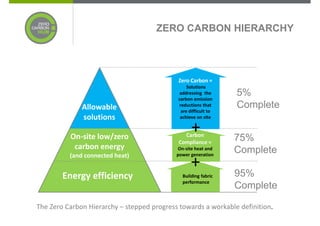

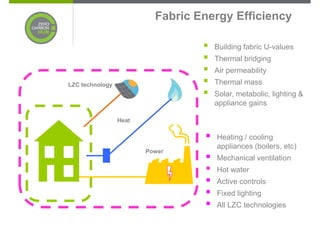

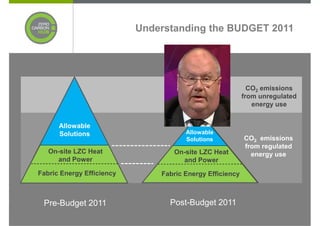

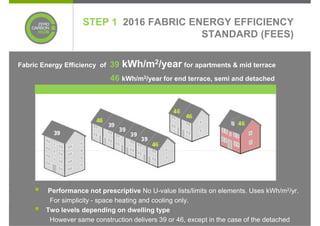

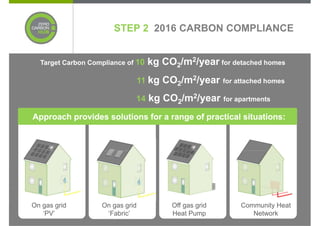

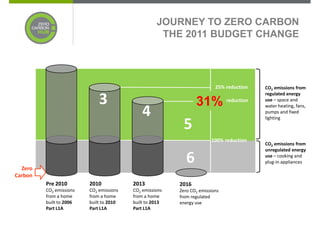

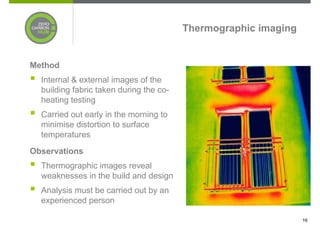

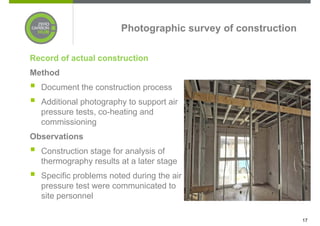

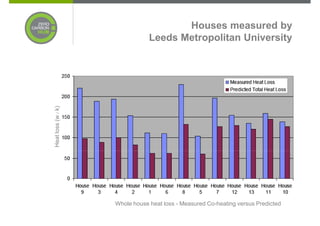

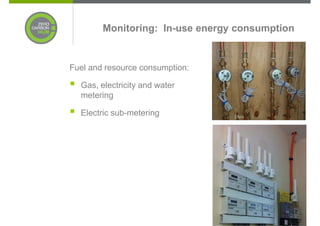

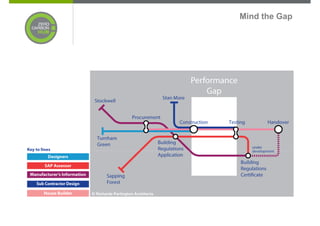

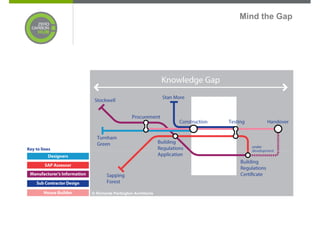

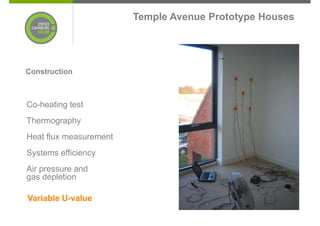

This document discusses a conference on beyond zero carbon housing held at the University of Nottingham. It begins by introducing the concept of a zero carbon hierarchy to help define zero carbon goals. It then covers topics discussed at the event including fabric energy efficiency standards, carbon compliance targets, understanding the impact of the 2011 budget changes, lessons from case studies on performance gaps between design and implementation, and monitoring in-use energy consumption.