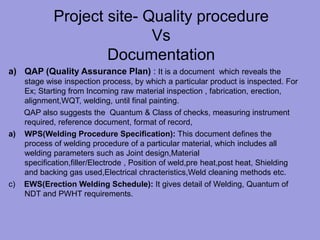

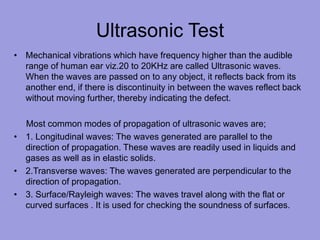

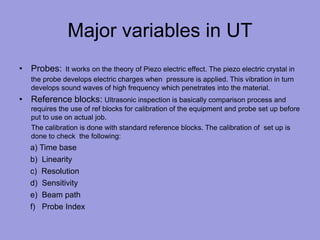

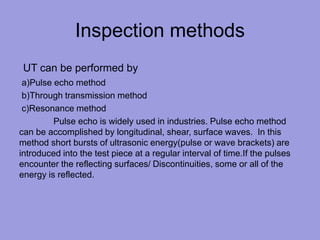

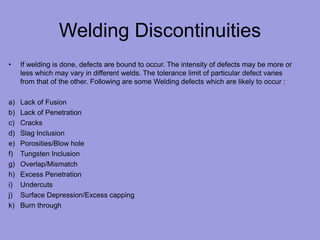

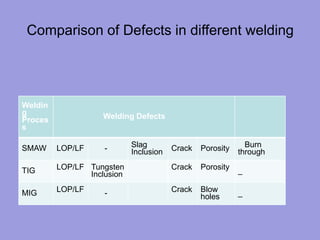

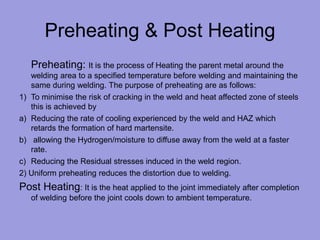

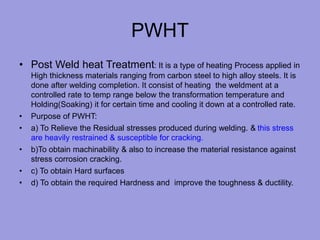

Quality control involves measuring quality characteristics of products and comparing them to standards to identify any deviations. Quality assurance provides confidence that quality achieved meets standards. Key quality documents include the quality assurance plan (QAP), welding procedure specification (WPS), and erection welding schedule (EWS). The QAP outlines inspection stages while the WPS defines welding parameters and the EWS details welding and non-destructive testing requirements. Non-destructive testing methods like radiography, ultrasonic testing, liquid penetrant testing, and magnetic particle inspection are used to identify flaws without damaging materials. Proper preheating, post heating, and post weld heat treatment are important to reduce welding defects and residual stresses.