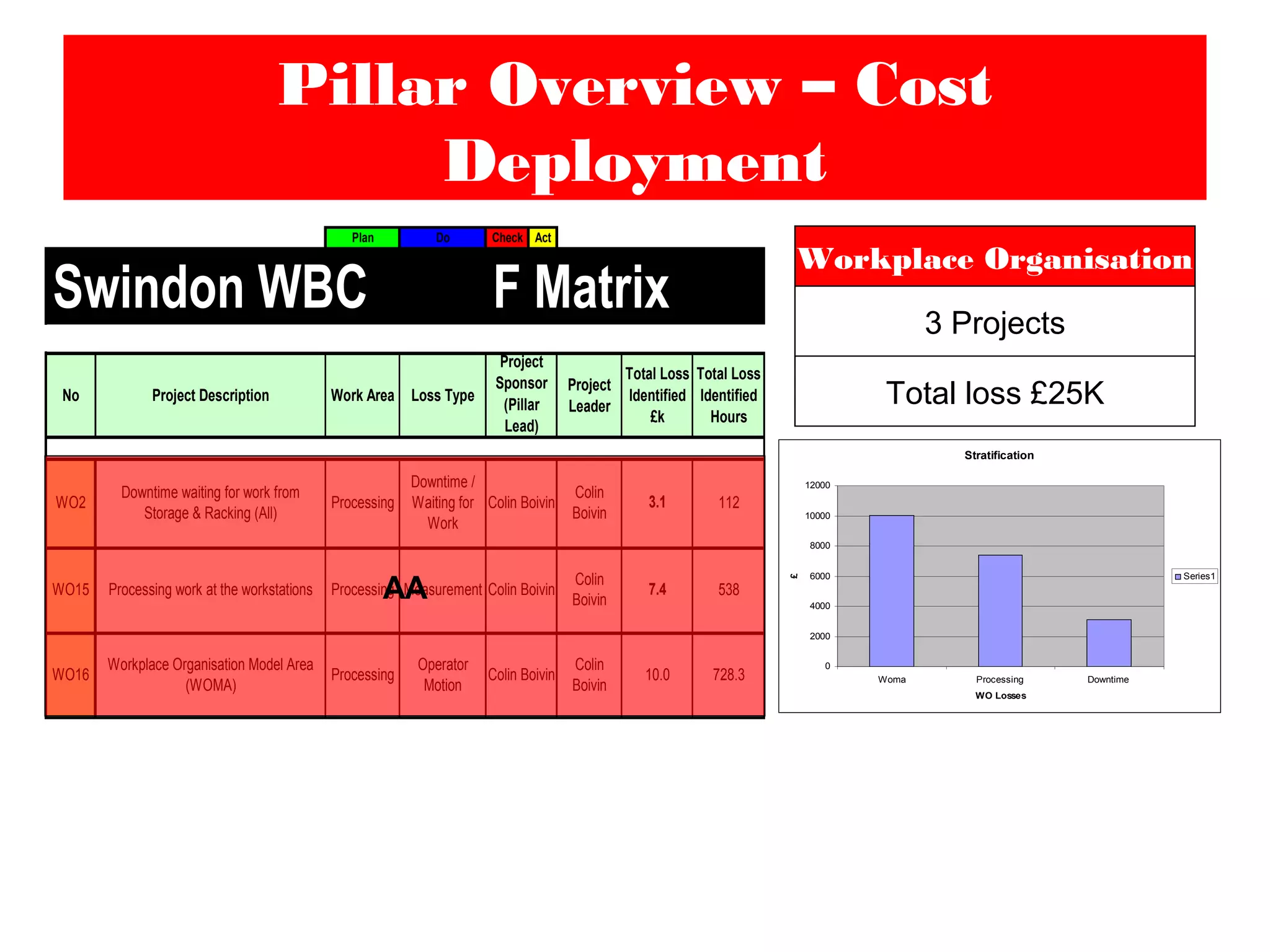

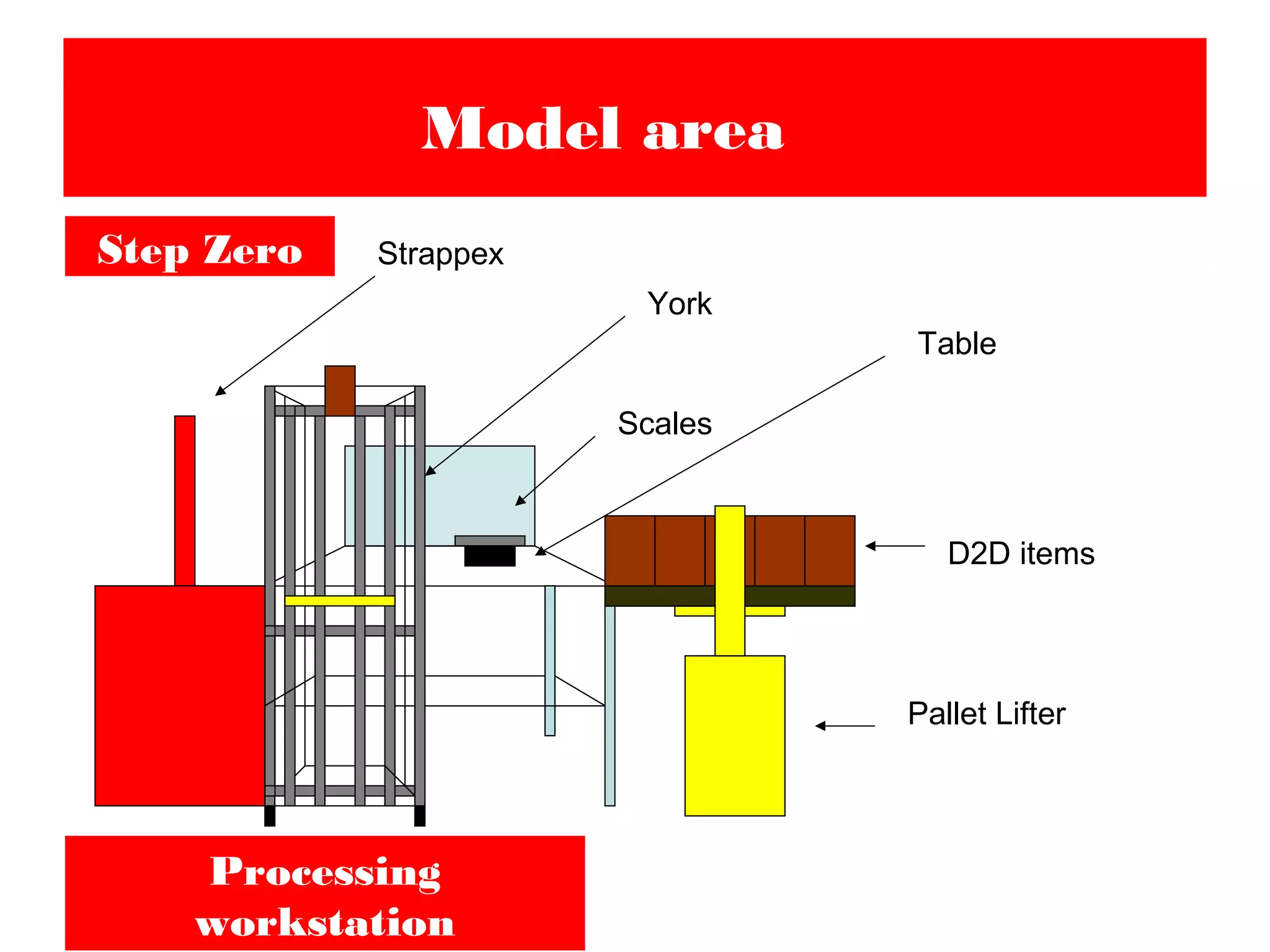

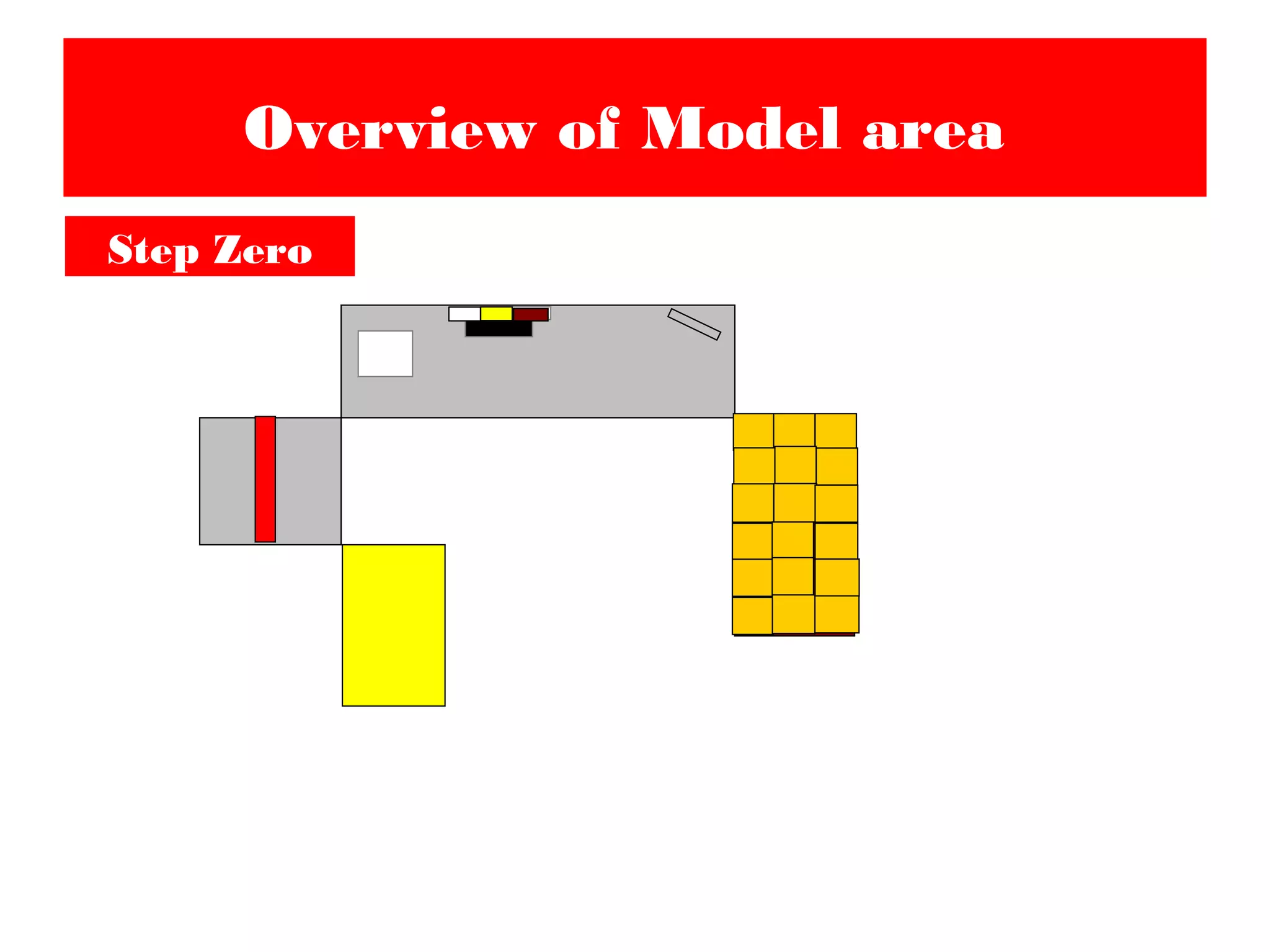

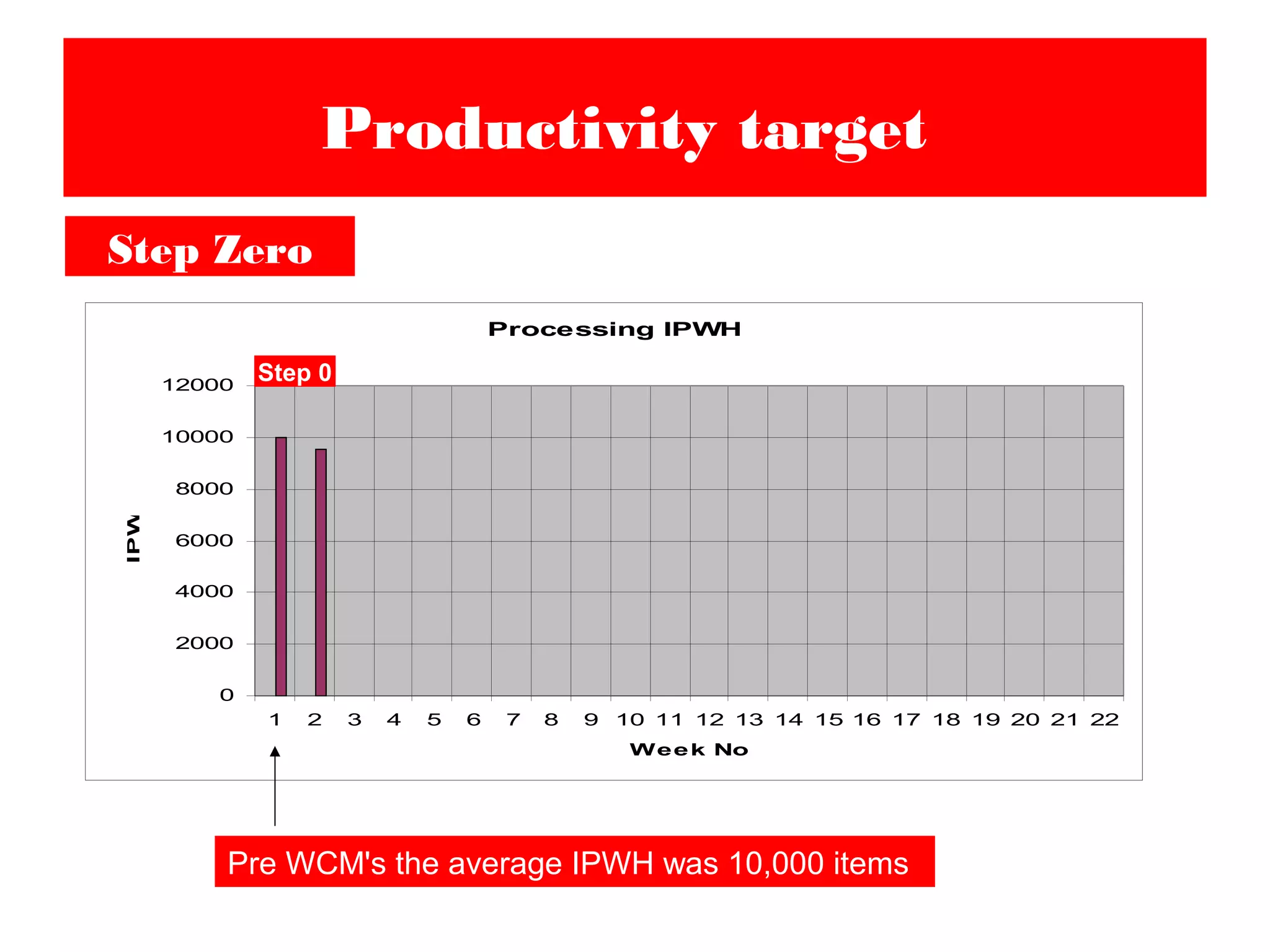

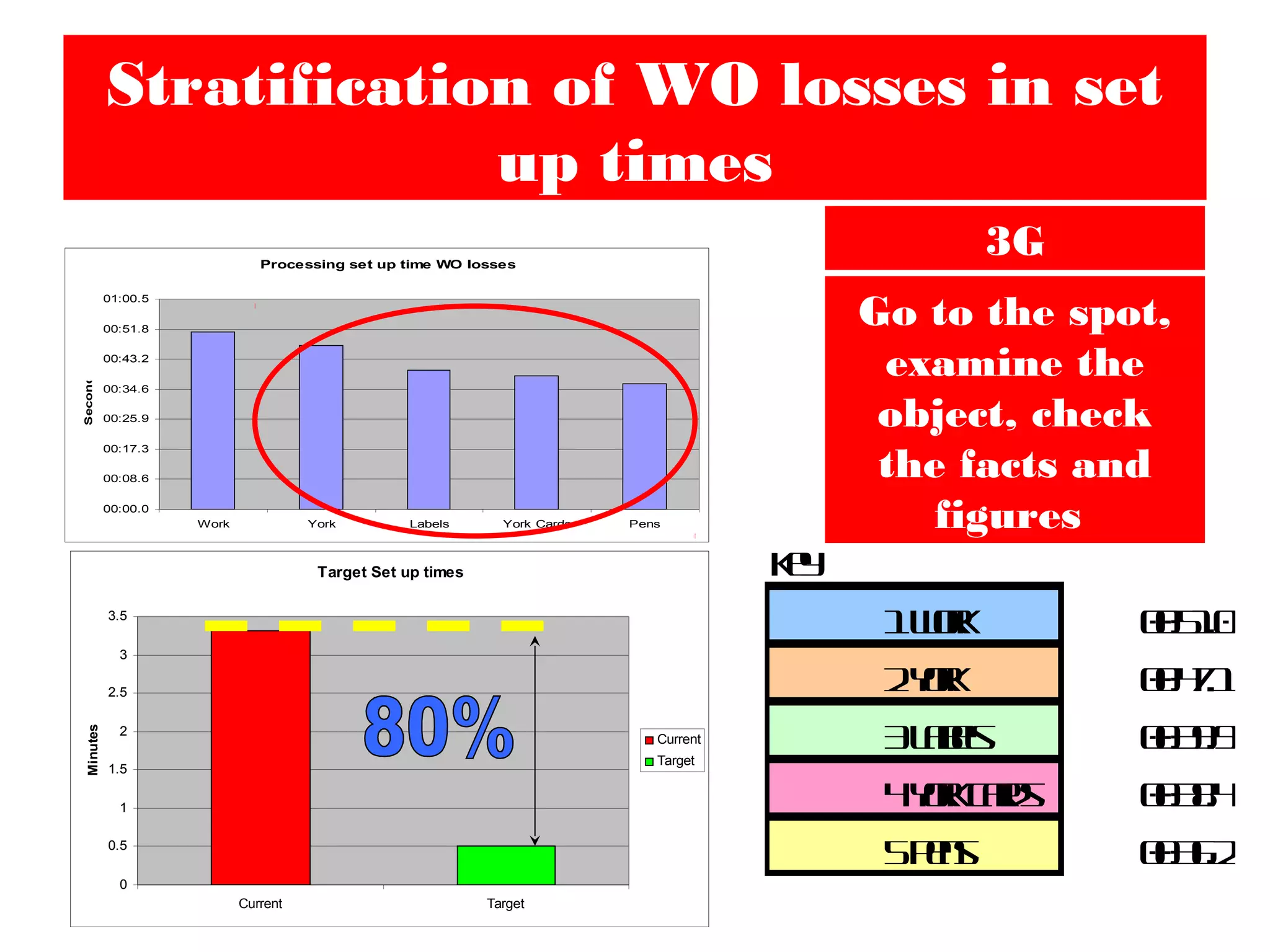

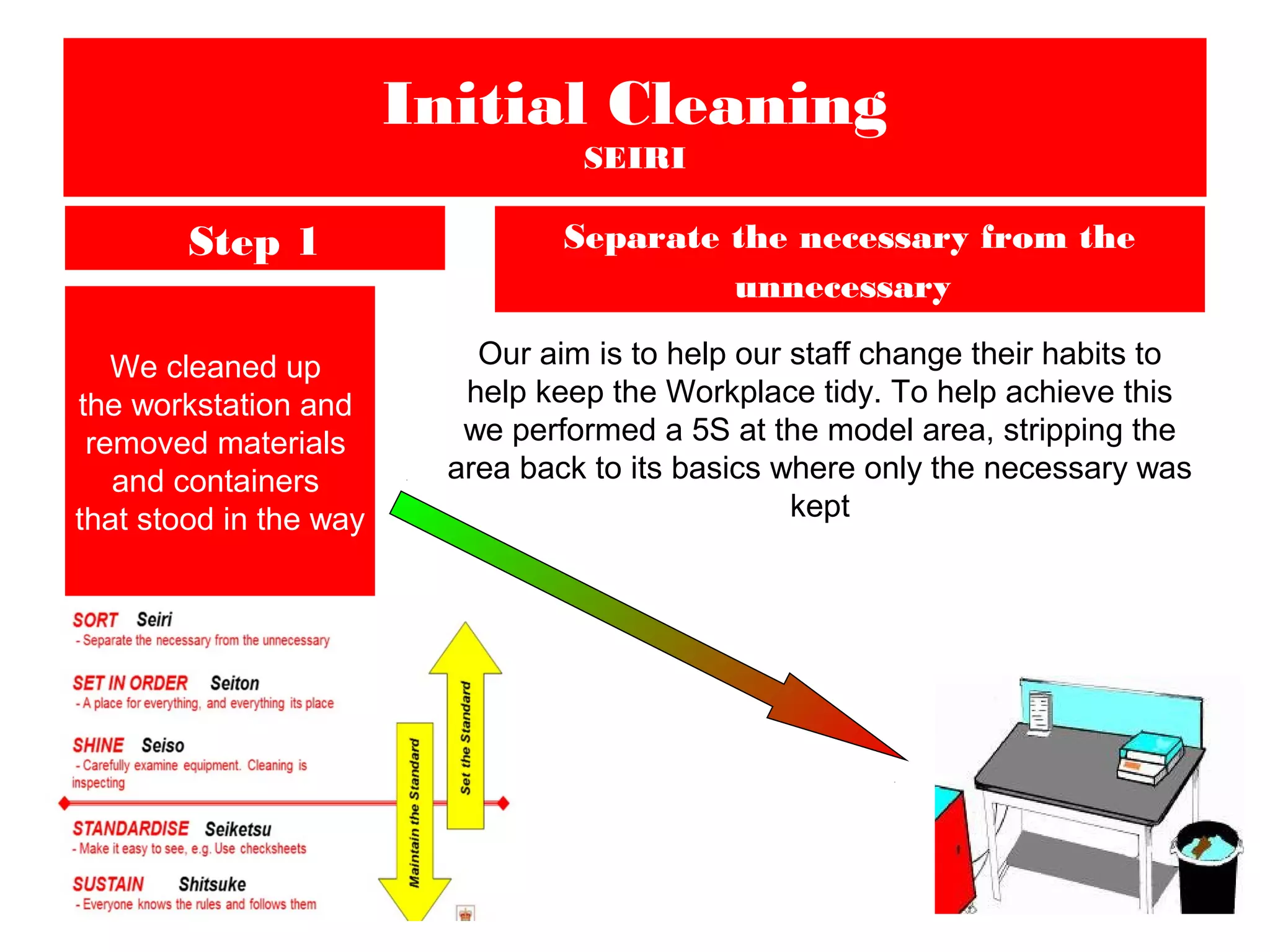

