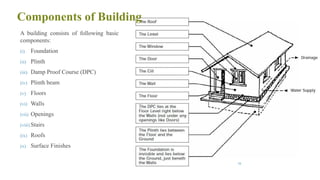

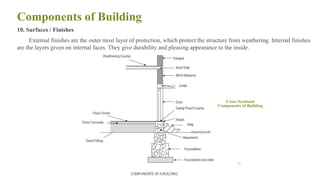

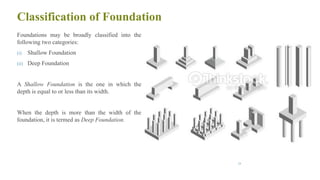

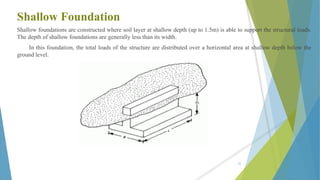

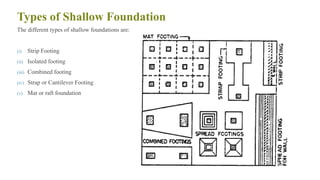

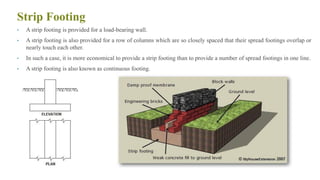

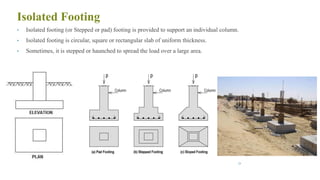

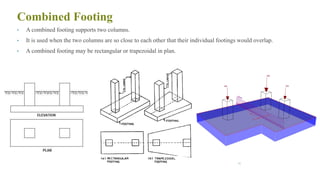

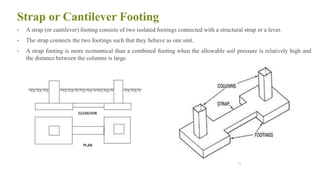

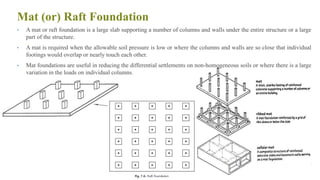

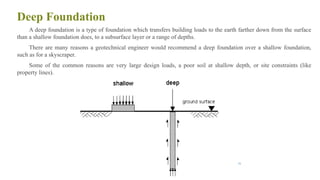

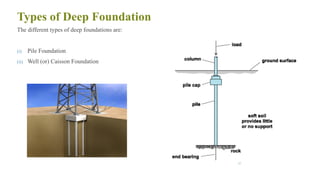

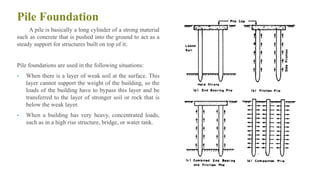

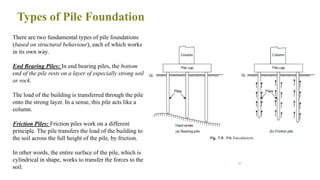

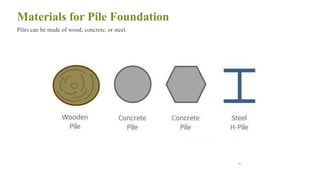

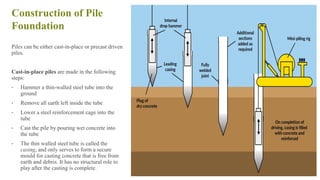

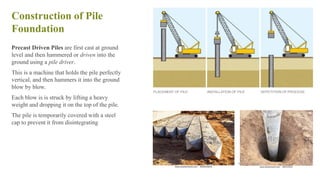

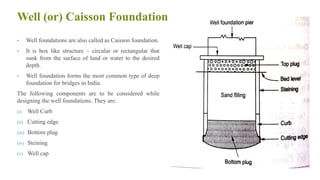

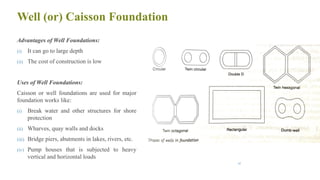

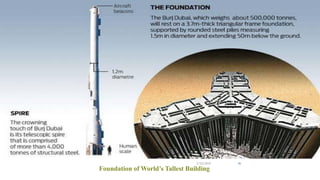

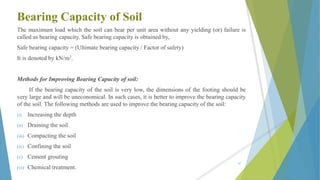

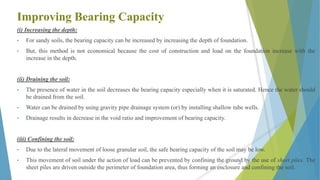

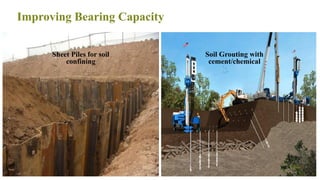

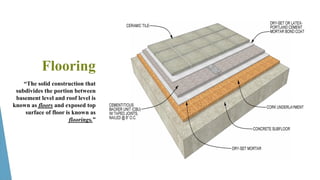

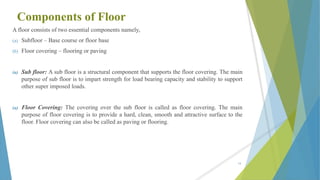

This document provides an overview of the syllabus for the Basic Civil Engineering course. The syllabus covers 5 units: (1) building materials, (2) building components, (3) planning aspects and regulations, (4) water supply and sanitary systems, and (5) surveying and transportation. Unit 2 discusses different types of building foundations, floors, roofs, and other building components. Shallow foundations include strip footings, isolated footings, combined footings, strap footings, and raft foundations. Deep foundations include pile foundations, which transfer loads to deeper subsurface layers, and well foundations.