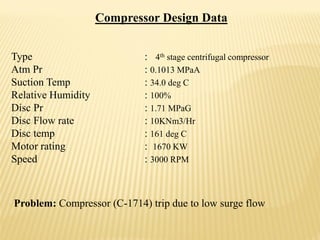

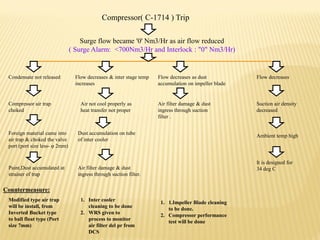

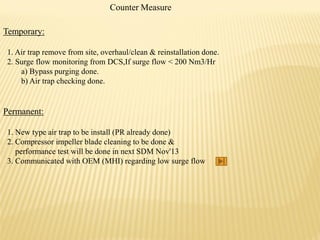

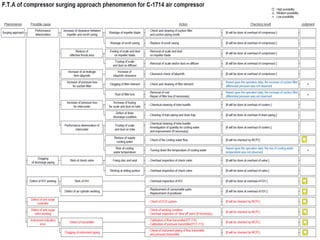

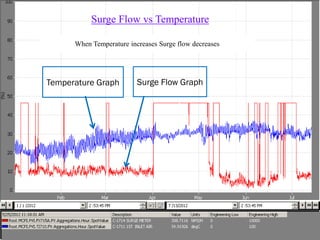

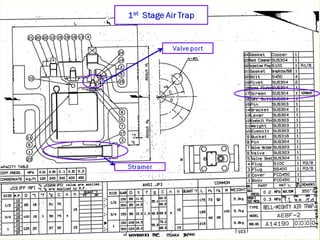

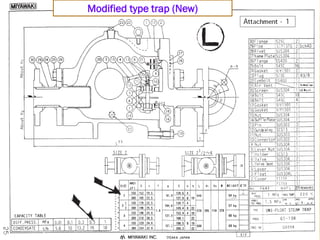

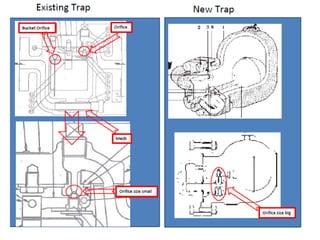

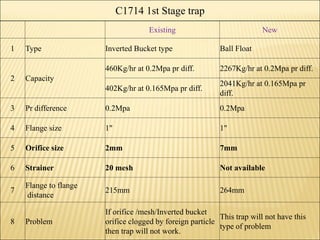

This case study describes a compressor (C-1714) tripping due to low surge flow. The surge flow dropped to 0 Nm3/Hr below the alarm limit of 700 Nm3/Hr. Potential causes identified include condensate not being released from the air trap, high ambient temperatures, and foreign material choking the air trap valve port. Permanent countermeasures proposed include installing a new ball float type air trap to replace the existing inverted bucket type, cleaning the compressor impeller blades, and conducting a performance test.