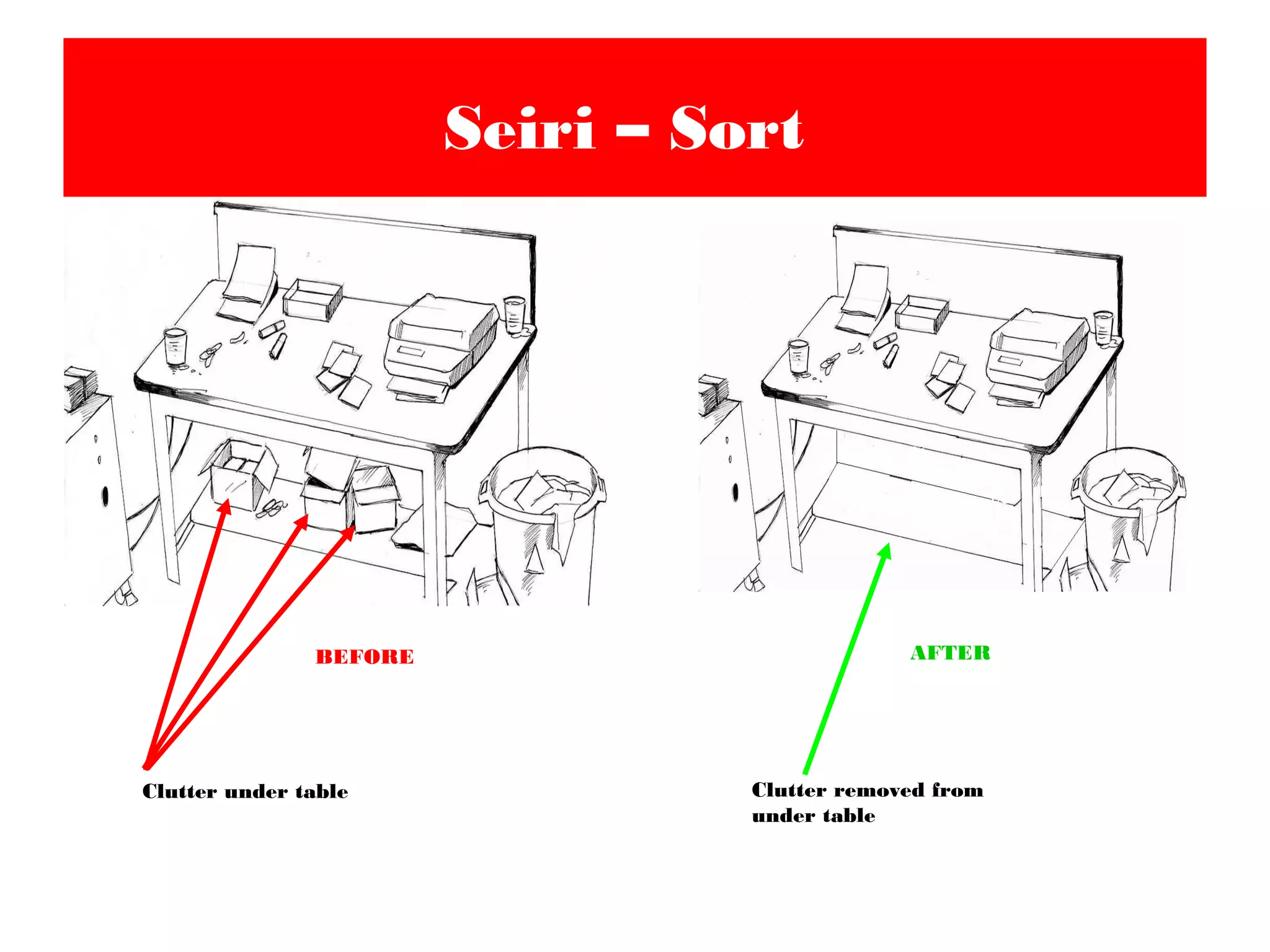

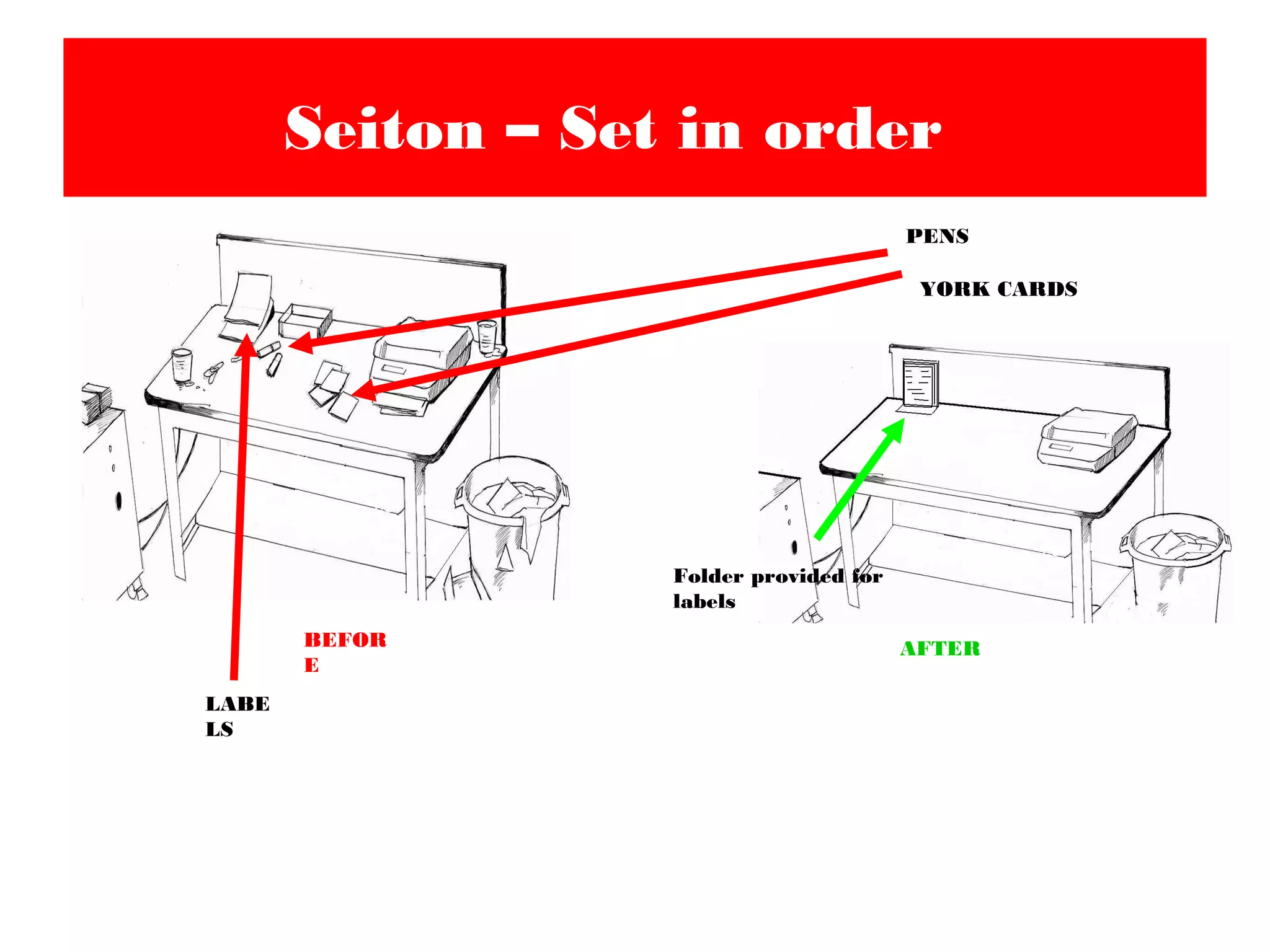

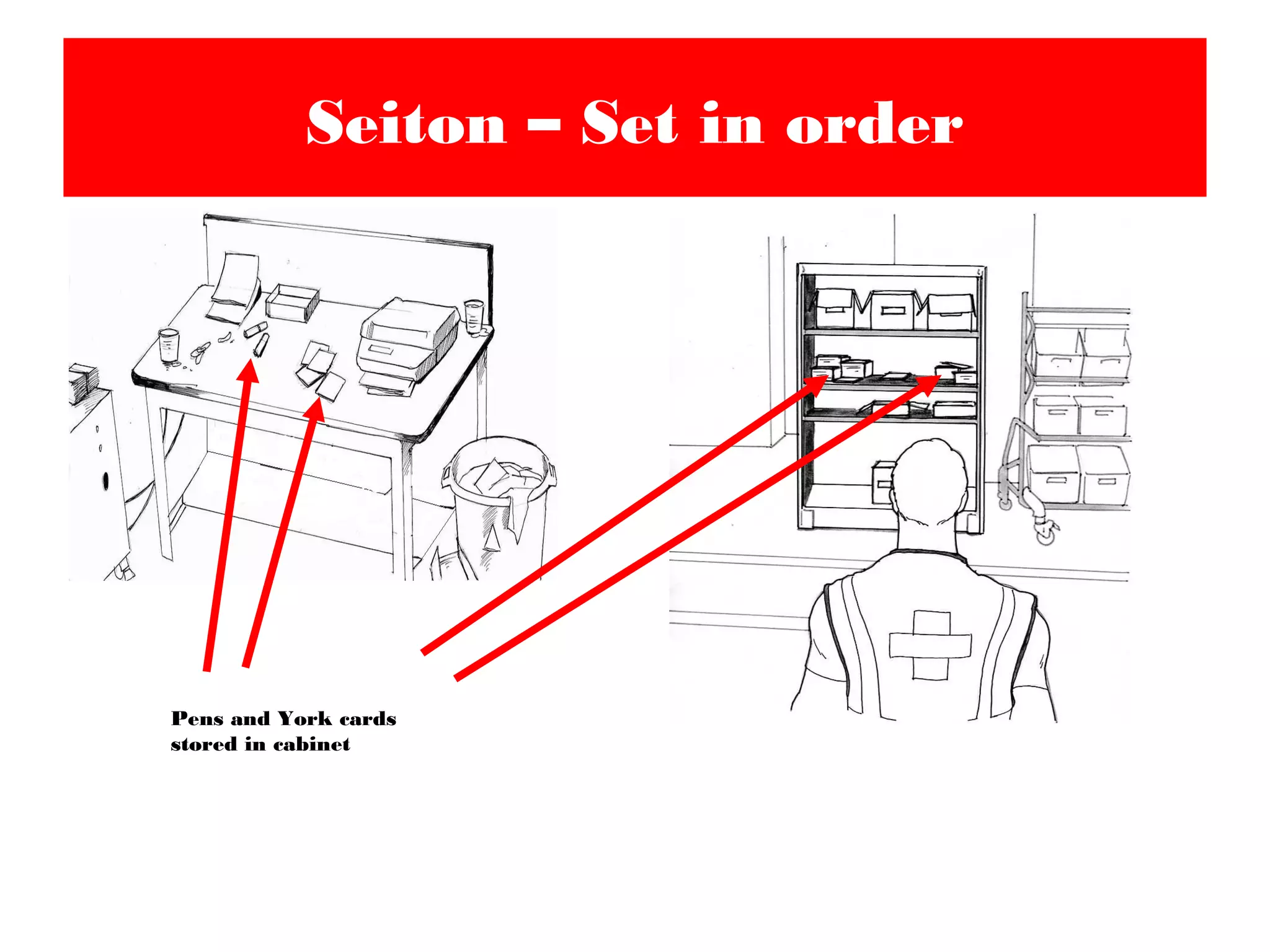

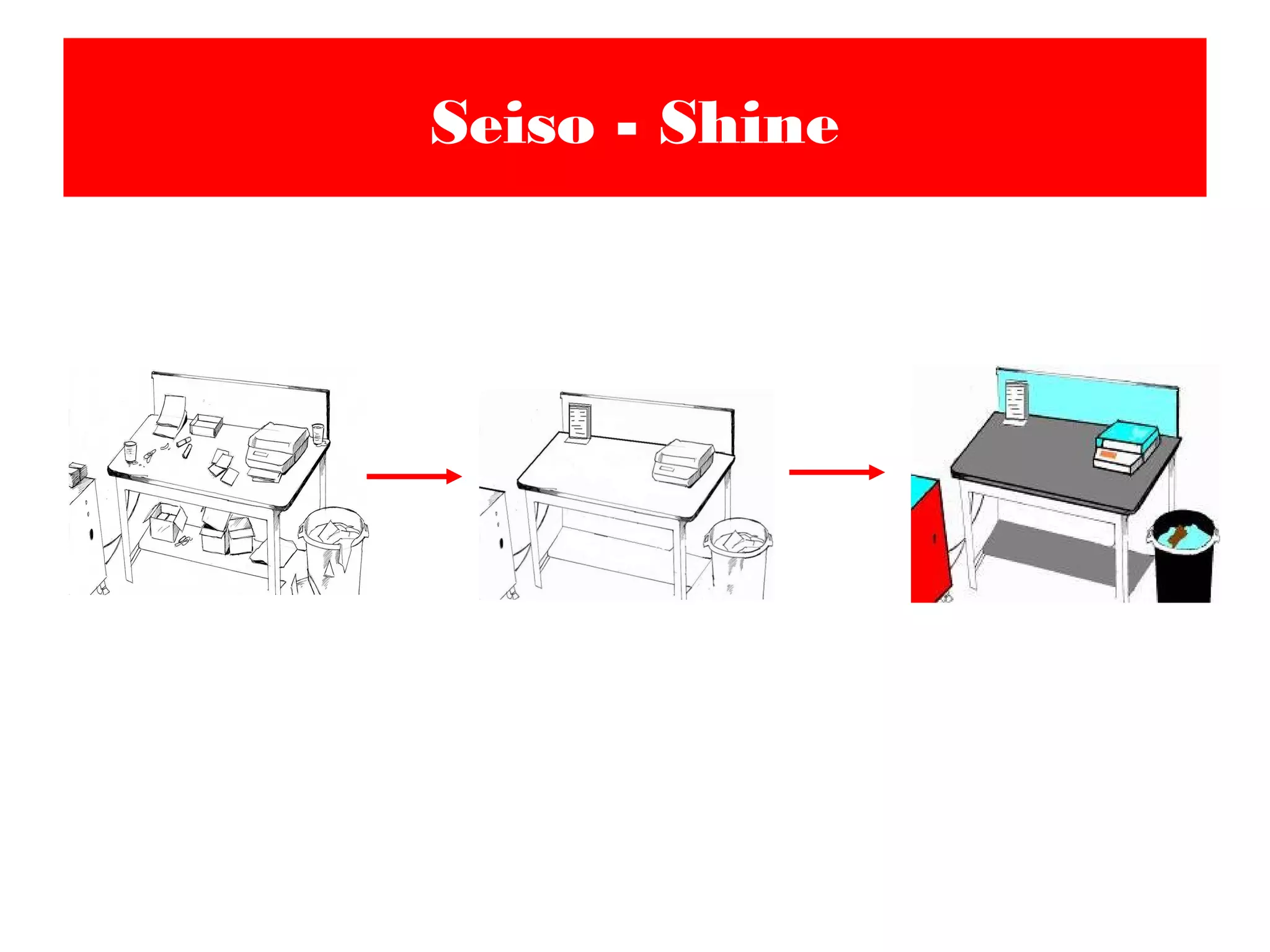

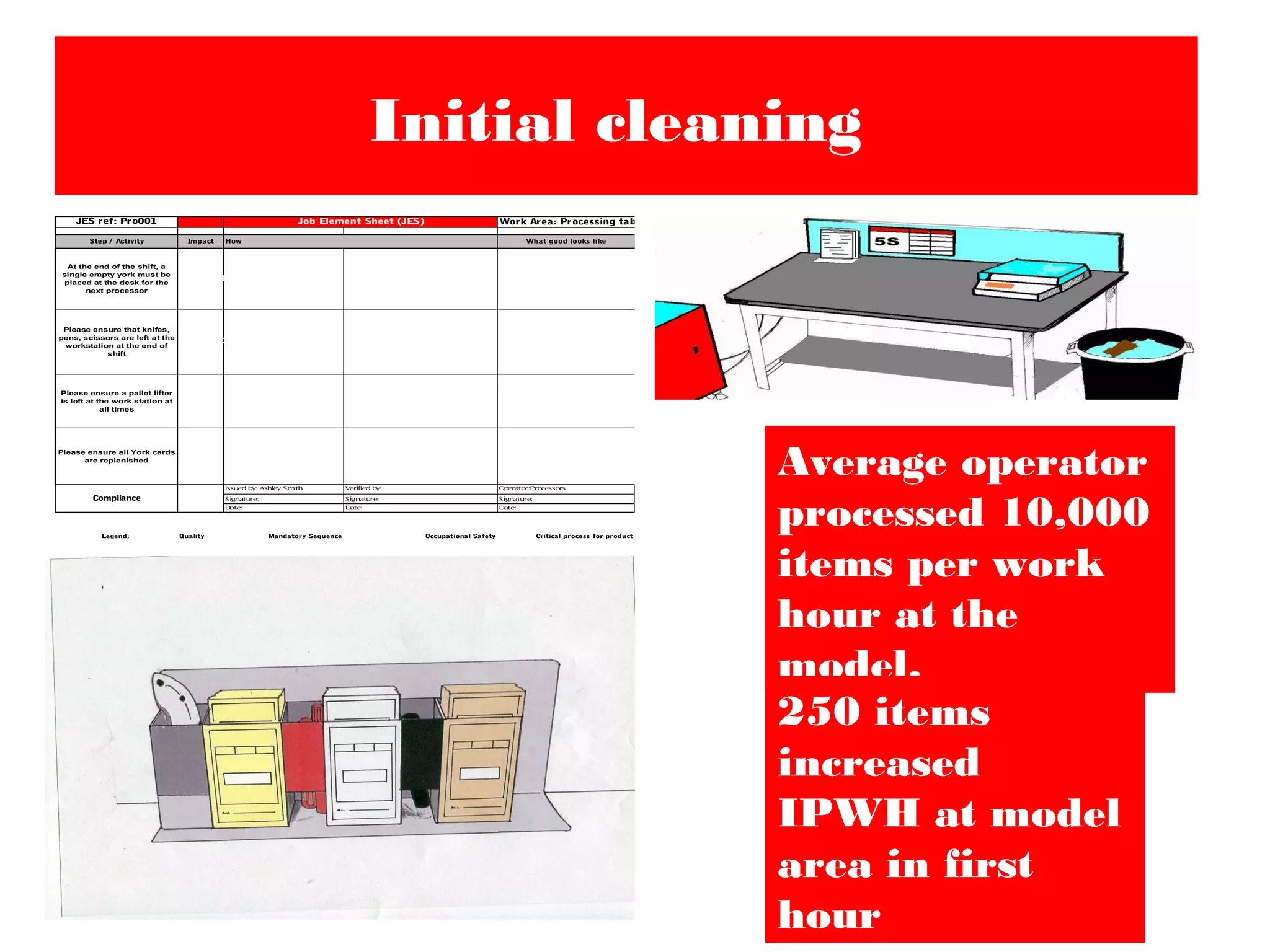

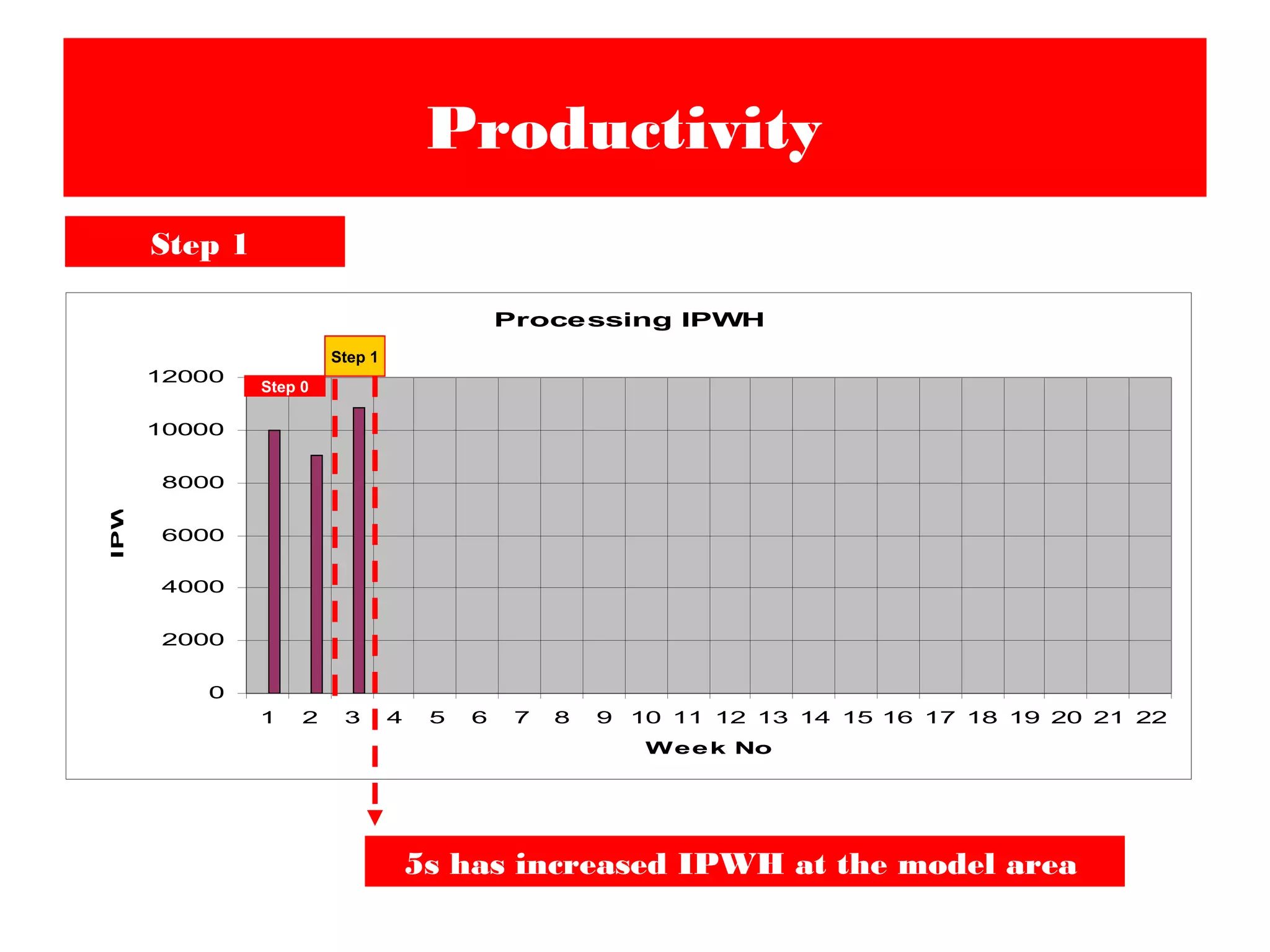

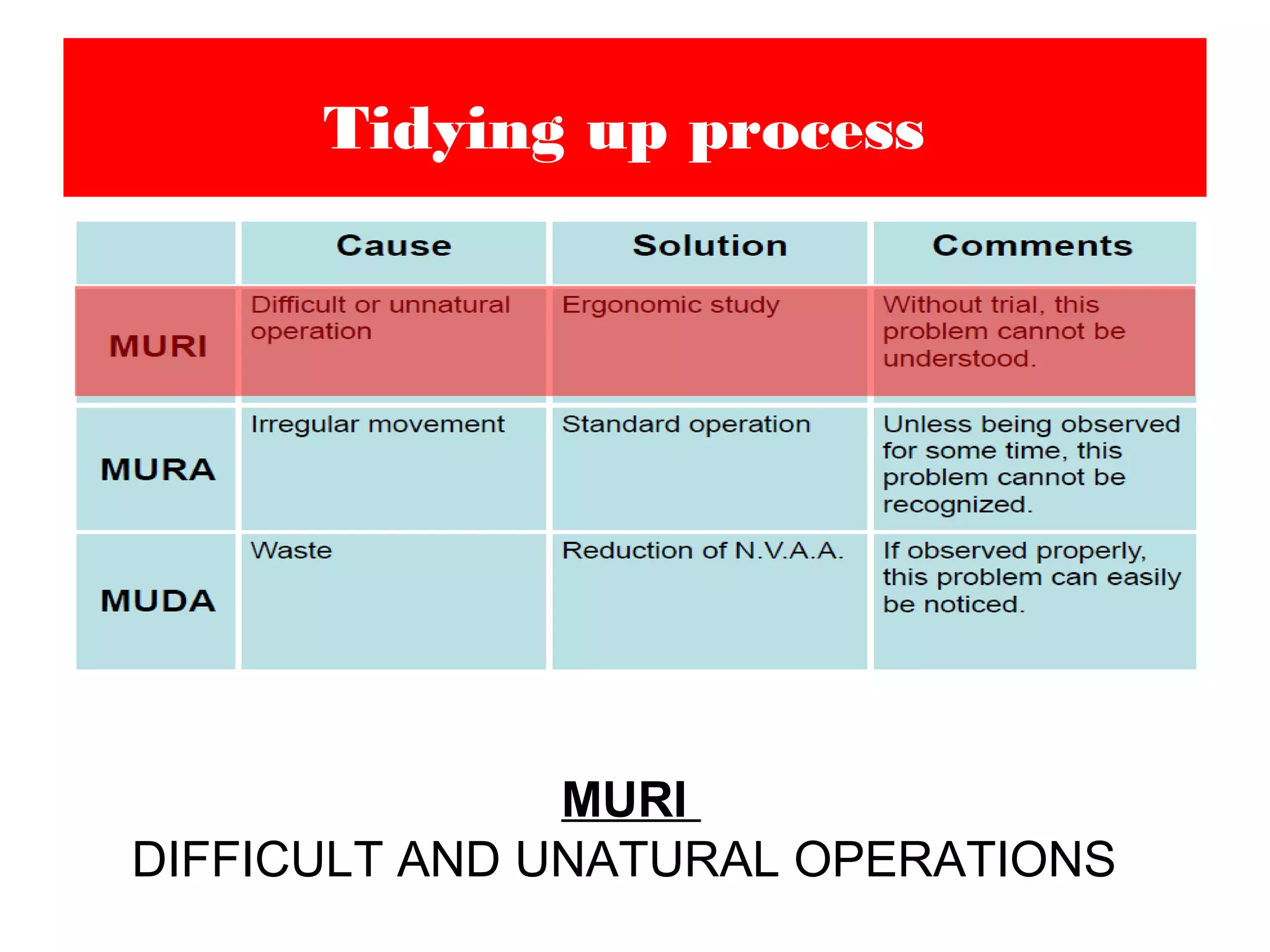

