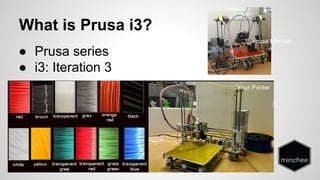

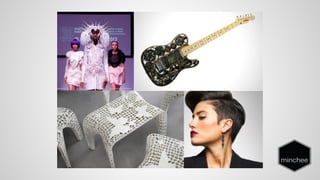

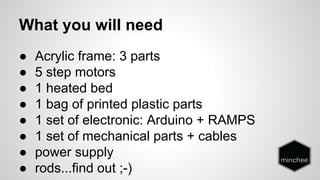

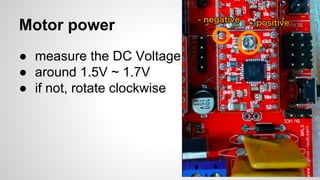

This document provides an overview of how to make your own 3D printer. It discusses RepRap open source 3D printers, the Prusa i3 model, technical specifications, common 3D printing materials like PLA and ABS, different 3D printing technologies, practical applications, the basic printing process, required materials and tools, assembly instructions, tips for use, and resources for support. The goal is to enable readers to build their own low-cost but high quality 3D printer.