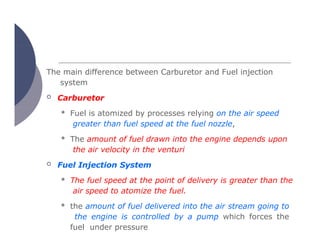

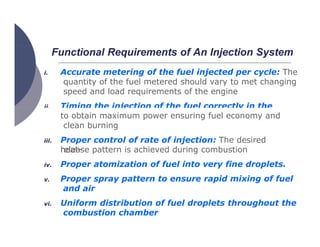

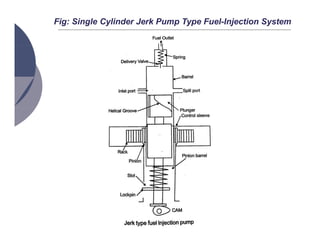

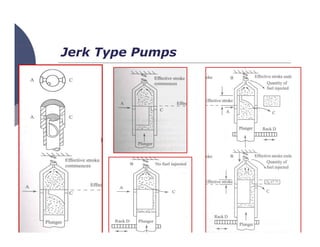

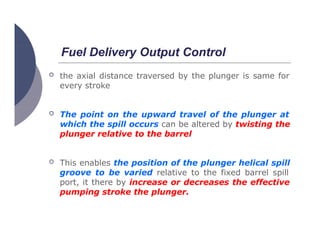

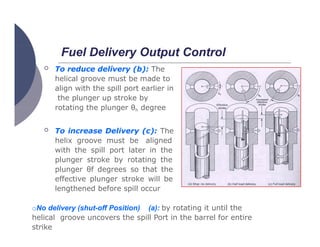

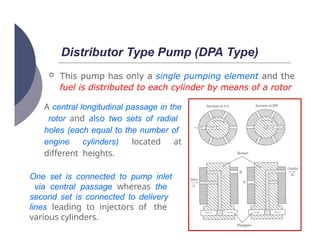

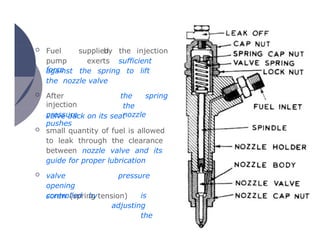

The document provides an overview of fuel injection systems, detailing their functions in enhancing engine performance, fuel economy, and the combustion process. It distinguishes between carburetors and fuel injection systems, describes various injection pump types, and explains injector mechanics and nozzle types. Additionally, it addresses critical functional requirements, classifications, and specific characteristics of different injection systems and nozzles.