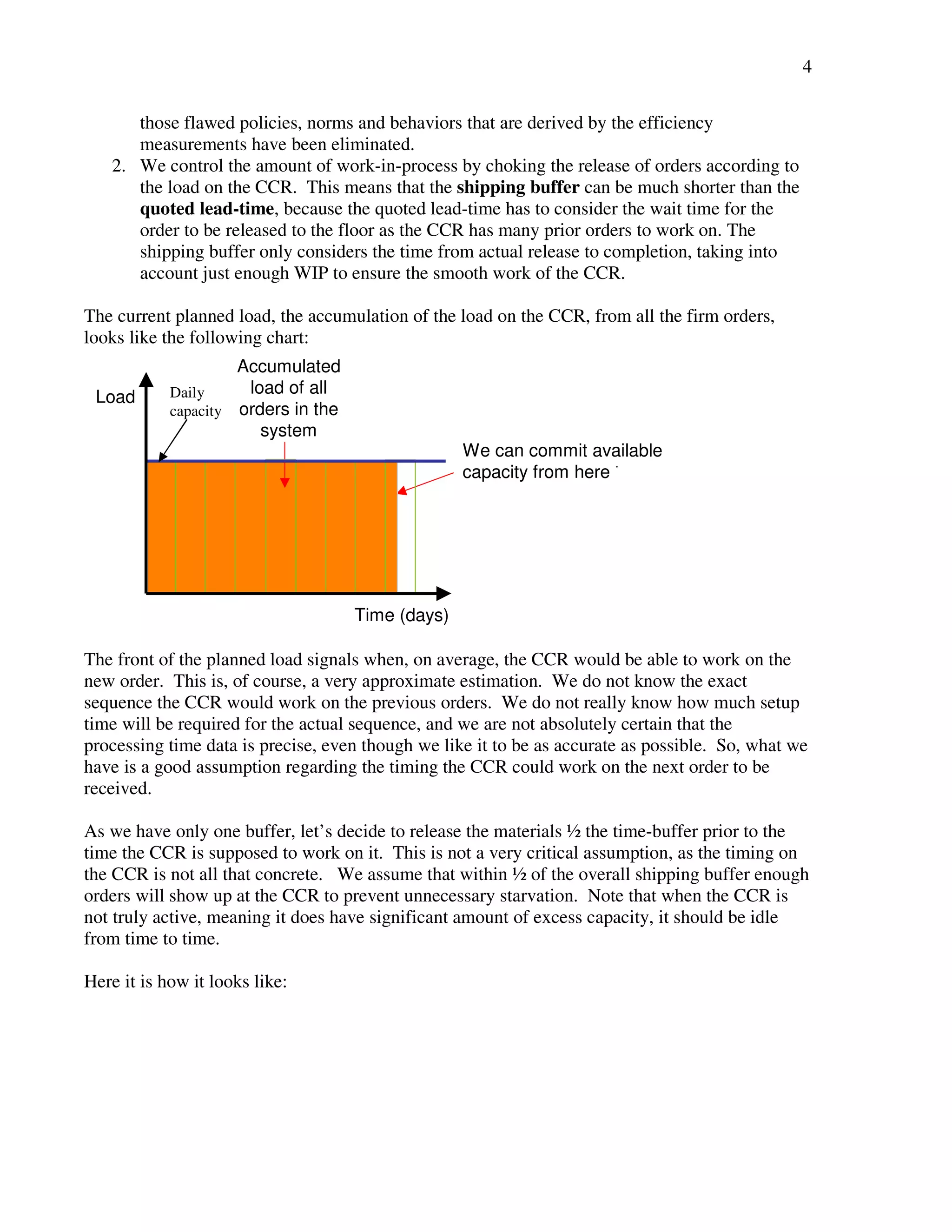

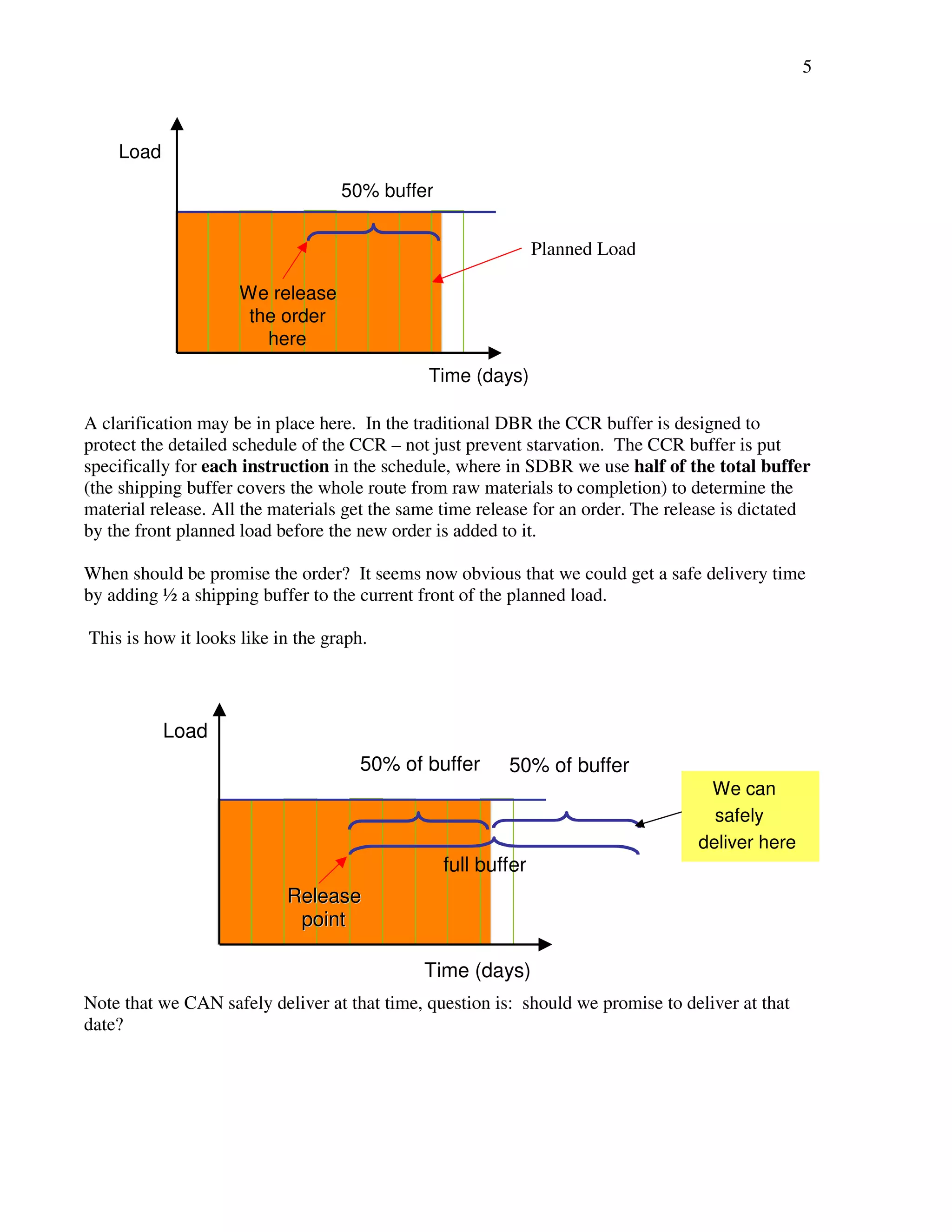

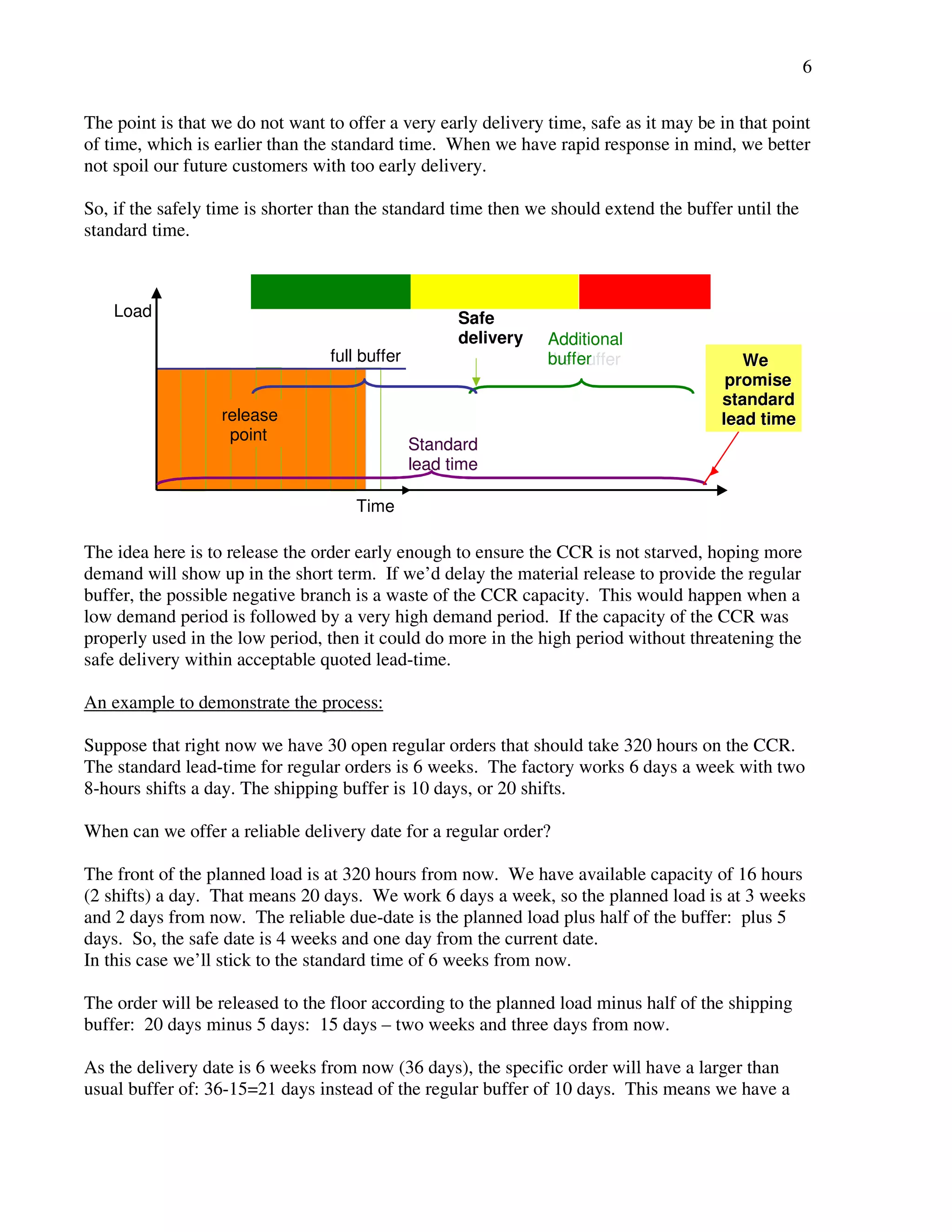

