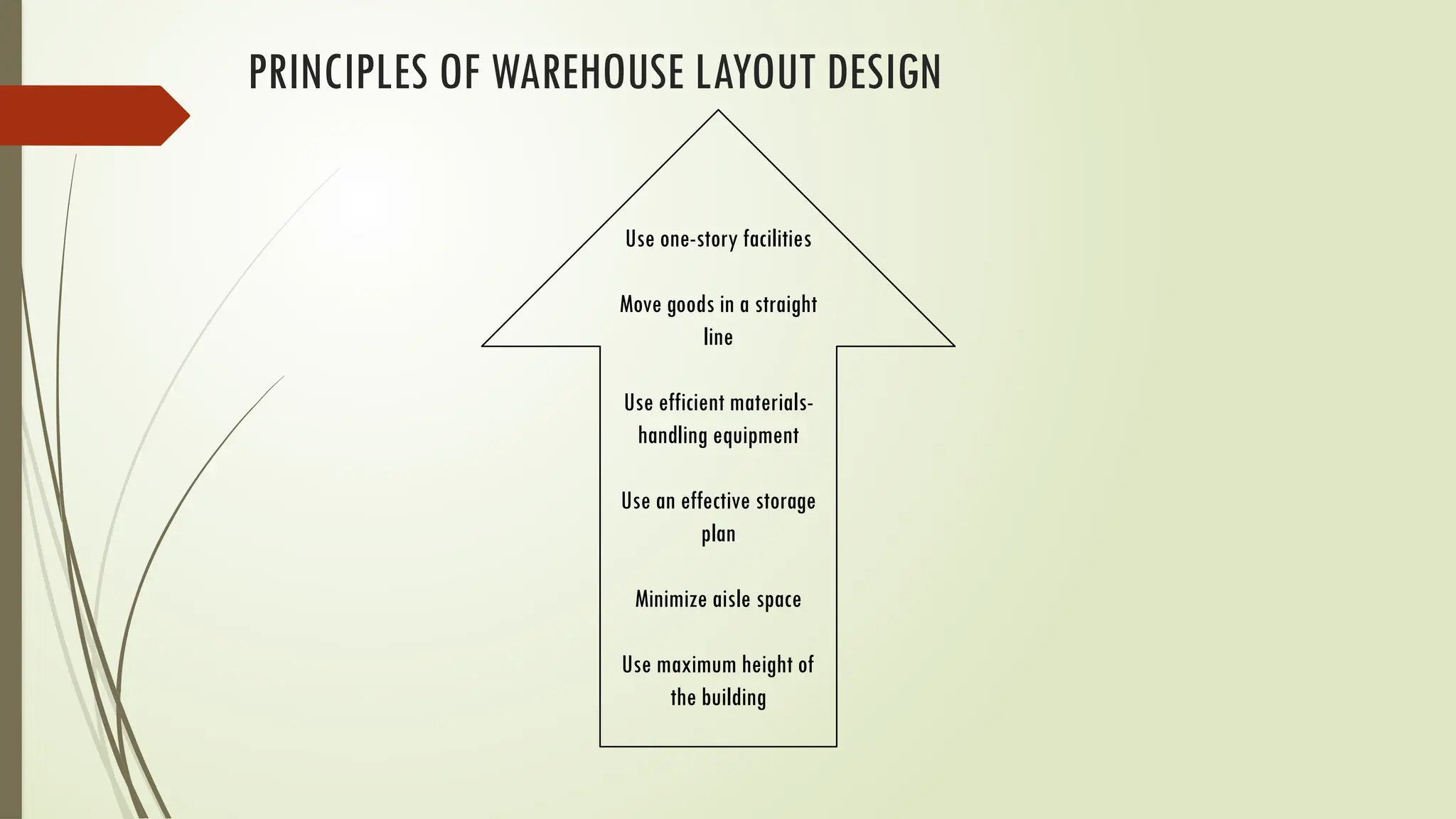

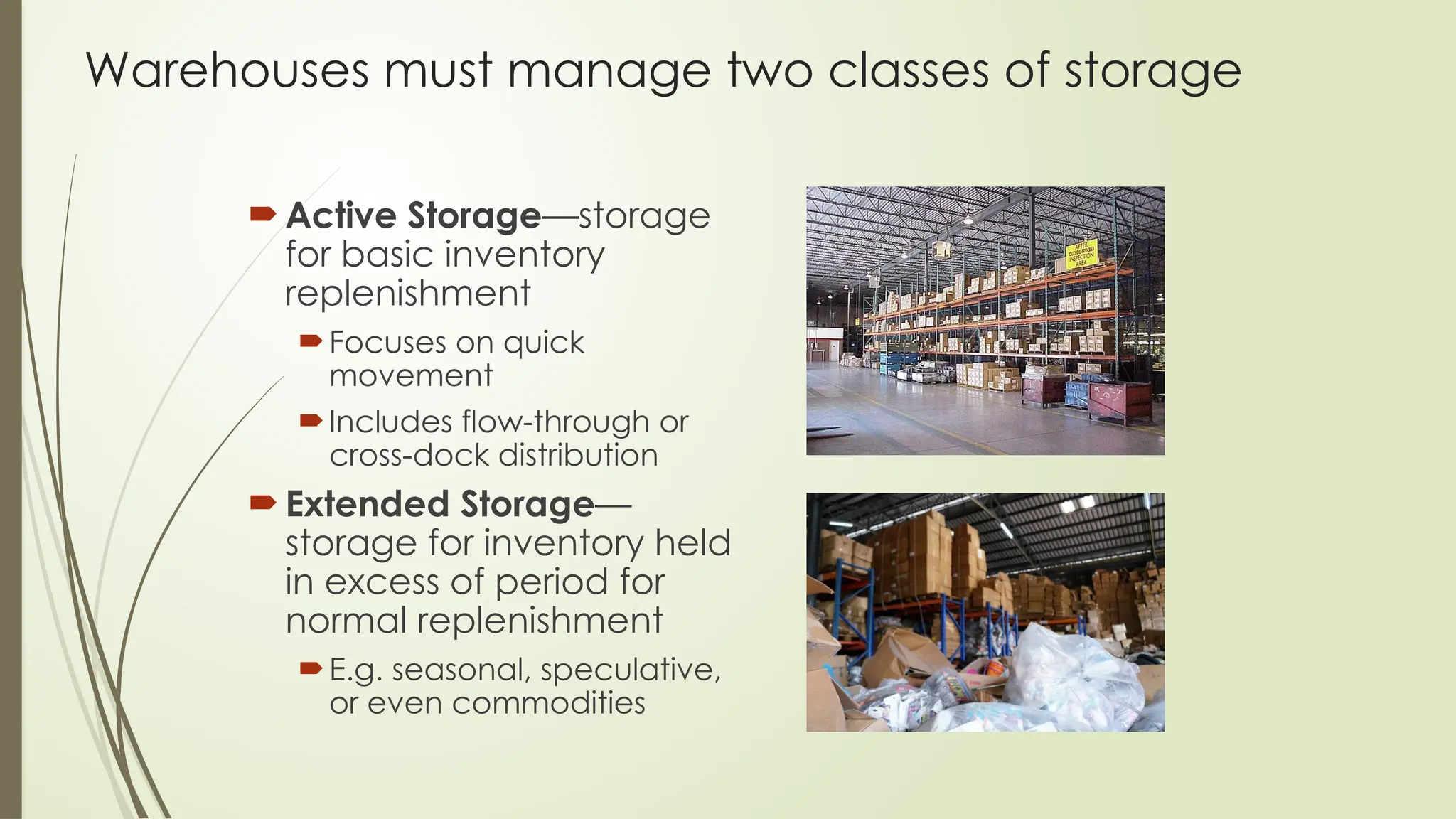

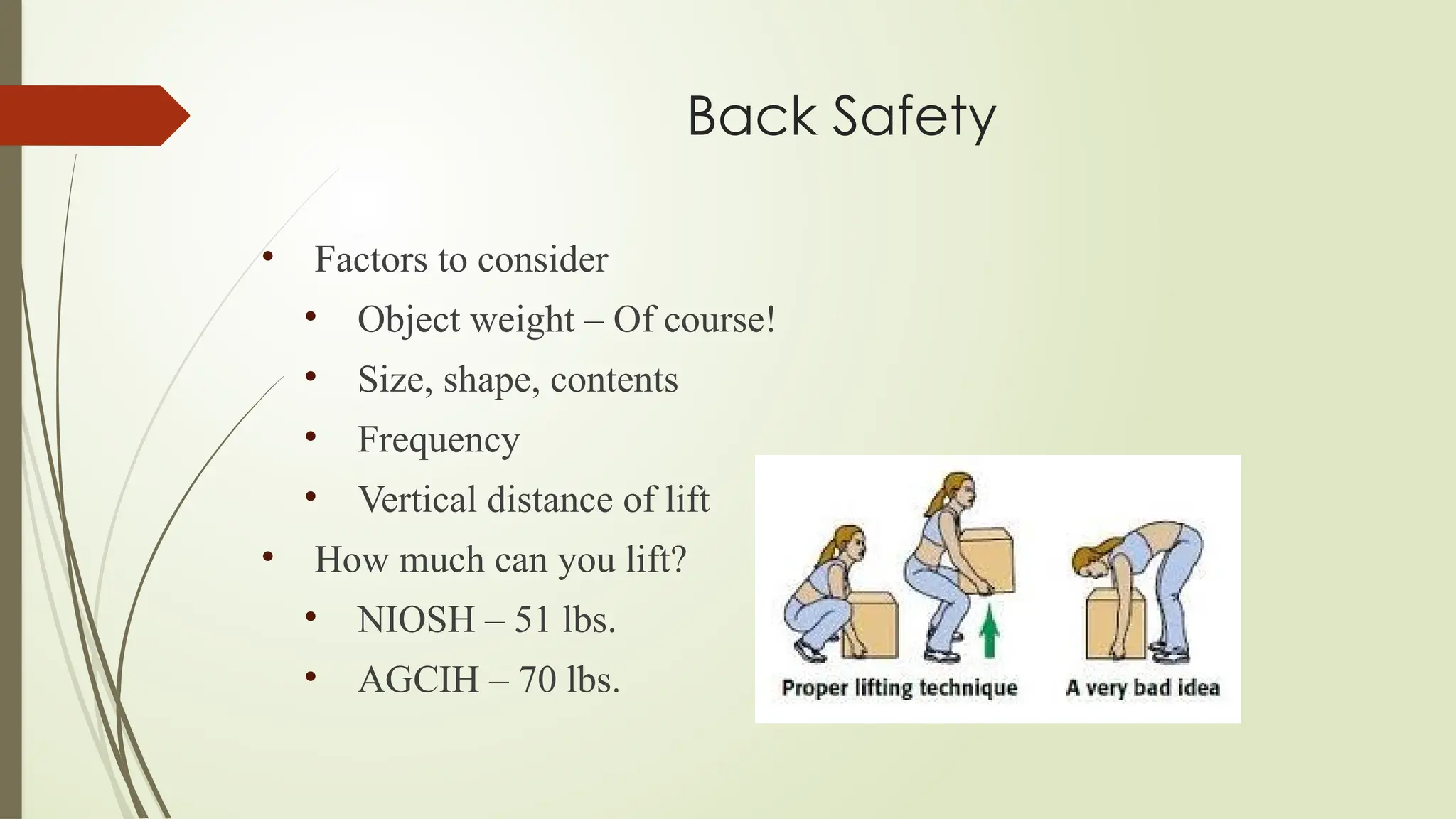

