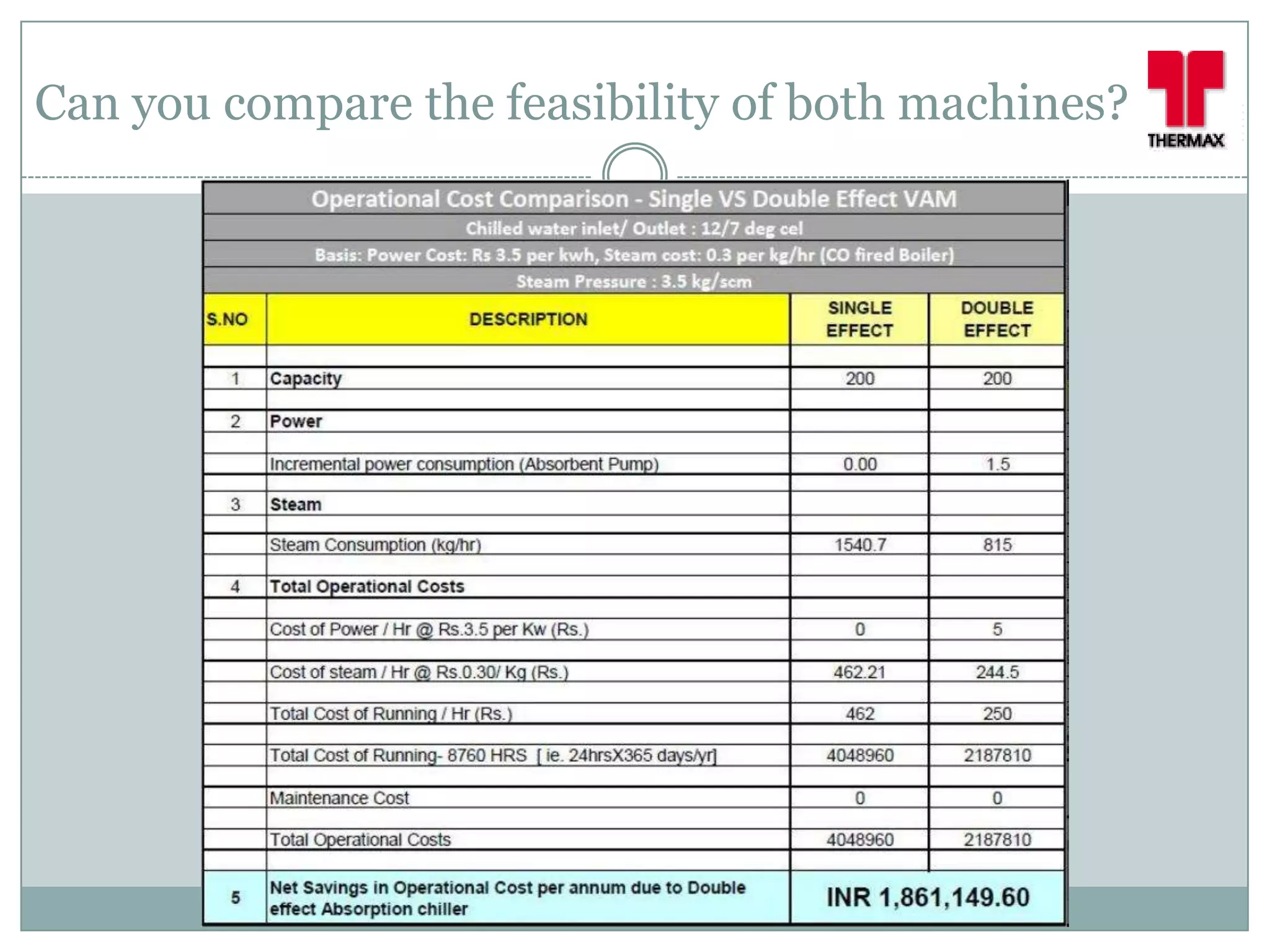

There are two main types of absorption machines: single effect and double effect. Single effect uses a single generator to regenerate the refrigerant and absorbent using a lower grade heat source, resulting in a COP of around 0.7. Double effect uses two generators and a medium grade heat source to regenerate the refrigerant and absorbent in two stages, improving efficiency with a COP of 1.36 to 1.43. Double effect machines are generally more feasible than single effect when medium grade heat sources are available due to their higher performance. It is difficult to design a single machine to operate effectively across both low and high-grade heat sources.