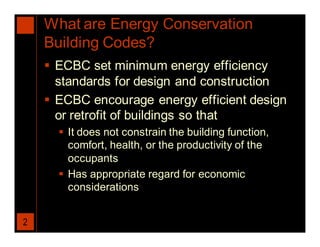

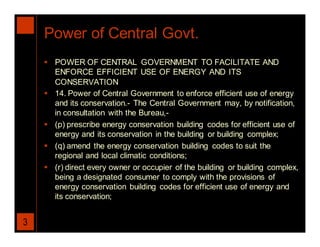

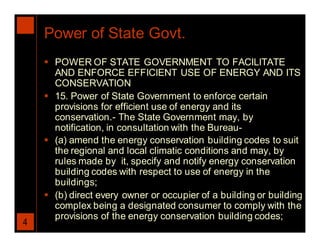

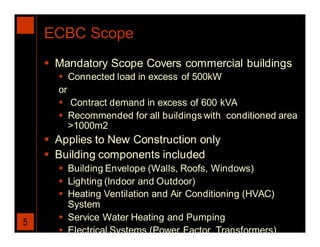

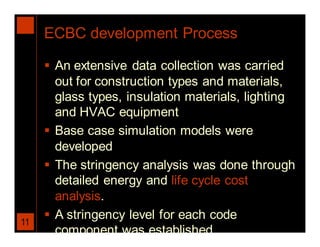

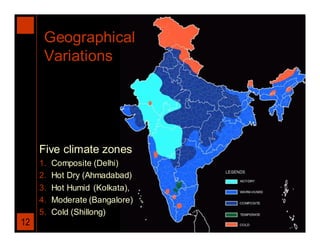

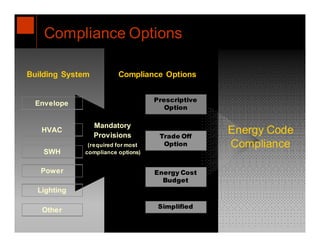

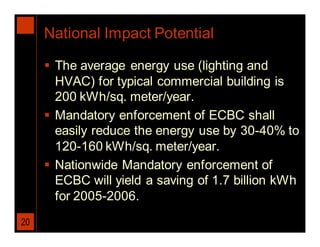

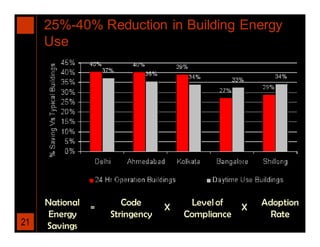

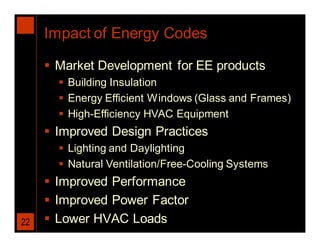

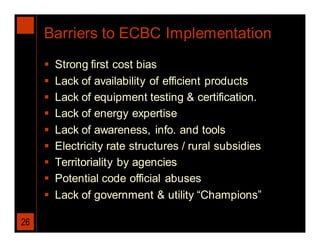

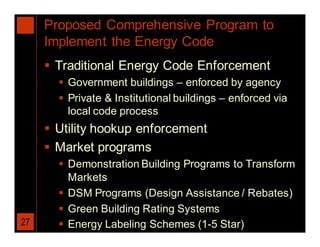

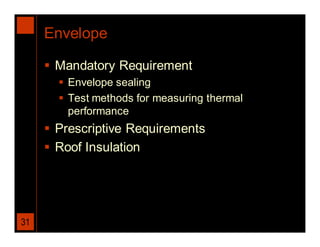

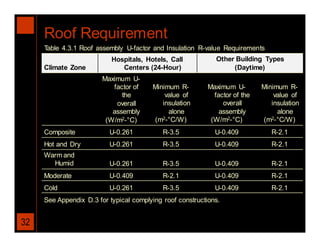

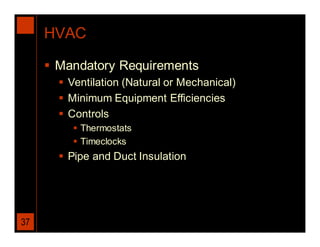

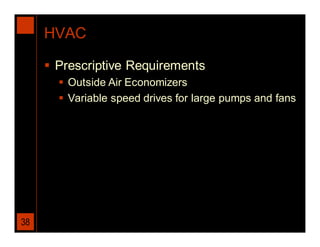

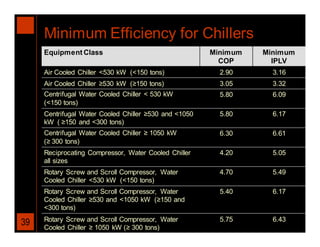

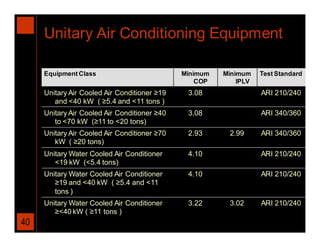

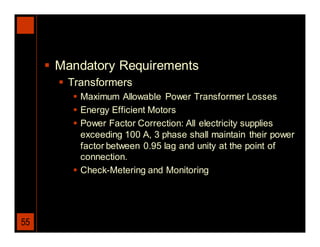

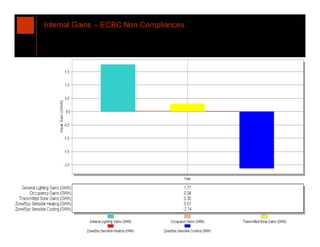

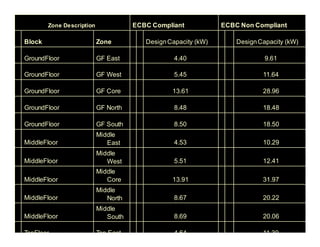

The document discusses India's Energy Conservation Building Code (ECBC). It aims to set minimum energy efficiency standards for building design and construction. The ECBC encourages energy efficient practices that do not compromise occupant comfort or economic considerations. It provides the central and state governments powers to enforce compliance. The ECBC is estimated to reduce building energy use by 25-40% through requirements for the building envelope, lighting, HVAC, and other systems. Widespread adoption could yield annual national energy savings of over 1.7 billion kWh. Implementation faces barriers around first costs, product availability, and testing/certification.

![Energy Conservation Building

Code [ECBC]

Hisham Ahmad

Environmental Design Solutions [EDS]

1](https://image.slidesharecdn.com/ecbcheatingandpumping-121212070214-phpapp01/75/Ecbc-heating-and-pumping-1-2048.jpg)