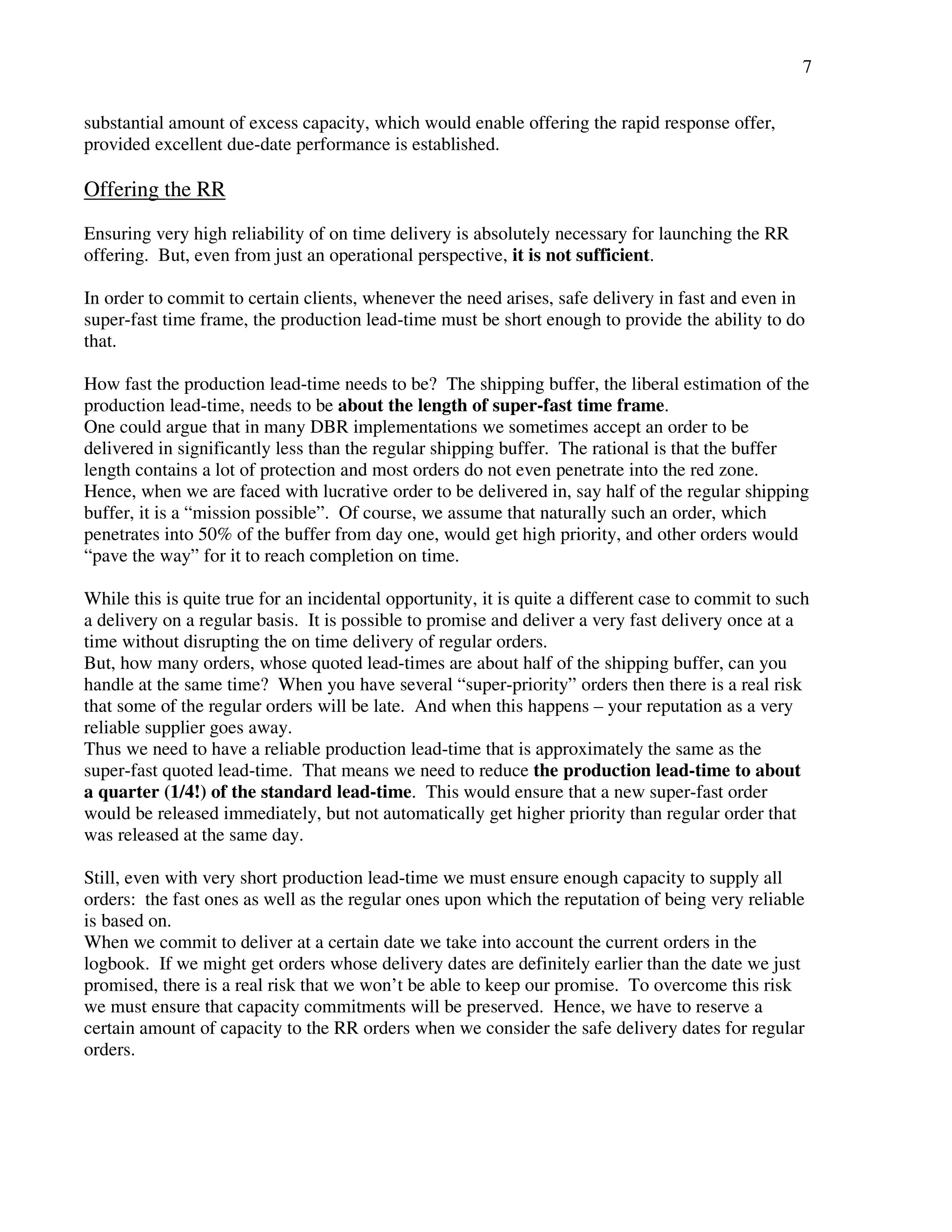

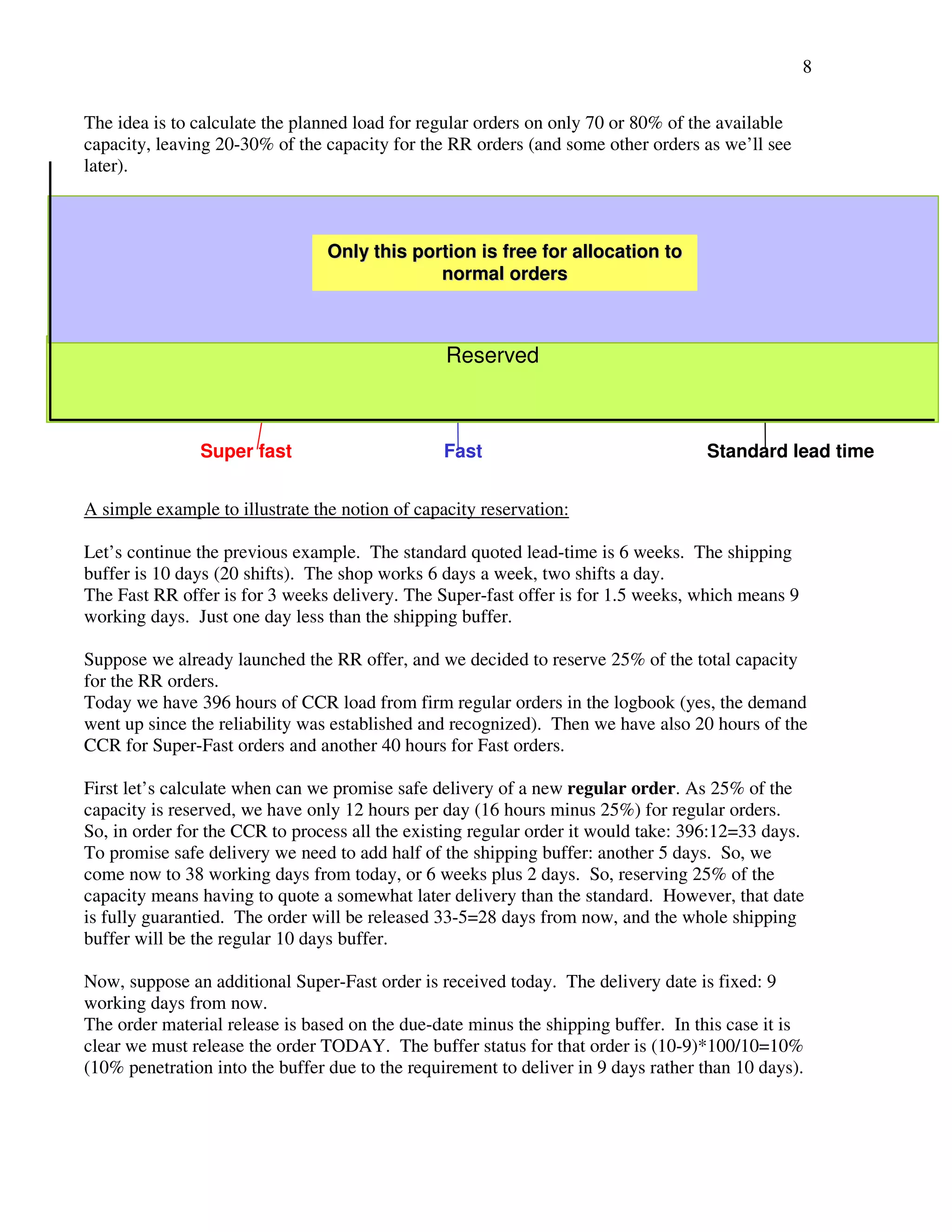

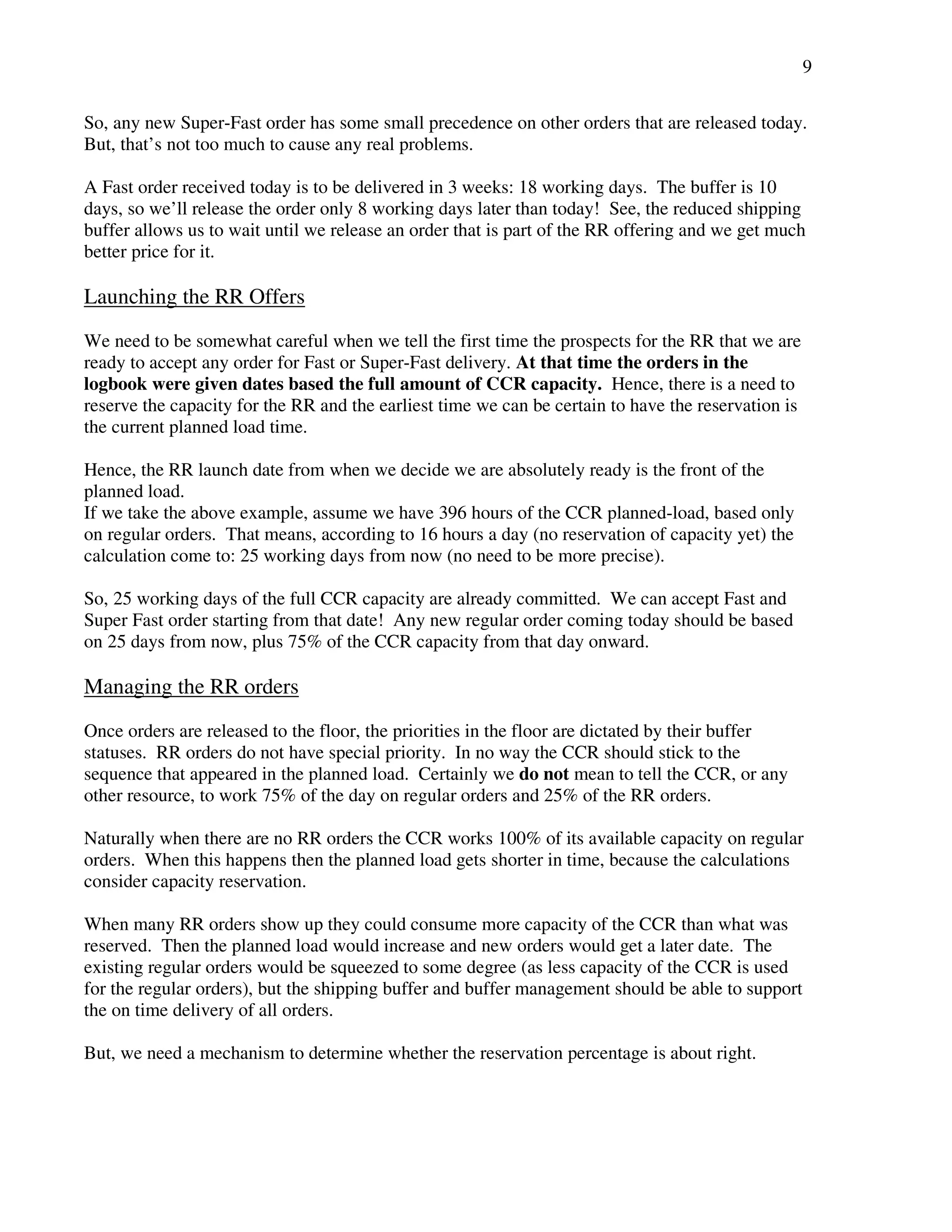

