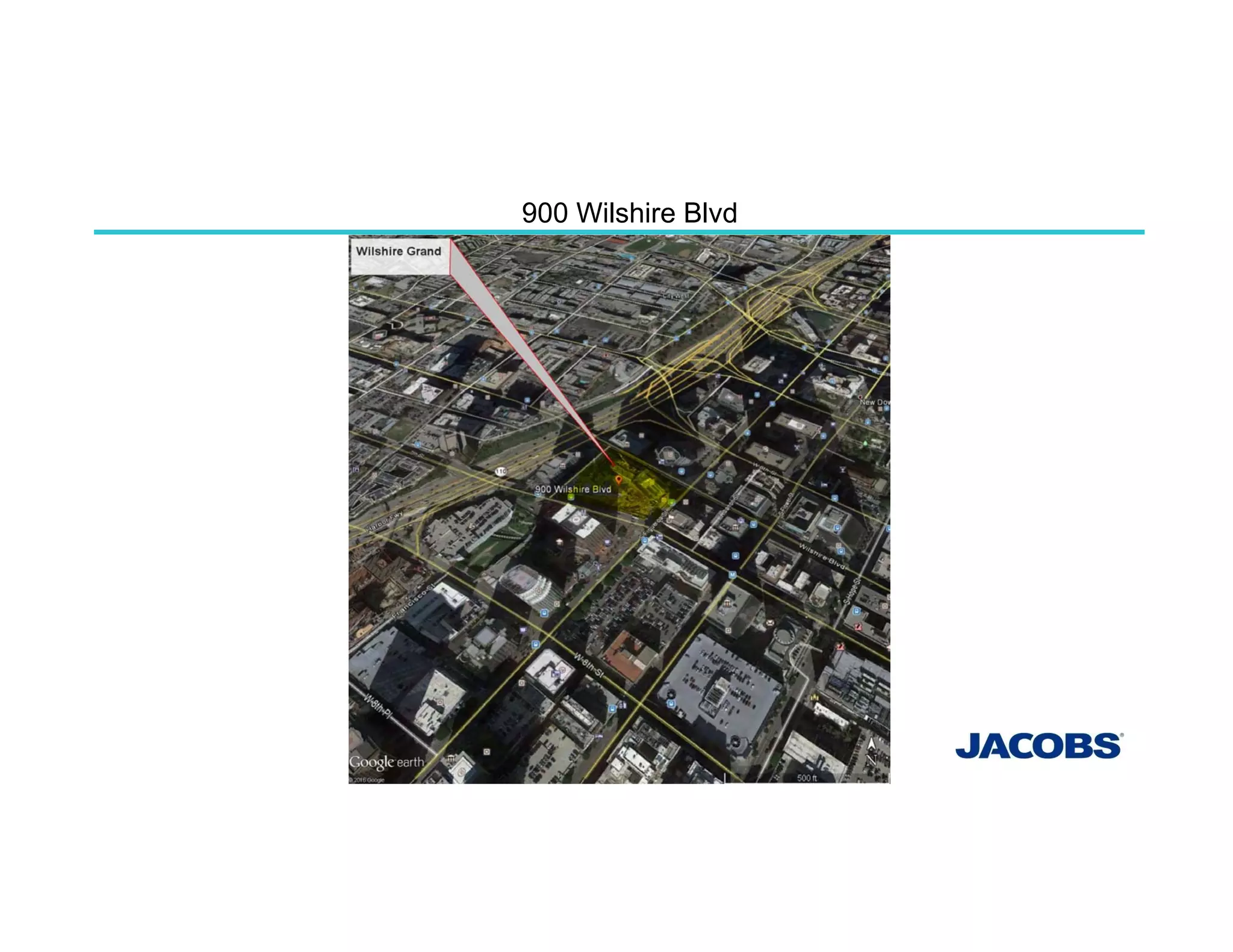

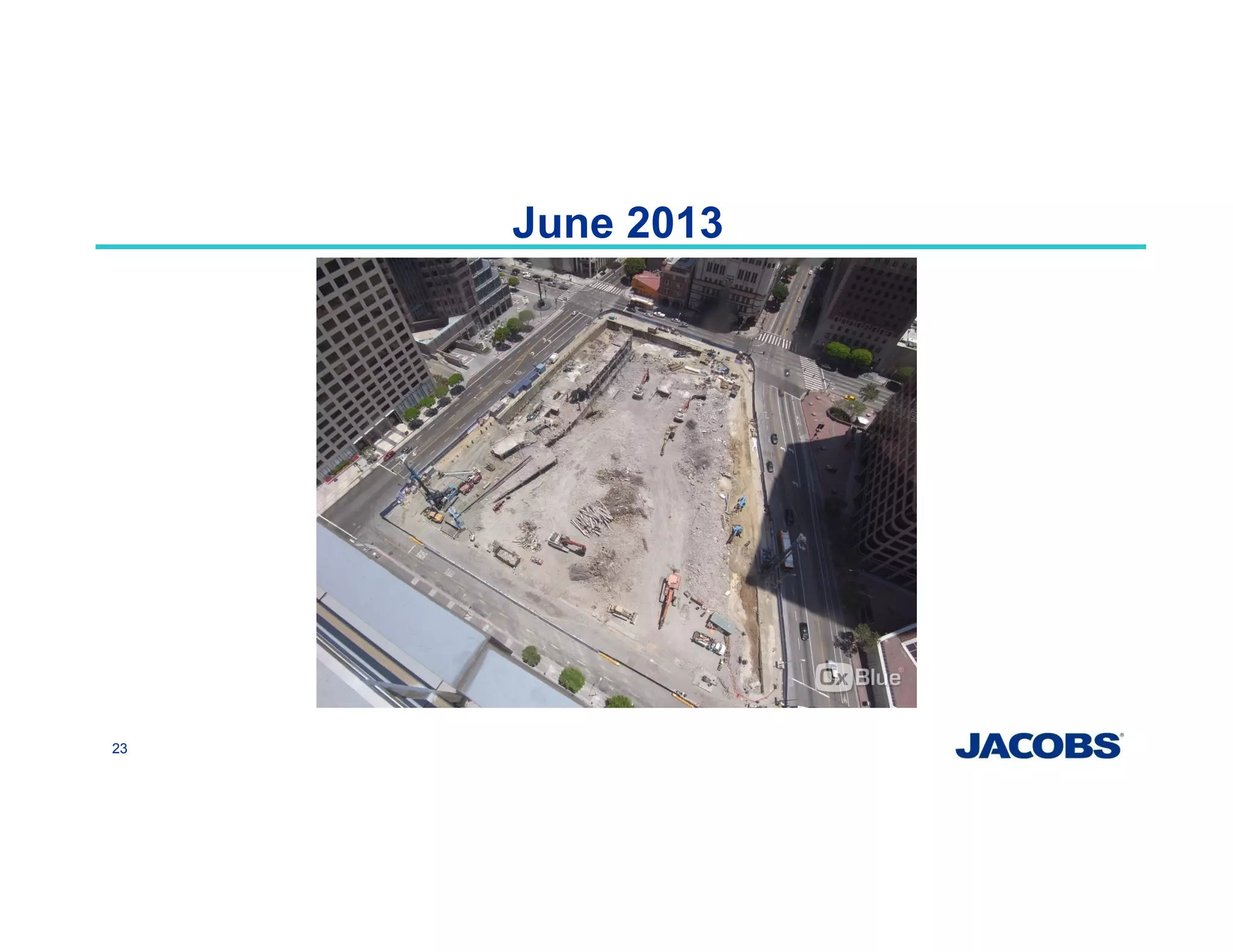

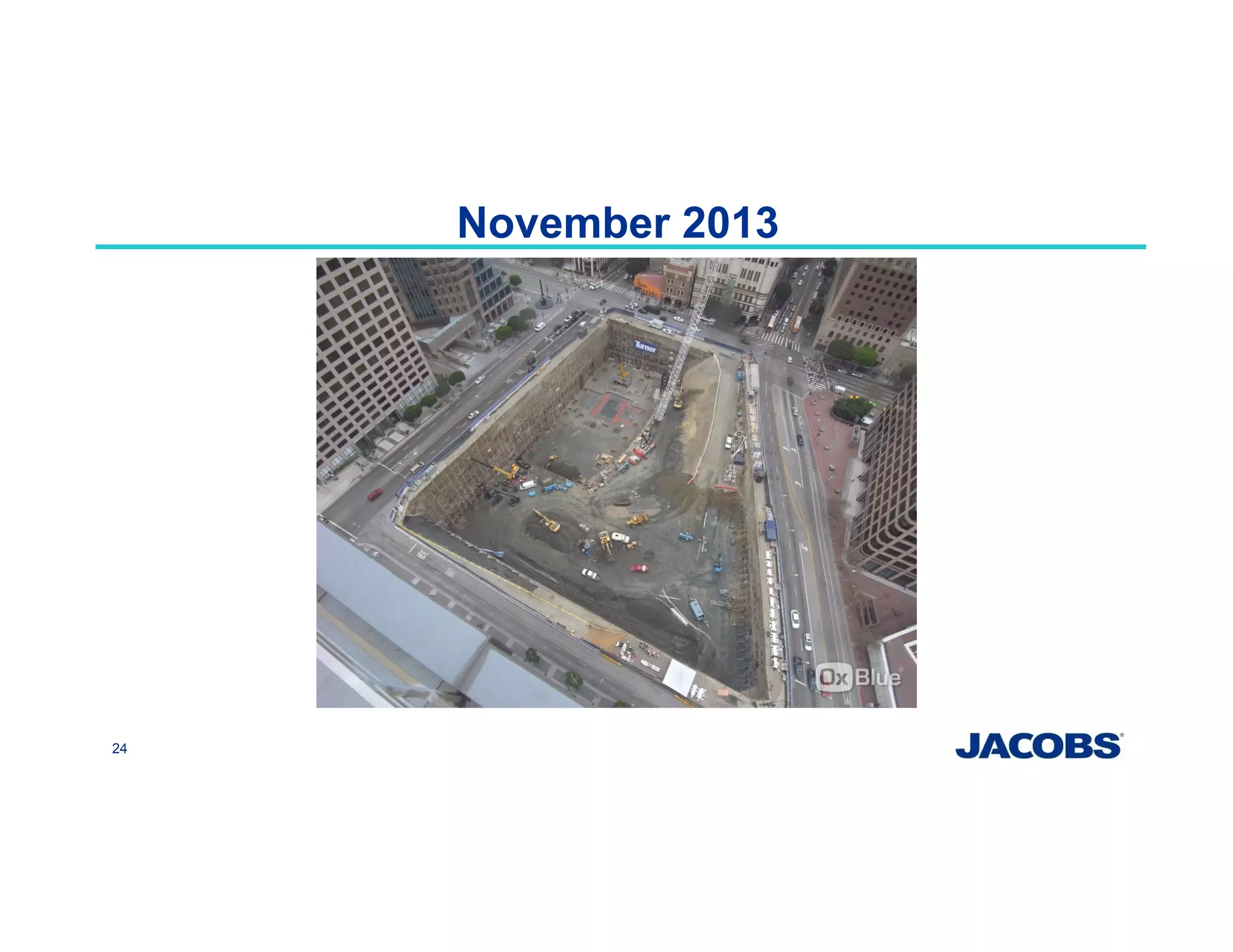

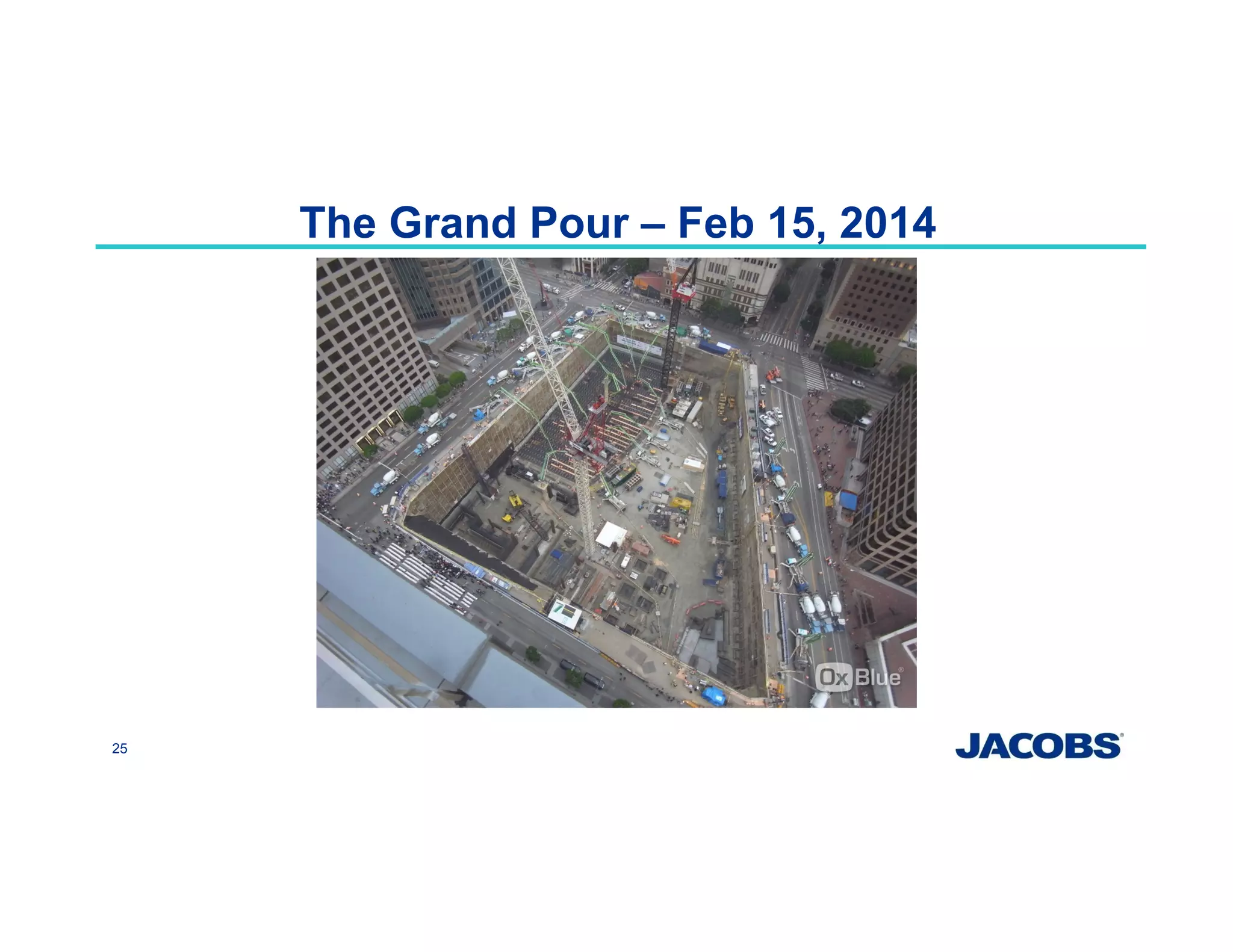

