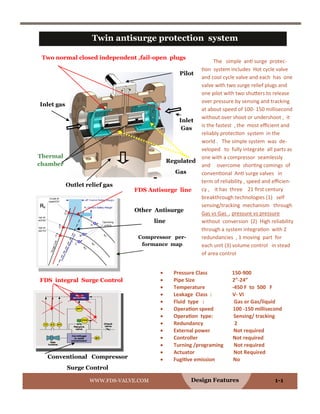

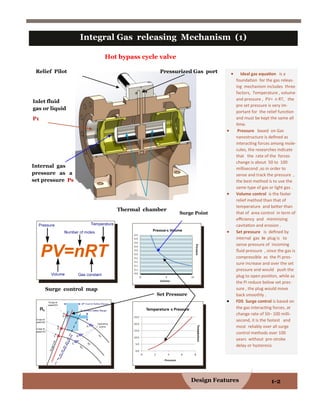

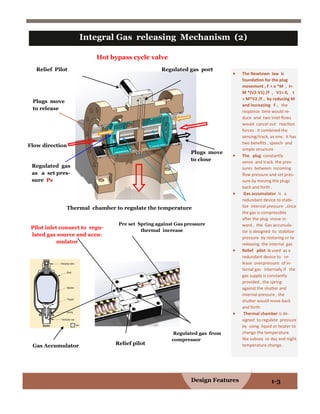

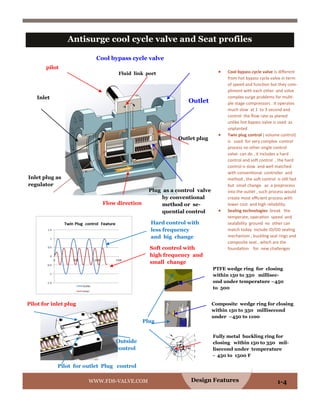

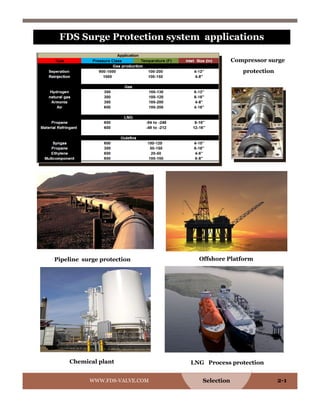

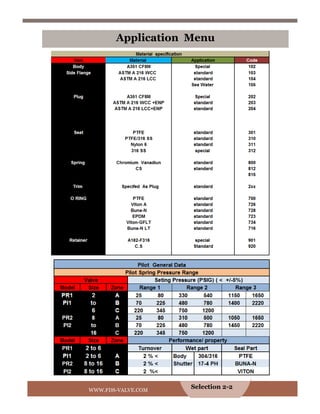

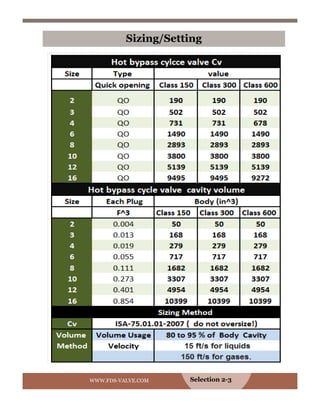

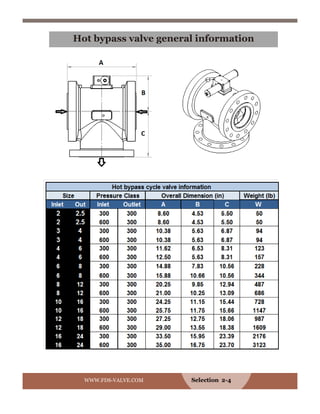

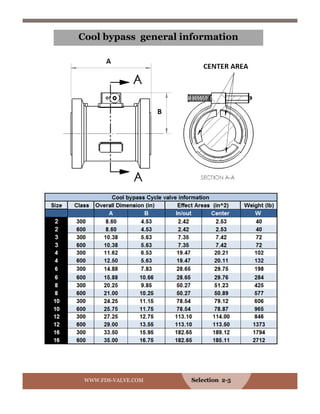

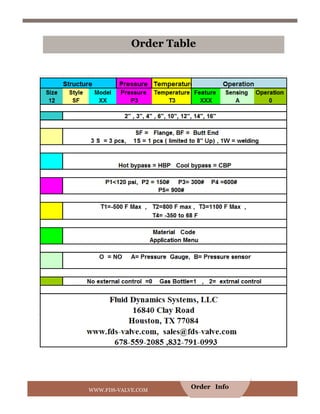

The document describes a twin antisurge protection system that uses two surge relief valves - a hot cycle valve and cool cycle valve. Each valve uses two surge relief plugs and a pilot to rapidly release overpressure within 100-150 milliseconds without overshoot or undershoot. This makes it the fastest, most efficient, and reliable surge protection system. It integrates all parts seamlessly and overcomes reliability, speed, and efficiency shortcomings of conventional systems through self-sensing tracking mechanisms and high reliability from system integration and redundancy.