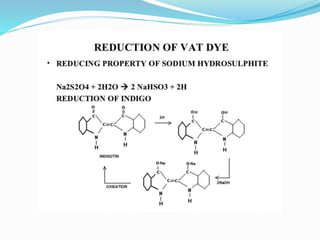

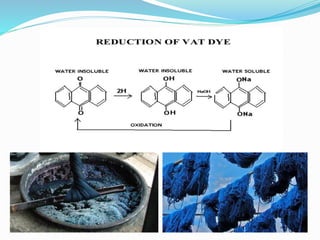

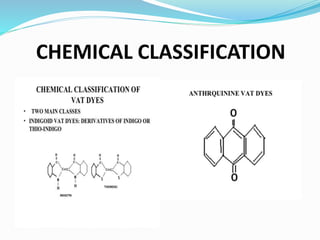

Vat dyes are water-insoluble dyes that can be converted to a water-soluble form through chemical reduction. They were first developed in the 1850s as synthetic dyes and include indigo dye. The vat dyeing process involves three steps - vatting to convert the dye to its soluble leuco form, oxidation to convert it back to insoluble form in the fiber, and after treatment. Vat dyes have high color fastness but more limited shades than other dyes and their application process is complex and time-consuming.