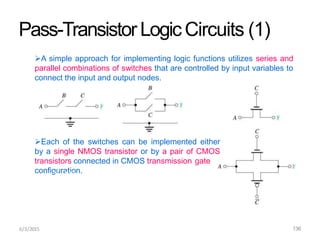

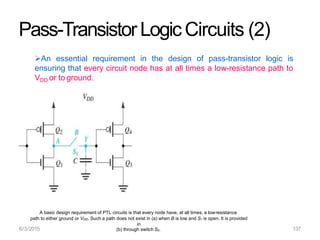

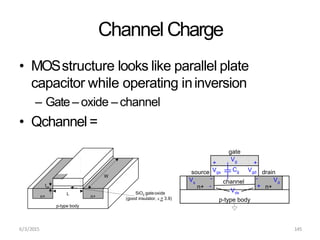

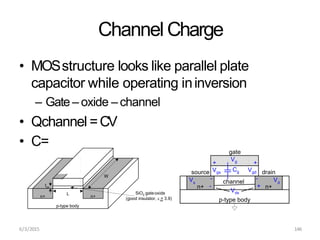

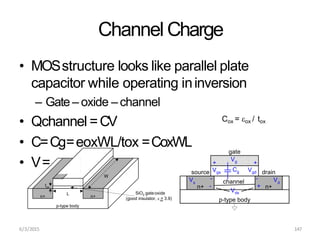

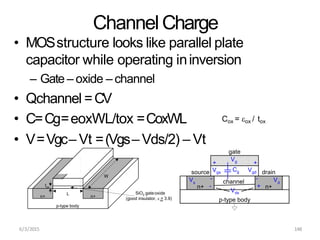

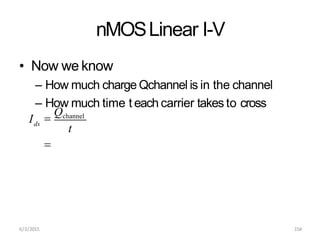

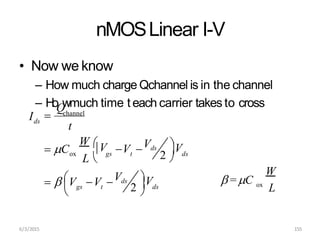

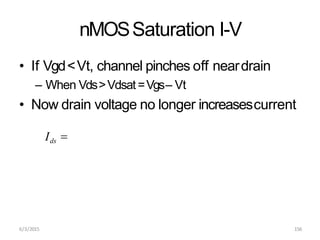

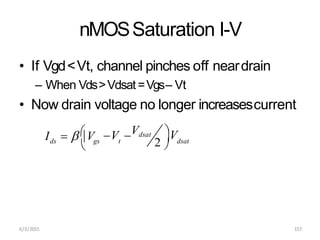

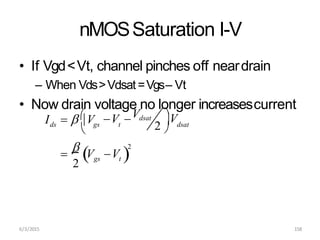

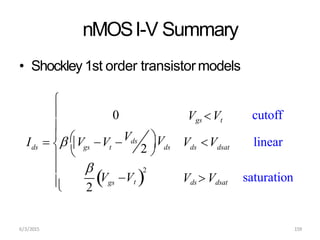

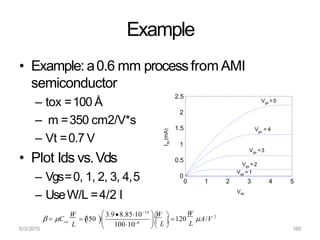

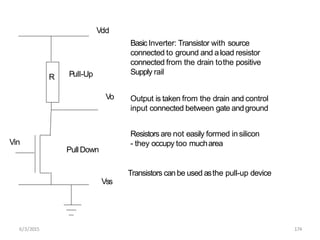

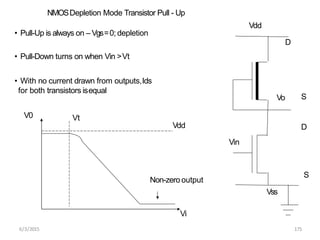

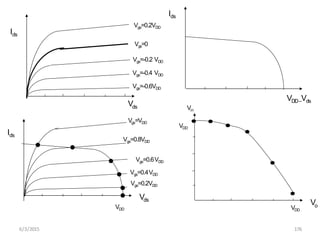

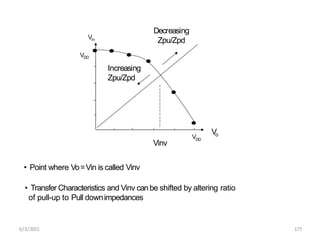

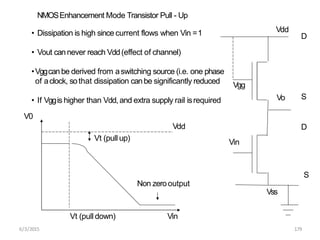

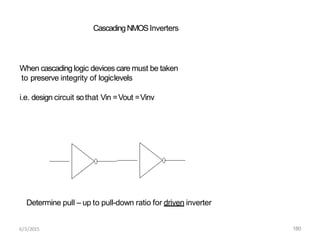

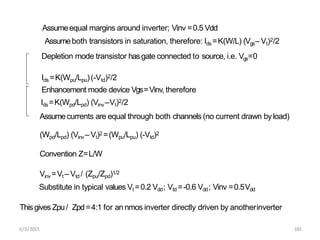

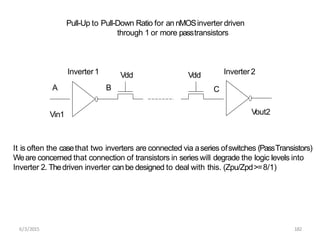

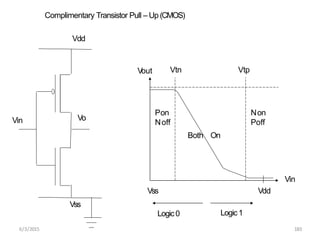