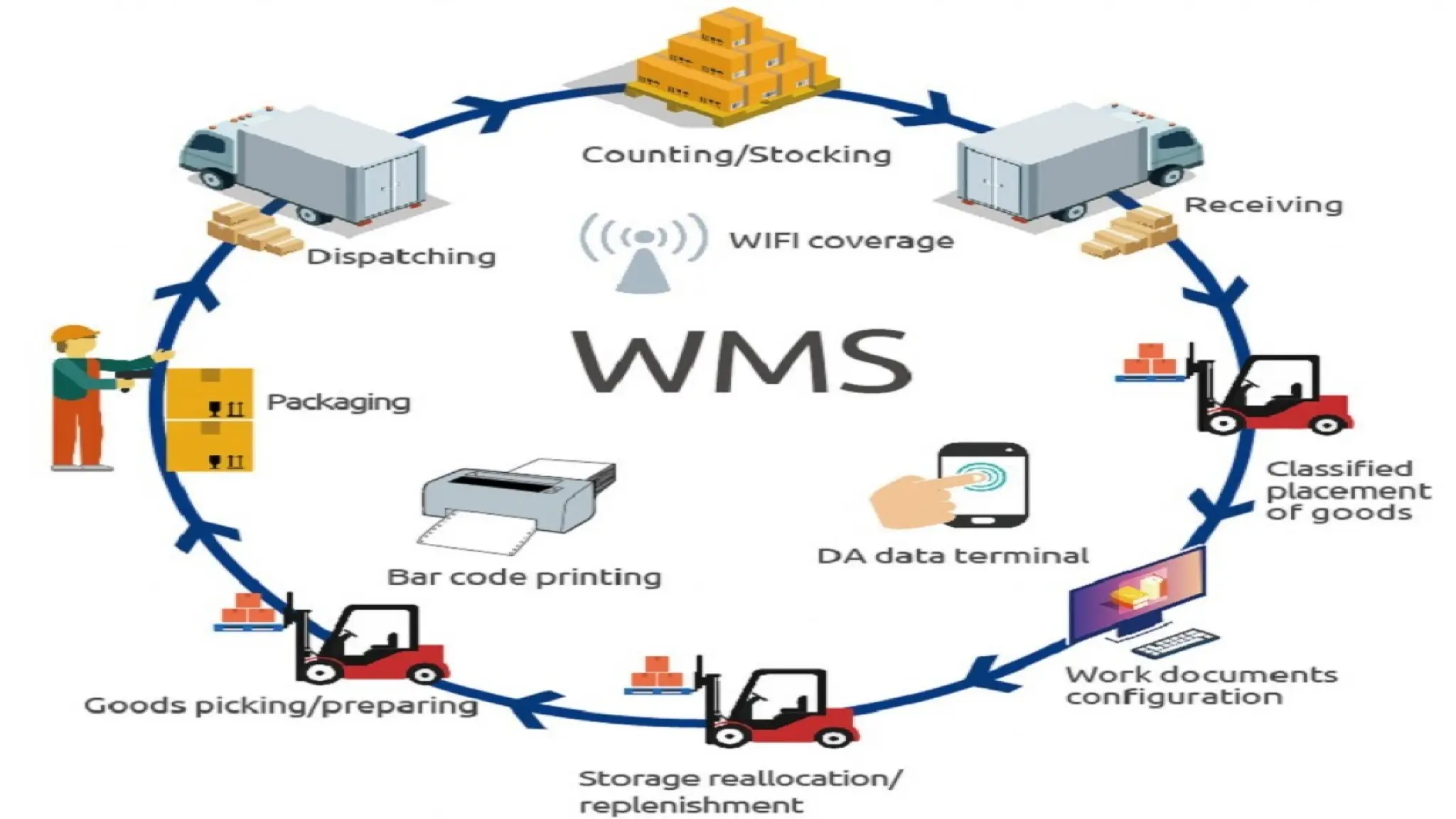

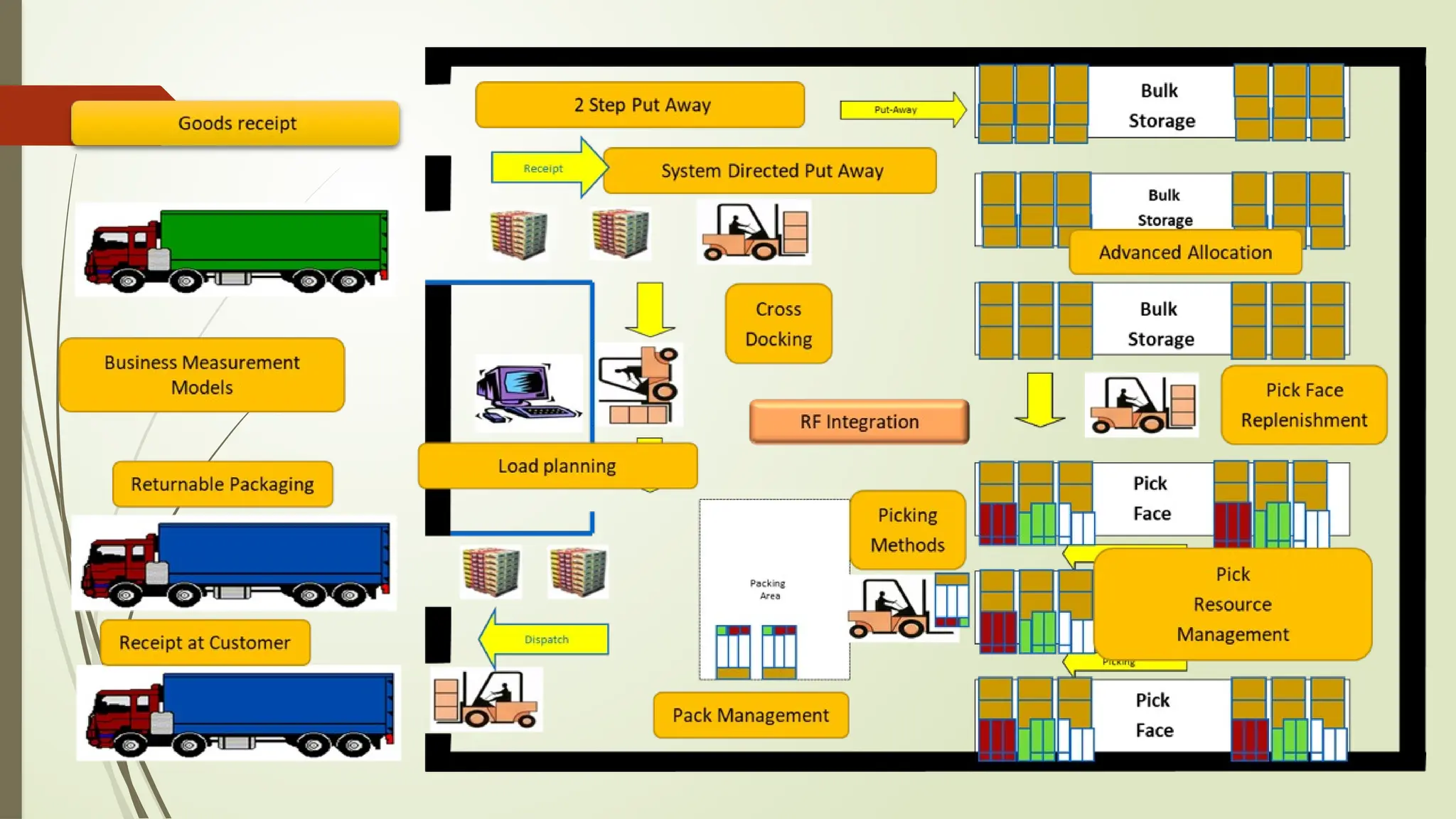

