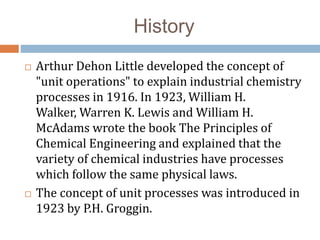

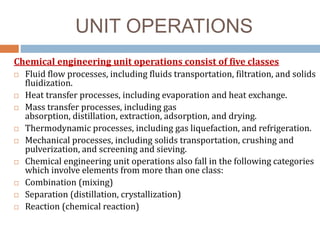

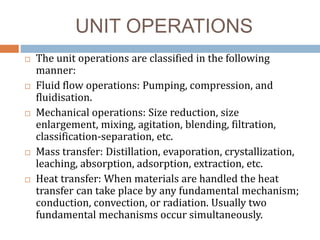

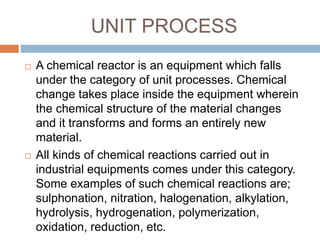

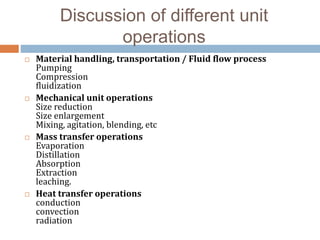

This document discusses unit operations and unit processes in chemical engineering. It defines unit operations as physical processes without chemical reactions, involving changes like separation and crystallization. Unit processes involve chemical transformations in reactors. The document outlines the main categories of unit operations, including fluid flow, heat and mass transfer, and mechanical processes. It also provides examples of specific unit operations and unit processes used in chemical engineering.