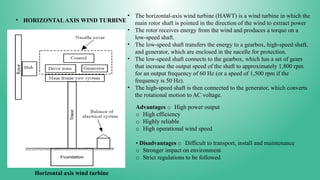

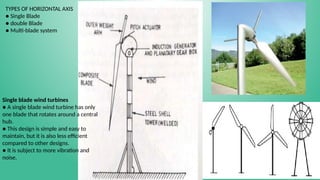

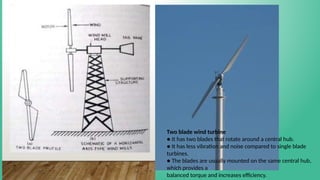

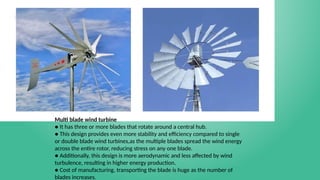

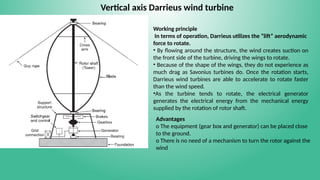

The document discusses wind energy, its causes, and how it's harnessed through wind turbines, which convert kinetic energy from wind into electricity. It highlights India's growing wind power capacity, challenges associated with wind energy, and the impact on wildlife and the environment. Additionally, it covers various types of wind turbines, their advantages, disadvantages, and design principles, along with a brief mention of tidal and ocean thermal energy.

![AERODYNAMIC CONSIDERATIONS IN WIND MILL DESIGN

There are two primary physical principles by which energy

can be extracted from the wind. These are through the

creation of either lift or drag force

Air flow over a stationary airfoil produces two forces, a lift

force perpendicular to the air flow and a drag force in the

direction of air flow

The existence of the lift force depends upon laminar flow

over the airfoil, which means that the air flows smoothly

over both sides of the airfoil. If turbulent flow exists rather

than laminar flow, there will be little or no lift force.

Lift Force: The lift force (FL) arises in a direction that is

perpendicular to the airstream caused by Bernoulli’s effect

that lowers the pressure on the top of the airfoil when

compared with the pressure on its bottom. The curvature on

the top leads to a higher stream velocity than at the bottom

and hence a lower pressure.

Let (FL) is the lift force in Newton, (SL) is the cross-

sectional area of airfoil in m2, ρ is the air density in

kg/m2, and V is the wind speed in m/s2. Then, lift

coefficient (CL) is

defined as follows

CL = [FL/SL} / [(1/2) ρV2]](https://image.slidesharecdn.com/4thmodulences-read-only-241114035731-40b2fb17/85/4TH-MODULE-NCES-Read-Oaeryrhtrshnly-pptx-20-320.jpg)

![Drag force (FD): It is described as follows, Where CD = drag coefficient and SD = Effective area of airfoil

in the direction of drag force.

CD = [FD/SD] / [(1/2) ρV2]](https://image.slidesharecdn.com/4thmodulences-read-only-241114035731-40b2fb17/85/4TH-MODULE-NCES-Read-Oaeryrhtrshnly-pptx-21-320.jpg)