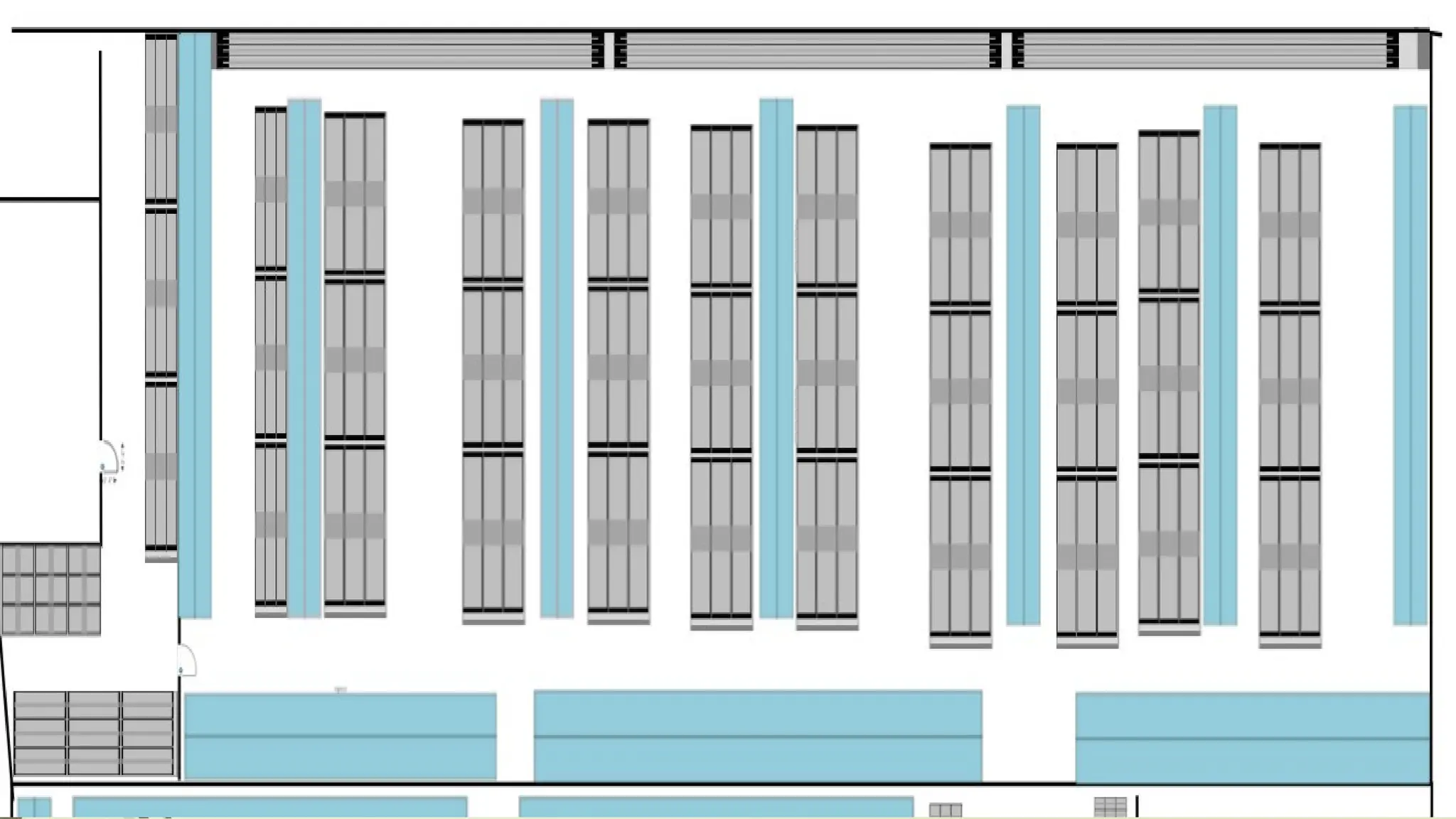

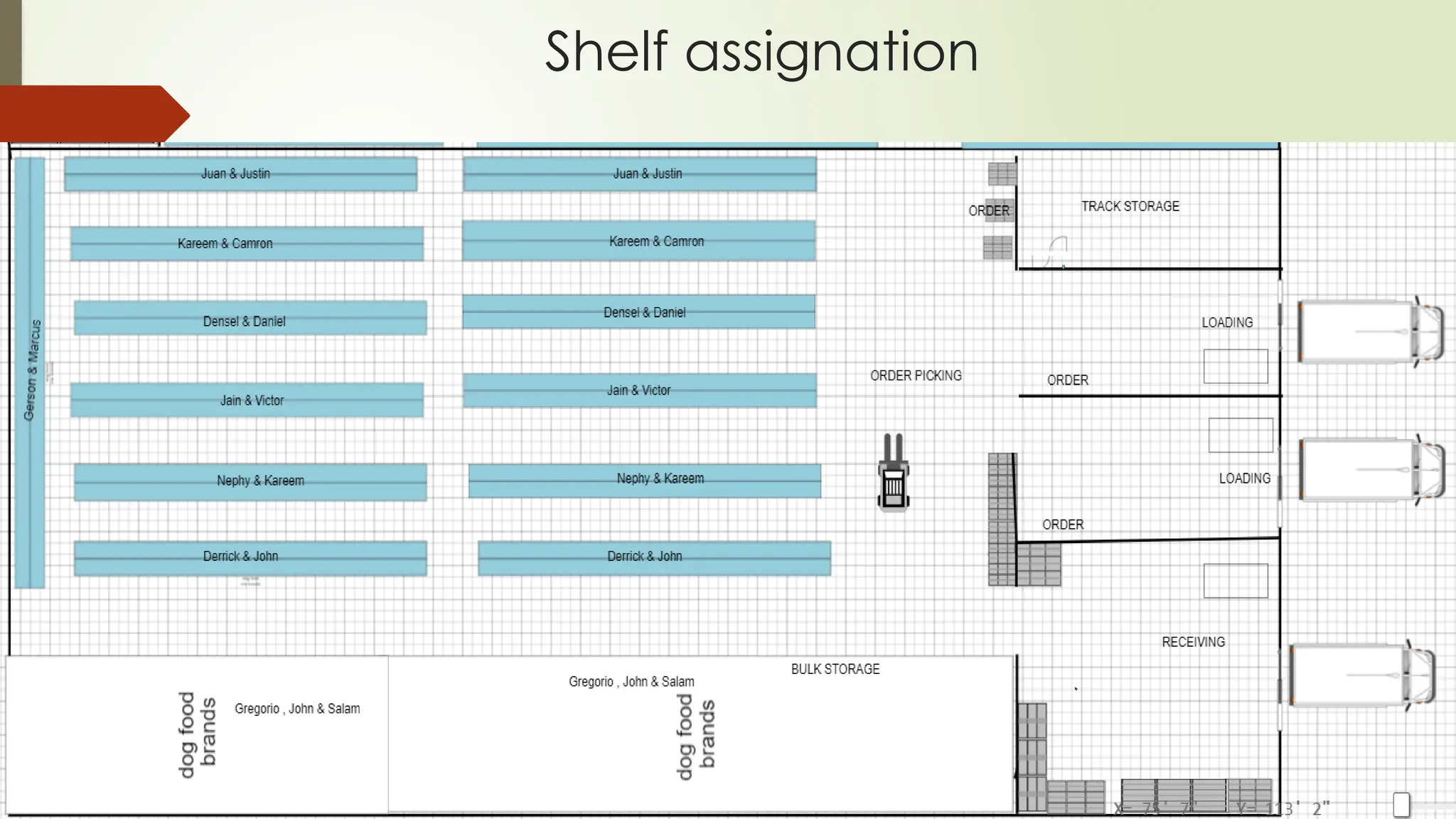

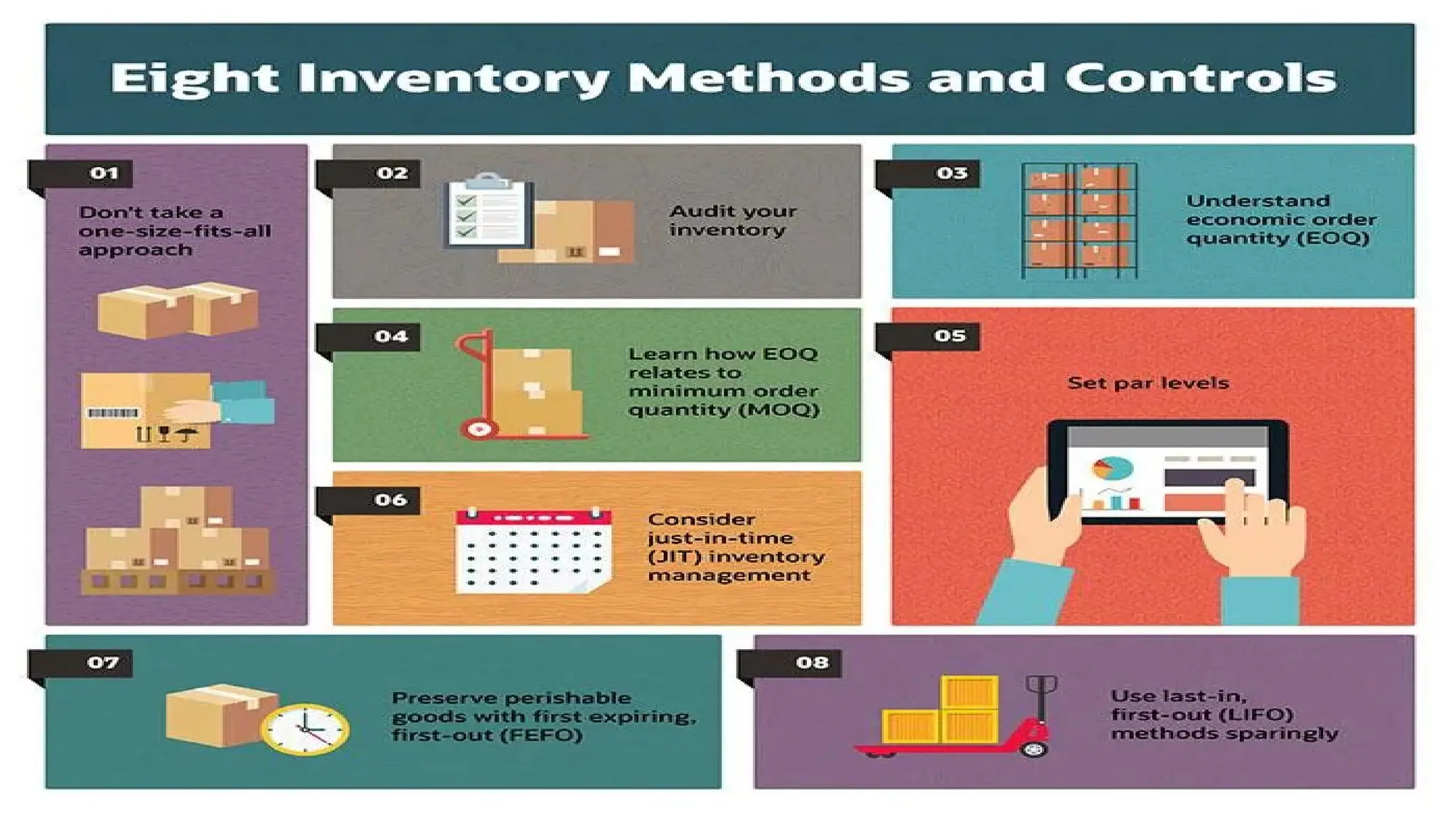