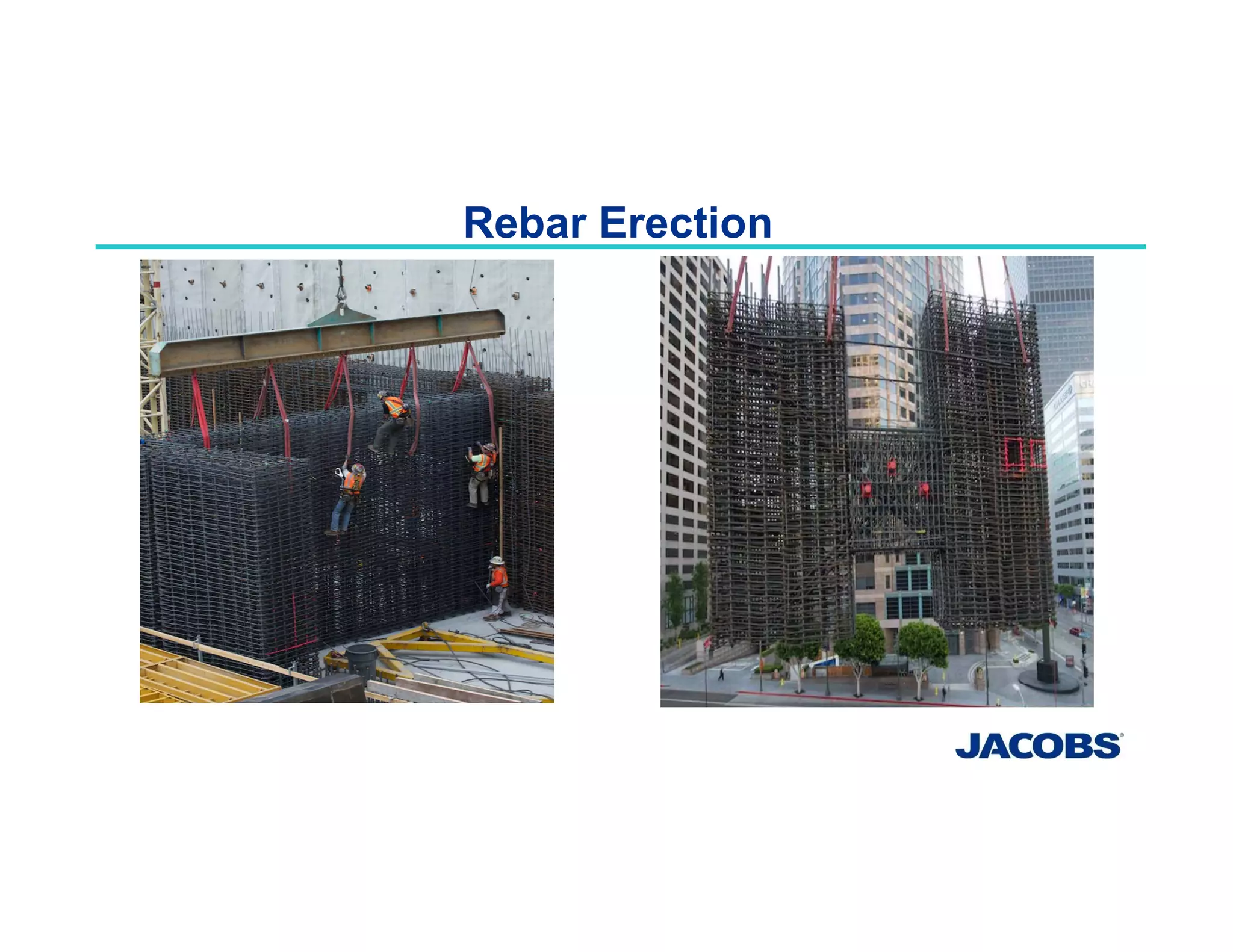

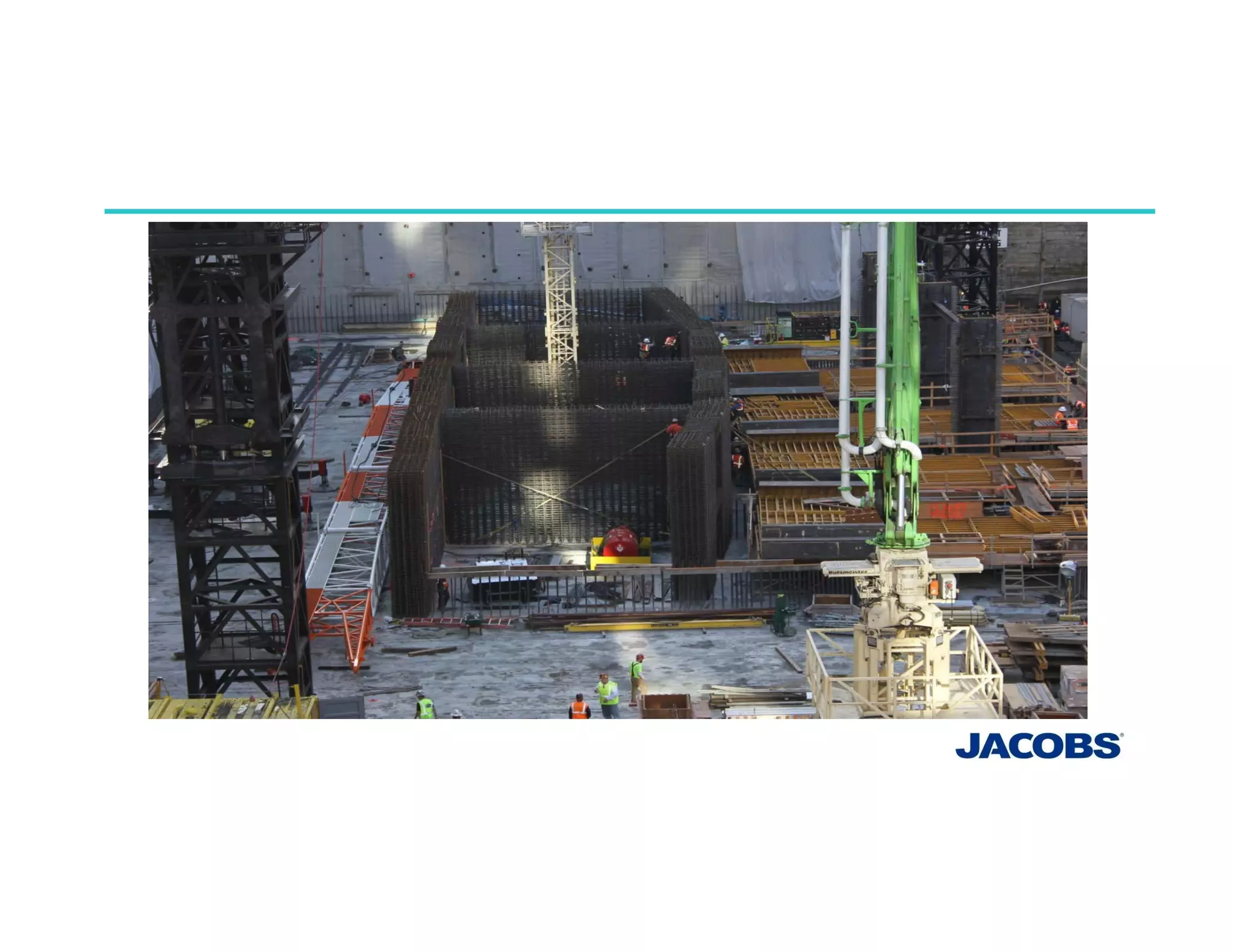

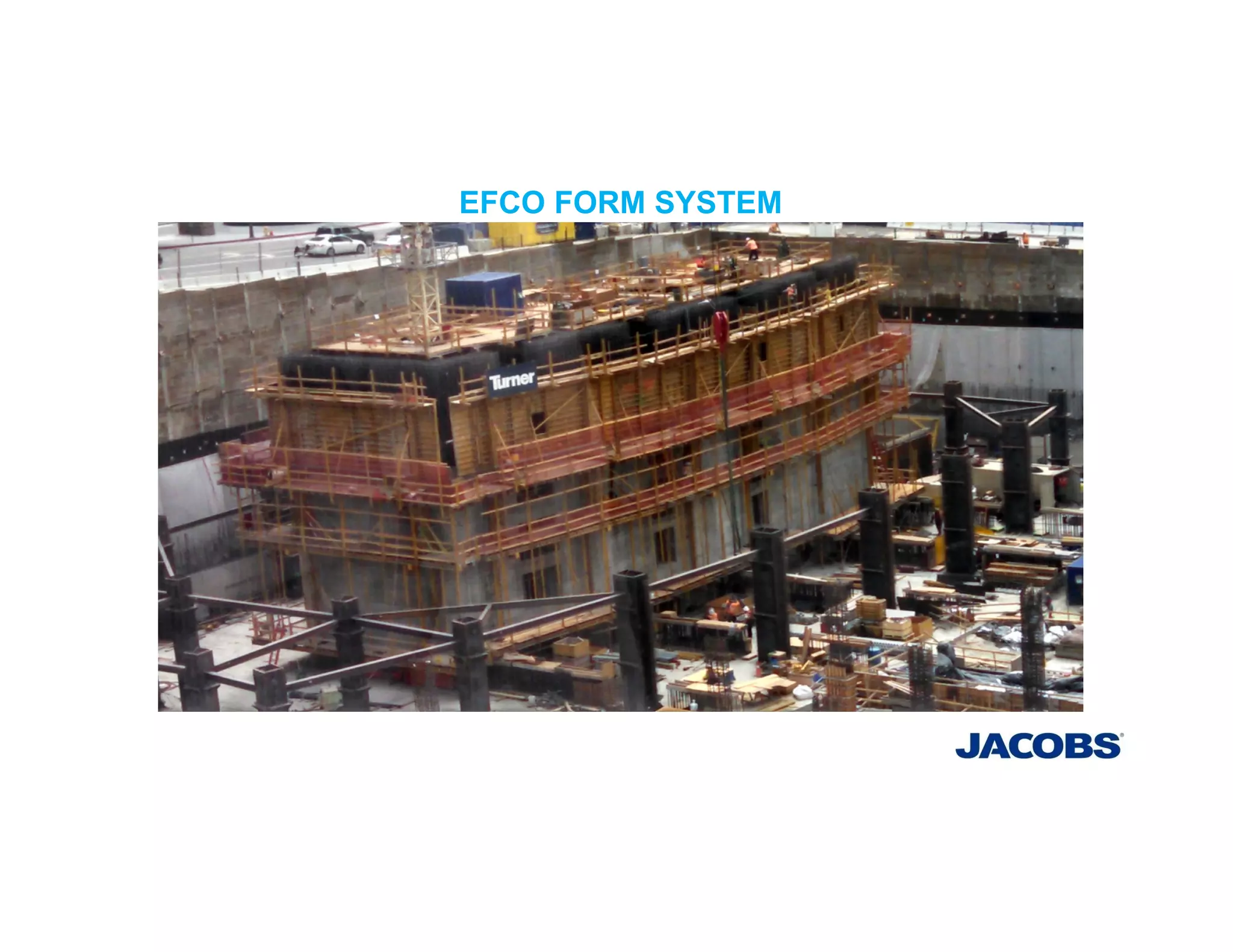

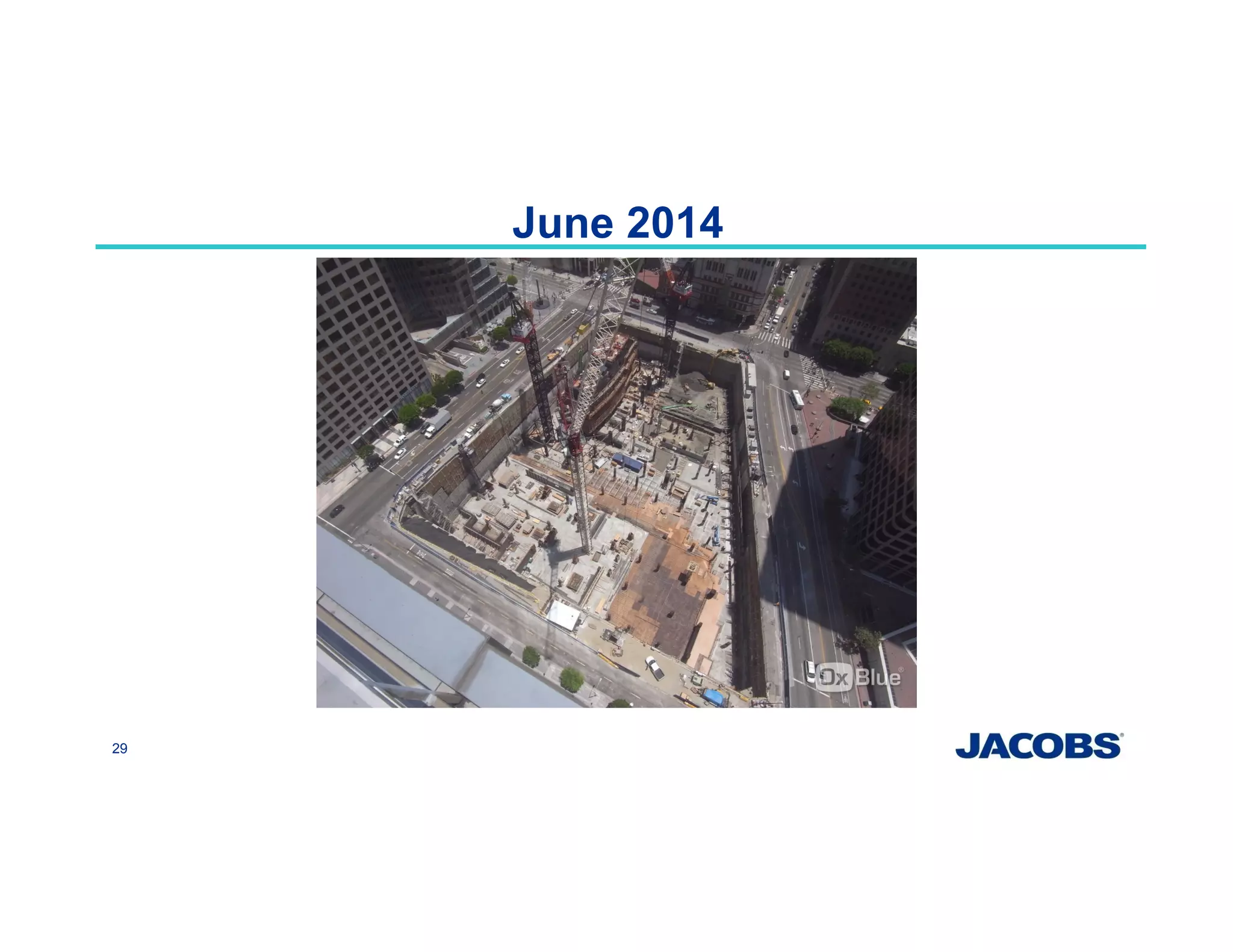