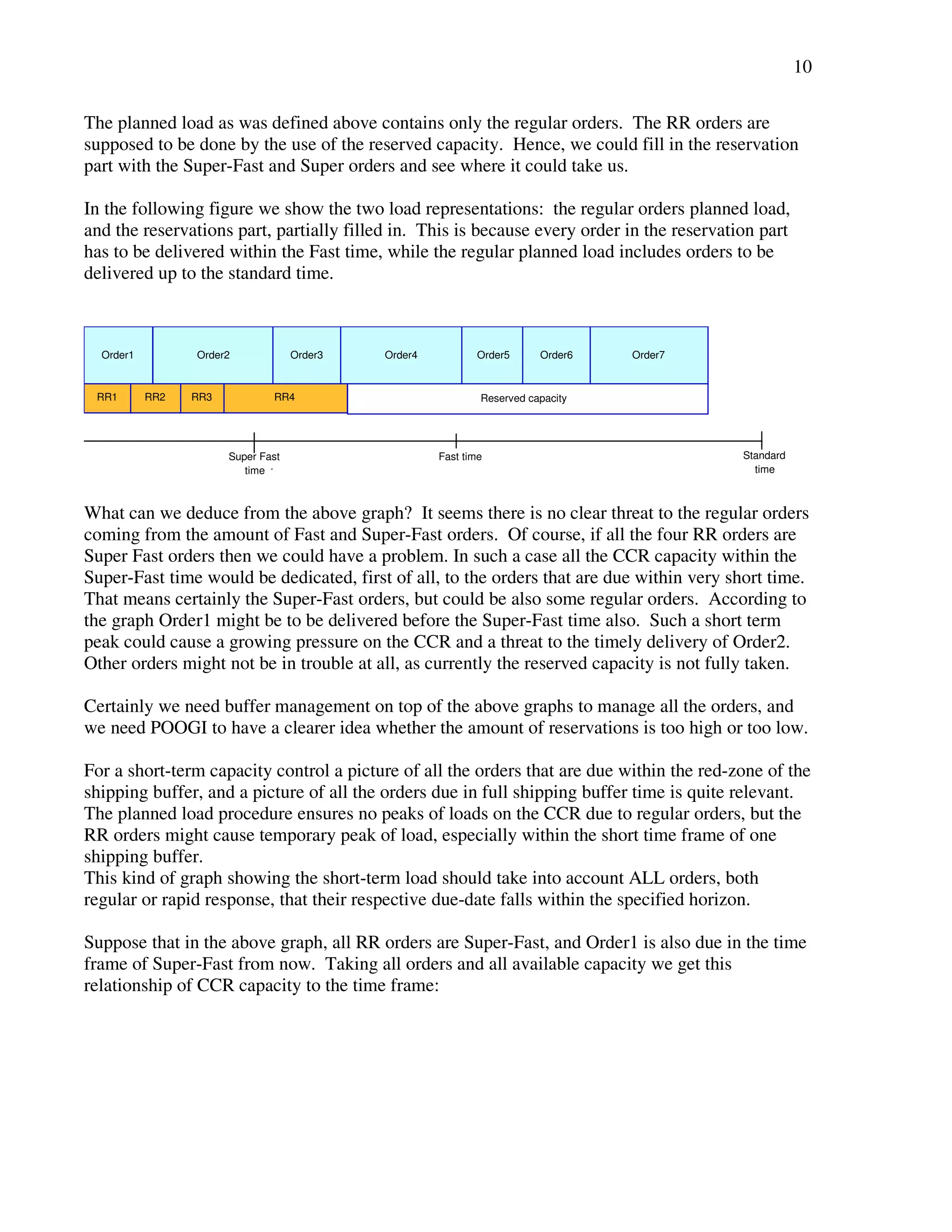

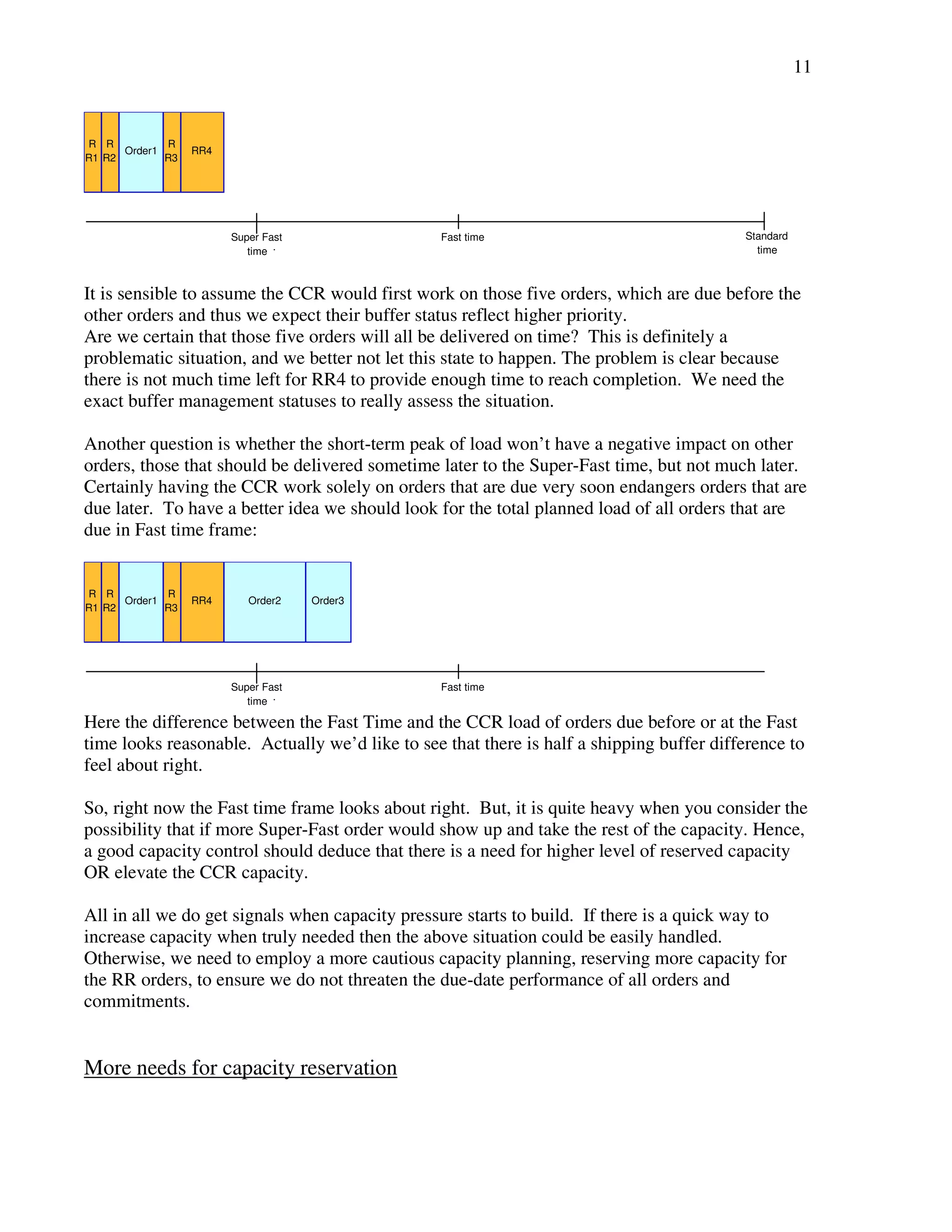

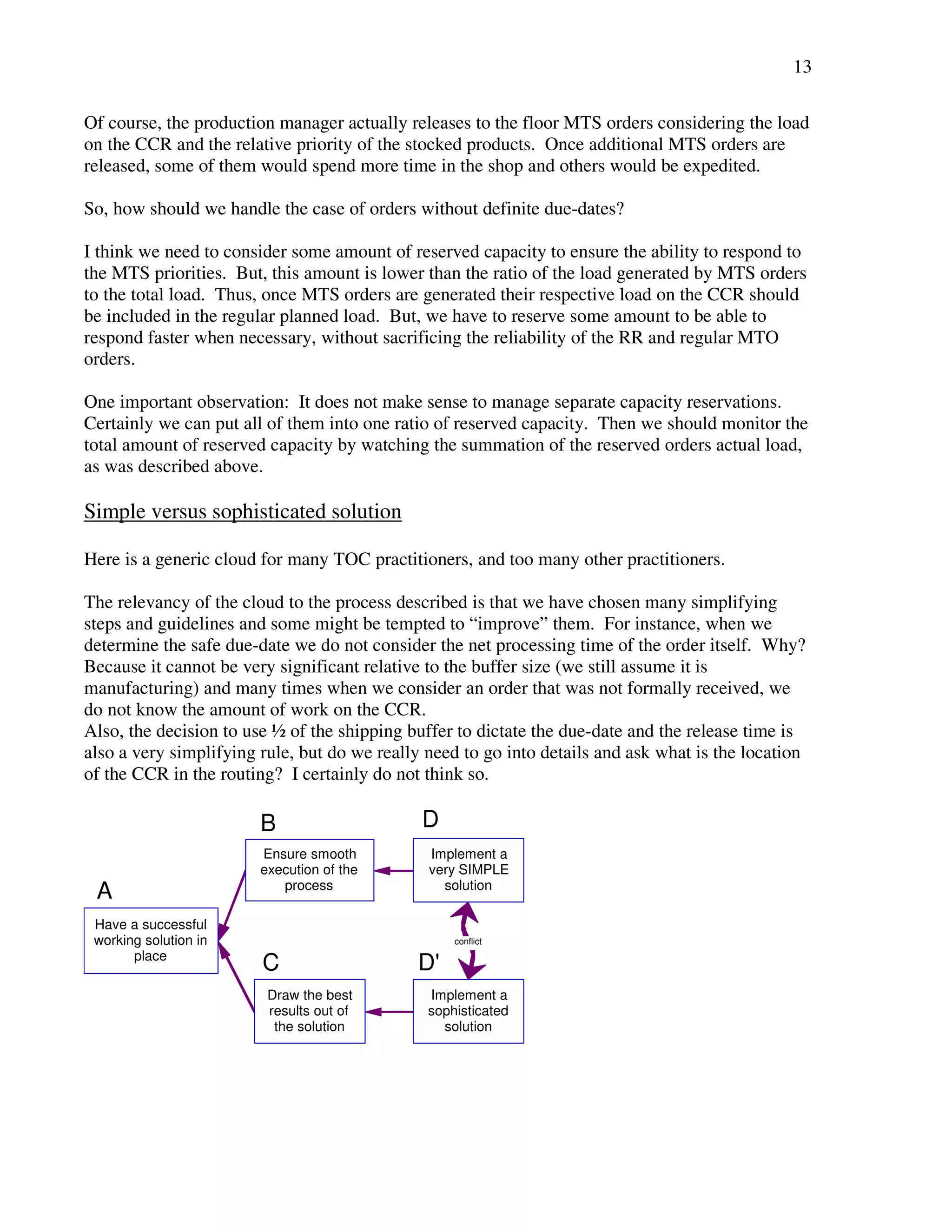

This document discusses how to implement Simplified Drum-Buffer-Rope (SDBR) production planning for rapid response (RR) projects while maintaining commitments to regular orders. It proposes reserving capacity on the capacity-constrained resource (CCR) for RR orders so they do not impact regular order due dates. A planned load concept is used to determine safe due dates for regular orders based on projected CCR workload rather than a detailed schedule. The document outlines calculating planned load, quoting safe due dates, reserving CCR capacity for RR orders, and execution rules for the implementation.