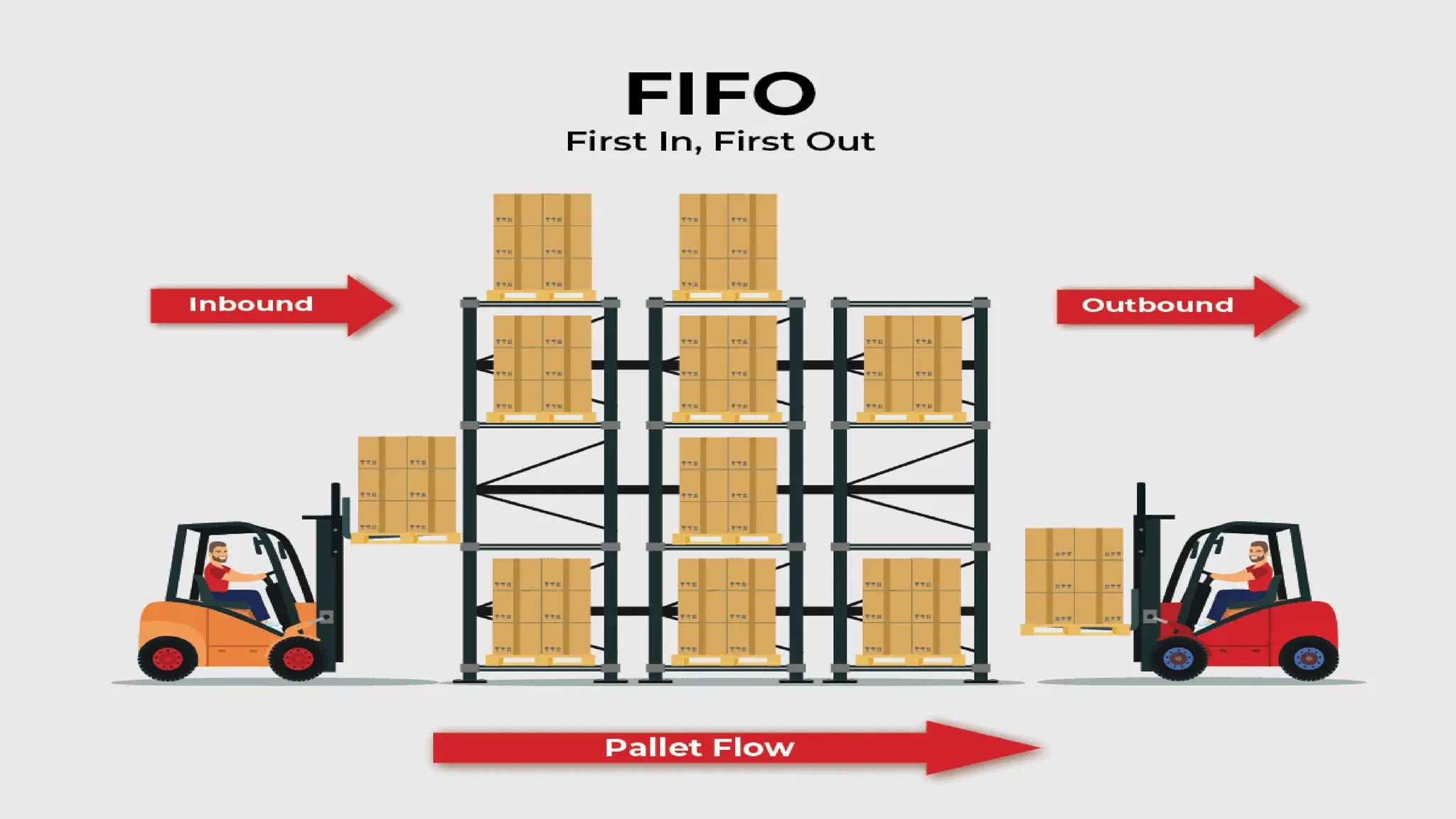

The document outlines the objectives and processes involved in effective inventory planning and warehouse management, emphasizing customer satisfaction, cost control, and safety. It details warehouse layout design, handling and storage processes, inventory velocity management, and the importance of personal protective equipment to ensure worker safety. Additionally, it discusses best practices for housekeeping, action plans for efficient operations, and inventory control methods like ABC analysis.