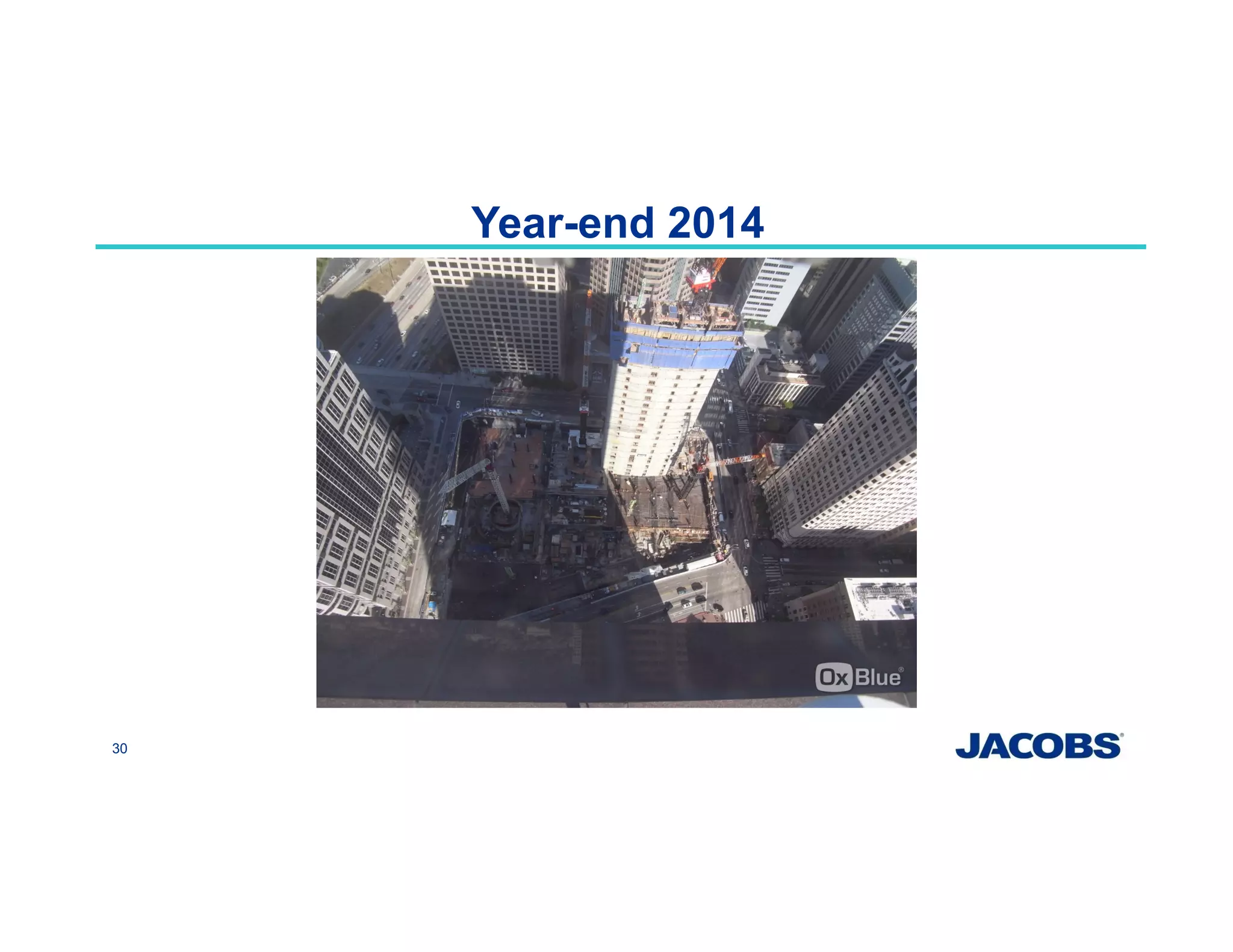

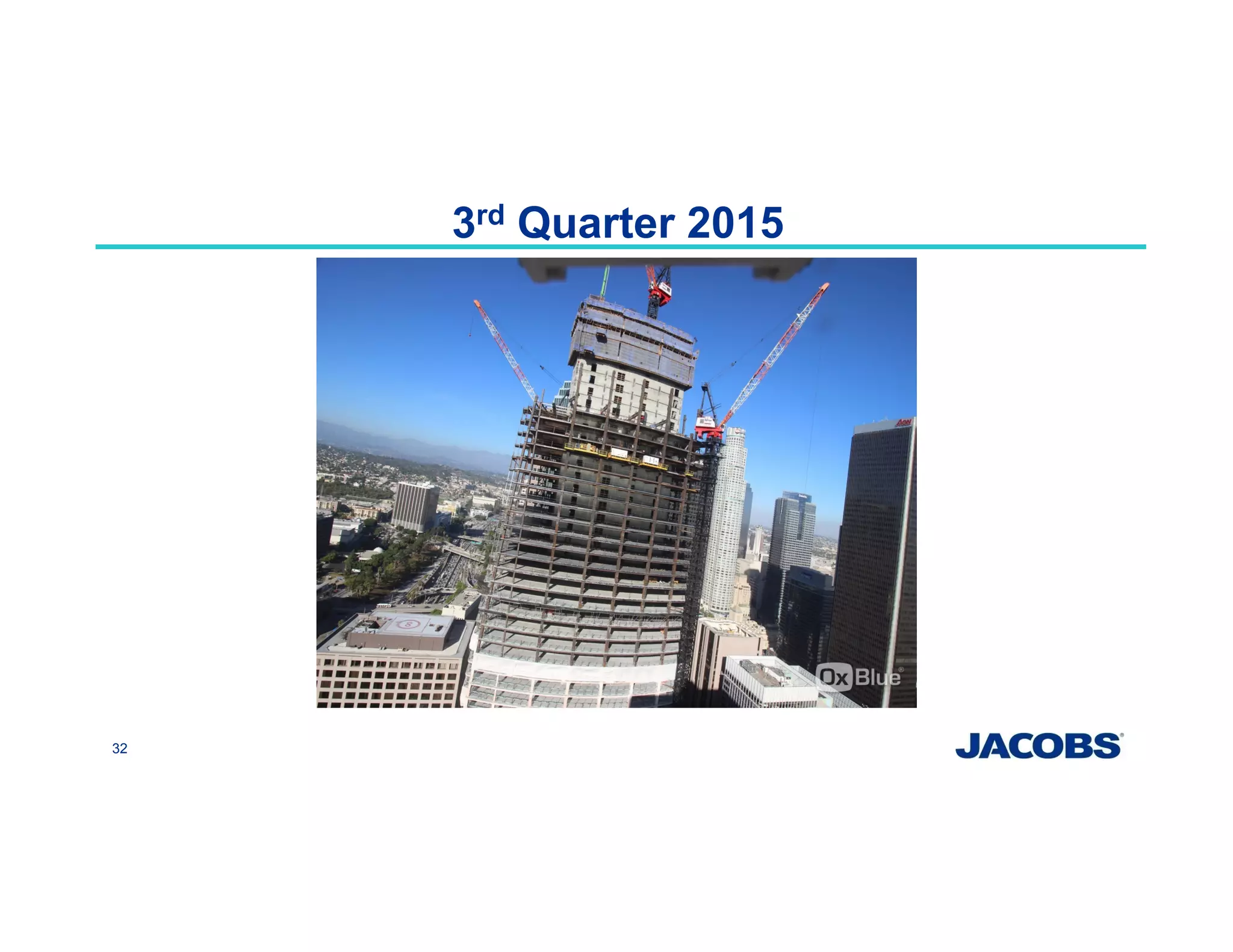

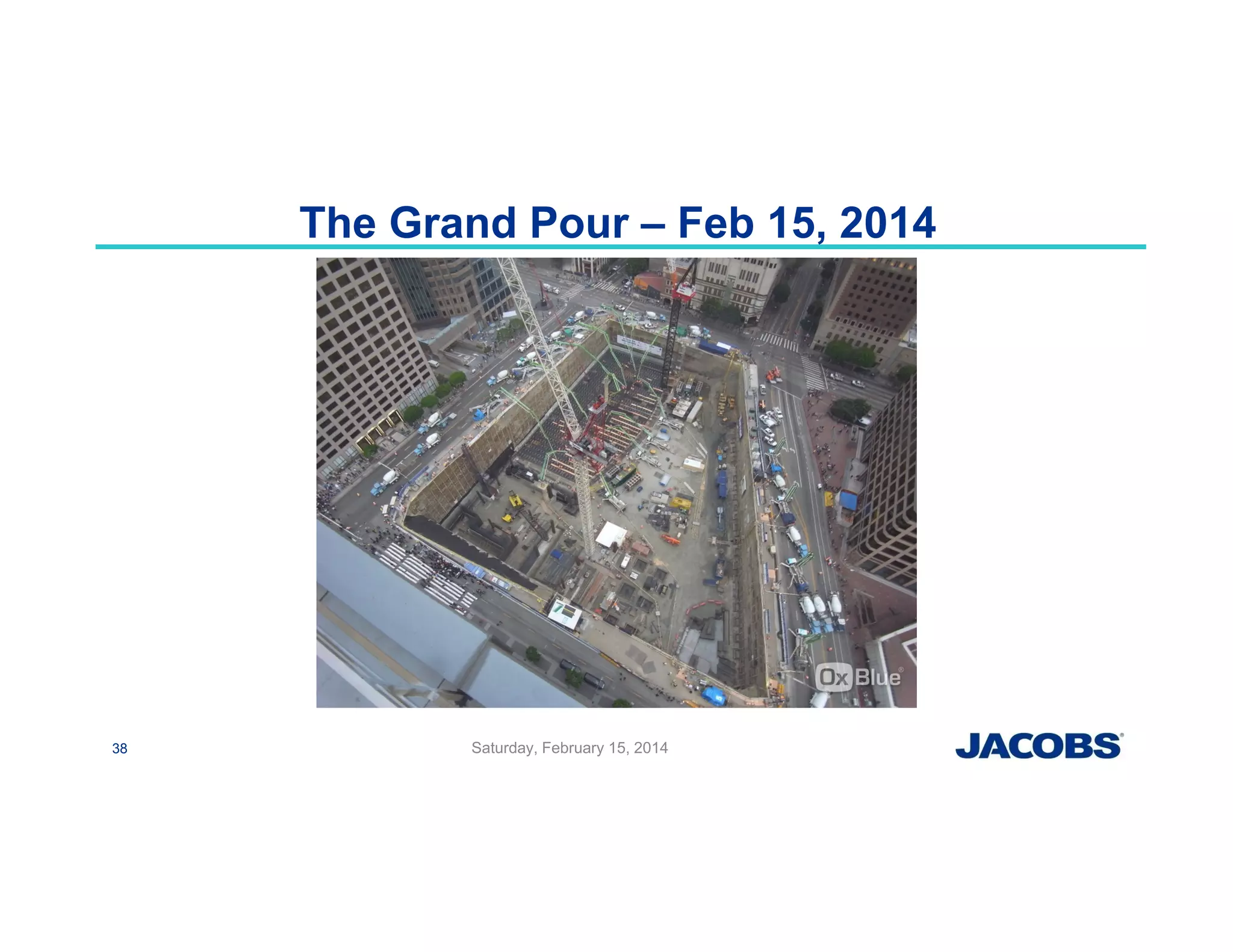

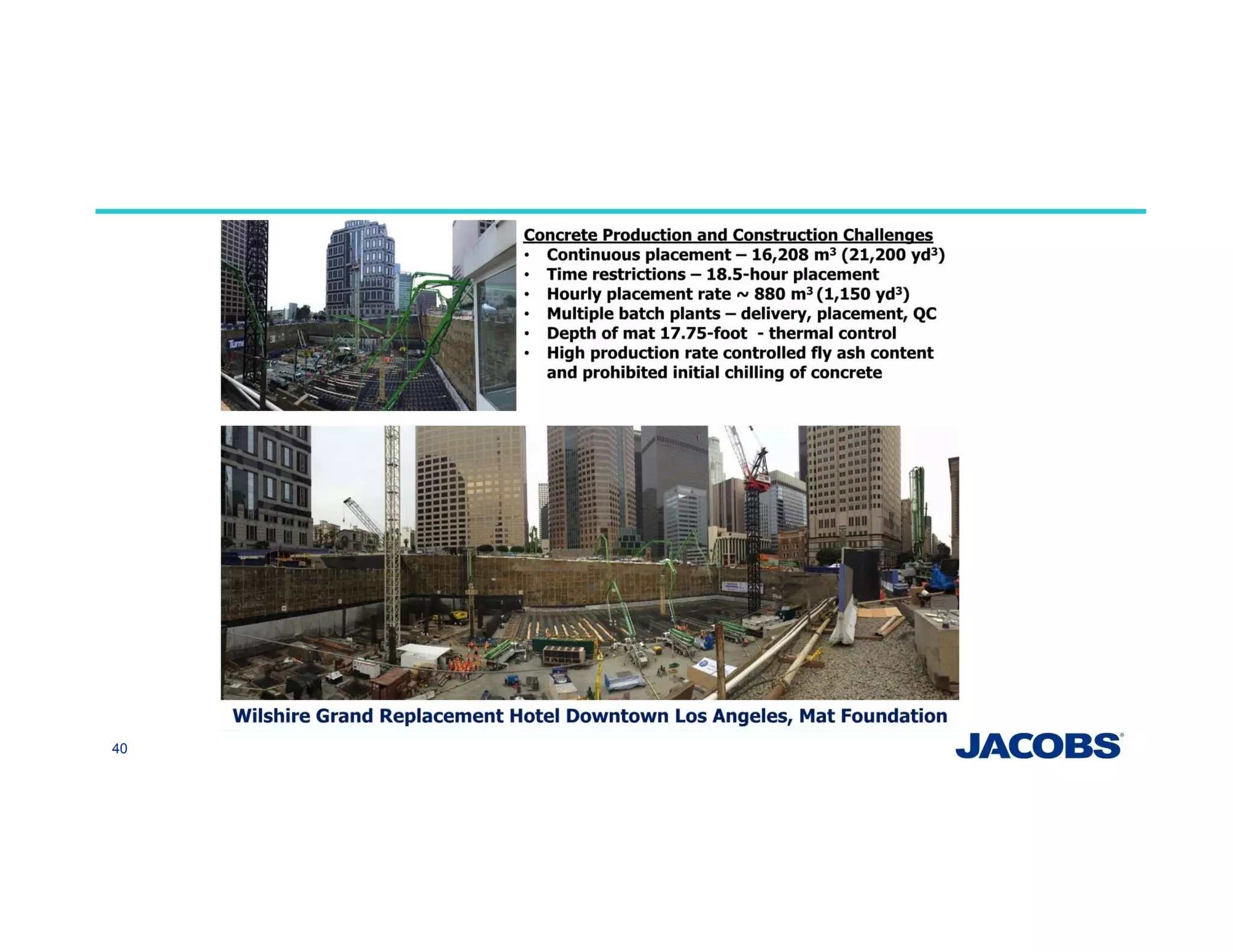

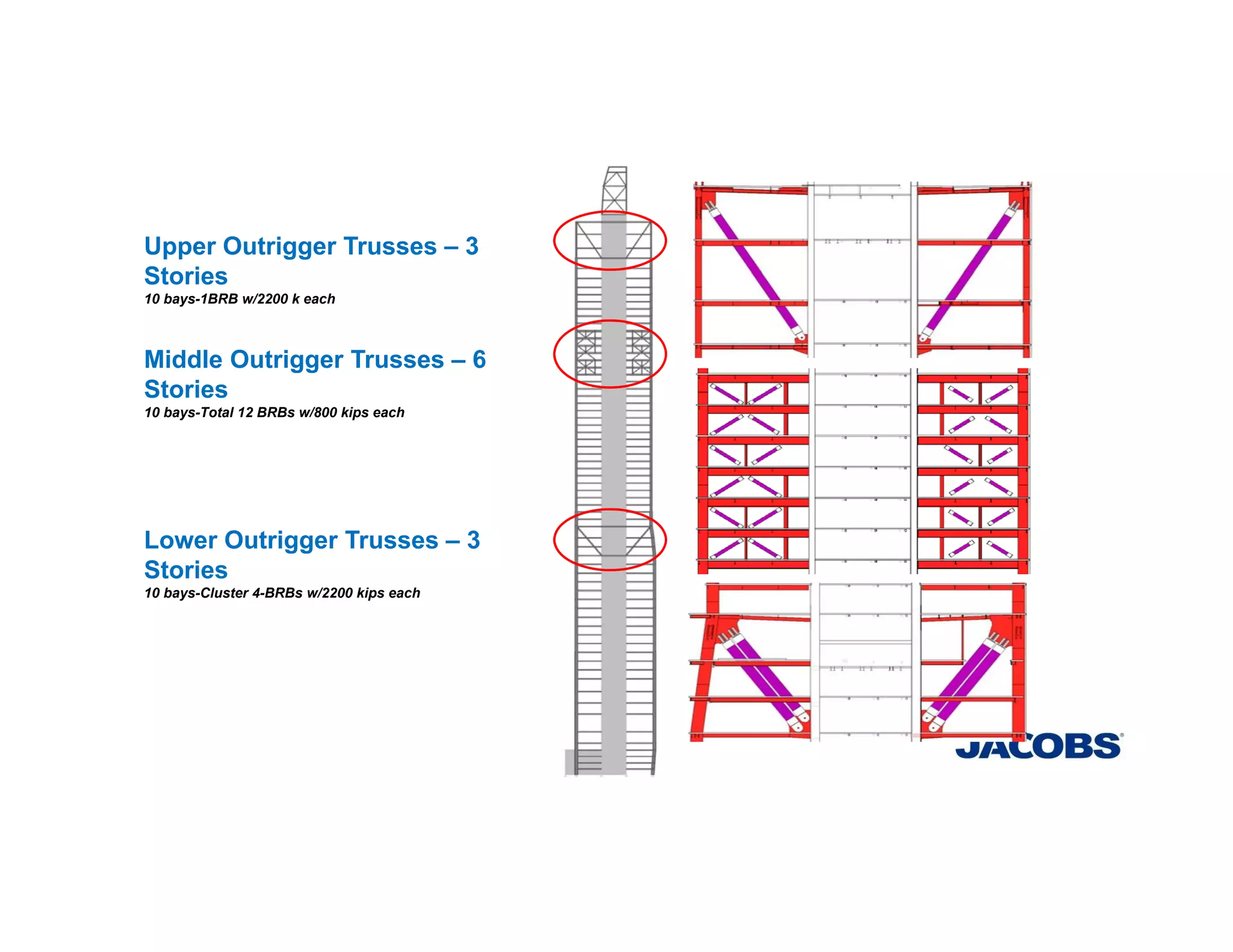

