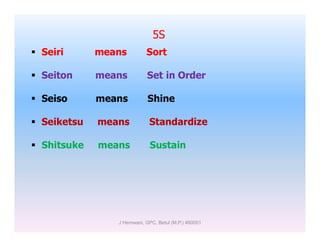

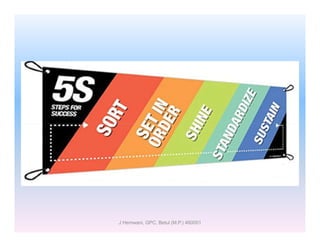

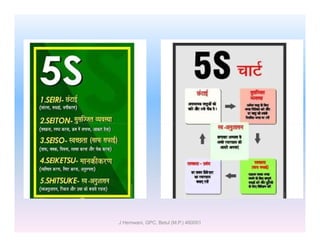

5S is a system for organizing and standardizing workspaces for efficiency, effectiveness, and safety. It involves five steps: sorting (seiri), setting in order (seiton), shining (seiso), standardizing (seiketsu), and sustaining (shitsuke). The steps involve removing unnecessary items, properly storing and labeling necessary items, cleaning the workspace, creating routines and standards, and maintaining the system over time. Implementing 5S can help reduce costs, increase productivity and quality, and create a safer work environment.