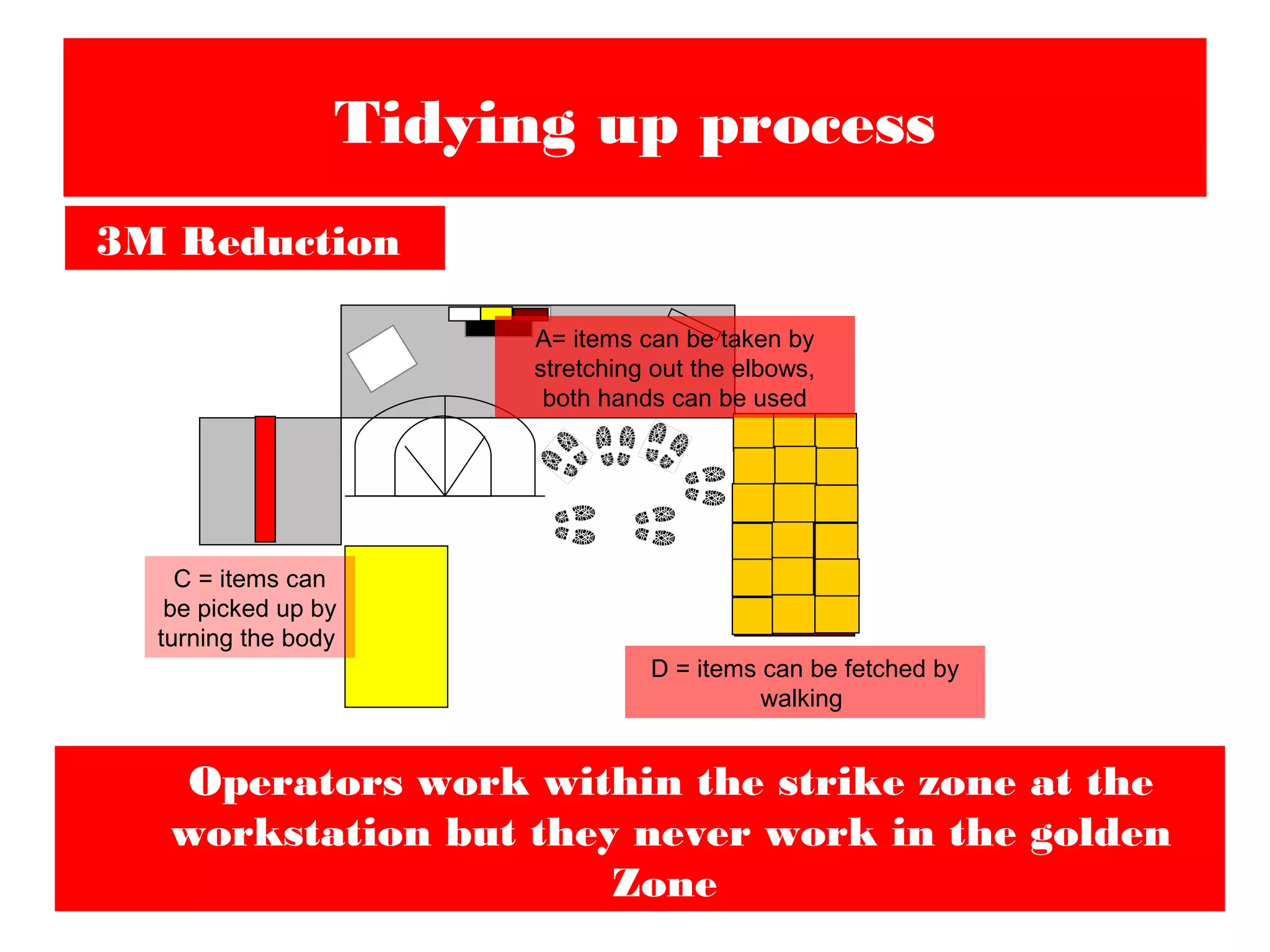

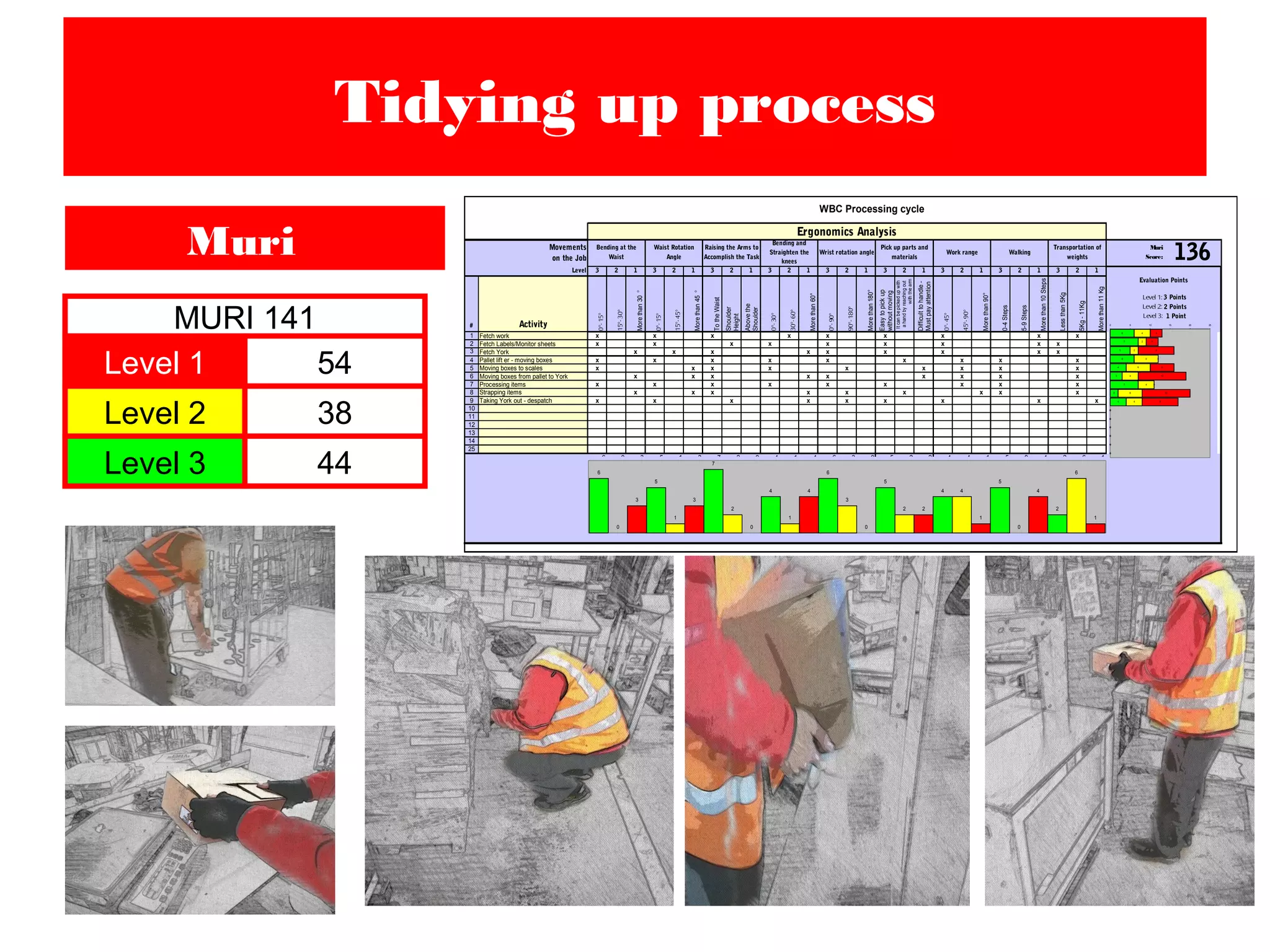

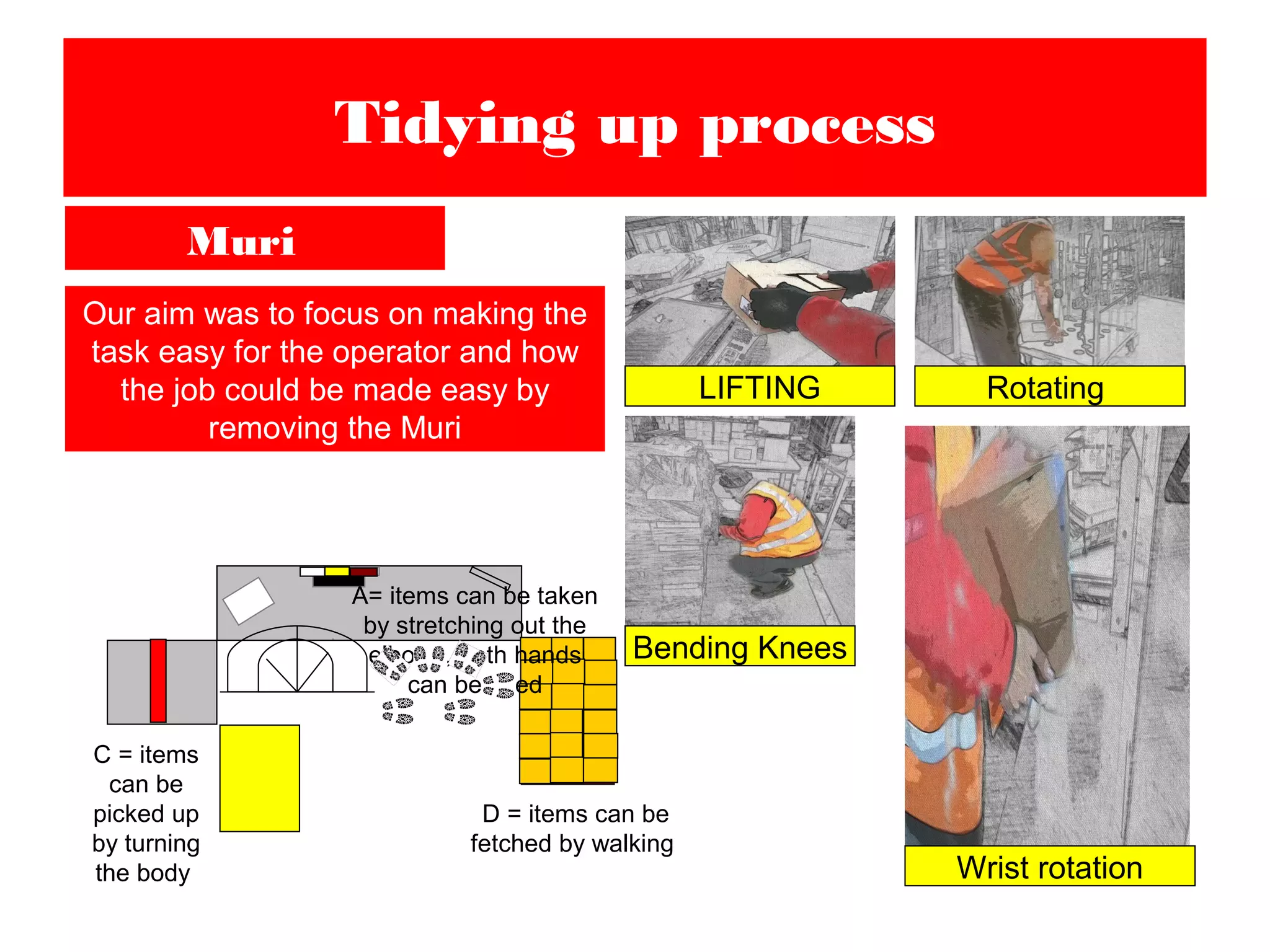

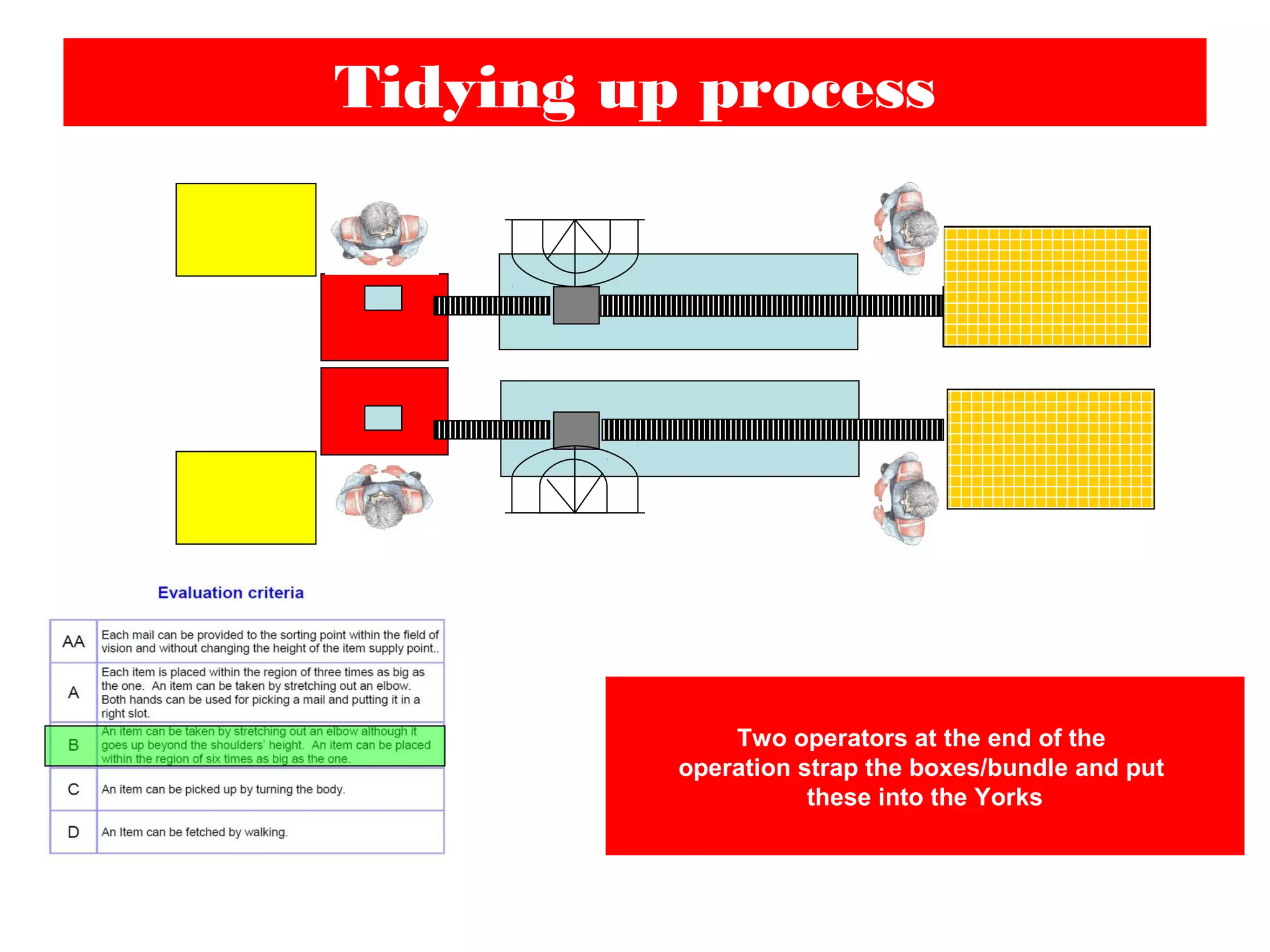

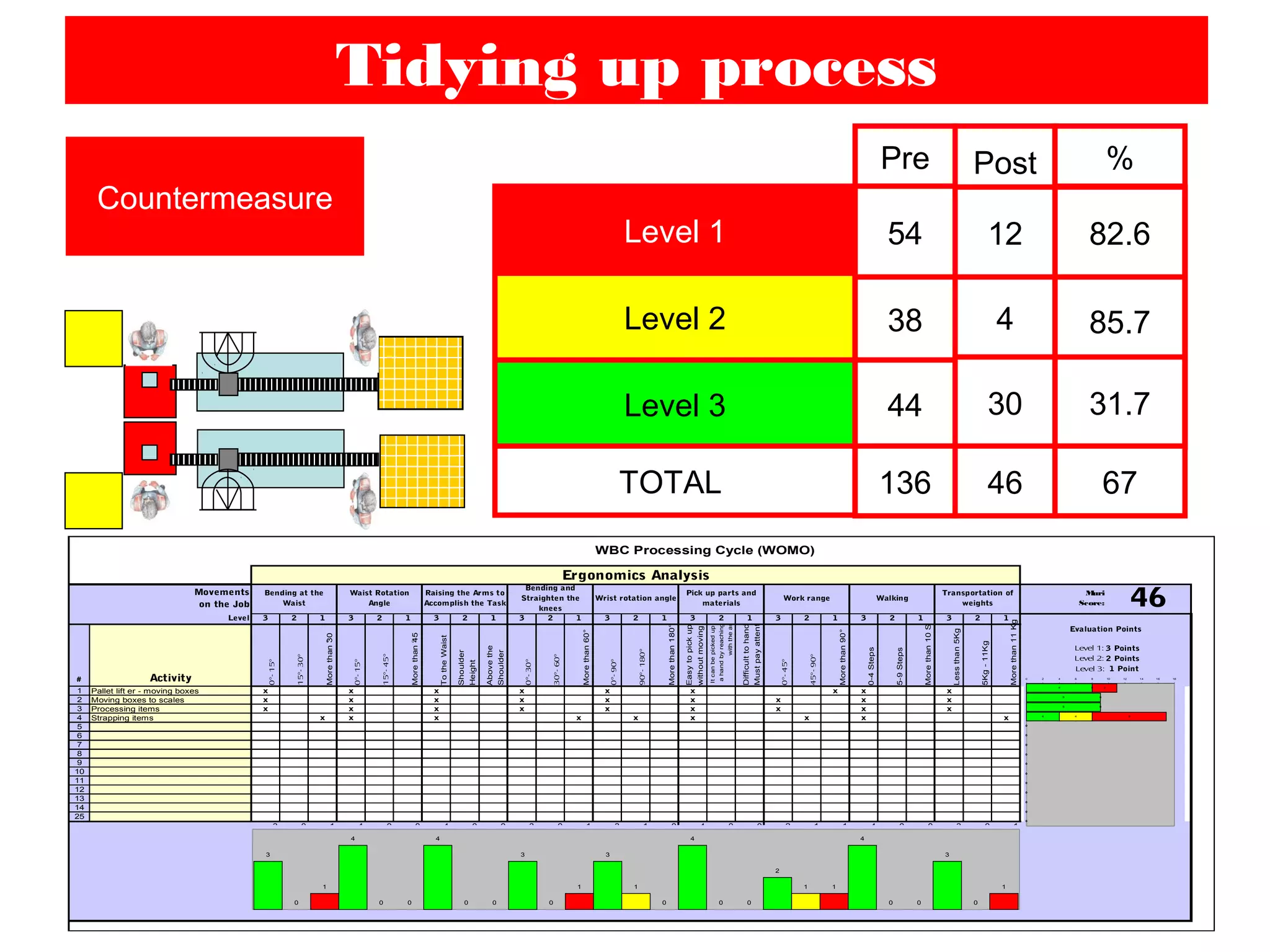

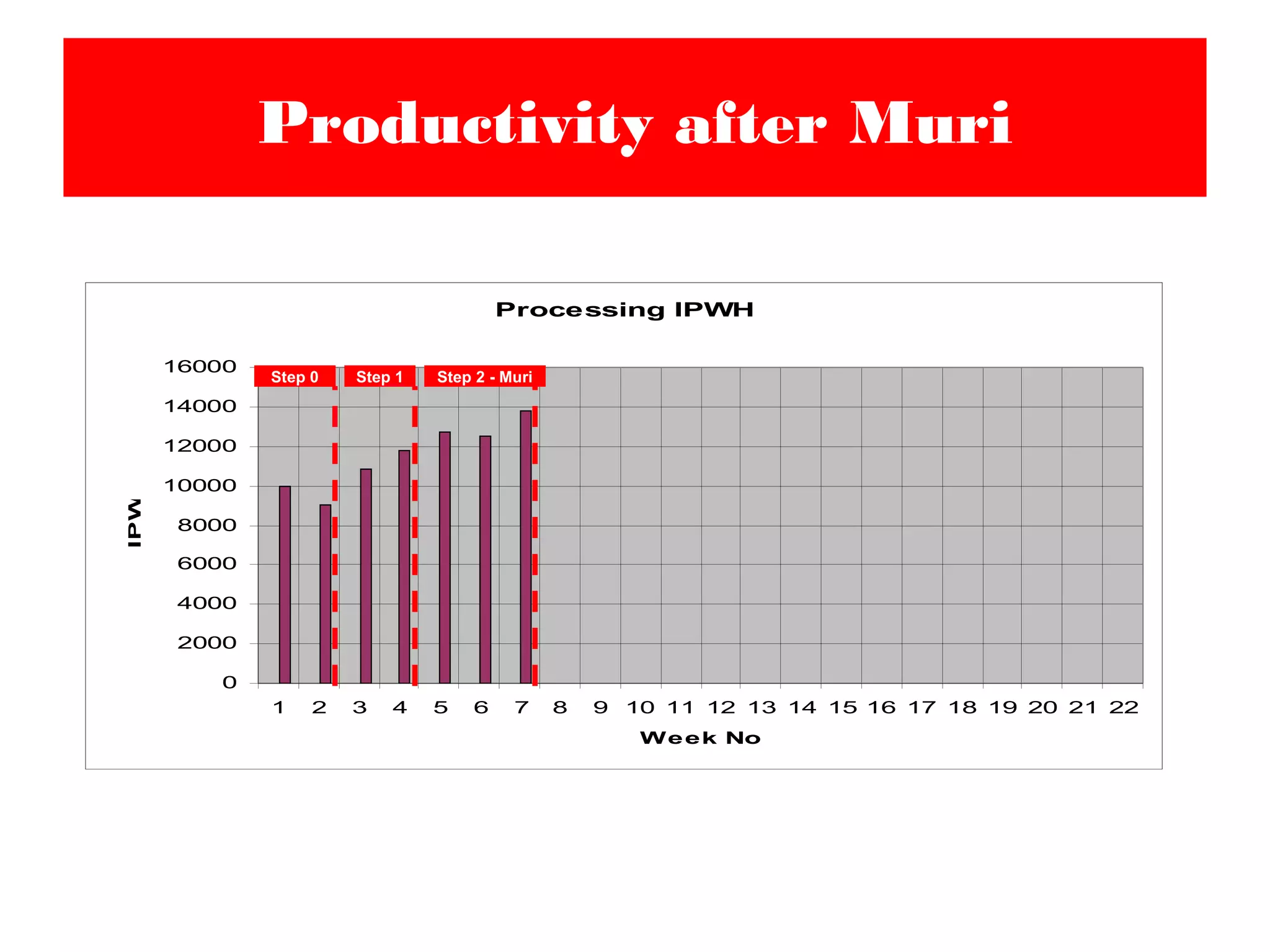

