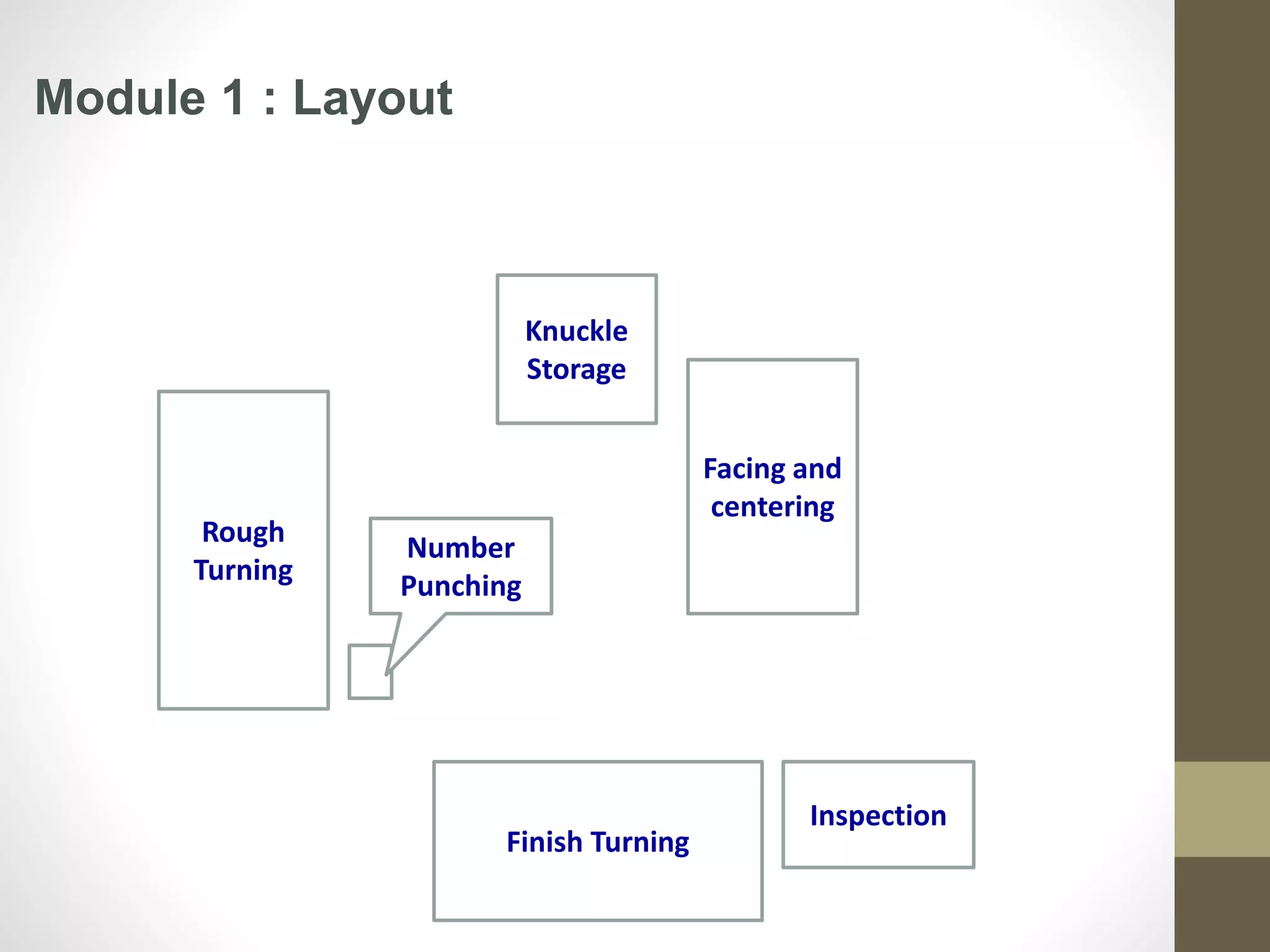

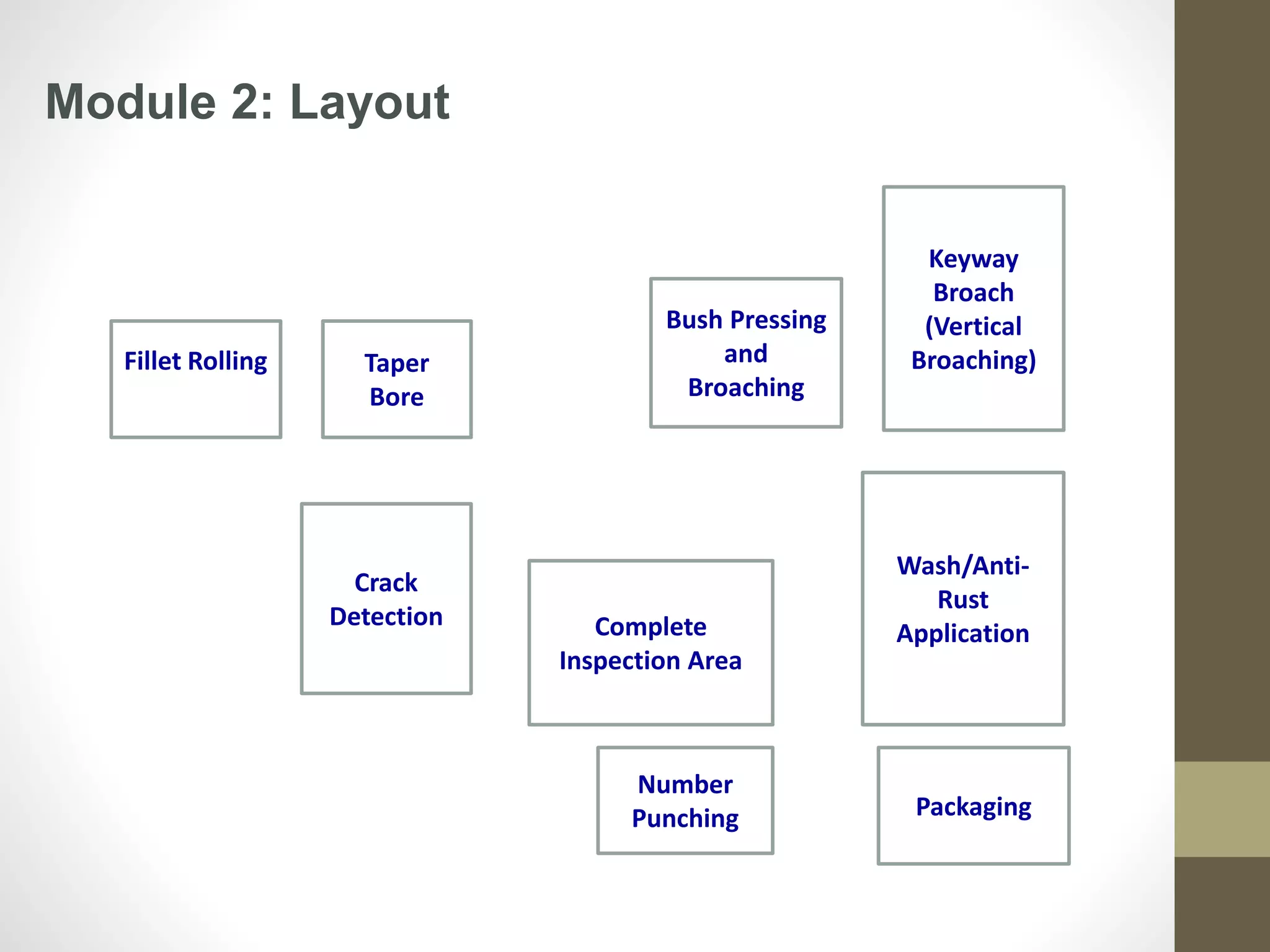

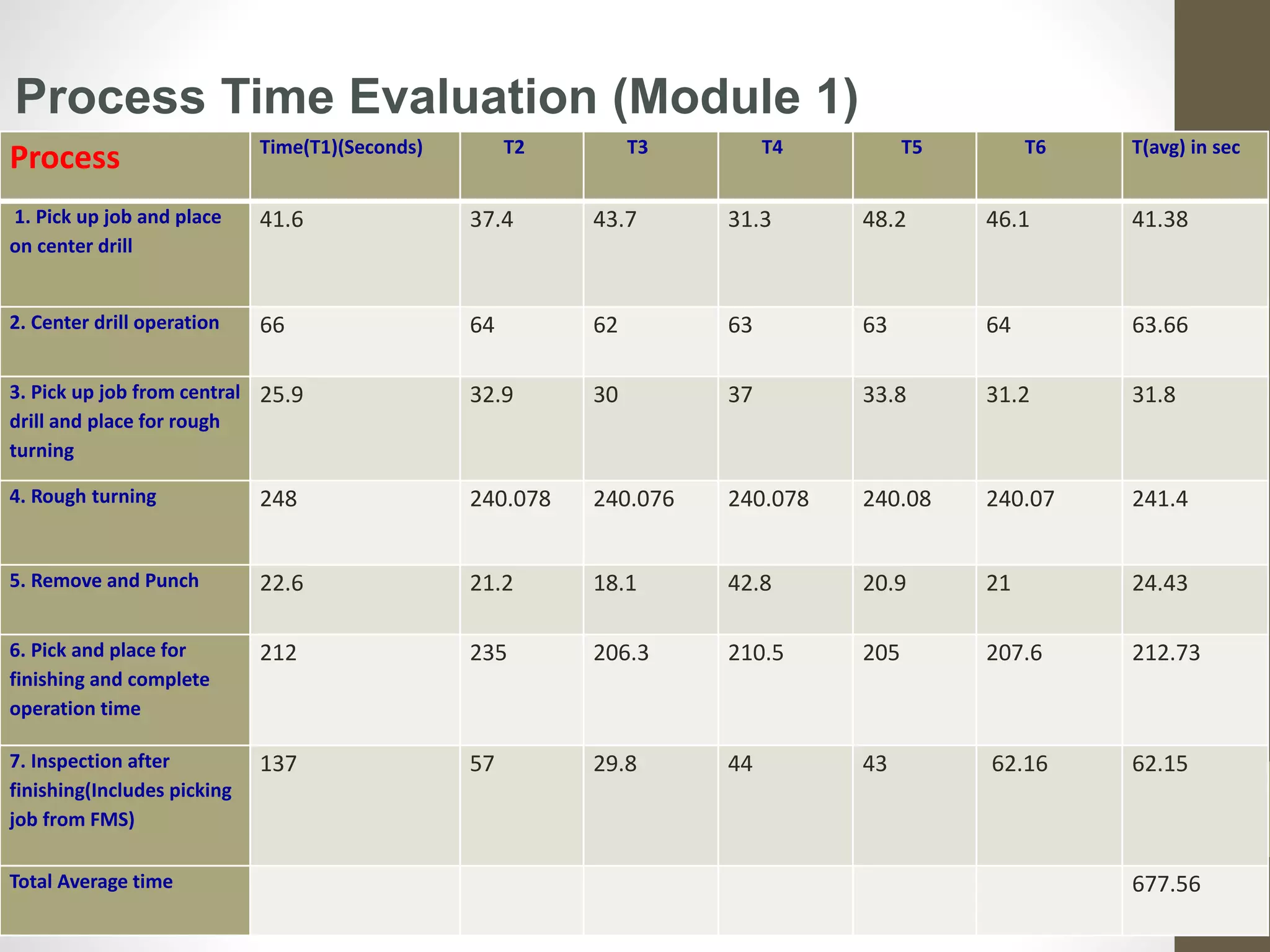