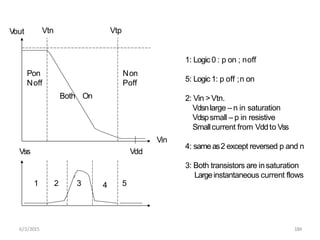

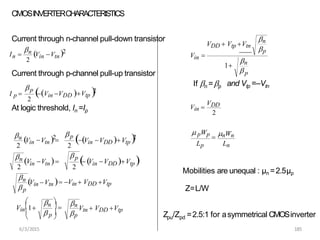

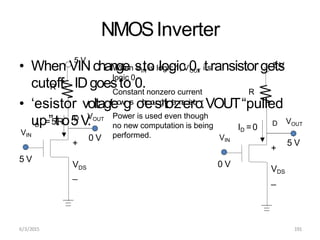

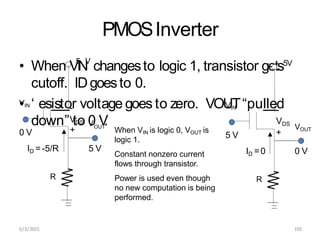

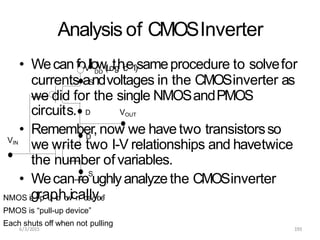

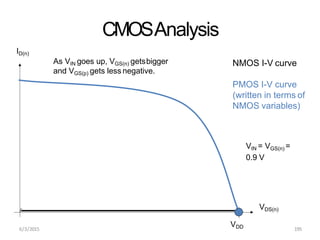

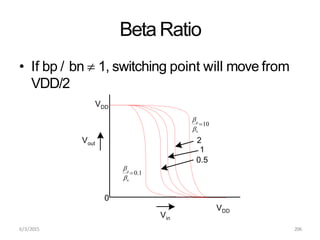

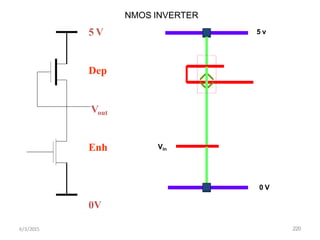

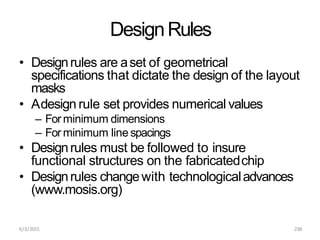

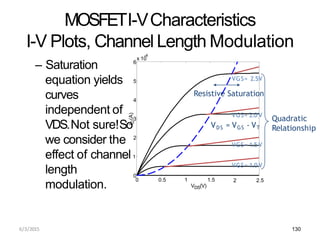

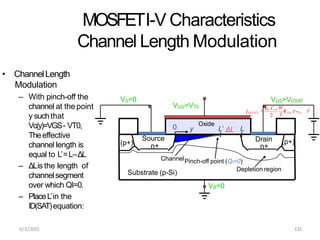

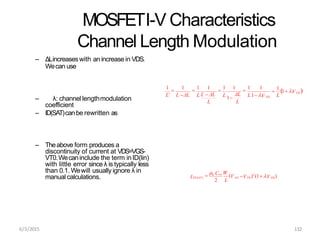

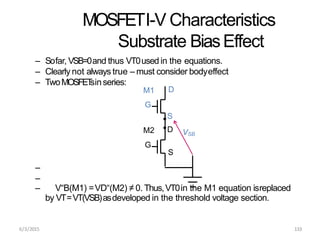

The document discusses the electrical properties and characteristics of MOS and BiCMOS circuits, focusing on parameters such as sheet resistance, channel length modulation, and MOSFET I-V characteristics. It also covers pass-transistor logic circuits and the design requirements for ensuring low-resistance paths in circuit nodes. Additionally, it outlines the operation of NMOS inverters and discusses the impact of various parameters on the device performance.