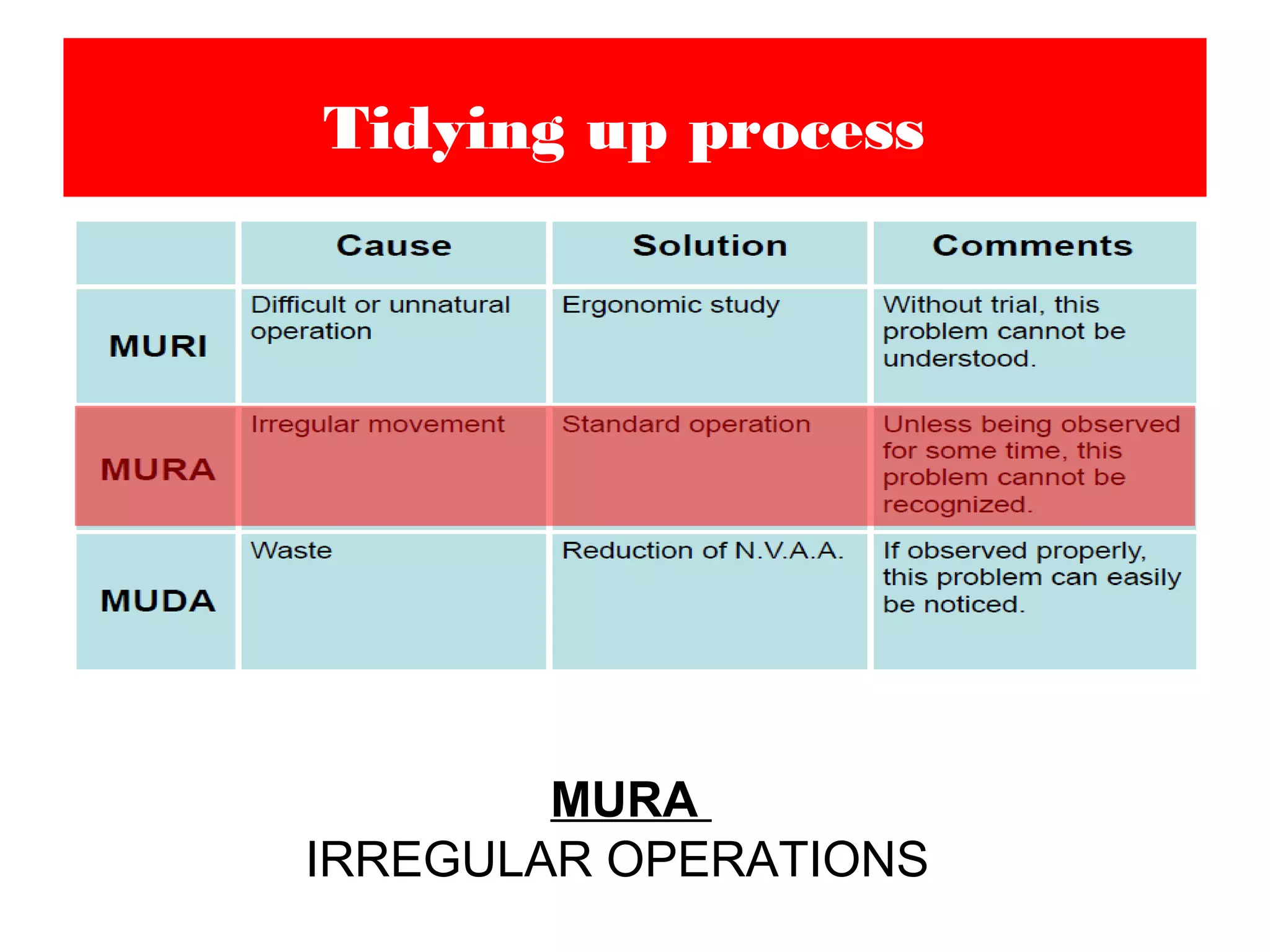

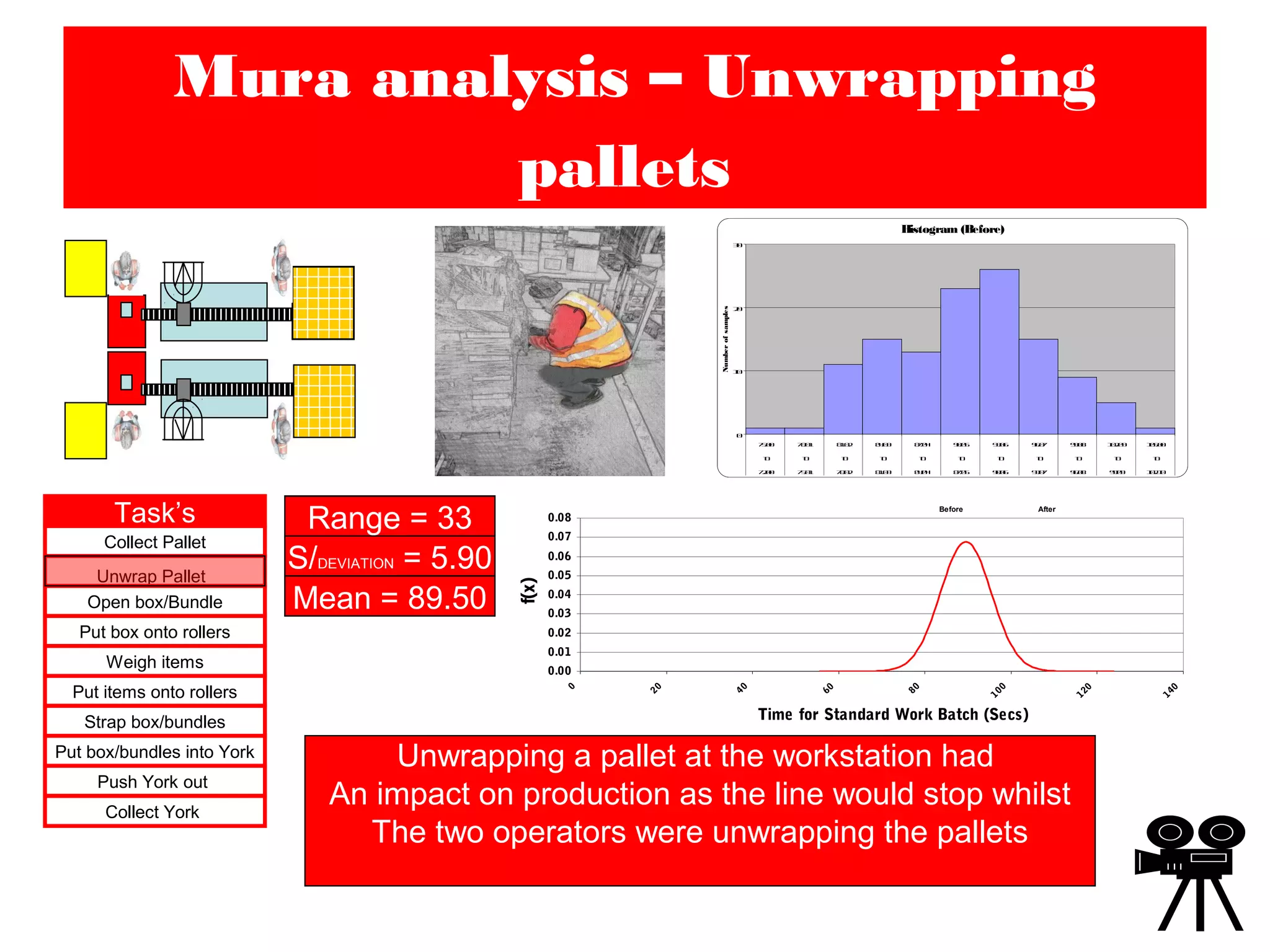

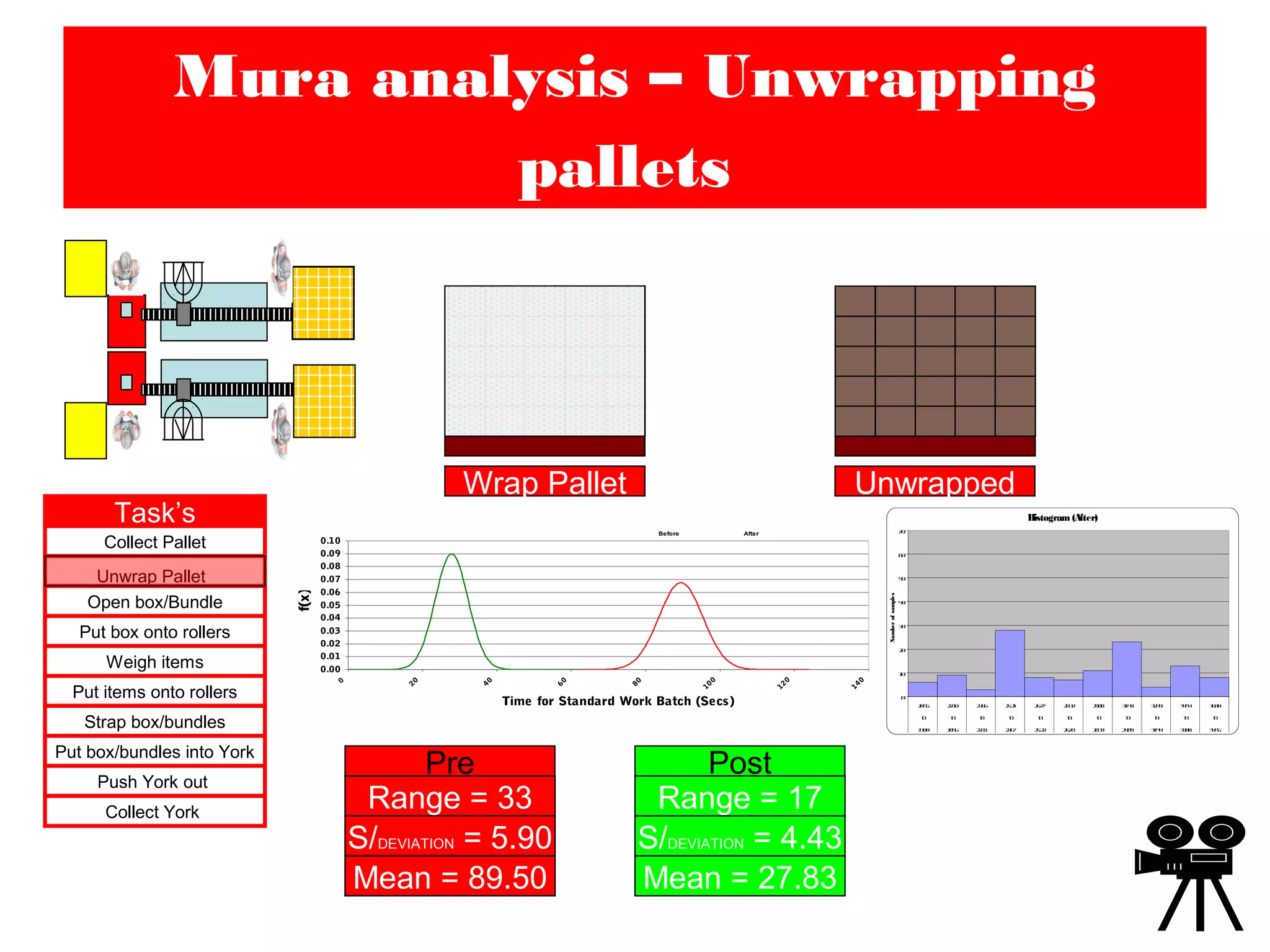

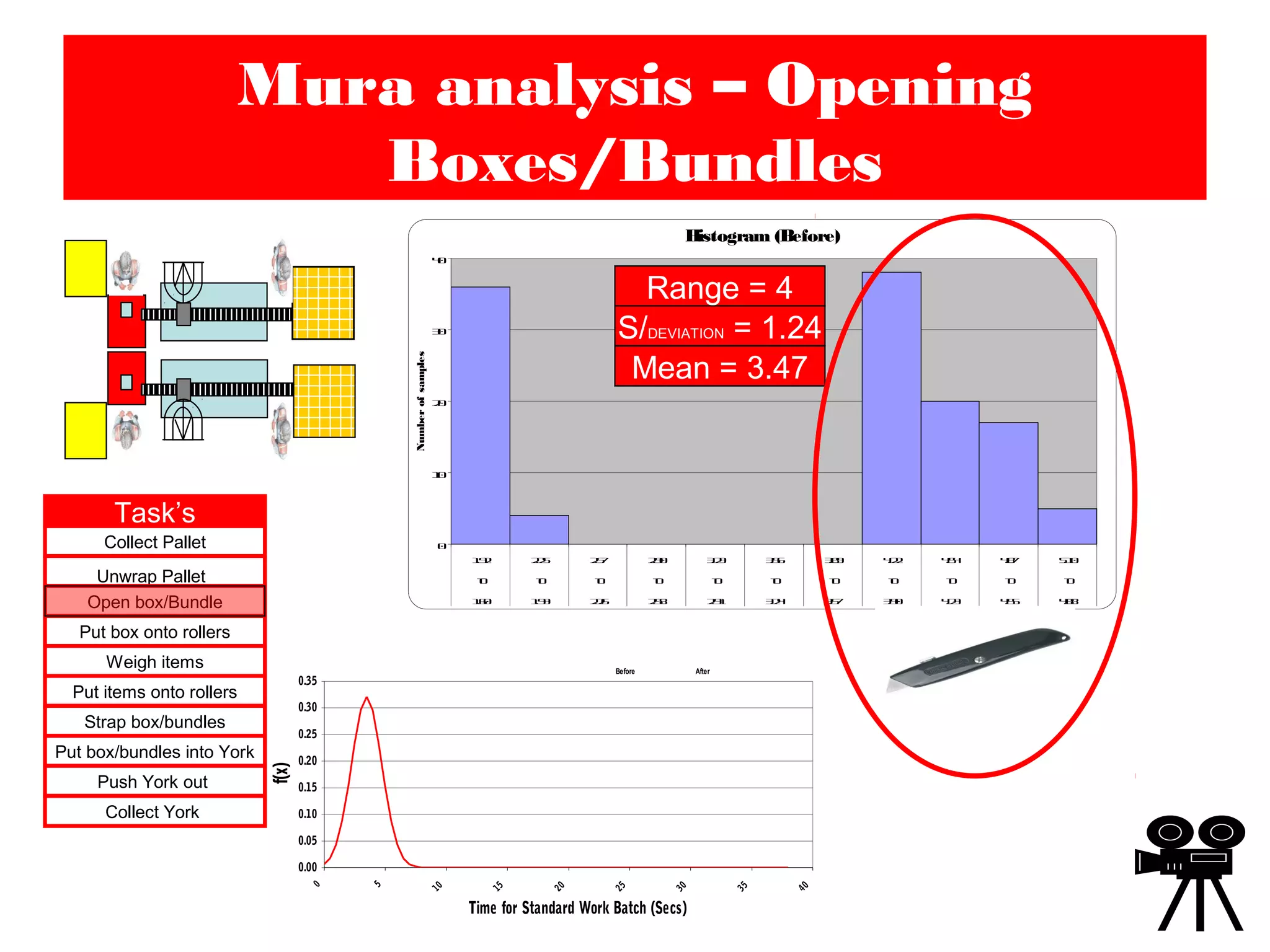

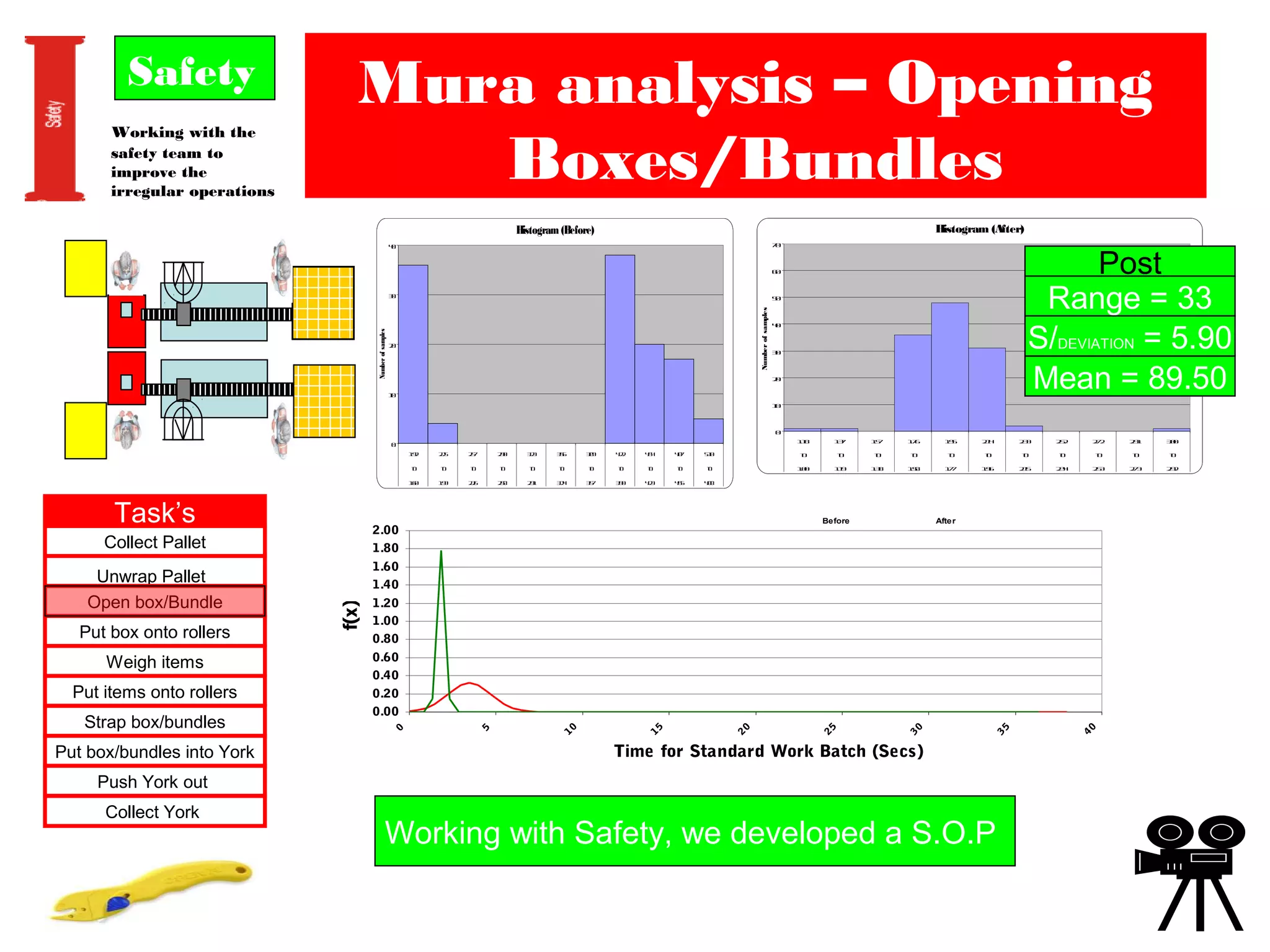

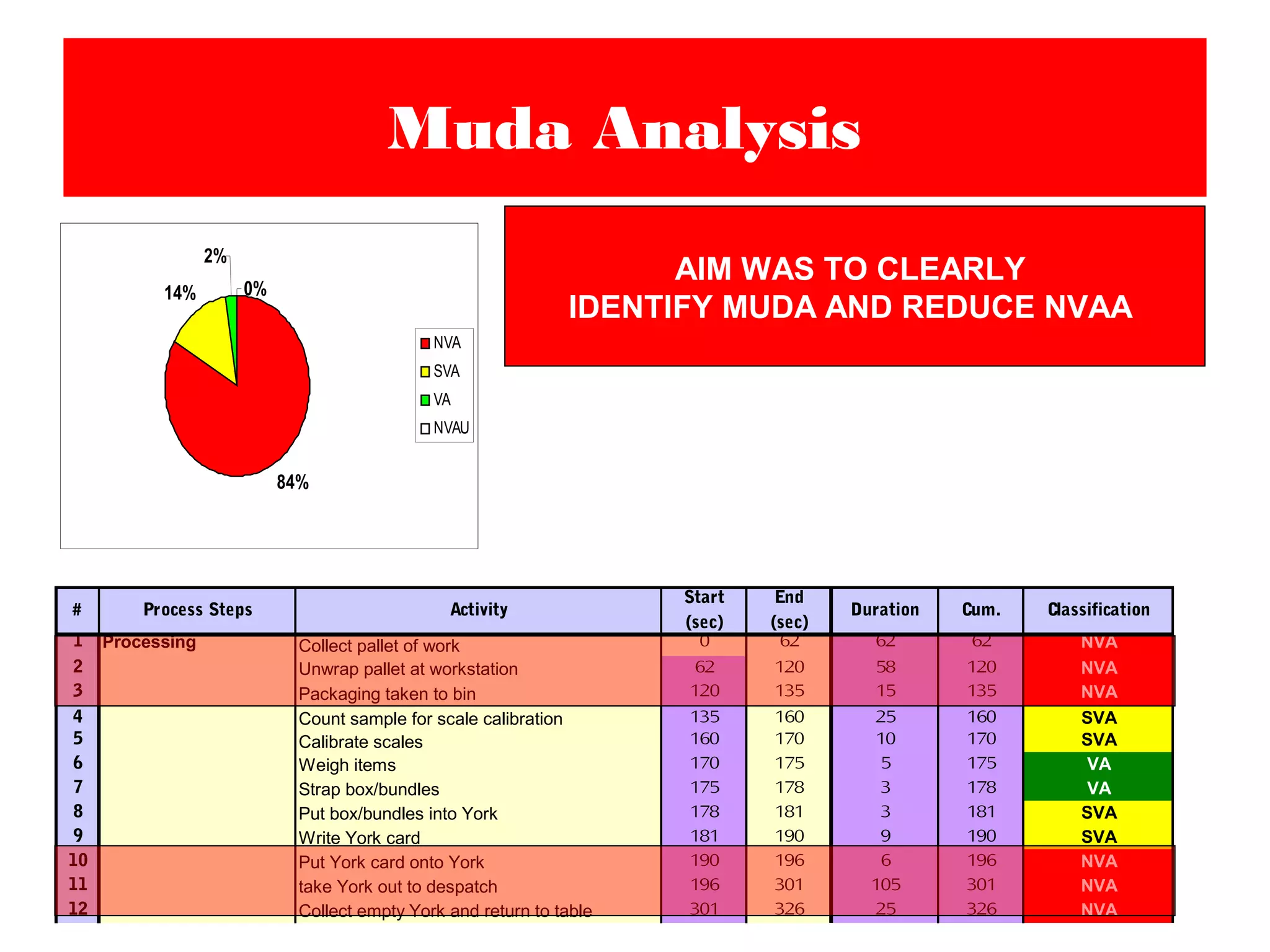

