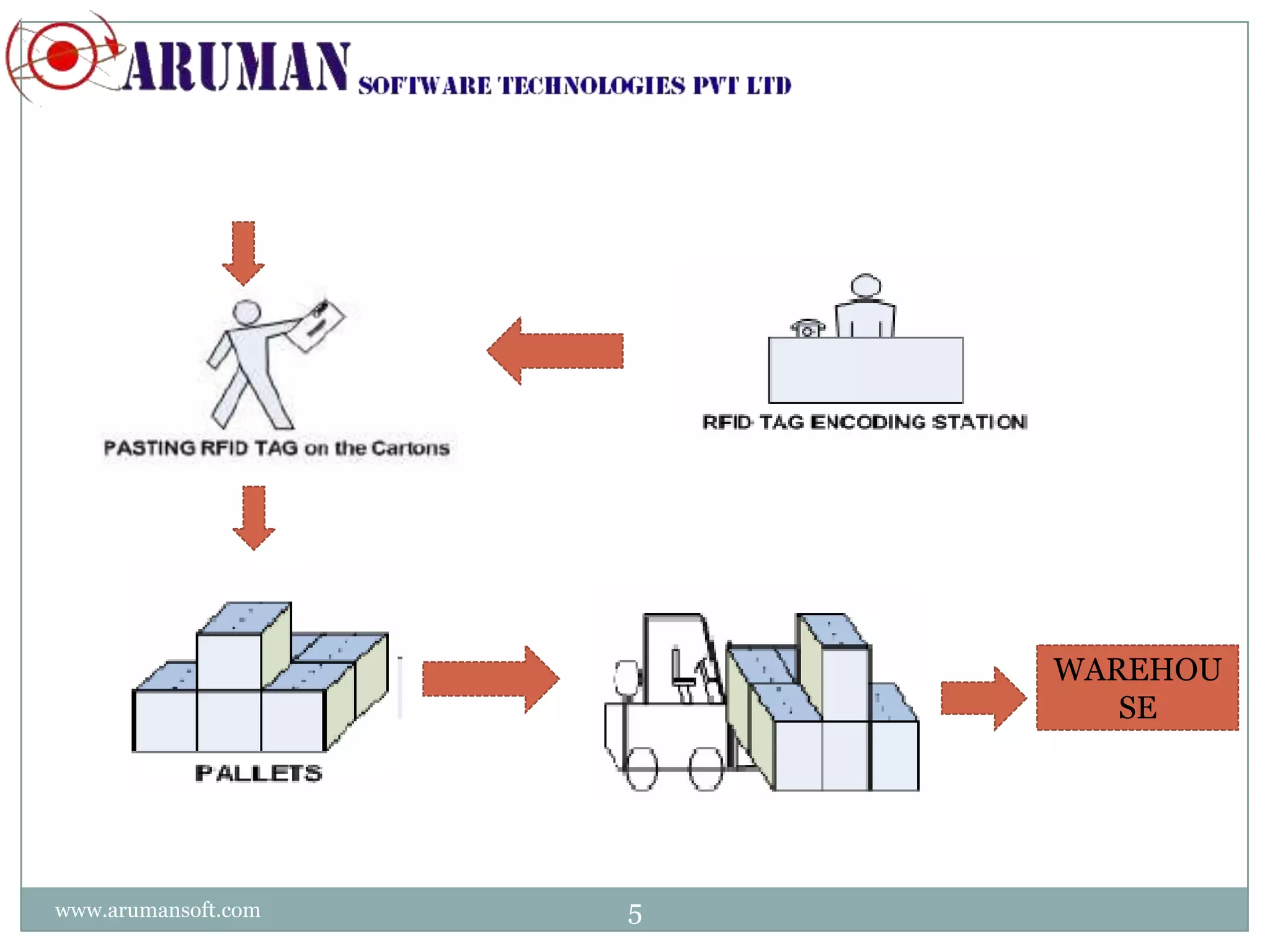

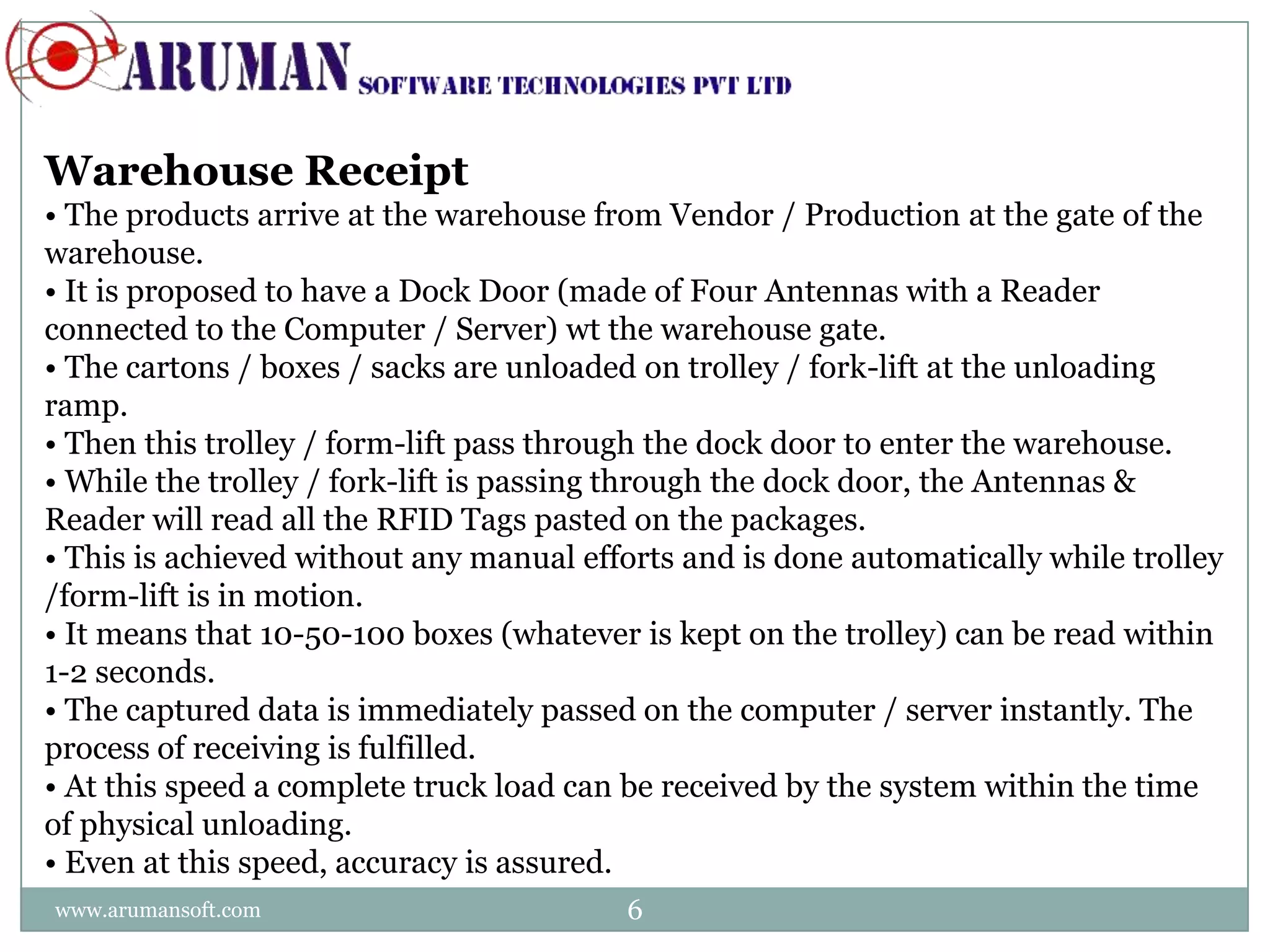

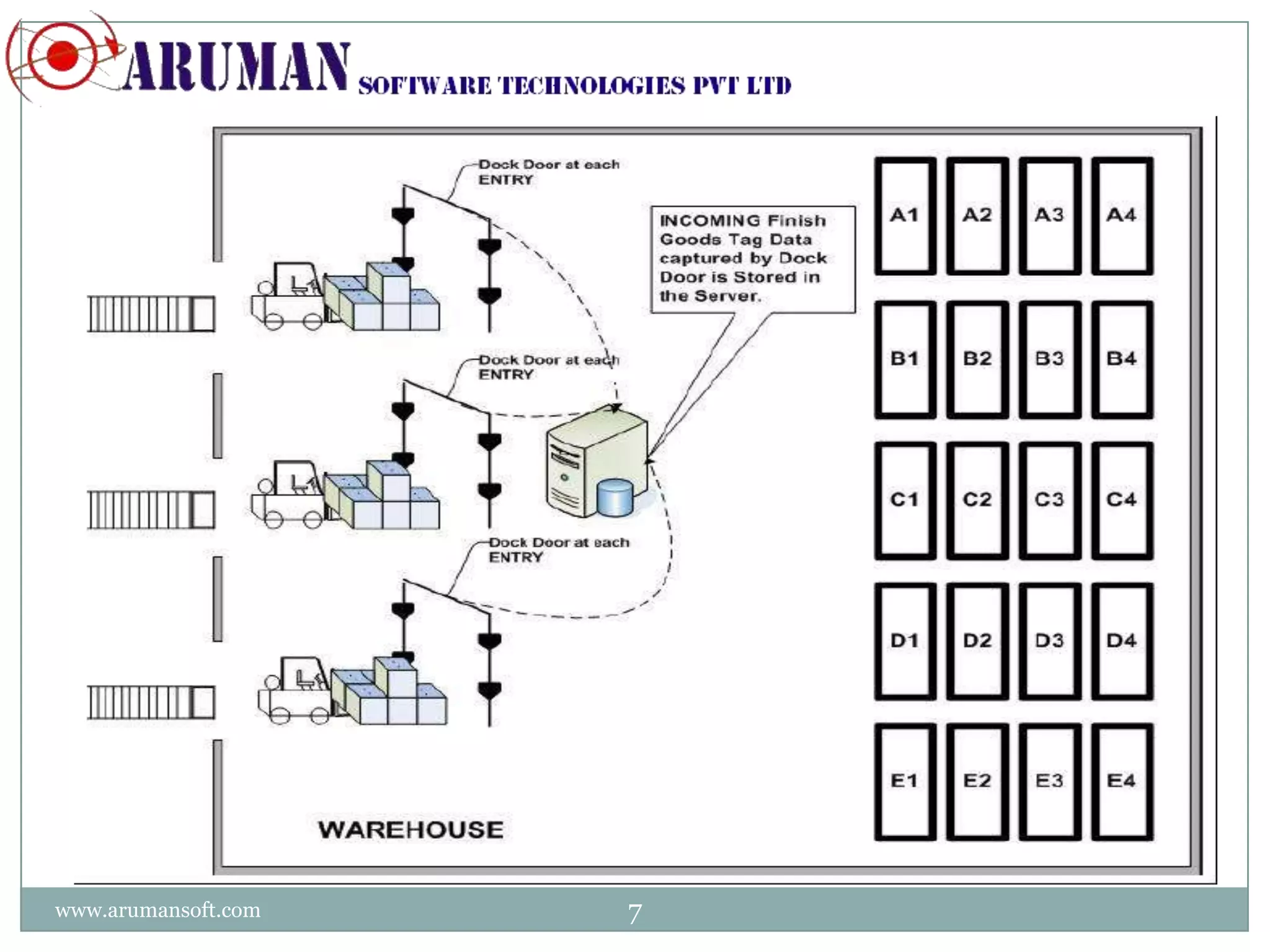

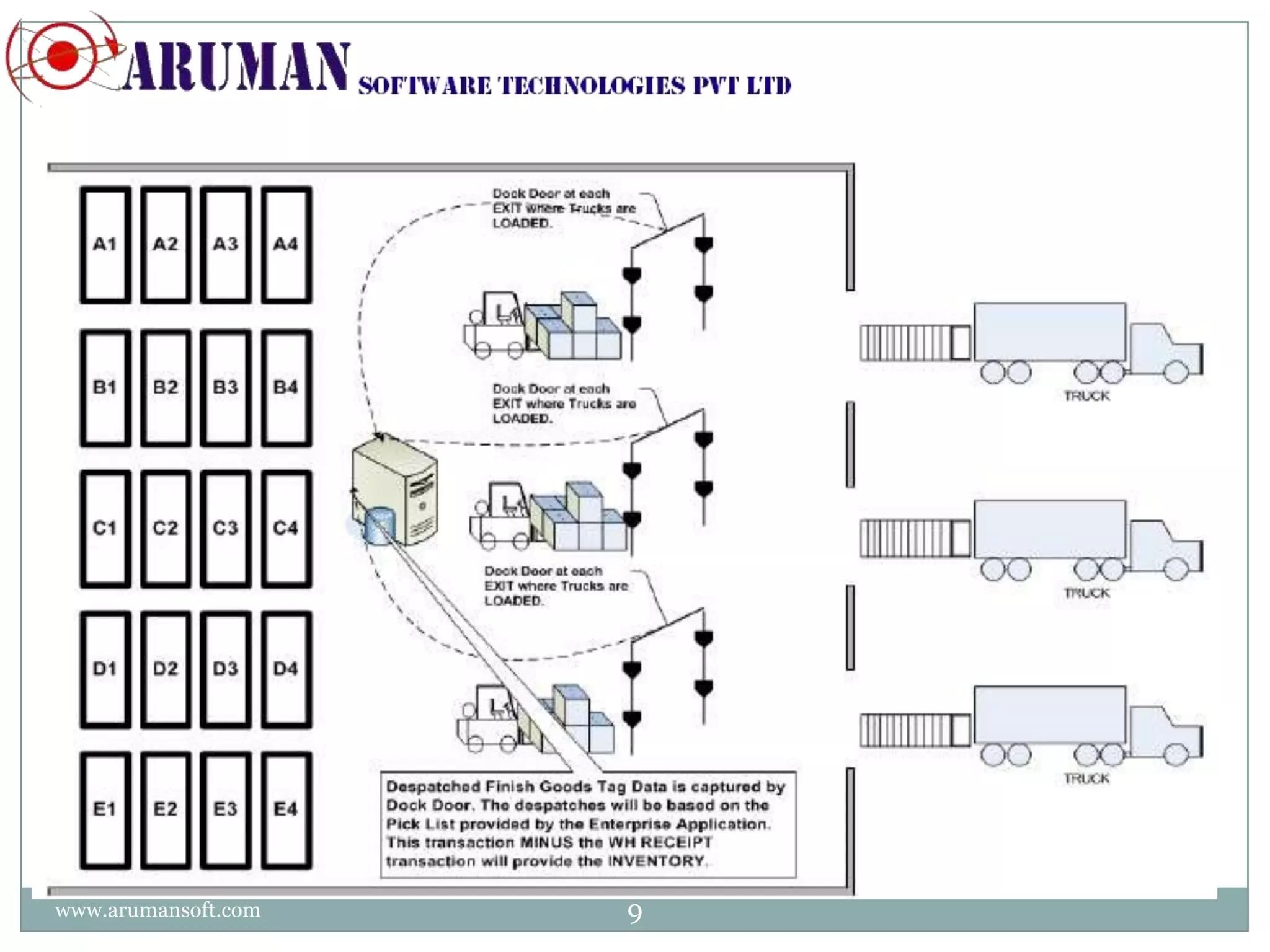

The document outlines the importance of warehouse management systems (WMS) in controlling the storage and movement of materials, detailing features such as real-time inventory visibility and automatic data capture using RFID technology. It explains the proposed implementation of RFID tags to enhance the efficiency of warehouse operations, including automated receiving and dispatch processes. Additionally, the document lists suggested hardware for RFID systems and highlights the advantages of warehouse automation, such as improved accuracy and real-time data collection.