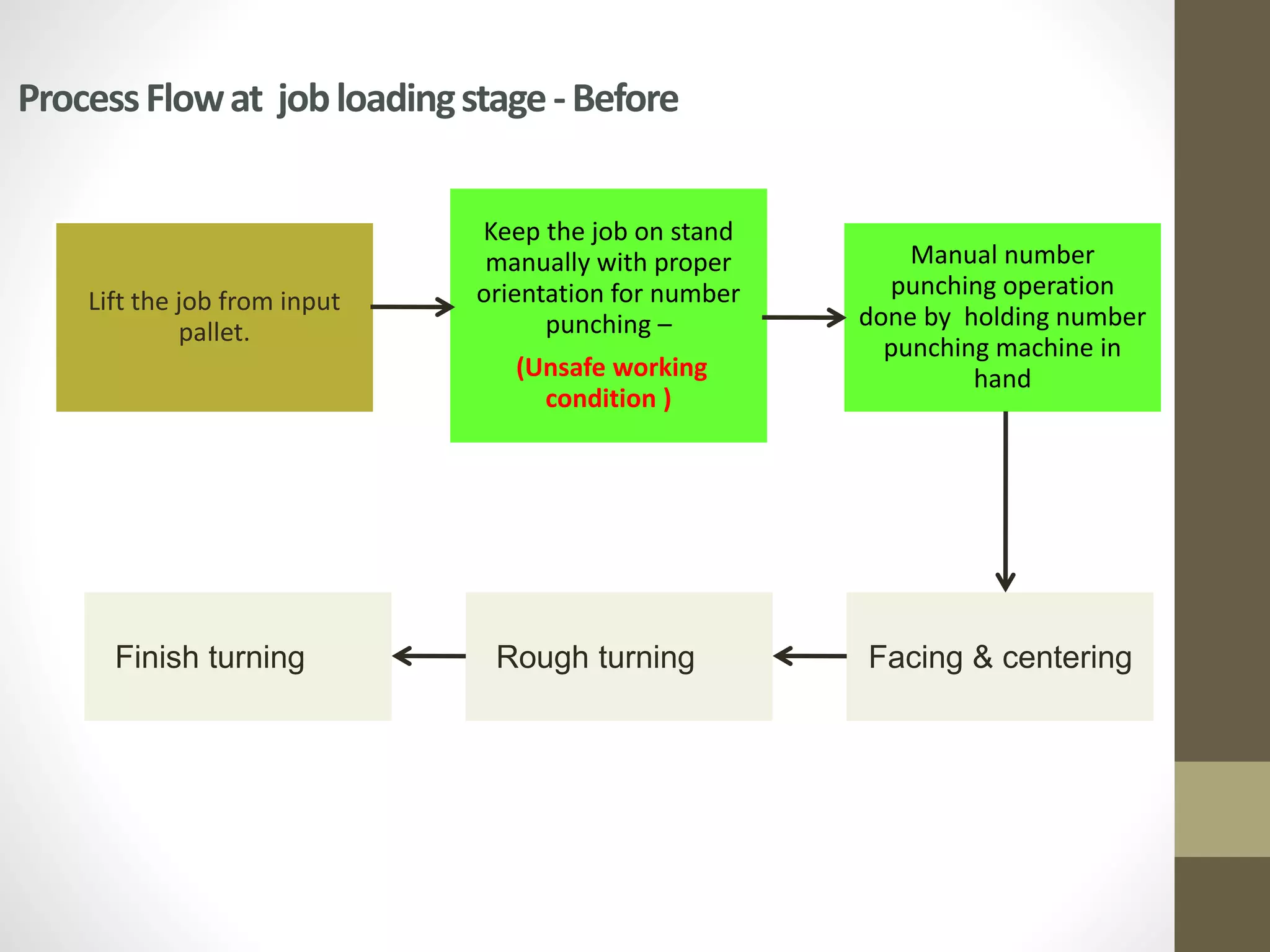

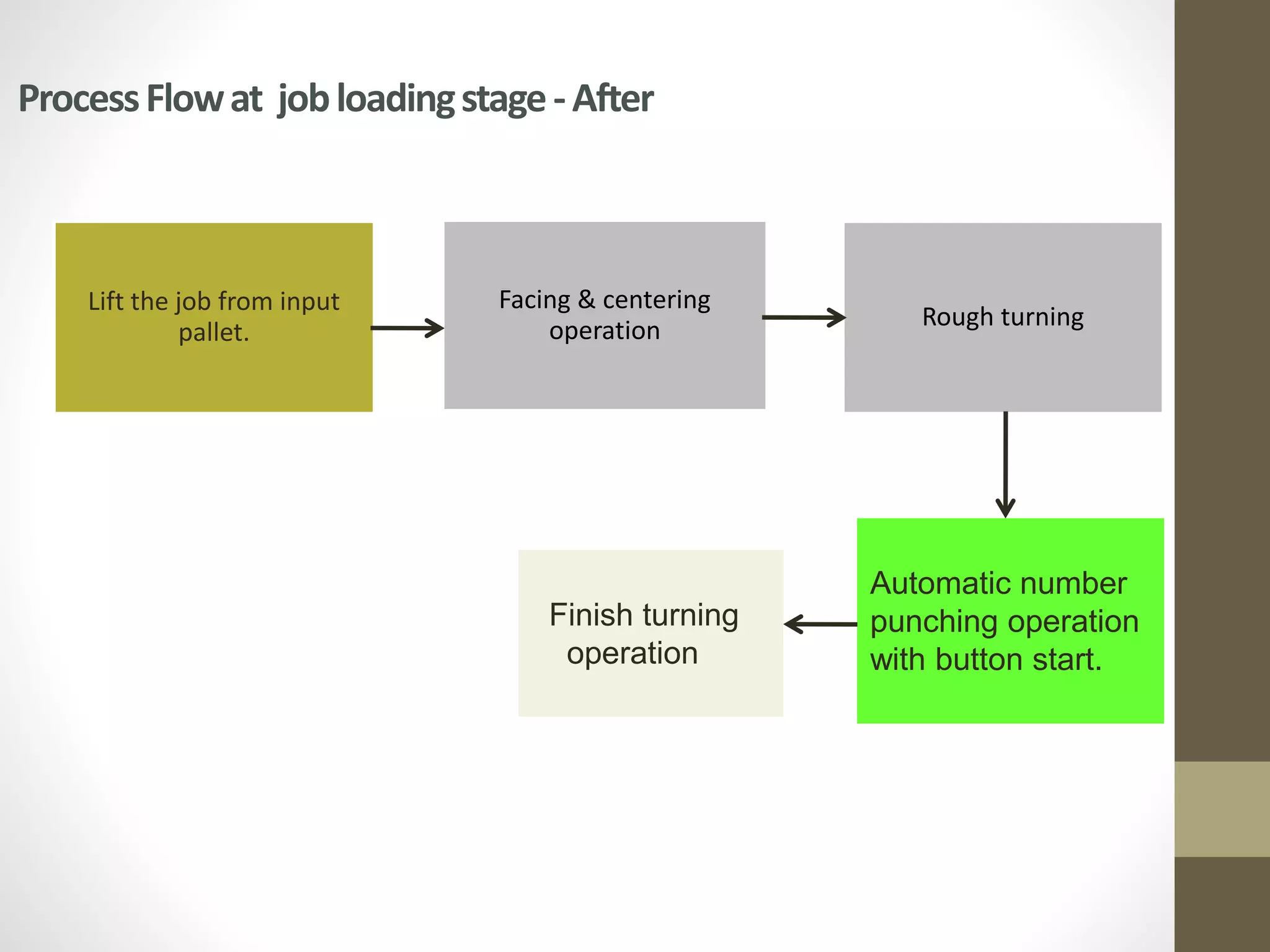

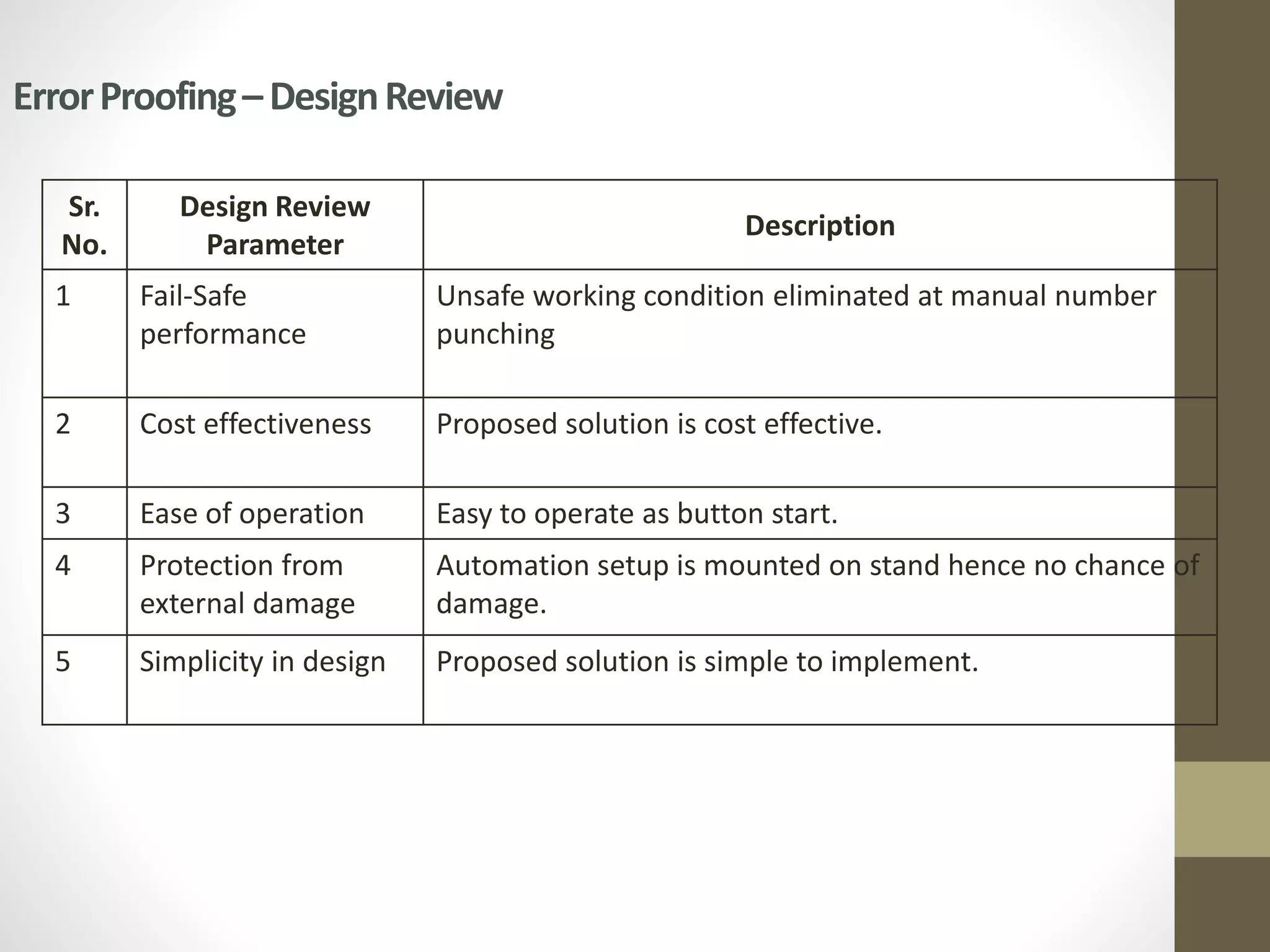

The document discusses cycle time reduction in the manufacturing of knuckle components, detailing the processes involved and presenting an evaluation of time spent on various operations. It identifies issues such as manual number punching and the need for automation to enhance efficiency, while proposing solutions to mitigate defects and streamline operations. An action plan is suggested to save time and improve ergonomics in the grinding and hardening processes.