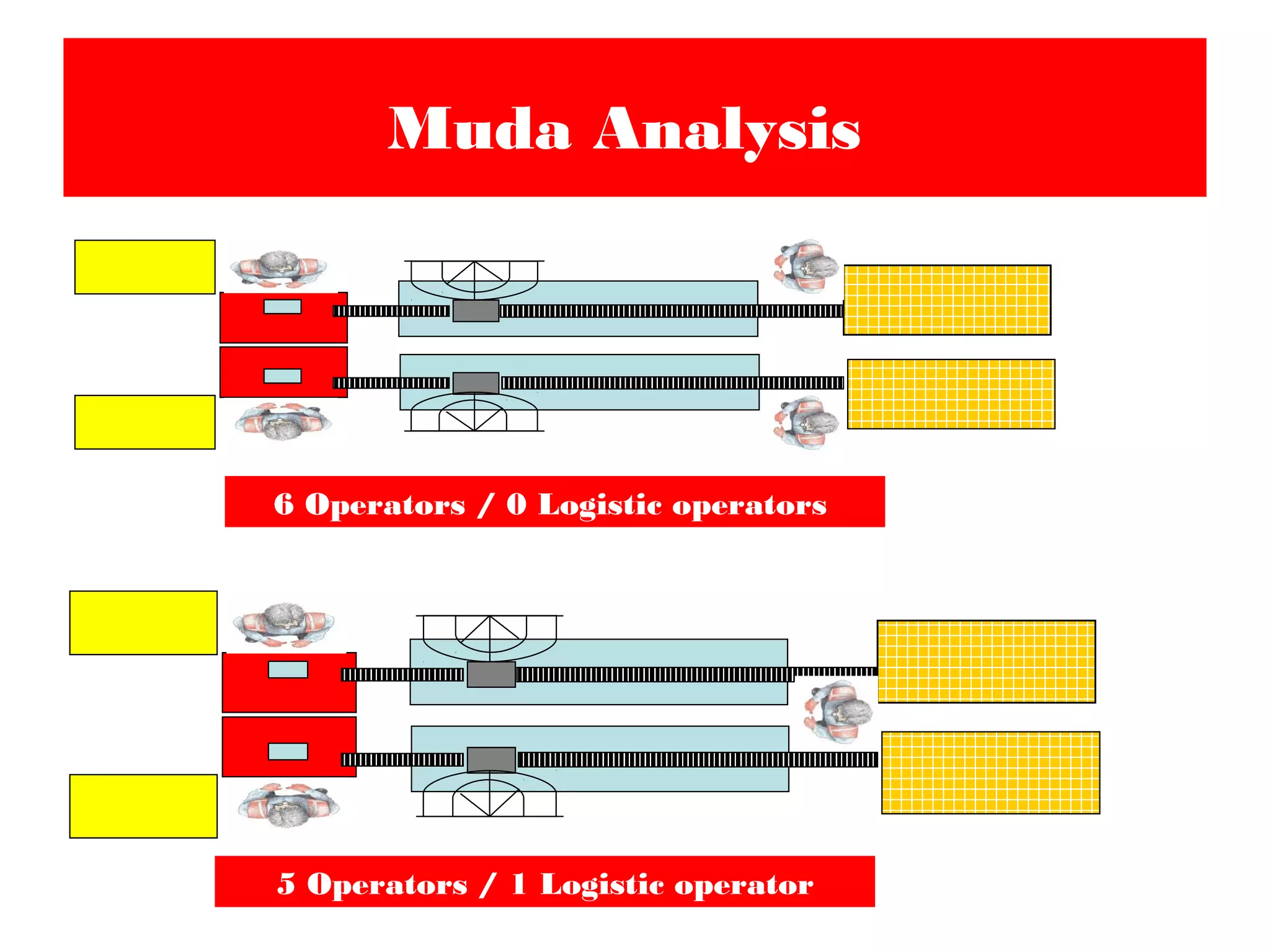

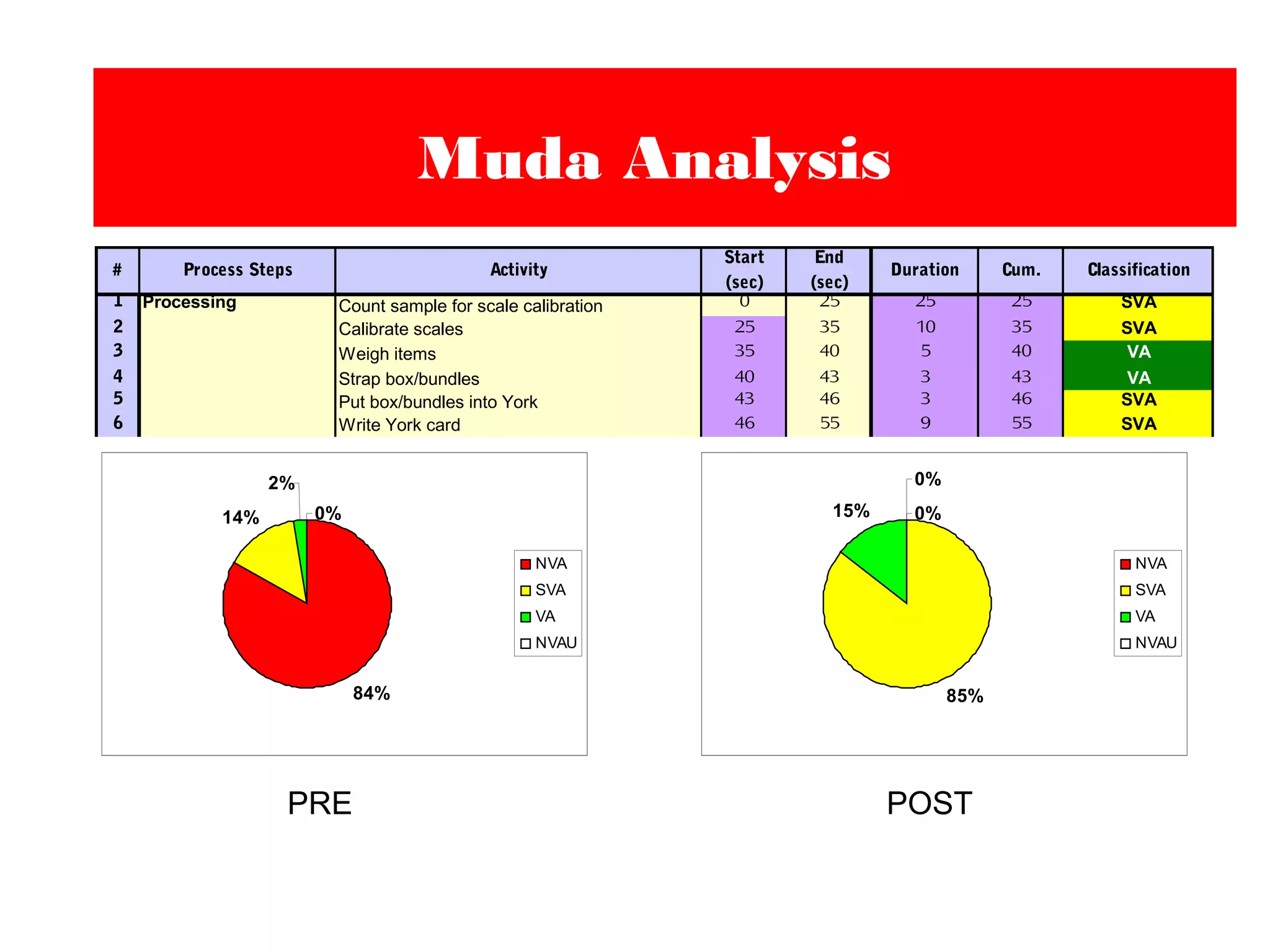

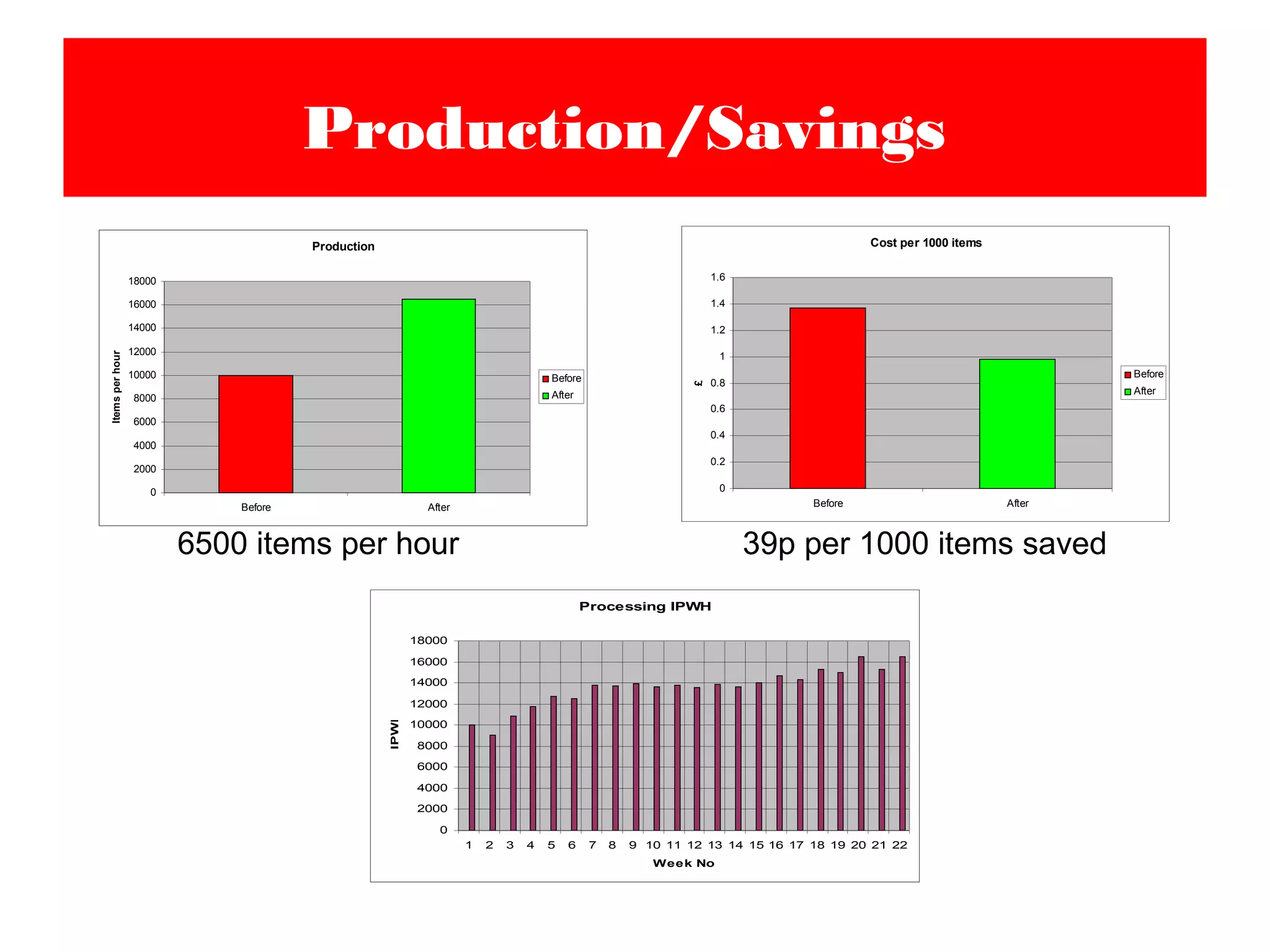

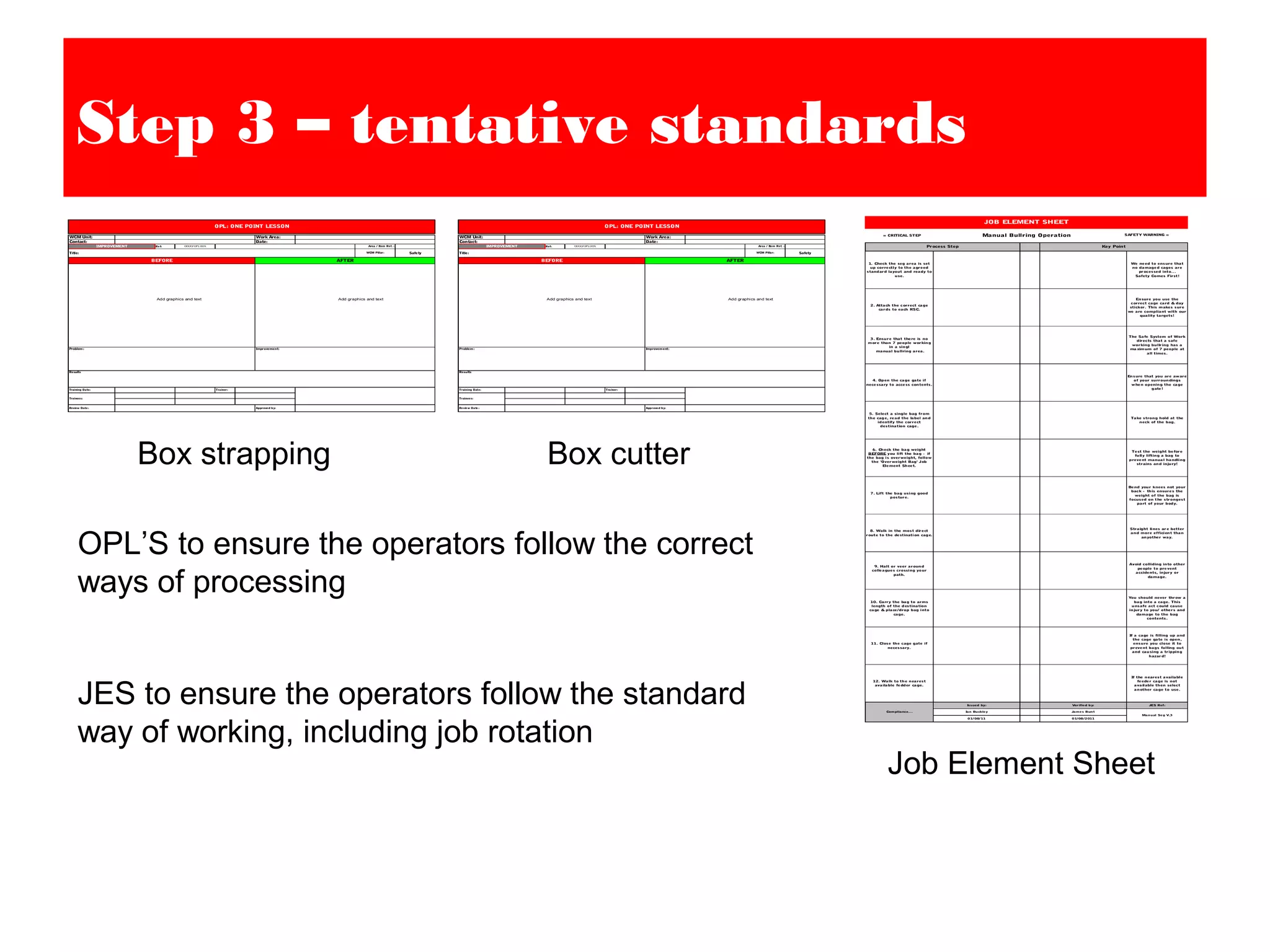

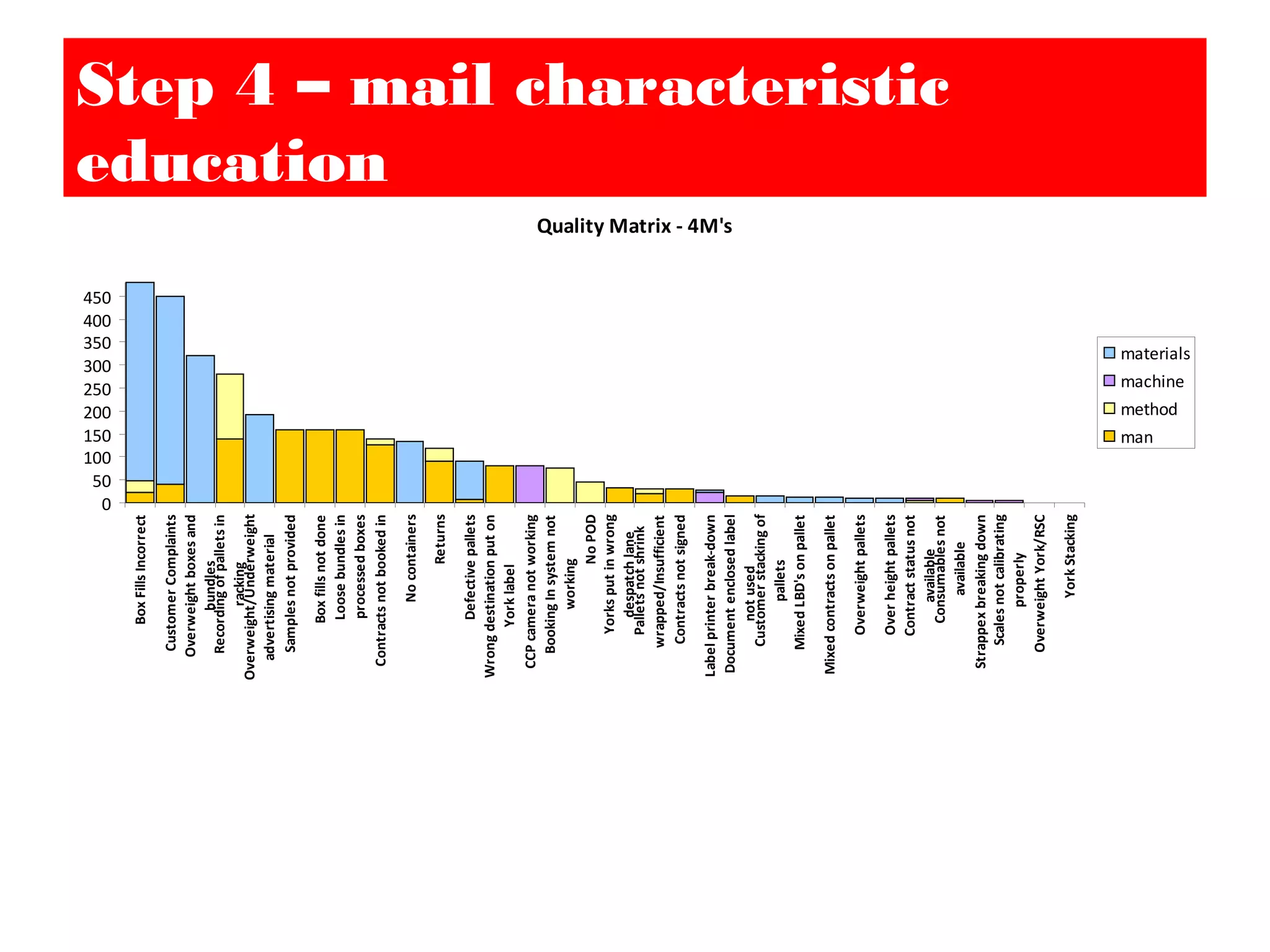

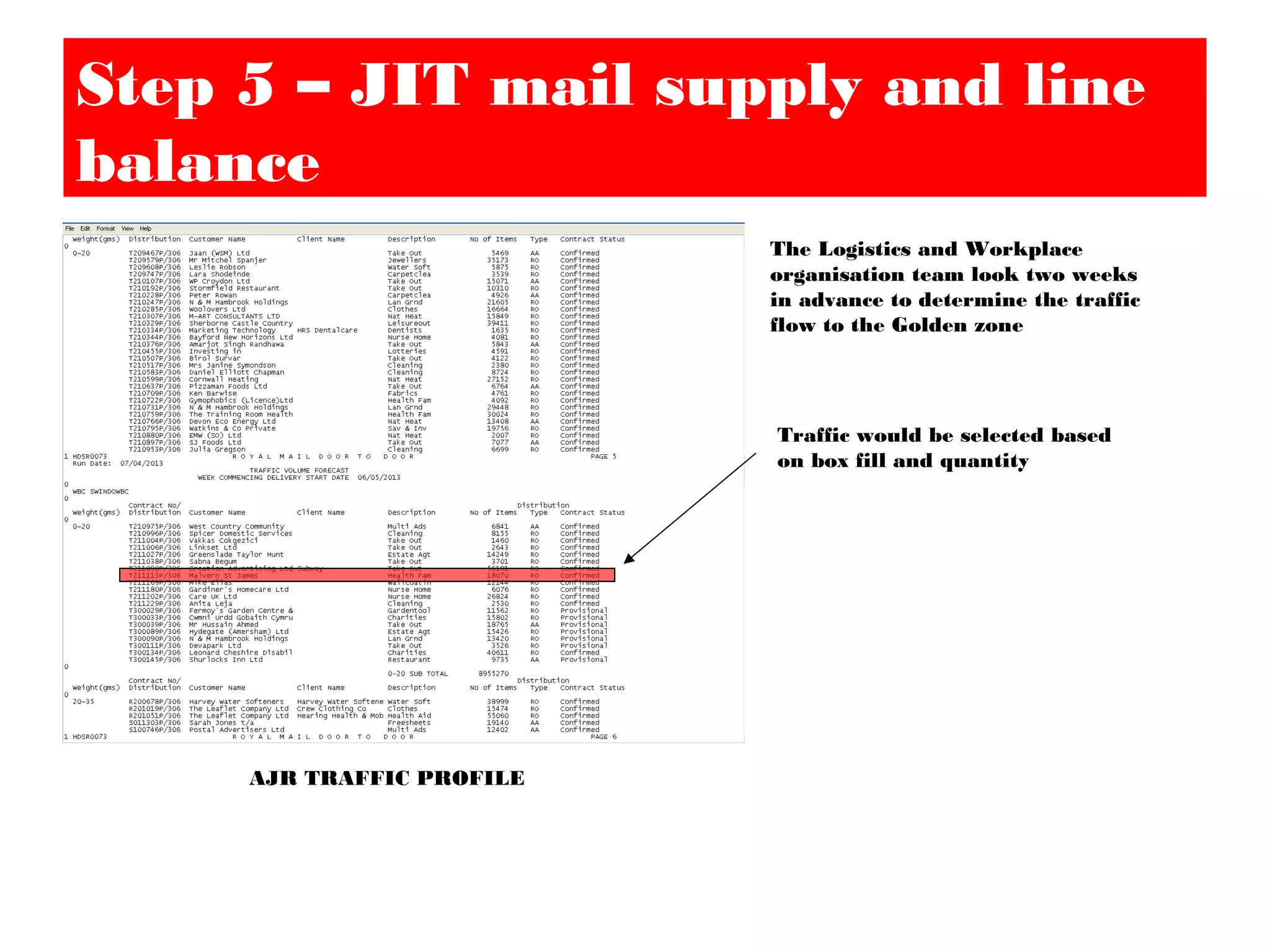

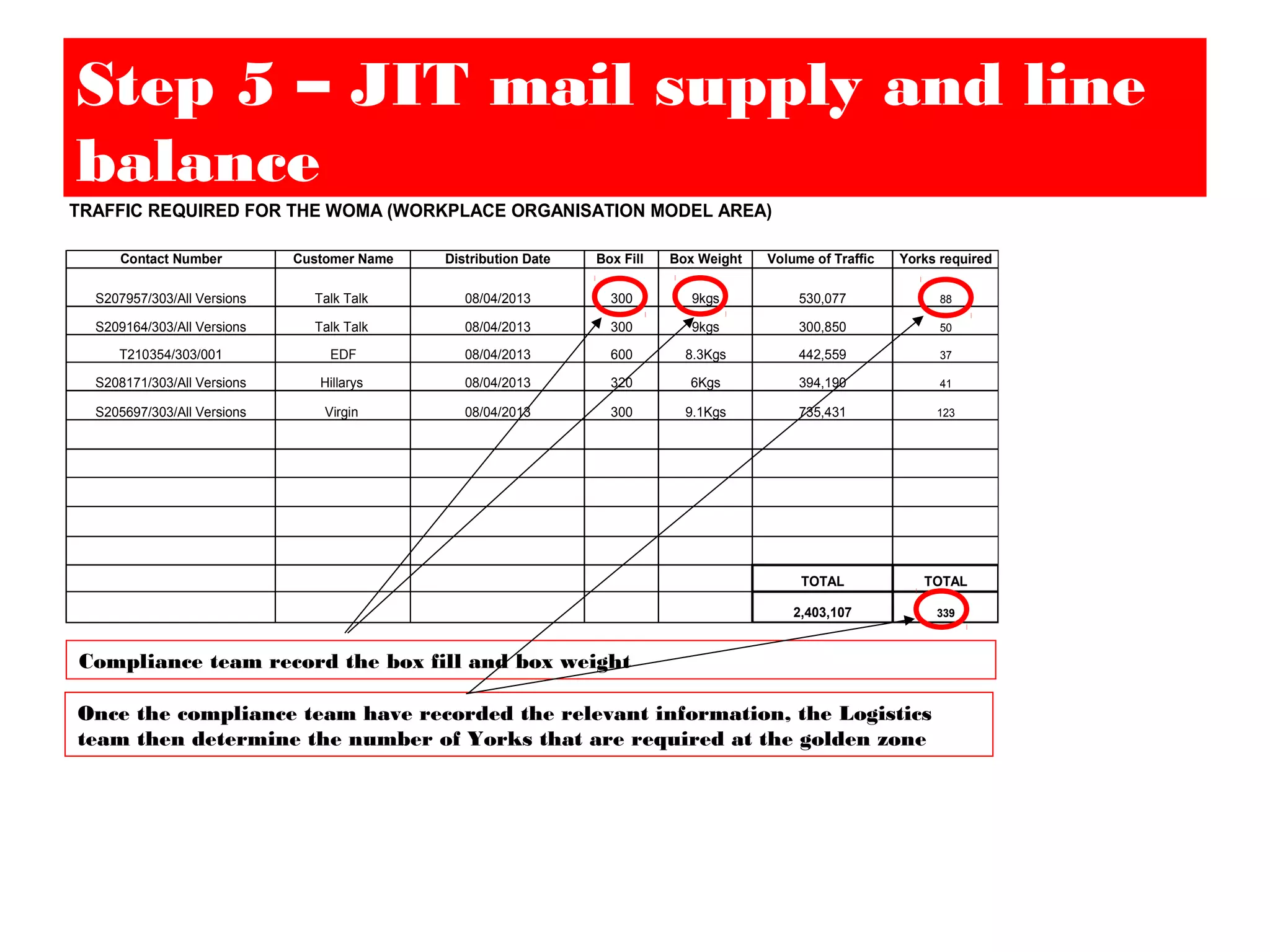

