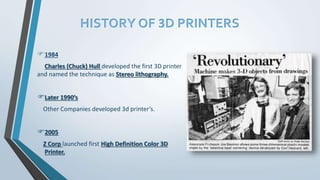

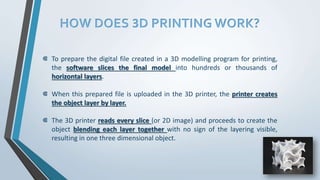

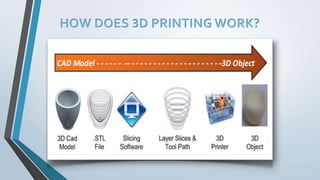

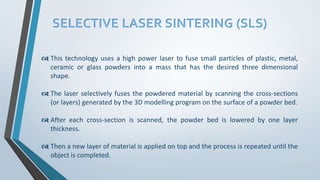

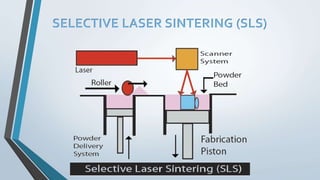

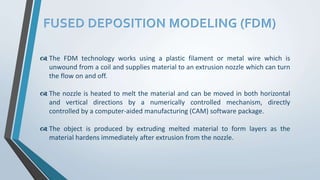

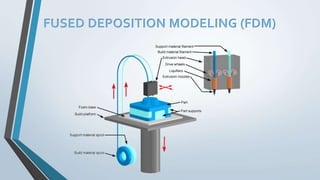

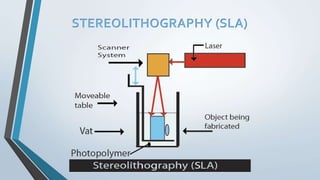

3D printing, or additive manufacturing, transforms digital designs into physical objects by layering materials. Major technologies include Selective Laser Sintering (SLS), Fused Deposition Modeling (FDM), and Stereolithography (SLA), each utilizing distinct methods for building layers. The technology is rapidly advancing, presenting opportunities for broader manufacturing capabilities while highlighting the need for product regulation.