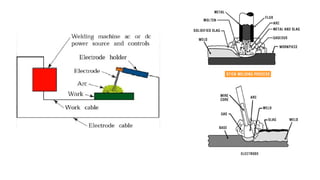

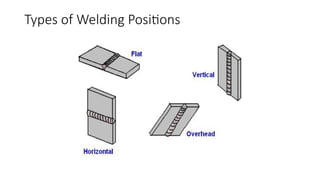

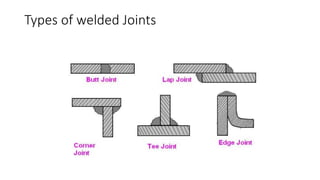

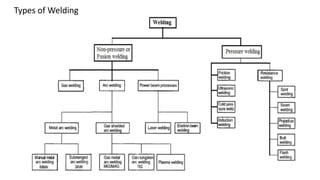

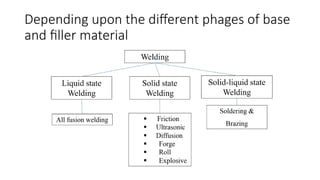

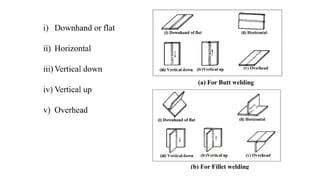

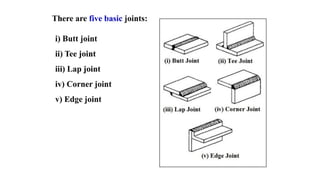

The document discusses various fabrication methods in robotics, particularly emphasizing welding and machining processes. It defines fabrication and contrasts it with manufacturing, highlighting the role of welding in creating permanent joints for various applications. Additionally, it details the machining process for shaping components by removing excess material to achieve desired specifications.