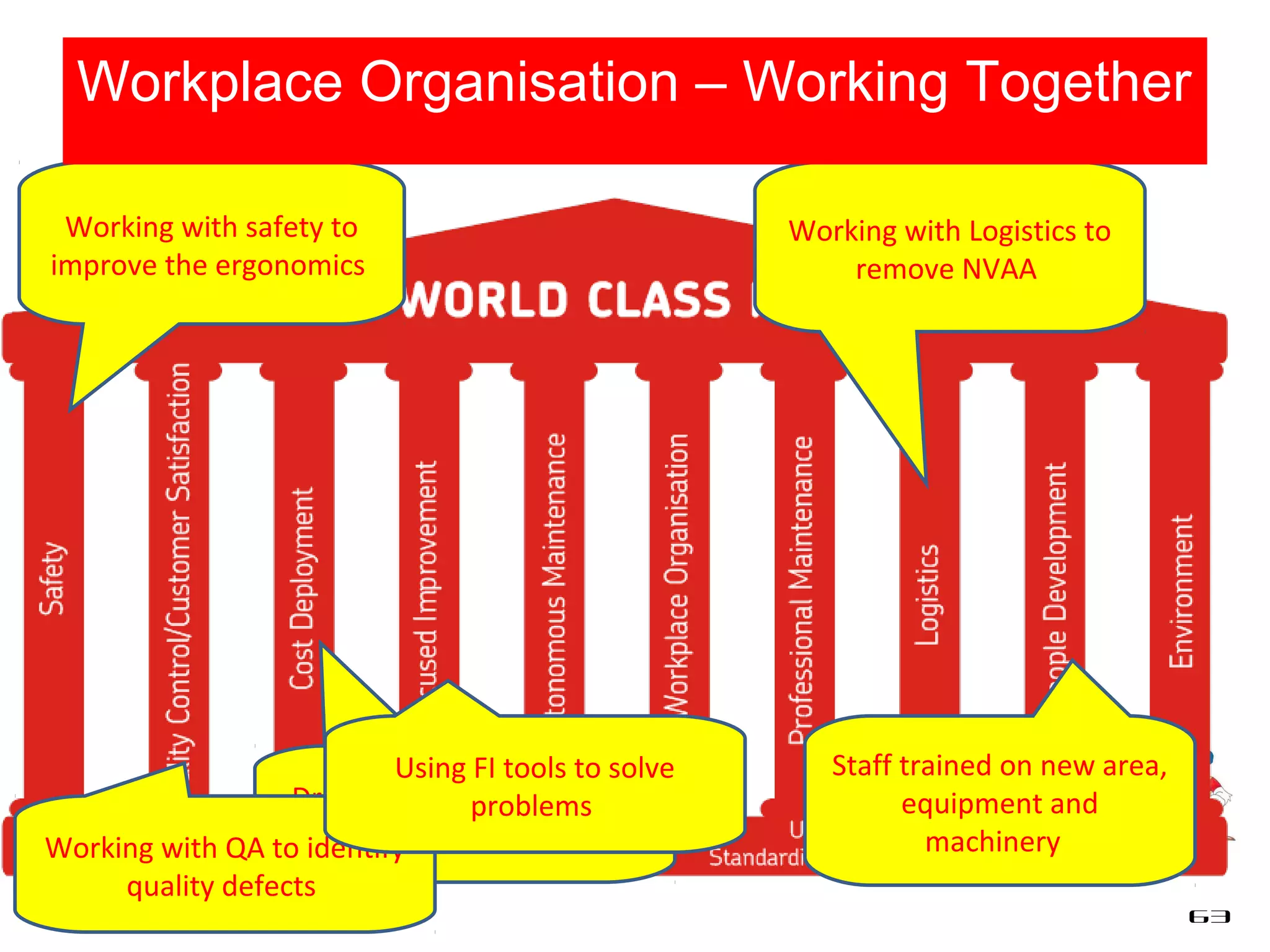

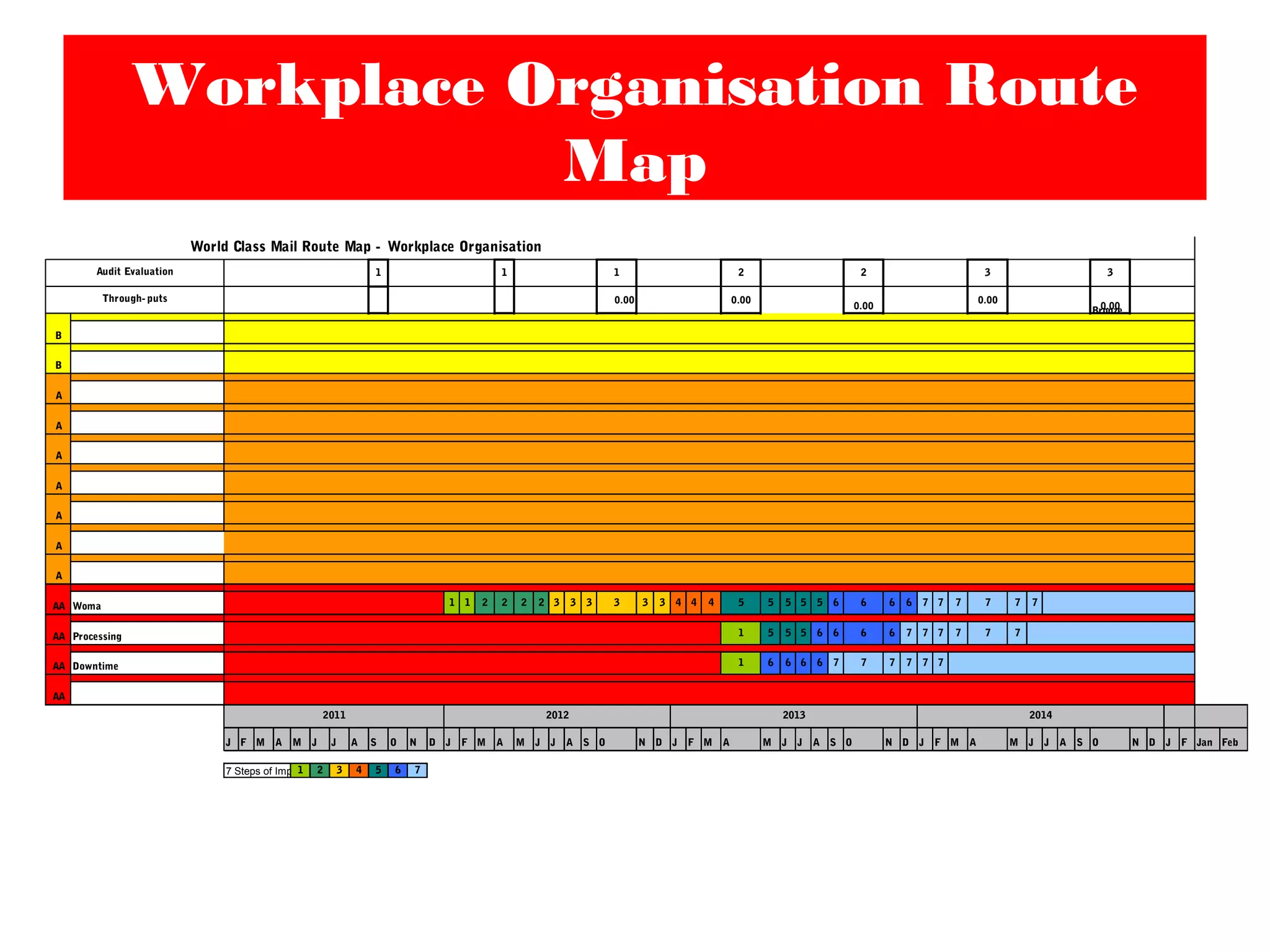

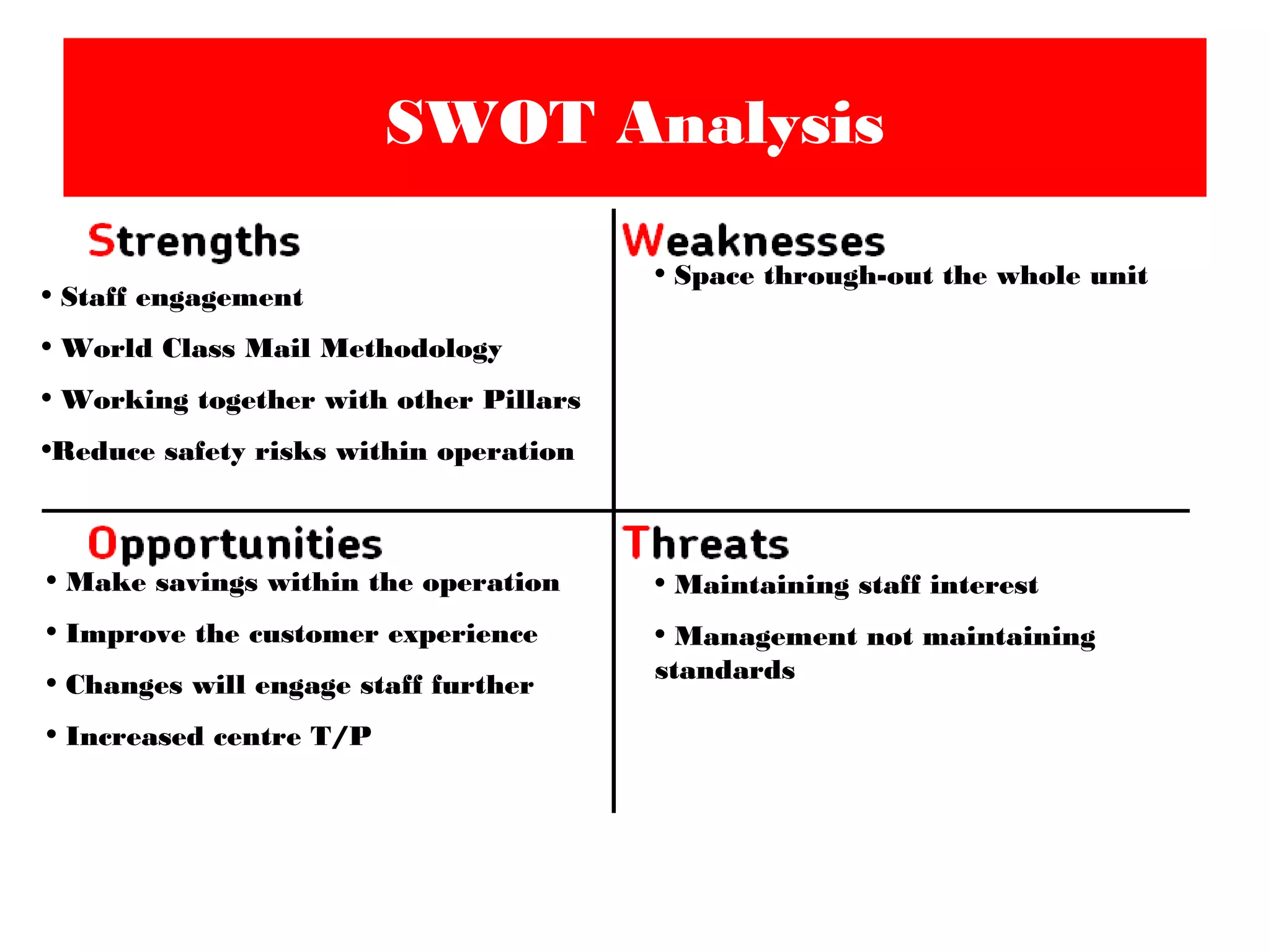

The document discusses improving workplace organization at a mail processing facility through a 7 step model area approach. It begins with initial cleaning using 5S principles to organize the workstation. Measurement found average productivity increased by 250 items per work hour after implementing 5S. Further steps involve analyzing processing tasks to identify difficult motions, standardizing work procedures, and establishing just-in-time parts supply to optimize the workflow. The overall goal is to continuously enhance productivity by reducing waste and improving ergonomics through employee involvement in transformation of the model area.