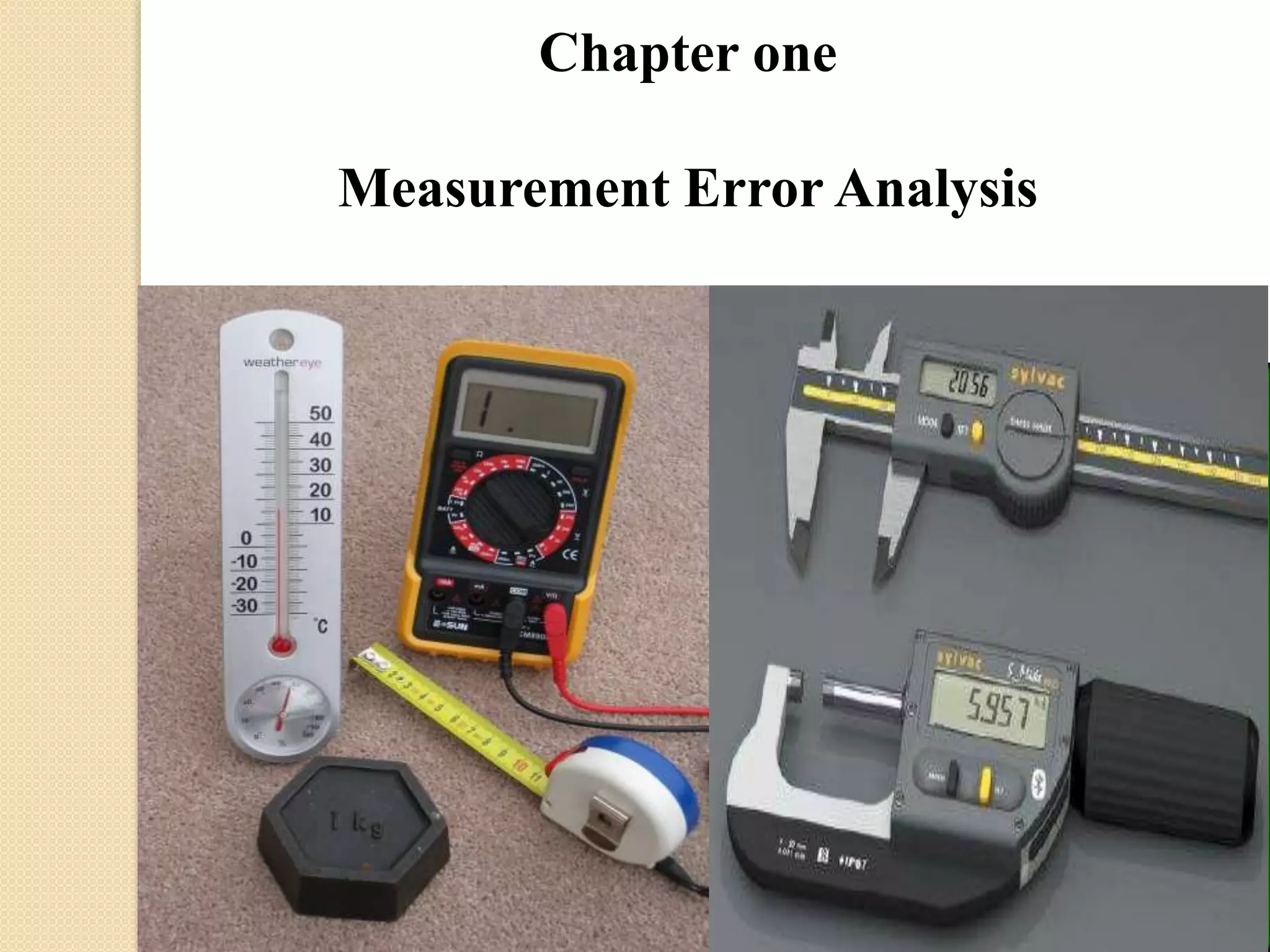

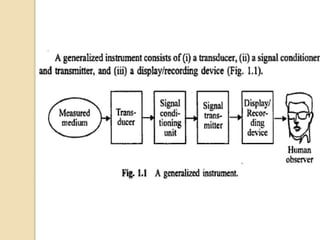

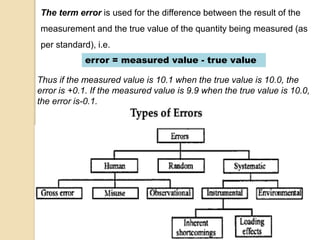

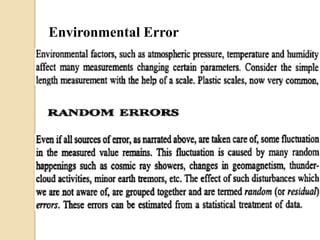

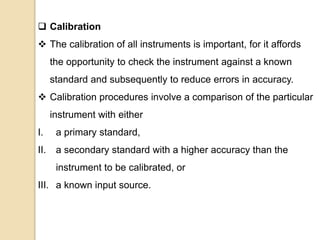

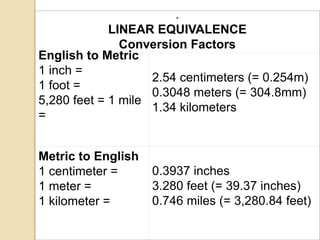

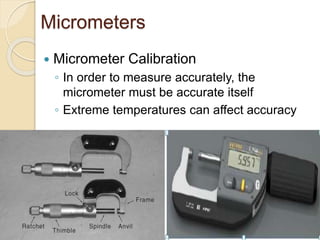

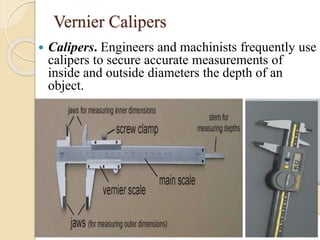

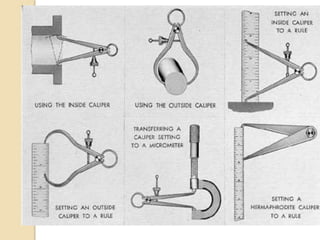

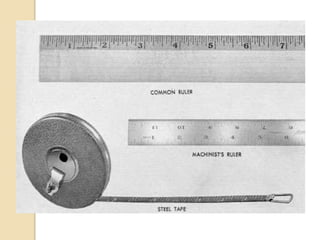

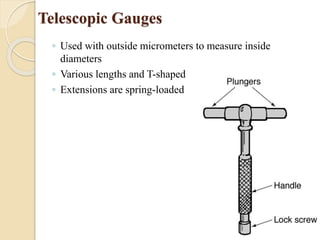

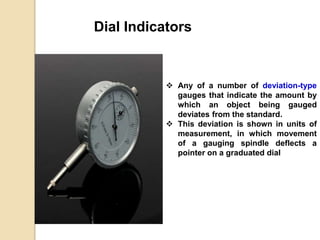

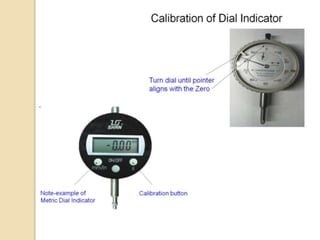

This document summarizes key concepts related to measurement systems and instrumentation. It discusses how measurement systems are used for monitoring processes, controlling processes, and analysis. It then defines instrumentation as a system that maintains a relationship between a measured property and physical variable, communicating this to an observer. Transducers are described as sensing the measured variable and converting it to a signal. Measurement errors are defined as the difference between the measured and true values. Finally, it discusses common mechanical measurement instruments like micrometers, vernier calipers, dial indicators, and gauges.