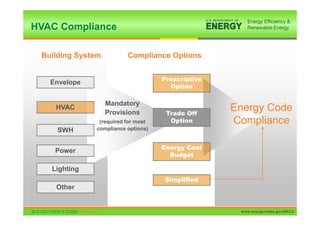

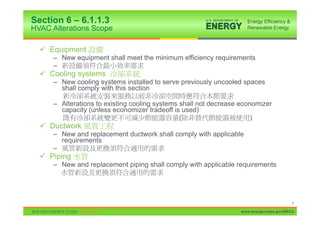

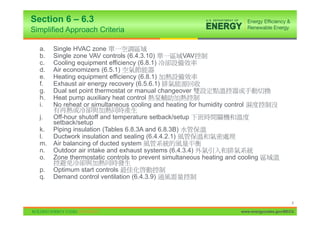

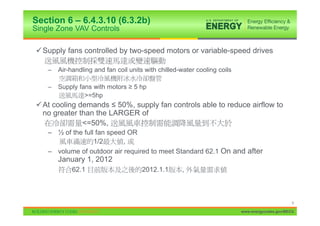

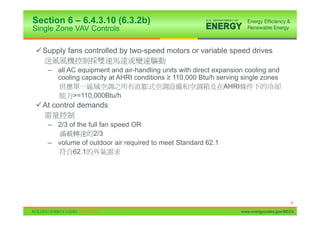

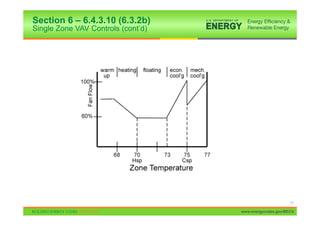

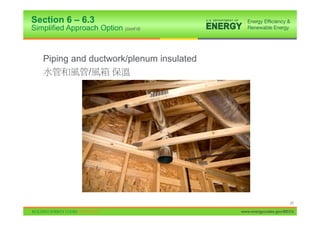

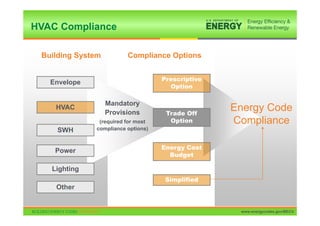

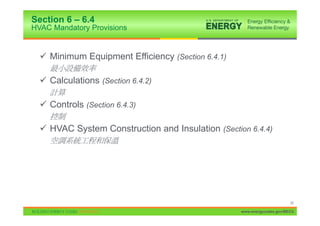

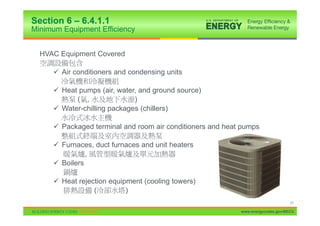

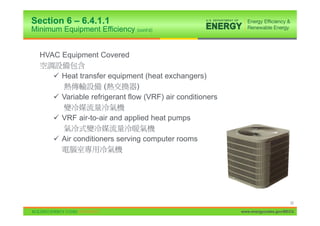

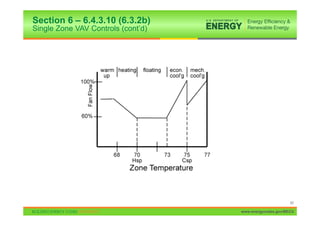

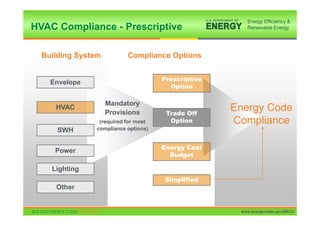

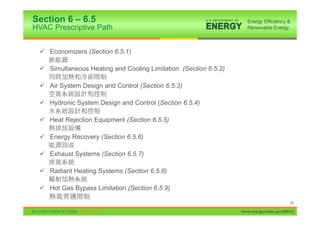

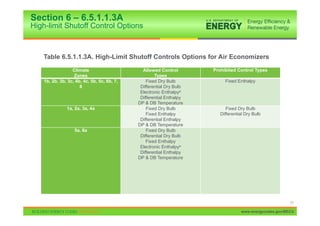

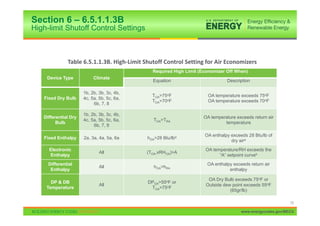

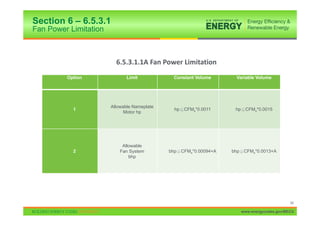

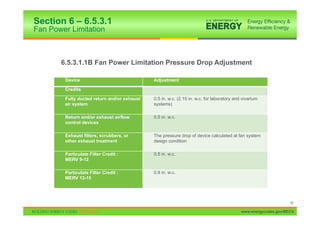

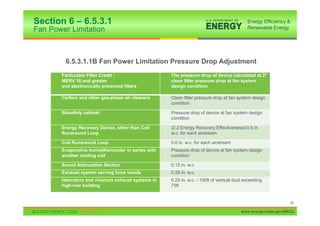

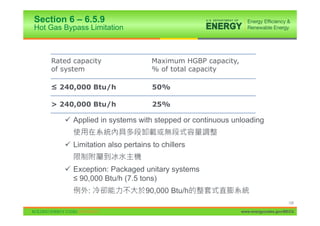

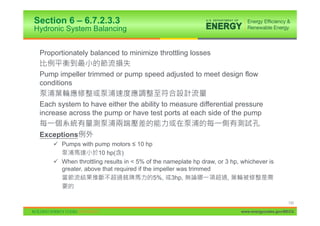

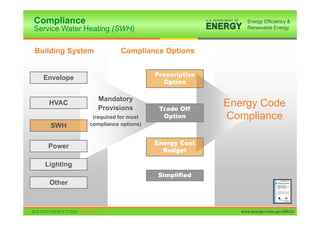

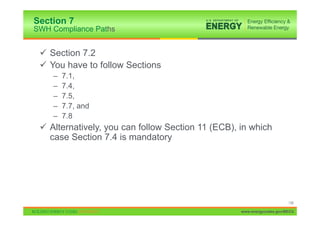

This document summarizes key requirements for HVAC compliance from ANSI/ASHRAE/IES Standard 90.1-2010. It discusses compliance options including prescriptive and trade-off options. For alterations to existing HVAC systems, the standard requires meeting certain provisions while providing exceptions. It also summarizes the simplified compliance approach available for small buildings, including criteria for single zone VAV controls, equipment efficiency standards, economizer requirements, and exceptions.