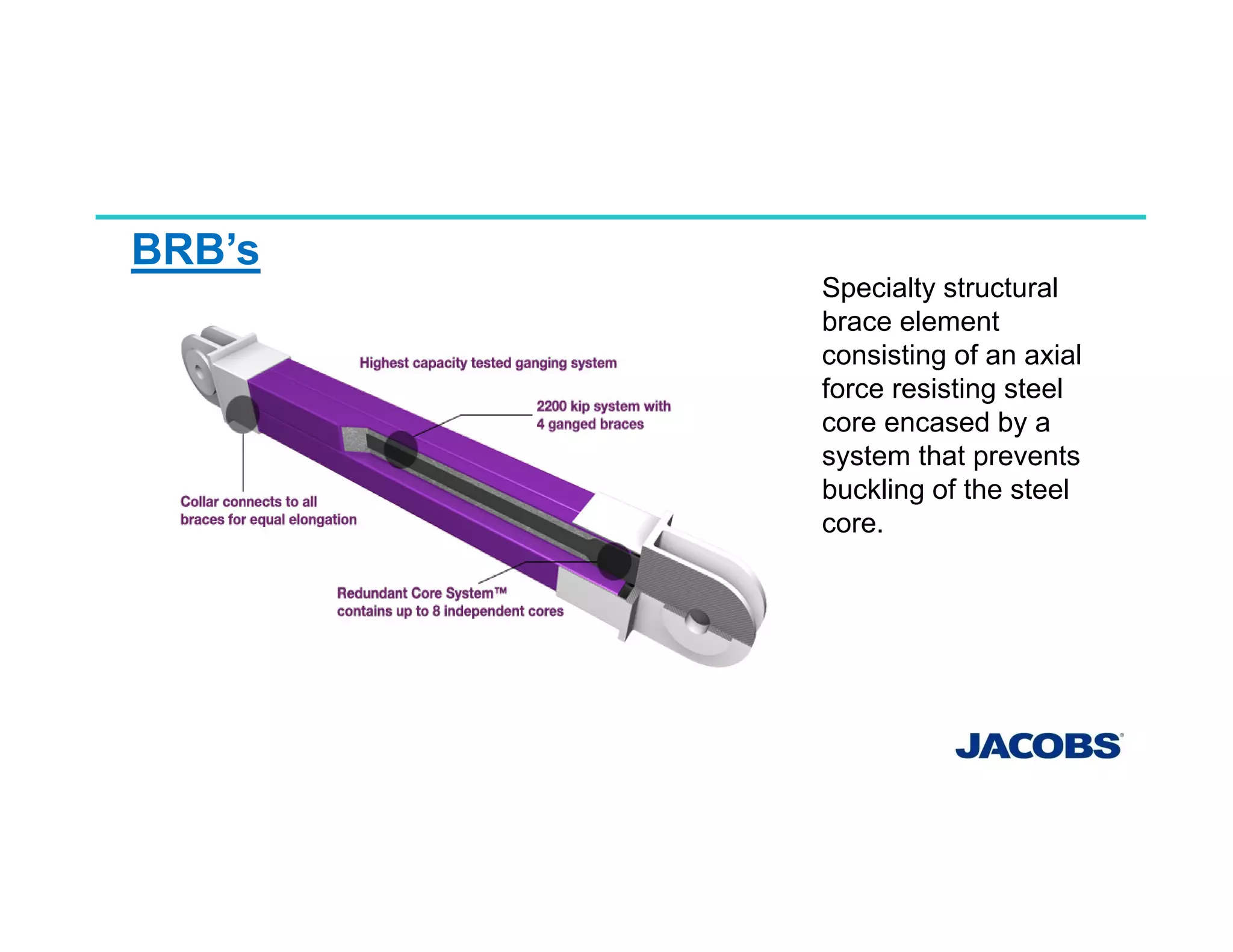

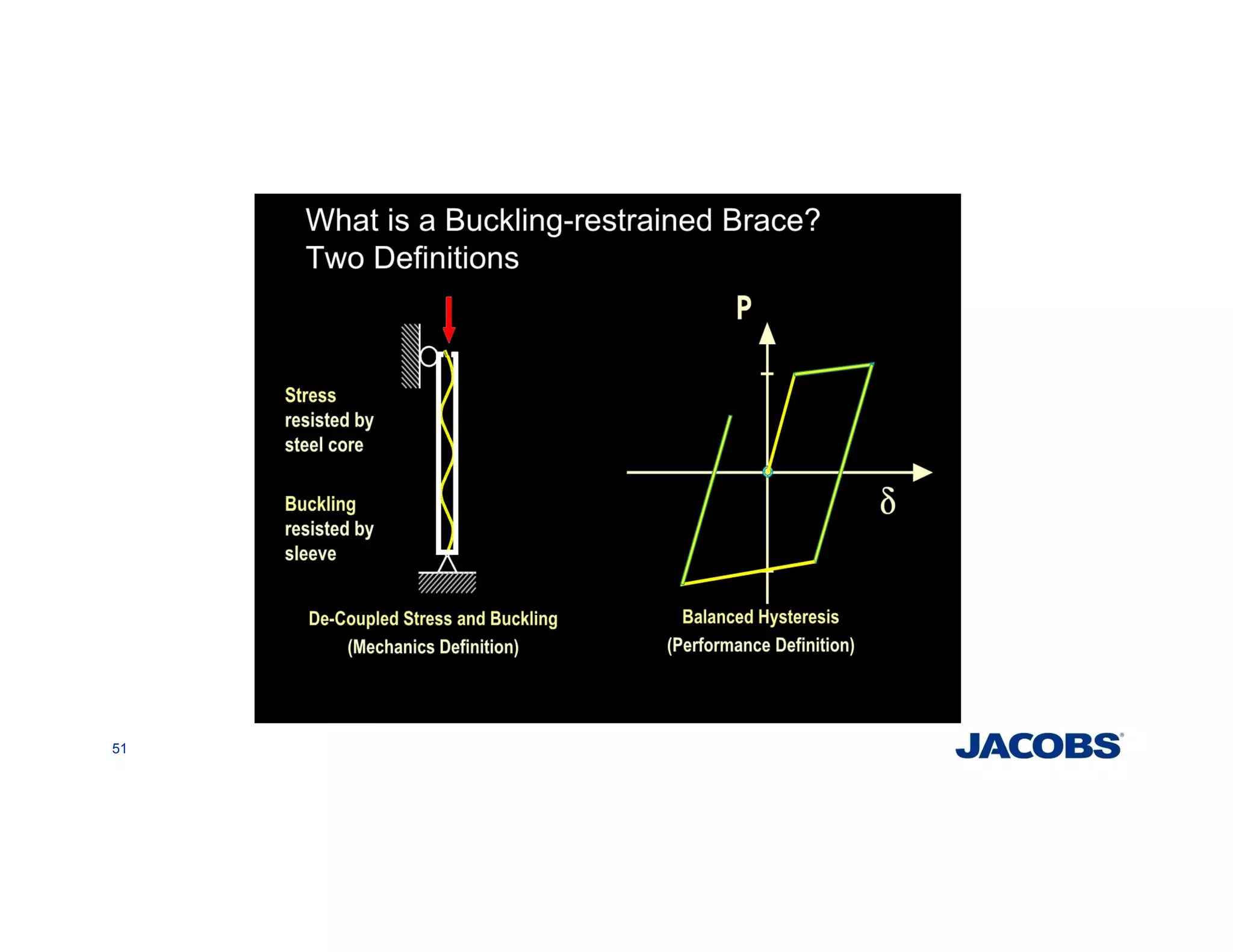

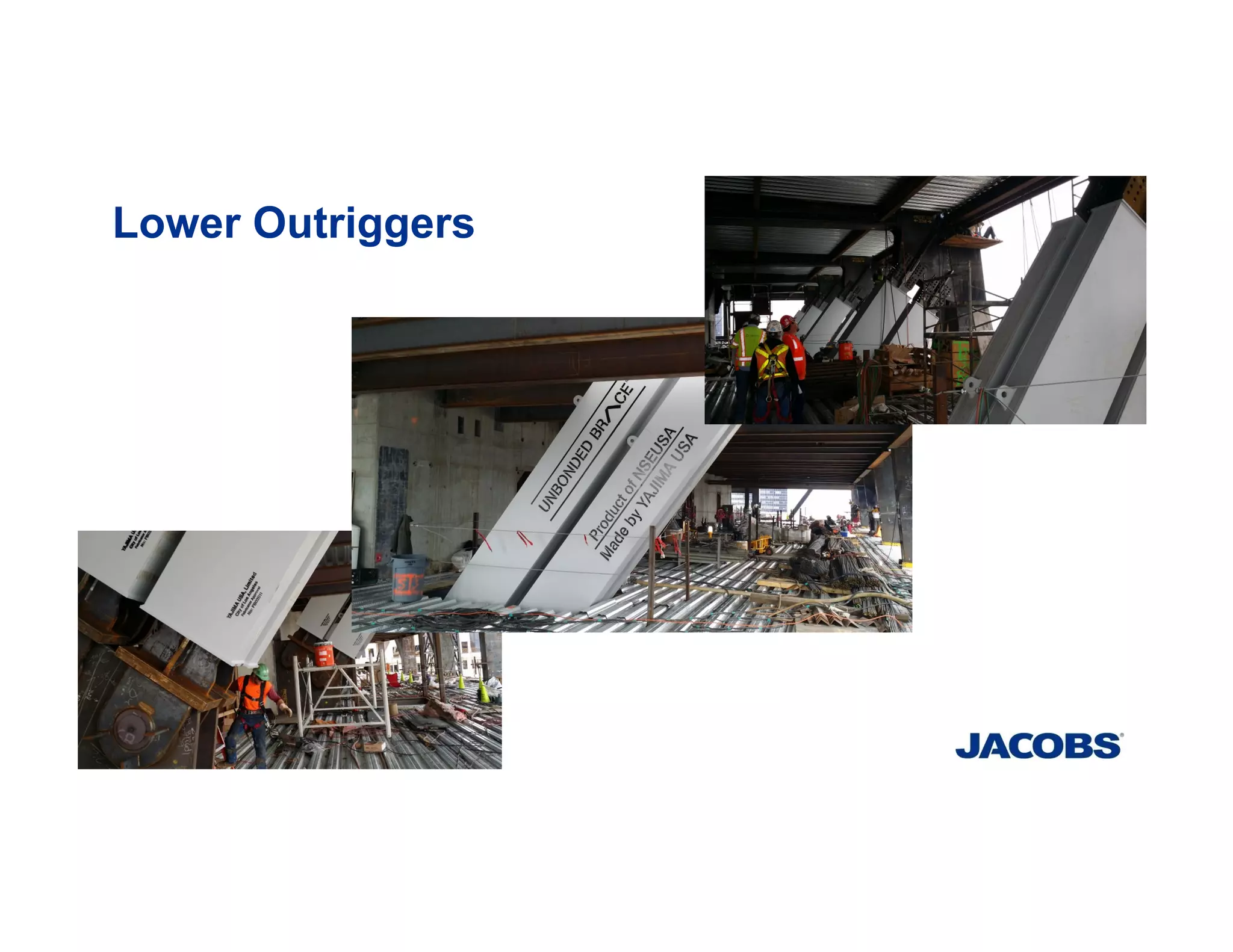

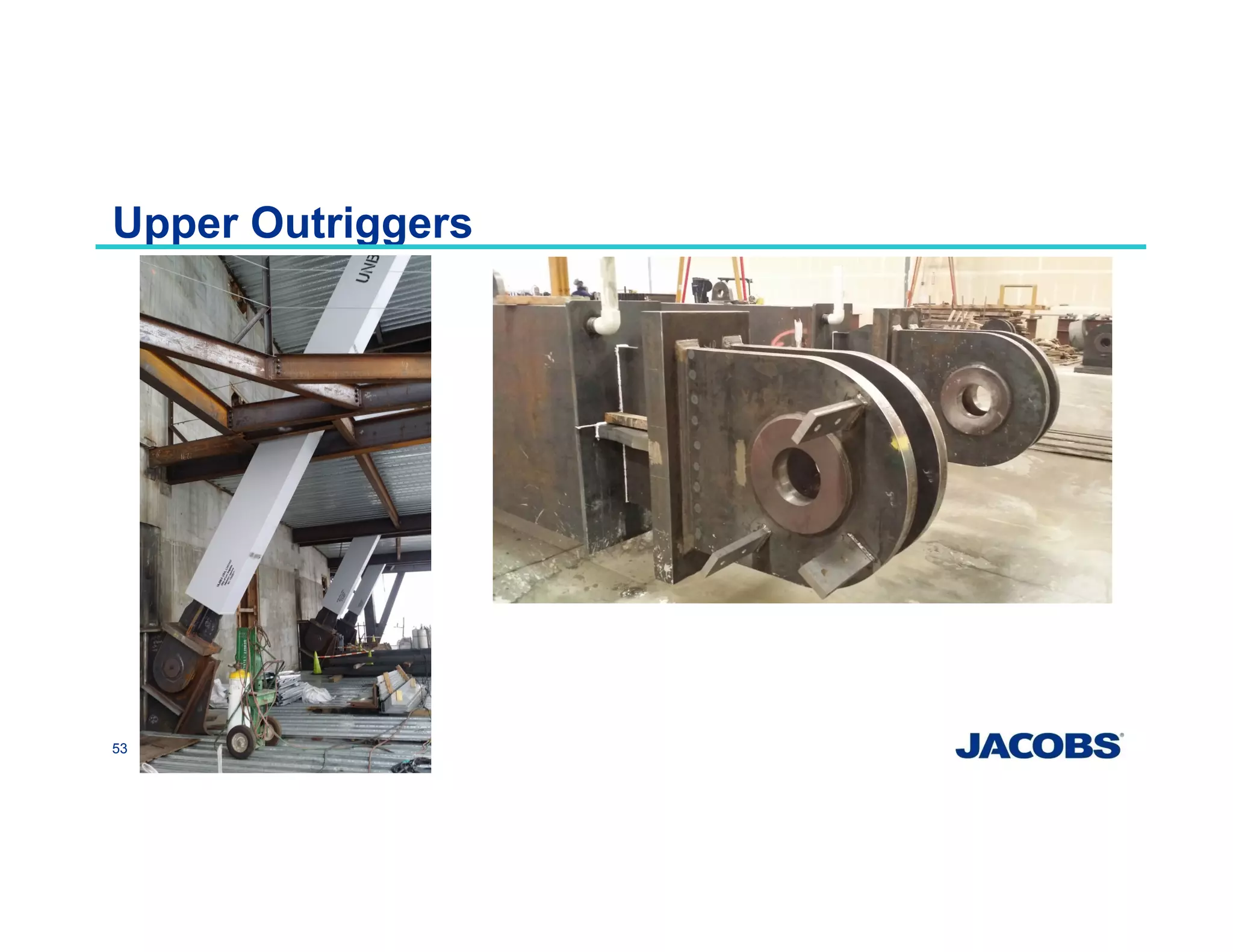

