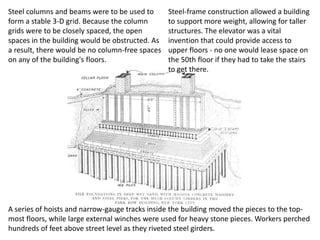

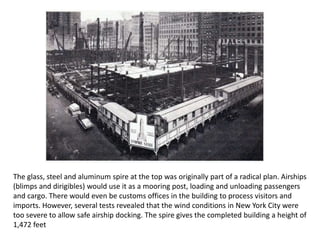

The Empire State Building, completed in 1931, is an iconic 102-story Art Deco skyscraper in New York City, standing at 1,250 feet and showcasing advanced steel-frame architecture. Designed by Shreve, Lamb & Harmon, it features a limestone and granite exterior with aluminum accents, providing 2 million square feet of office space and advanced structural elements like coupled shear walls and belt trusses for stability. Notably, the building's original spire was intended for airship docking, but high wind conditions ultimately rendered this impractical.