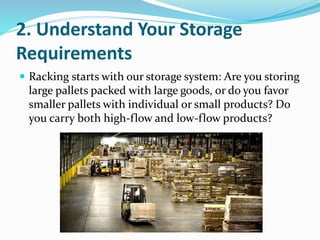

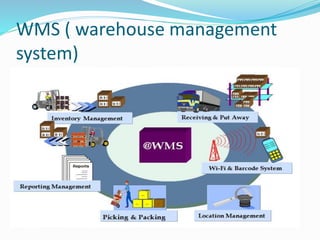

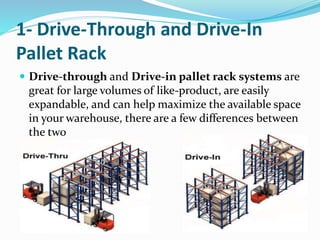

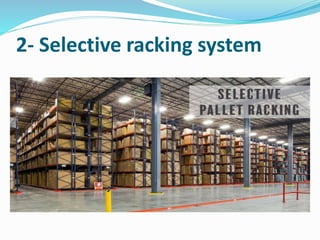

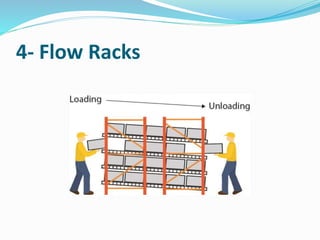

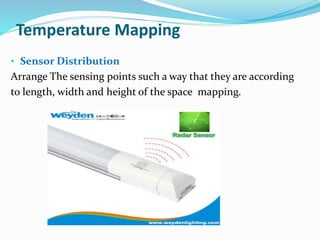

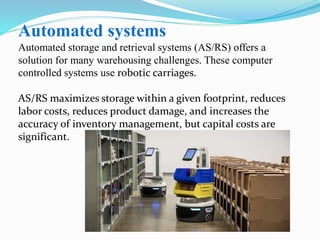

The document discusses racking and mapping in warehouses. It defines different types of warehouse racking systems like drive-through racks, selective racks, push back racks, and flow racks. It also outlines best practices for designing an efficient warehouse racking layout, such as consulting contractors, understanding storage needs, maximizing space, planning for expansion, and choosing a durable racking system. Additionally, it discusses the importance of warehouse mapping to analyze temperature, humidity, and identify critical storage zones.