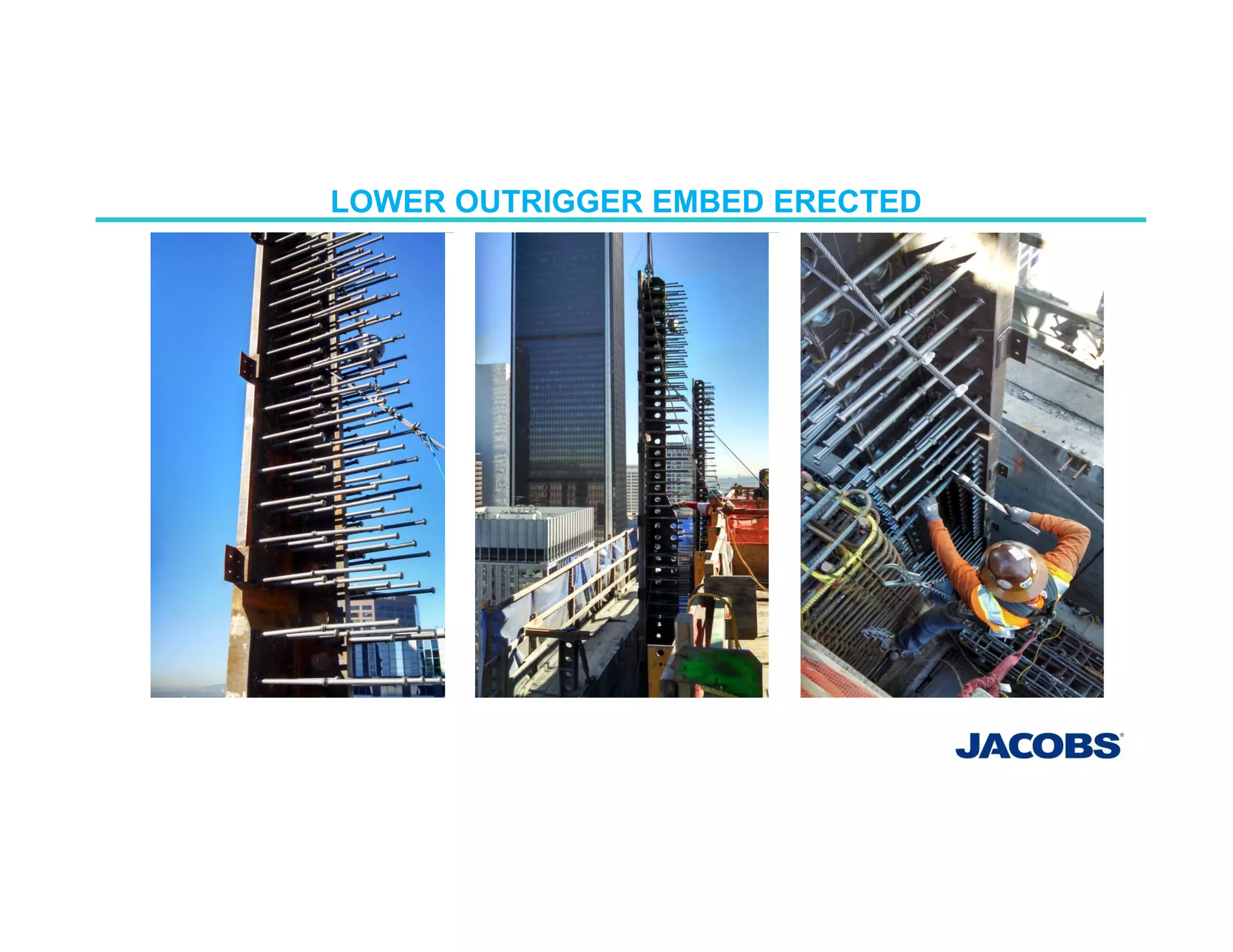

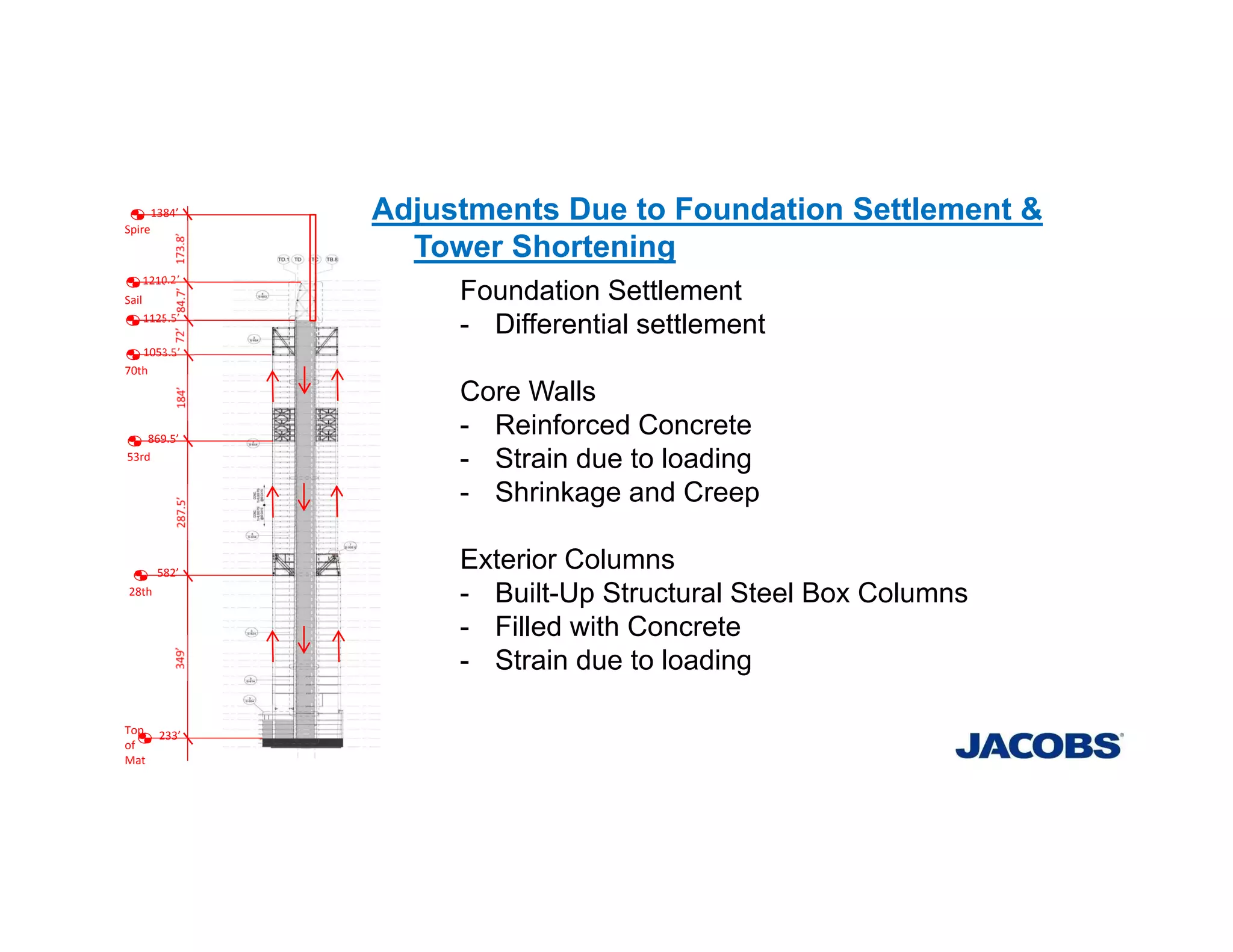

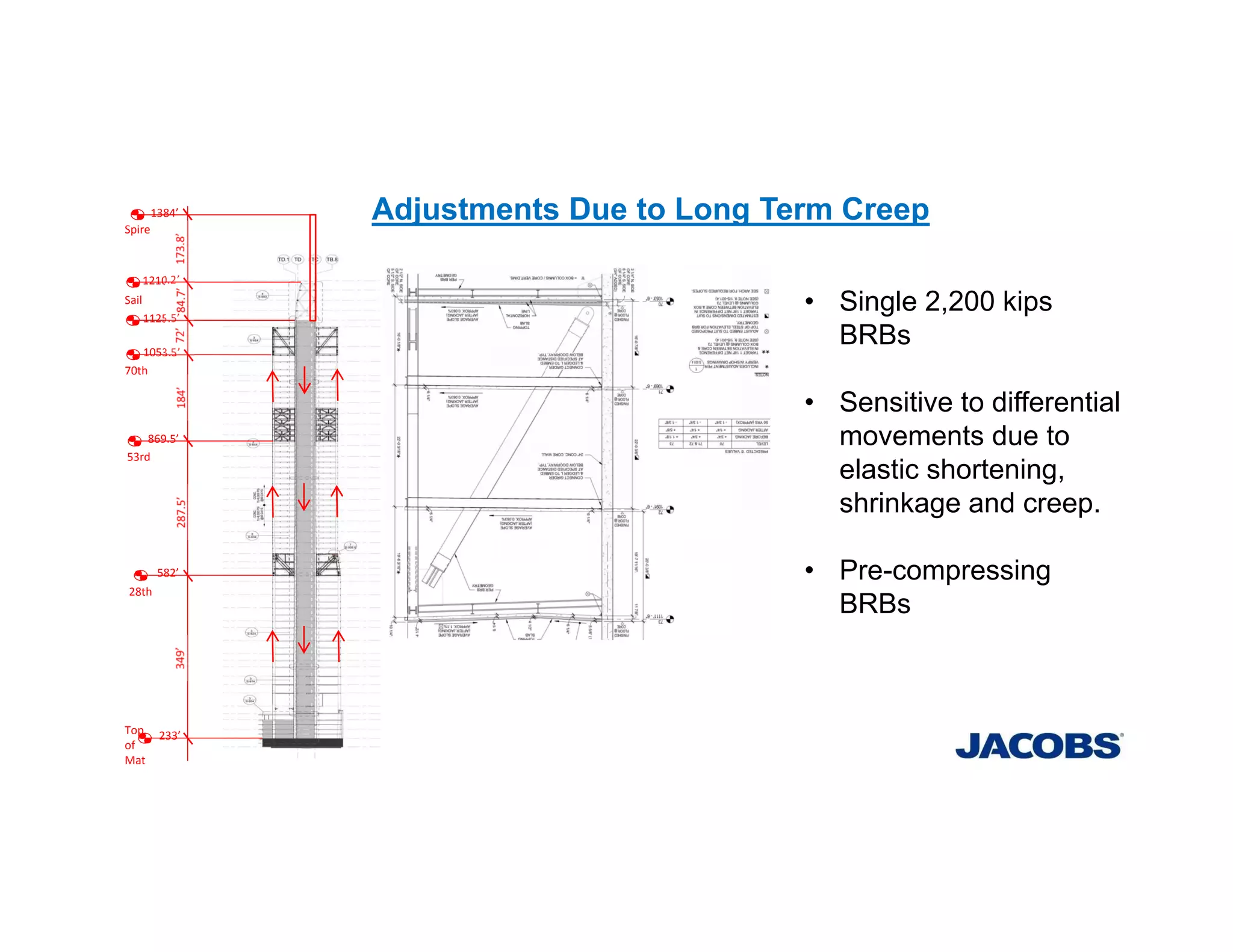

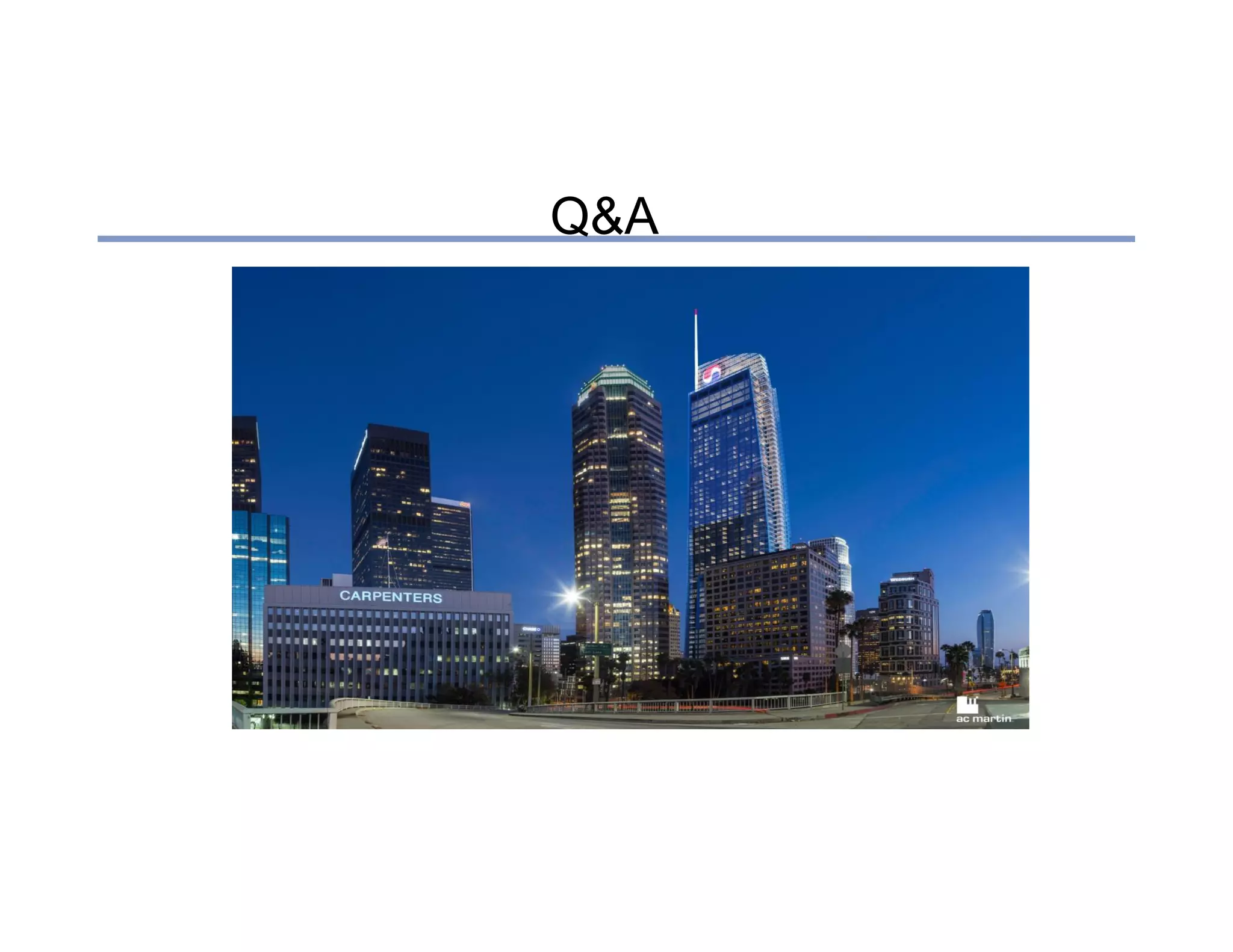

The document summarizes the Wilshire Grand Redevelopment Project in Los Angeles, California. It describes the project as a 2.1 million square foot, 73-story tower containing 892 hotel rooms, 365,000 square feet of office space, and amenities. Construction highlights include the largest continuous concrete pour in February 2014 and structural design considerations for seismic performance. Pre-loading of upper bracing elements was done to protect the building from permanent deformation due to long-term effects like creep.