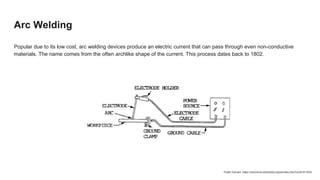

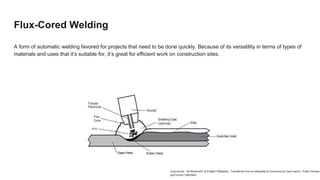

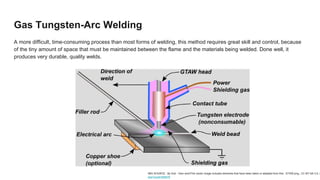

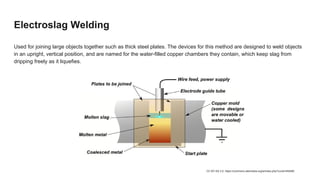

Welding is a method of joining materials through applied heat and pressure, with various techniques such as arc welding, flux-cored welding, gas tungsten-arc welding, and others. Each technique has distinct advantages and applications, ranging from quick automatic processes to manual methods requiring skill. The document highlights these methods along with their particular uses and specifications.