![MOSFETI-V Characteristics

Summary of AnalyticalEquations

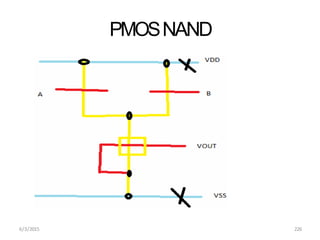

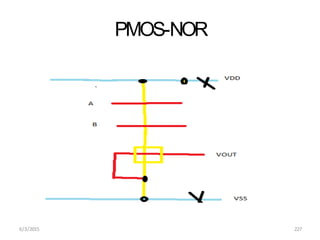

– Thevoltage directions and relationships for thethree

modes of pMOSare in contrast to those ofnMOS.

G

D

B

S

VSB VDS

VGS ID

G

S

VDS

VSB

B

VGS

ID

D

nMOS

Mode ID Voltage Range

Cut-off 0 VGS<VT

Linear (µnCox/2)(W/L)[2(VGS

- VT)VDS-VDS

2]

VGSVT,VDS< VGS

-VT

Saturatio

n

(µnCox/2)(W/L)(VGS-

VT)2(1+hVDS)

VGS VT,VDS

VGS -VT

pMOS

Cut-off 0 VGS>VT

Linear (µnCox/2)(W/L)[2(VGS

- VT)VDS-VDS

2]

VGS VT,VDS>

VGS -VT

Saturatio

n

(µnCox/2)(W/L)(VGS-

V )2(1+hV )

VGS VT,VDS135

V -V

6/3/2015](https://image.slidesharecdn.com/vlsi-unit-2-ppt-240717122813-7b1d5057/85/VLSI-UNIT-2-sheet-Resistance-and-Electrical-Properties-8-320.jpg)