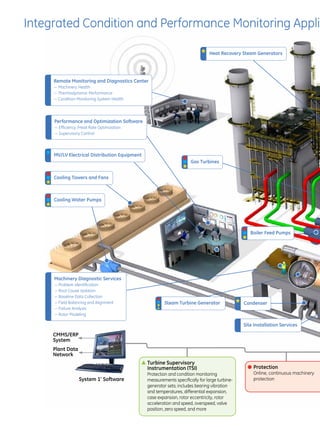

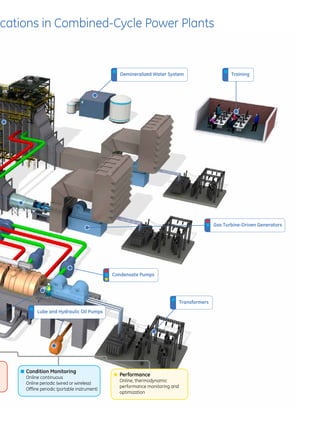

This document discusses GE's asset condition monitoring solutions for combined cycle power plants. It begins by providing background on the history and importance of gas turbine power plants. It then describes GE's portfolio of condition monitoring systems that can monitor various assets across a combined cycle plant, such as gas turbines, steam turbines, pumps, fans and more. It discusses how these systems help customers minimize downtime, reduce costs, protect critical equipment, and optimize maintenance through predictive analytics. Customers can see returns through increased availability, reduced maintenance durations and costs, and extended time between outages. The document provides an overview of how GE's solutions can be applied across a combined cycle plant.