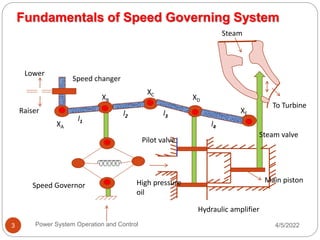

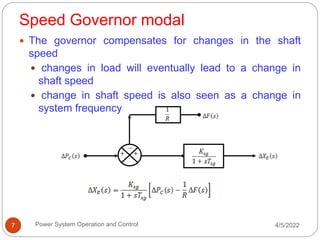

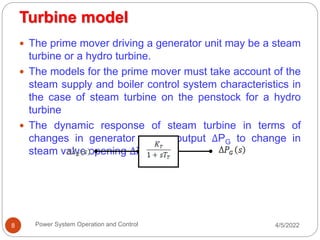

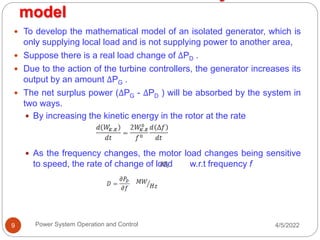

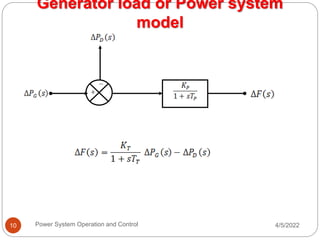

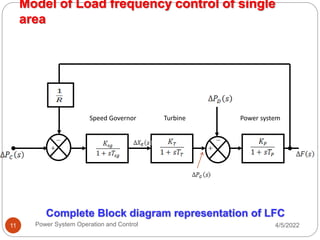

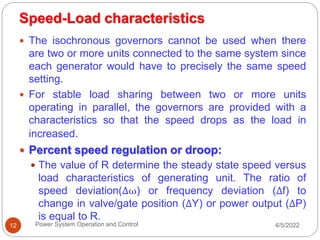

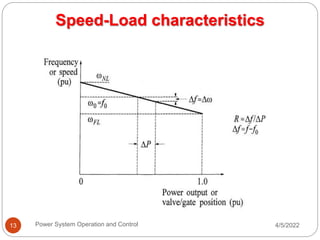

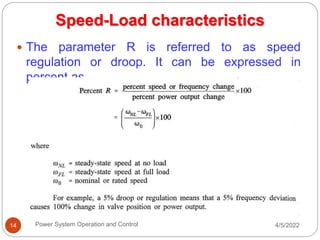

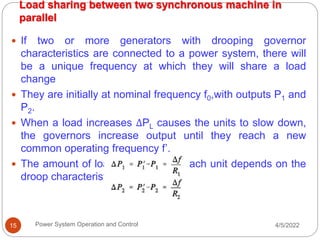

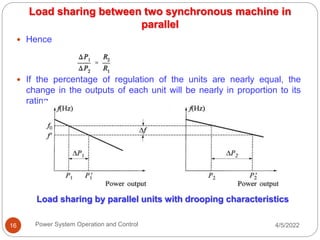

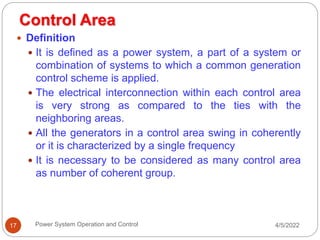

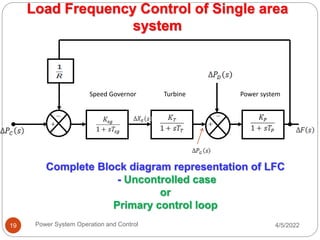

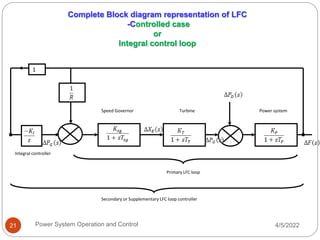

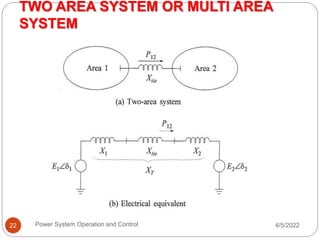

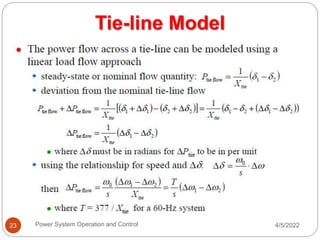

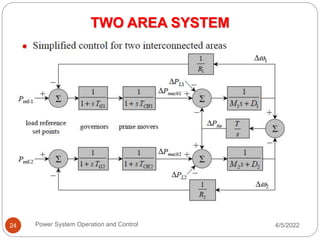

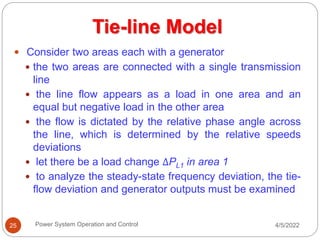

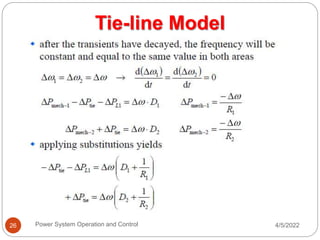

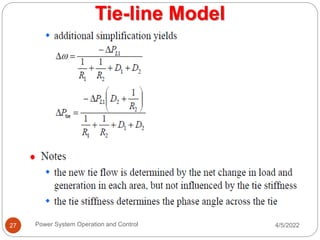

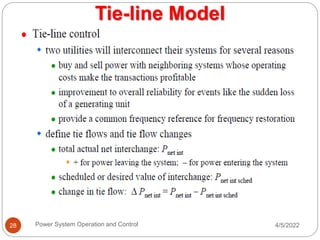

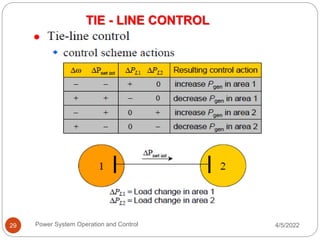

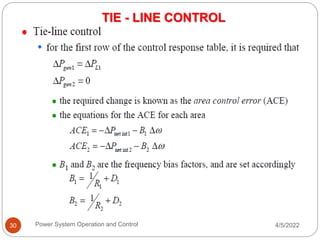

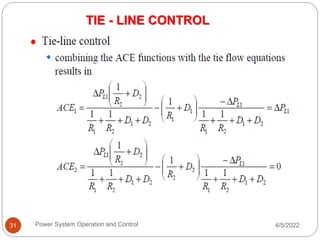

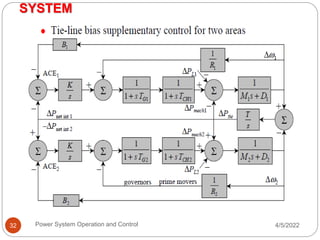

The document discusses load frequency control (LFC) in power systems. It covers the basics of speed governing mechanisms, load sharing between generators, the control area concept, and modeling of single-area and multi-area LFC systems. Key aspects covered include flyball governors that sense frequency changes, hydraulic amplifiers that control steam valves, droop characteristics for load sharing, and tie-line frequency bias control for multi-area systems. Mathematical models are presented for generator dynamics, turbine response, and LFC control loops.